Application of METSIM on vanadium extraction from vanadium bearing steel slag with pressure strengthening

-

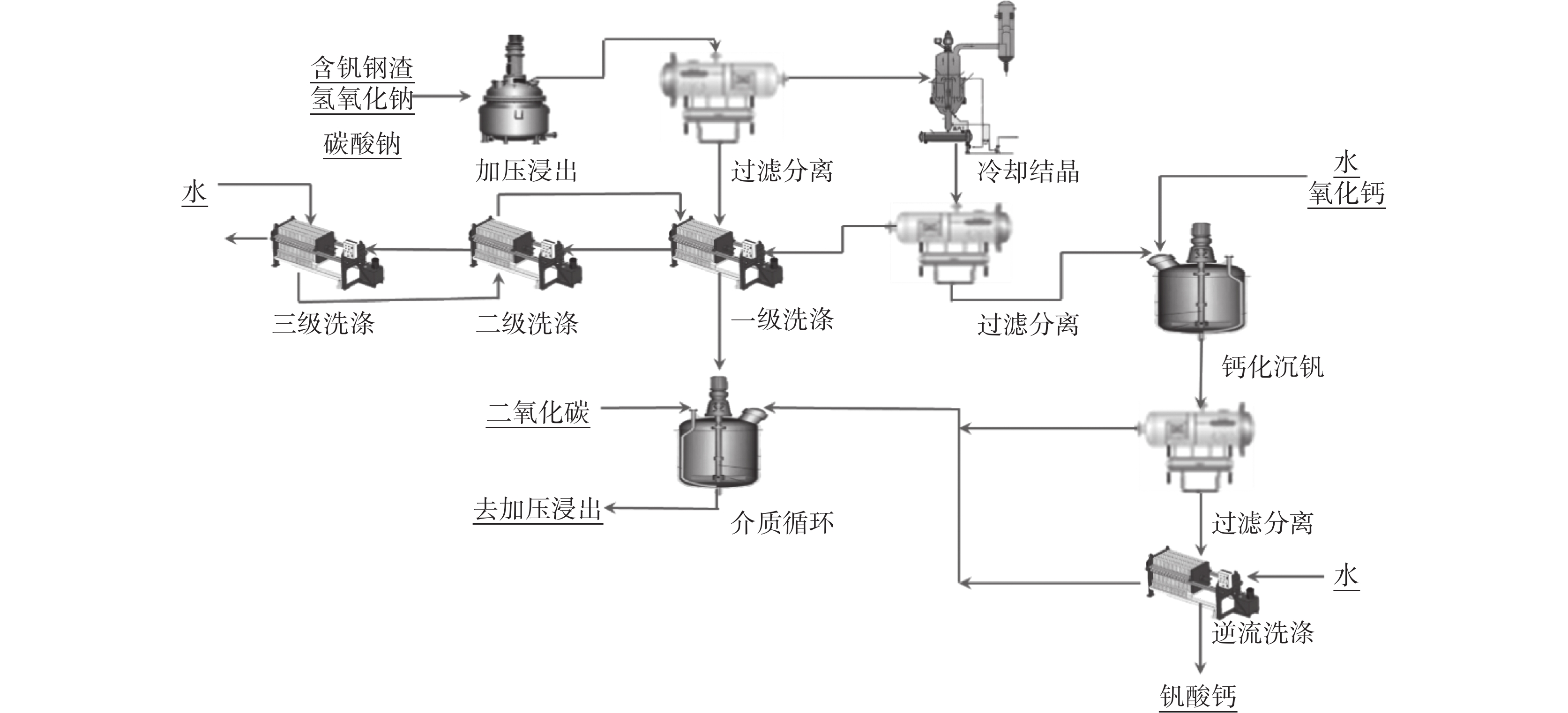

摘要: 针对提钒工艺中的关键环节,采用METSIM软件对含钒钢渣加压强化提钒工艺进行了工艺建模和物料衡算,得到了整个工艺过程中各物流的质量流量以及所包含的物质的详细信息。模拟过程可清晰了解每种物质详细走向,为工艺的设计及优化提供参考。结合上述模拟结果和产线实际运行中存在的蒸发水量较大的问题,设计了优先处理尾渣中钒酸钙,其次再进行优化尾渣洗涤的方式。结果表明通过模拟分析可进一步优化实际工艺方案,模拟结果使提钒工艺中总用水量减少7552 t/a,蒸发水量减少7521 t/a,显著降低了提钒工艺能耗。Abstract: In this paper, in view of the key steps in the vanadium extraction process, METSIM software was used to carry out the process modeling and material balance in the extraction process from vanadium bearing steel slag using pressure strengthening , and the mass flow rate of each logistics and the detailed information of the substance in the whole process were obtained. The simulation process could clearly understand the detailed trend of each substance, and provided a reference for the design and optimization of the process. Combined with the above simulation results and the problem of large amount of evaporative water in the actual operation of the production line, the calcium vanadate in the tail slag was firstly treated, and then the washing method of the tail slag was optimized. The results show that the actual process scheme can be further optimized by simulation analysis. The total water consumption and evaporation water in vanadium extraction process can be reduced respectively by 7552 t/a and 7521 t/a, and the energy consumption of vanadium extraction process can be significantly reduced by the simulation results.

-

表 1 含钒钢渣的主要成分

Table 1. Composition of steel slag containing vanadium

% V2O5 CaO TiO2 MnO2 Cr2O3 FeO Al2O3 SiO2 MgO P2O5 2.57 41.09 1.90 1.57 0.57 24.28 1.85 7.94 11.90 2.45 表 2 总物料的平衡

Table 2. Balance of total materials

t/a 输入 输出 名称 质量流量 名称 质量流量 含钒钢渣 100000 尾渣 195272 碳酸钠 1585 钒酸钙 7549 氧化钙 2359 冷凝水 147480 水 227597 二氧化碳 18760 合计 350301 合计 350301 表 3 优化前后主要物流质量流量对比

Table 3. Comparison of main logistics mass flow before and after optimization

t/a 碳酸钠 总用水量 蒸发水量 尾渣 钒酸钙 V2O5 H2O NaOH Na2CO3 V2O5 H2O NaOH Na2CO3 优化前 1585 227597 147480 399 76971 945 164 2171 2909 105 4 优化后 1635 220045 139959 400 76846 1065 168 2170 2996 21 0.7 -

[1] Moskalyk R R, Alfantazi A M. Processing of vanadium: A review[J]. Minerals Engineering, 2003,16(8):793−805. [2] 孙诗淋. 航空航天级钒铝中间合金制备工艺研究[D]. 大连: 大连理工大学, 2015: 14-16.Sun Shilin. Study on preparation technology of aerospace grade vanadium-aluminum intermediate alloy[D]. Dalian: Dalian University of Technology, 2015: 14-16. [3] Feng Junning, Hu Zhijie, Ma Zhongxian, et al. Intermediate alloys for titanium alloys and their standardization[J]. World Non-ferrous Metals, 2016,(2):49−52. (冯军宁, 胡志杰, 马忠贤, 等. 钛合金用中间合金及其标准化[J]. 世界有色金属, 2016,(2):49−52. [4] Chol C, Kim S, Kim R, et al. A review of vanadium electrolytes for vanadium redox flow batteries[J]. Renewable & Sustainable Energy Reviews, 2017,69:263−274. [5] Yan Chuanwei. Development of large-scale long-term energy storage and all-vanadium flow battery industry[J]. Solar Energy, 2022,5:14−22. (严川伟. 大规模长时储能与全钒液流电池产业发展[J]. 太阳能, 2022,5:14−22. [6] Zhang Huamin, Zhang Yu, Li Xianfen, et al. Development and industrialization of all-vanadium liquid flow battery energy storage technology[J]. High Technology and Industrialization, 2018,4:59−63. (张华民, 张宇, 李先锋, 等. 全钒液流电池储能技术的研发及产业化[J]. 高科技与产业化, 2018,4:59−63. [7] Yang Linlin, Liao Wenjun, Su Qing, et al. Development status of all-vanadium flow-through battery technology[J]. Energy Storage Science and Technology, 2013,2(2):140−145. (杨霖霖, 廖文俊, 苏青, 等. 全钒液流电池技术发展现状[J]. 储能科学与技术, 2013,2(2):140−145. doi: 10.3969/j.issn.2095-4239.2013.02.007 [8] Li Xiumin, Zhang Yimin, Huang Jing, et al. Effect of leaching aid on acid leaching of vanadium from vanadium tailings of Panzhihua Iron & Steel Co., Ltd.[J]. Metal Mine, 2012,(7):158−160,168. (李秀敏, 张一敏, 黄晶, 等. 助浸剂对攀钢钒尾渣酸浸提钒的影响[J]. 金属矿山, 2012,(7):158−160,168. doi: 10.3969/j.issn.1001-1250.2012.07.043 [9] Zhu Guangjun, Qiu Huidong, Yang Zhili, et al. Study on kinetics of vanadium extraction from steel slag by chlorination leaching[J]. Materials Review, 2011,25:258−260. (朱光俊, 邱会东, 杨治立, 等. 钢渣氯化浸取提钒工艺的动力学研究[J]. 材料导报, 2011,25:258−260. [10] Ye Guohua, He Wei, Lu Lu, et al. Study on direct leaching of vanadium by sulfuric acid from vanadium bearing steel slag under normal temperature and pressure[J]. Rare Metals, 2013,37(5):807−813. (叶国华, 何伟, 路璐, 等. 常温常压下含钒钢渣直接硫酸浸钒的研究[J]. 稀有金属, 2013,37(5):807−813. doi: 10.3969/j.issn.0258-7076.2013.05.020 [11] Gao Minglei, Chen Donghui, Li Lanjie, et al. Leaching behavior of vanadium from vanadium bearing steel slag in KOH molten salt medium[J]. Journal of Process Engineering, 2011,11(5):761−766. (高明磊, 陈东辉, 李兰杰, 等. 含钒钢渣中钒在KOH 亚熔盐介质中溶出行为[J]. 过程工程学报, 2011,11(5):761−766. [12] Fu Zibi, Peng Yi, Zhang Lin, et al. Experimental study on vanadium extraction from steel slag by waste acid leaching of titanium dioxide[J]. Progress in Titanium Industry, 2009,26(5):33−37. (付自碧, 彭毅, 张林, 等. 钛白废酸浸出钢渣提钒试验研究[J]. 钛工业进展, 2009,26(5):33−37. doi: 10.3969/j.issn.1009-9964.2009.05.009 [13] Yang Subo, Luo Zezhong, Wen Yongcai, et al. Extraction and recovery of vanadium from vanadium-bearing converter steel slag[J]. Iron and Steel, 2005,40(4):72−75. (杨素波, 罗泽中, 文永才, 等. 含钒转炉钢渣中钒的提取与回收[J]. 钢铁, 2005,40(4):72−75. doi: 10.3321/j.issn:0449-749X.2005.04.019 [14] Preblinger H. Vanadium in converter slags[J]. Steel Research, 2002,73(12):522−525. doi: 10.1002/srin.200200022 [15] Zhu Guilin, Sun Shushan, Zhao Qun, et al. Current situation and development trend of metallurgical slag resource utilization[J]. Comprehensive Utilization of Resources in China, 2002,3(6):29−32. (朱桂林, 孙树杉, 赵 群, 等. 冶金渣资源化利用的现状与发展趋势[J]. 中国资源综合利用, 2002,3(6):29−32. [16] Gu Longjian. Progress and present situation of vanadium extraction by fire method in China[J]. Vanadium Titanium, 1992,13(6):29−36. (古隆建. 我国火法提钒技术的进展及现状[J]. 钒钛, 1992,13(6):29−36. [17] Tian Maoming, Tang Dajun, Zhang Qi. Vanadium extraction from vanadium bearing steel slag and its main technology[J]. Journal of Chongqing University of Science and Technology (Natural Science Edition), 2009,11(2):59−60. (田茂明, 唐大均, 张 奇. 含钒钢渣提钒工艺及其主要技术[J]. 重庆科技学院学报(自然科学版), 2009,11(2):59−60. doi: 10.19406/j.cnki.cqkjxyxbzkb.2009.02.019 [18] 刘彪, 杜浩, 李兰杰, 等. 一种含钒钢渣加压强化提钒的方法: 中国, CN107236866B[P]. 2020-04-03.Liu Biao, Du Hao, Li Lanjie, et al. A method of extracting vanadium from vanadium containing steel slag by pressure strengthening: China, CN107236866B[P]. 2020-04-03. [19] Ding Shurong. Application of METSIM in hydrometallurgical design[J]. Colored Equipment, 2020,34(4):57−61. (丁淑荣. 全流程工艺计算模拟软件METSIM在湿法冶金设计中的应用实践[J]. 有色设备, 2020,34(4):57−61. [20] Xiao Peng, Wang Hongjun, Ye Fengchun, et al. Simulation and calculation of co-smelting process of selenium and tellurium based on METSIM[J]. Nonferrous Metals (Smelting Part), 2020,(11):55−59. (肖鹏, 王红军, 叶逢春, 等. 基于METSIM的硒碲协同熔炼工艺流程模拟计算[J]. 有色金属(冶炼部分), 2020,(11):55−59. [21] Wang Dehua. Application of METSIM software in vanadium extraction from vanadium slag[J]. Energy Saving of Nonferrous Metallurgy, 2016,32(6):19−22. (汪德华. METSIM软件在钒渣提钒中的应用[J]. 有色冶金节能, 2016,32(6):19−22. [22] Lv Yeqing, Zheng Shili, Wang Shaona, et al. Application of METSIM in clean production process design of vanadium slag from molten salt process[J]. Journal of Process Engineering, 2013,13(2):270−274. (吕页清, 郑诗礼, 王少娜, 等. METSIM在亚熔盐法钒渣清洁生产工艺流程设计中的应用[J]. 过程工程学报, 2013,13(2):270−274. [23] Cai Wang, Yuan Aiwu. Application of METSIM software in the process design of acid production from smelting flue gas[J]. Sulfuric Acid Industry, 2021,(4):10−12. (蔡旺, 袁爱武. METSIM软件在冶炼烟气制酸工艺设计中的应用[J]. 硫酸工业, 2021,(4):10−12. doi: 10.3969/j.issn.1002-1507.2021.04.006 [24] Zhang Xiaodong, Zhao Feiyan, Wang Yongwang, et al. Application of METSIM in roasting magnesia from magnesite[J]. Coal and Chemical Industry, 2020,43(6):129−133. (张小东, 赵飞燕, 王永旺, 等. METSIM在菱镁矿焙烧氧化镁中的应用[J]. 煤炭与化工, 2020,43(6):129−133. [25] Cui Mu. Application of METSIM to the treatment of copper sludge and waste organic solvent by submerged combustion smelting technology[J]. China's Comprehensive Utilization of Resources, 2020,38(1):57−59. (崔沐. METSIM在浸没燃烧熔池熔炼技术处理含铜污泥及废有机溶剂上的应用[J]. 中国资源综合利用, 2020,38(1):57−59. -

下载:

下载: