Effect of heat treatment on the microstructure and properties of TiBw reinforced high-temperature titanium matrix composite

-

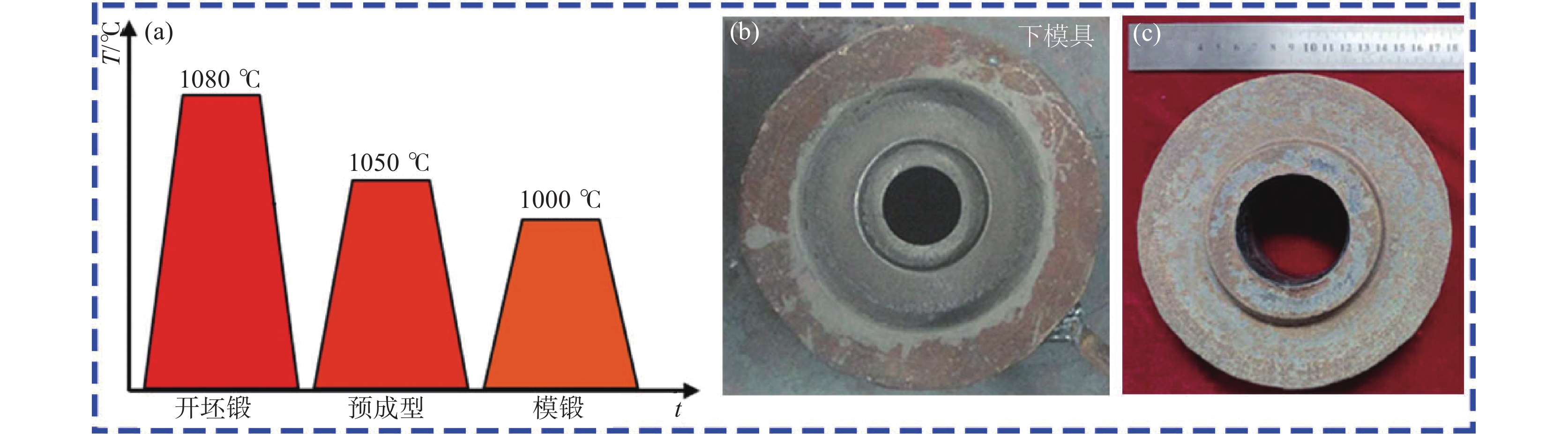

摘要: 采用扫描电镜、电子万能材料试验机研究了整体锻造成形的TiBw增强高温钛基复合材料锻件的组织和性能,以及不同热处理工艺对锻件组织和性能的影响。结果表明:锻件组织为双态组织,在650 ℃时表现出优异的高温性能,但在700 ℃时其强度出现了大幅下降。对锻件进行了不同的热处理,发现随着固溶温度的升高,α相含量和尺寸逐渐降低。另外,其拉伸强度随着固溶温度的升高而升高,但其塑性则会降低。当固溶温度为1030 ℃时,可以得到等轴α相含量为18.58%的双态组织,此时高温性能最为优异。其屈服强度为514.0 MPa,极限抗拉强度最高为594.0 MPa,延伸率为13.9%。

-

关键词:

- TiBw增强高温钛基复合材料 /

- 固溶温度 /

- 微观组织 /

- 力学性能

Abstract: The microstructure and properties of TiBw reinforced high-temperature titanium matrix composite forgings formed by integral forging and the effects of different heat treatment processes on the microstructure and properties of forgings were studied by scanning electron microscope and electronic universal material testing machine. The results show that the microstructure of the forgings is bimodal structure, which shows excellent high-temperature performance at 650 ℃, but its strength decreases significantly at 700 ℃. Different heat treatments were performed on the forgings, and it was found that the content and size of the α phase gradually decreased with the increase of the solution temperature. In addition, its tensile strength increases with increasing solid solution temperature, but its plasticity decreases. When the solid solution temperature is 1030 ℃, a bimodal structure with an equiaxed α-phase content of 18.58% can be obtained, and the high-temperature performance is the best. The yield strength is 514.0 MPa, the ultimate tensile strength is 594.0 MPa, and the elongation is 13.9%. -

表 1 锻后零件的三种热处理工艺参数

Table 1. Three heat treatment parameters of forged parts

样品 固溶温度/℃ 保温时间/h 冷却方式 时效温度/℃ 时效时间/h 冷却方式 HT1 970 0.5 空冷 650 6 空冷 HT2 1000 0.5 空冷 650 6 空冷 HT3 1030 0.5 空冷 650 6 空冷 -

[1] Tian Yongwu, Zhu Lele, Li Weidong, et al. Application and development of high temperature titanium alloys[J]. Hot Working Technology, 2020,49(8):17−20. (田永武, 朱乐乐, 李伟东, 等. 高温钛合金的应用及发展[J]. 热加工工艺, 2020,49(8):17−20. doi: 10.14158/j.cnki.1001-3814.20183380 [2] Dong Guojun, Gao Shendong, Wang Lei. Three dimensional shape model of TiBw mesh reinforced titanium matrix composites in rotary ultrasonic grinding[J]. Journal of Manufacturing Processes, 2022,75:682−692. doi: 10.1016/j.jmapro.2022.01.039 [3] Le Jianwen, Han Yuanfei, Qiu Peikun, et al. Insight into the formation mechanism and interaction of matrix/TiB whisker textures and their synergistic effect on property anisotropy in titanium matrix composites[J]. Journal of Materials Science & Technology, 2022,110:1−13. [4] Wang Qiang, Zhang Zhaohui, Su Tiejian, et al. A TiB whisker-reinforced titanium matrix composite with controllable orientation: A novel method and superior strengthening effect[J]. Materials Science and Engineering:A, 2022,830:142309. doi: 10.1016/j.msea.2021.142309 [5] Cai Jianming, Tian Feng, Liu Dong, et al. Research progress in manufacturing technology of 600 ℃ high temperature titanium alloy dual property blisk forging[J]. Journal of Materials Engineering, 2018,46(5):36−43. (蔡建明, 田丰, 刘东, 等. 600 ℃高温钛合金双性能整体叶盘锻件制备技术研究进展[J]. 材料工程, 2018,46(5):36−43. doi: 10.11868/j.issn.1001-4381.2018.000004 [6] Lv S. Effects of heat treatment on interfacial characteristics and mechanical properties of titanium matrix composites reinforced with discontinuous carbon fibers[J]. Journal of Alloys and Compounds, 2021,(877):160313. [7] Sun Yonggang, Zhang Changjiang, Ji Xiang, et al. Microstructure evolution of TiBw/Ti composites during severe plastic deformation: spheroidization behavior[J]. Materials Characterization, 2021,171:110725. doi: 10.1016/j.matchar.2020.110725 [8] Wang Yichao, Xue Xiangyi, Kou Hongchao, et al. Improvement of microstructure homogenous and tensile properties of powder hot isostatic pressed TA15 titanium alloy via heat treatment[J]. Materials Letters, 2022,311:131585. doi: 10.1016/j.matlet.2021.131585 [9] Pang Haoyu, Luo Jiao, Ye Peng. Effect of heat treatment temperature on the microstructure of deformed TC17 alloy[J]. Journal of Netshape Forming Engineering, 2020,12(6):28−36. (庞昊宇, 罗皎, 叶鹏. 热处理温度对变形后TC17合金微观组织的影响[J]. 精密成形工程, 2020,12(6):28−36. doi: 10.3969/j.issn.1674-6457.2020.06.004 [10] Zhang Min, Shuai Meirong, Li Haibin, et al. Effect of heat treatment on microstructure and properties of titanium alloy bars prepared by different deformation processes[J]. Transactions of Materials and Heat Treatment, 2022,43(3):35−42. (张旻, 帅美荣, 李海斌, 等. 热处理对不同形变工艺钛合金棒材显微组织与性能的影响[J]. 材料热处理学报, 2022,43(3):35−42. doi: 10.13289/j.issn.1009-6264.2021-0434 [11] Fu Binguo, Wang Hongwei, Zou Chunming, et al. The effects of Nb content on microstructure and fracture behavior of near α titanium alloys[J]. Materials & Design, 2015,66:267−273. [12] Ma Fengcang, Wang Chaohu, Liu Ping, et al. Microstructure and mechanical properties of Ti matrix composite reinforced with 5vol. % TiC after various thermo-mechanical treatments[J]. Journal of Alloys and Compounds, 2018,758:78−84. doi: 10.1016/j.jallcom.2018.05.134 [13] Kato Masaharu, Fujii Toshiyuki, Onaka Susumu. Elastic strain energies of sphere, plate and needle inclusions[J]. Materials Science & Engineering A, 1996,211(1-2):95−103. [14] Wang Jiheng, Guo Xianglong, Qin Jining, et al. Microstructure and mechanical properties of investment casted titanium matrix composites with B4C additions[J]. Materials Science & Engineering:A, 2015,628:366−373. [15] Lonarelli I, Gey N, Wenk H R, et al. In situ observation of texture evolution during α→β and β→α phase transformations in titanium alloys investigated by neutron diffraction[J]. Acta Materialia, 2007,55(17):5718−5727. doi: 10.1016/j.actamat.2007.06.017 -

下载:

下载: