Preparation and properties of composite cementitious materials containing vanadium-titanium iron ore tailings

-

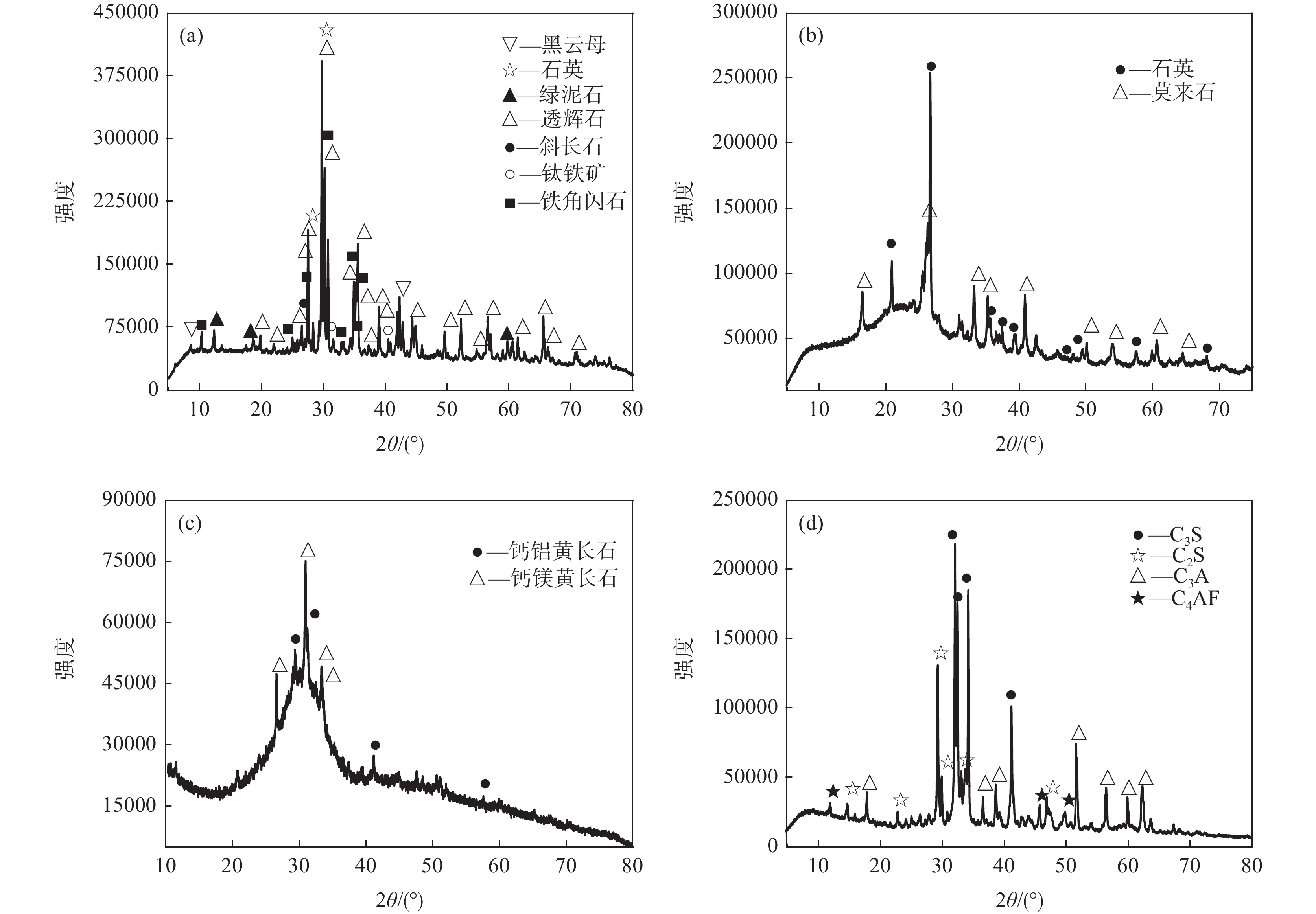

摘要: 为促进钒钛铁尾矿高质量、规模化地有效利用,以钒钛铁尾矿为主要原料制备复合胶凝材料,采用粒度分析、力学性能测试、X 射线衍射(XRD)及扫描电镜(SEM)测试等手段,研究了钒钛铁尾矿粉磨特性、掺量对复合胶凝材料性能影响及复合胶凝材料的水化机理。结果表明:粉磨30 min的钒钛铁尾矿比表面积达到400 m2/kg,其 28 d 活性指数接近70%;当钒钛铁尾矿掺量为27%,胶砂比为 1∶3,水胶比为0.4时,所制备的复合胶凝材料3 d和28 d 抗压强度分别为14.9 MPa和 32.6 MPa,标准稠度为32.6%,凝结时间为125 min(初凝)和396 min(终凝),复合胶凝材料净浆试样14 d的收缩值较同龄期P·O 42.5水泥净浆试样收缩值低51.8%;在标准养护条件下,复合胶凝材料的水化产物主要为C-S-H凝胶、Ca(OH)2、Mg(OH)2和钙矾石(AFt),钒钛铁尾矿水化反应后残余矿物相石英和透辉石颗粒与水化产物的凝聚效应为复合胶凝材料的强度提供了保障,透辉石水化生成Mg(OH)2对胶凝体系早期自收缩起到抑制作用。Abstract: In order to improve the high-quality and large-scale effective utilization of vanadium-titanium iron ore tailings (VIOTs), composite cementitious materials (CCM) were prepared with VIOTs as the main raw materials. The effects of grinding characteristics of VIOTs, content of VIOTs on the properties of CCM and hydration mechanism of CCM were investigated via means of particle size analysis, mechanical property test, X-ray diffraction (XRD) and scanning electron microscope (SEM). The results show that the specific surface area of VIOTs grinding for 30 minutes reaches 400 m2/kg, and its 28-day activity index is close to 70%. When the content of VIOTs is 27%, the cement-sand ratio is 1∶3 and the water-binder ratio is 0.4, the 3-day and 28-day compressive strength of the CCM are 14.9 MPa and 32.6 MPa respectively, the standard consistency is 32.6%, the initial setting time is 125 min and the final setting time is 396 min. The 14-day shrinkage value of CCM paste is 51.8% lower than that of P·O 42.5 cement paste at the same age. The hydration products of the CCM are mainly C-S-H gel, Ca(OH)2, Mg(OH)2 and ettringite (AFt) under standard curing conditions, and the coagulation effect of quartz and diopside particles and hydration products after the hydration reaction of vanadium-titanium iron ore tailings is the guarantee for the strength of the CCM. The hydration of diopside to form Mg(OH)2 can inhibit the early self-shrinkage of the cementitious system.

-

表 1 原料的化学成分

Table 1. Chemical compositions of raw materials

% 原料 CaO SiO2 Fe2O3 MgO Al2O3 TiO2 Na2O K2O SO3 烧失量 其他 钒钛铁尾矿 21.62 44.47 10.78 11.21 7.39 0.86 0.55 0.23 0.09 2.08 0.72 粉煤灰 3.25 45.94 4.36 0.40 35.17 1.35 0.42 0.31 7.86 0.94 矿渣粉 39.12 29.88 0.78 9.06 14.77 2.19 0.53 0.41 1.81 0.62 0.83 水泥 56.10 23.26 2.69 3.96 6.89 0.40 0.46 0.67 2.12 3.02 0.43 表 2 水泥的主要理化性质

Table 2. Main physical and chemical properties of cement

表观密度/(kg·m−3) 细度/(m2·kg−1) 凝结时间/min 28 d强度/MPa 初凝 终凝 抗折 抗压 3.08×103 356 55 365 7.2 60.7 表 3 不同粉磨时间钒钛铁尾矿的特征粒径及比表面积

Table 3. Characteristic particle size and specific surface area of VIOTs at different grinding times

磨矿时间/min 特征粒径/μm 比表面积/(m2·kg−1) D10 D50 D90 10 6.839 99.462 277.966 158 20 2.733 35.251 135.541 354 30 1.822 18.245 79.059 400 40 1.417 13.395 65.356 485 50 1.120 10.408 58.900 566 表 4 复合胶凝材料配合比

Table 4. Mix proportion of CCM

编号 原材料配比/% 抗压强度/MPa 水泥 钒钛铁尾矿粉 矿渣粉 粉煤灰 3 d 28 d A0 100 25.4 52.6 B1 30 35 35 15.1 32.6 B2 30 35 35 14.6 31.1 B3 30 35 35 9.7 21.7 C1 30 15 39 16 16.4 34.9 C2 30 27 27 16 14.9 32.6 C3 30 39 15 16 13.5 28.4 表 5 复合胶凝材料的工作性能

Table 5. Working property of CCM

标准稠度/% 凝结时间/min 安定性/mm 初凝 终凝 试件1 试件2 均值 32.6 125 396 2.0 2.5 2.25 -

[1] Nielsen P, Boone M, Horckmans L, et al. Accelerated carbonation of steel slag monoliths at low CO2 pressure–microstructure and strength development[J]. Journal of CO2 Utilization, 2019,36:124−134. [2] Yan W, Meng Z H, Zou M Y, et al. Neutralization reaction in synthesis of carbon materials for supercapacitors[J]. Chemical Engineering Journal, 2020,381:122547. doi: 10.1016/j.cej.2019.122547 [3] Mo L, Zhang F, Deng M, et al. Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates[J]. Cement and Concrete Composites, 2017,83:138−145. doi: 10.1016/j.cemconcomp.2017.07.018 [4] Turner L K, Collins F G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete[J]. Construction and Build Materials, 2013,43:125−130. doi: 10.1016/j.conbuildmat.2013.01.023 [5] Wang Aiguo, He Maocan, Mo Liwu, et al. Research progress of building materials prepared from the carbonized curing steel slag[J]. Materials Repoters, 2019,33(17):2939−2948. (王爱国, 何懋灿, 莫立武, 等. 碳化养护钢渣制备建筑材料的研究进展[J]. 材料导报, 2019,33(17):2939−2948. doi: 10.11896/cldb.19040202 [6] Wang Changlong, Ye Pengfei, Zhang Kaifan, et al. Study on preparation and hydration mechanism of composite cementitious materials using molybdenum tailings[J]. Metal Mine, 2020,(9):41−47. (王长龙, 叶鹏飞, 张凯帆, 等. 钼尾矿复合胶凝材料的制备及其水化机理研究[J]. 金属矿山, 2020,(9):41−47. [7] Ghafari E, Ghahari S A, Costa H, et al. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete[J]. Construction and Build Materials, 2016,127:43−48. doi: 10.1016/j.conbuildmat.2016.09.123 [8] Meng W, Khayat K H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC[J]. Cement and Concrete Research, 2018,105:64−71. doi: 10.1016/j.cemconres.2018.01.001 [9] Shuai Y, Zhou W T, Han Y X, et al. Efficient enrichment of iron concentrate from iron tailings via suspension magnetization roasting and magnetic separation[J]. Journal of Material Cycles and Waste Management, 2020,22(1):1152−1162. [10] Wang W, Ye P F, Zhou X L, et al. Effects of reductant type on coal-based direct reduction of iron ore tailings[J]. Annales de Chimie Science des Matériaux, 2018,42(3):453−466. [11] Shuai Y, Zhang Q, Heng Y, et al. Efficient iron recovery from iron tailings using advanced suspension reduction technology: A study of reaction kinetics, phase transformation, and structure evolution[J]. Journal of Hazardous Materials, 2020,404:124067. [12] Menders B C, Pedroti L G, Fontes M P F, et al. Technical and environmental assessment of the incorporation of iron ore tailings in construction clay bricks[J]. Construction and Building Materials, 2019,227:1−13. [13] Cui X W, Geng Y, Li T, et al. Field application and effect evaluation of different iron tailings soil utilization technologies[J]. Resources, Conservation and Recycling, 2021,173:1−12. [14] Li X G, Wang P Q, Qin J Y, et al. Mechanical properties of sintered ceramsite from iron ore tailings affected by two-region structure[J]. Construction and Building Materials, 2020,240:117919. doi: 10.1016/j.conbuildmat.2019.117919 [15] Li C, Sun H H, Bai J, et al. Innovative methodology for comprehensive utilization of iron ore tailings[J]. Journal of Hazardous Materials, 2010,174(1-3):71−77. doi: 10.1016/j.jhazmat.2009.09.018 [16] Yang Fei, Sun Xiaomin. Preparation of ordinary portland cement clinker from vanadium-titanium magnetite tailing[J]. Iron Steel Vanadium Titanium, 2020,41(2):75−81. (杨飞, 孙晓敏. 利用钒钛磁铁矿尾矿制备普通硅酸盐水泥熟料的研究[J]. 钢铁钒钛, 2020,41(2):75−81. doi: 10.7513/j.issn.1004-7638.2020.02.015 [17] Cheng Y H, Huang F, Qi S S, et al. Durability of concrete incorporated with siliceous iron tailings[J]. Construction and Building Materials, 2020,242:118147. doi: 10.1016/j.conbuildmat.2020.118147 [18] 常宁. 钒钛磁铁尾矿复合胶凝材料制备隔声板材的研究[D]. 邯郸: 河北工程大学: 2020.Chang Ning. Study on preparation of soundproof board from vanadium titanium magnetite tailings composite cementitious material[D]. Handan: Hebei University of Engineering, 2020. [19] Ling G, Shui Z H, Gao X, et al. Utilizing iron ore tailing as cementitious material for eco-friendly design of ultra-high performance concrete (UHPC)[J]. Materials, 2021,14(8):1829−1843. doi: 10.3390/ma14081829 [20] Cheng Y, Huang F, Li W, et al. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete[J]. Construction and Build Materials, 2016,118:164−170. doi: 10.1016/j.conbuildmat.2016.05.020 [21] Yao G, Wang Q, Su Y W, et al. Mechanical activation as an innovative approach for the preparation of pozzolan from iron ore tailings[J]. Minerals Engineering, 2020,145:106068. doi: 10.1016/j.mineng.2019.106068 [22] Cui Xiaowei, Ni Wen, Geng Biyao, et al. Ash reactivity characteristics of diopside powder[J]. Chinese Journal of Engineering, 2018,40(6):658−664. (崔孝炜, 倪文, 耿碧瑶, 等. 透辉石粉的火山灰反应特性[J]. 工程科学学报, 2018,40(6):658−664. [23] Wang S, Wang C L, Wang Q H, et al. Study on cementitious properties and hydration characteristics of steel slag[J]. Polish Journal of Environmental Studies, 2018,27(1):357−364. doi: 10.15244/pjoes/74133 [24] Li N, Farzadnia N, Shi C J. Microstructural changes in alkali-activated slag mortars induced by accelerated carbonation[J]. Cement and Concrete Research, 2017,100:214−226. doi: 10.1016/j.cemconres.2017.07.008 [25] Wu M, Zhang Y S, Jia Y T, et al. Effects of sodium sulfate on the hydration and properties of lime-based low carbon cementitious materials[J]. Journal of Cleaner Production, 2019,220:677−687. doi: 10.1016/j.jclepro.2019.02.186 [26] Li Y, Qiao C Y, Ni W. Green concrete with ground granulated blast-furnace slag activated by desulfurization gypsum and electric arc furnace reducing slag[J]. Journal of Cleaner Production, 2020,269:122212. doi: 10.1016/j.jclepro.2020.122212 [27] Wang C L, Ren Z Z, Huo Z K, et al. Properties and hydration characteristics of mine cemented paste backfill material containing secondary smelting water-granulated nickel slag[J]. Alexandria Engineering Journal, 2021,60(6):4961−4971. doi: 10.1016/j.aej.2020.12.058 [28] Zhu Liping, Ni Wen, Gao Shujie, et al. Adaptability and early hydration of a cementing agent prepared with red mud, slag, flue gas desulphurization gypsum and a little cement clinker[J]. Chinese Journal of Engineering, 2015,37(4):414−421. (祝丽萍, 倪文, 高术杰, 等. 赤泥−矿渣−脱硫石膏−少熟料胶结剂的适应性及早期水化[J]. 工程科学学报, 2015,37(4):414−421. [29] Jiang L H, Li C Z, Wang C, et al. Utilization of flue gas desulfurization gypsum as an activation agent for high-volume slag concrete[J]. Journal of Cleaner Production, 2018,205:589−598. doi: 10.1016/j.jclepro.2018.09.145 [30] Duan S Y, Liao H Q, Cheng F Q, et al. Investigation into the synergistic effects in hydrated gelling systems containing fly ash, desulfurization gypsum and steel slag[J]. Construction and Building Materials, 2018,187:1113−1120. doi: 10.1016/j.conbuildmat.2018.07.241 [31] Cho B, Choi H. Physical and chemical properties of concrete using GGBFS-KR slag-gypsum binder[J]. Construction and Building Materials, 2016,123:436−443. doi: 10.1016/j.conbuildmat.2016.07.023 [32] Zhang G Q, Wu P C, Gao S J, et al. Preparation of environmentally friendly low autogenous shrinkage whole-tailings cemented paste backfill material from steel slag[J]. Acta Microscopica, 2019,28(5):961−971. -

下载:

下载: