Effect of C and N content on the microstructure and performance of 316H austenitic stainless steel used in sodium-cooled fast reactor heat exchanger

-

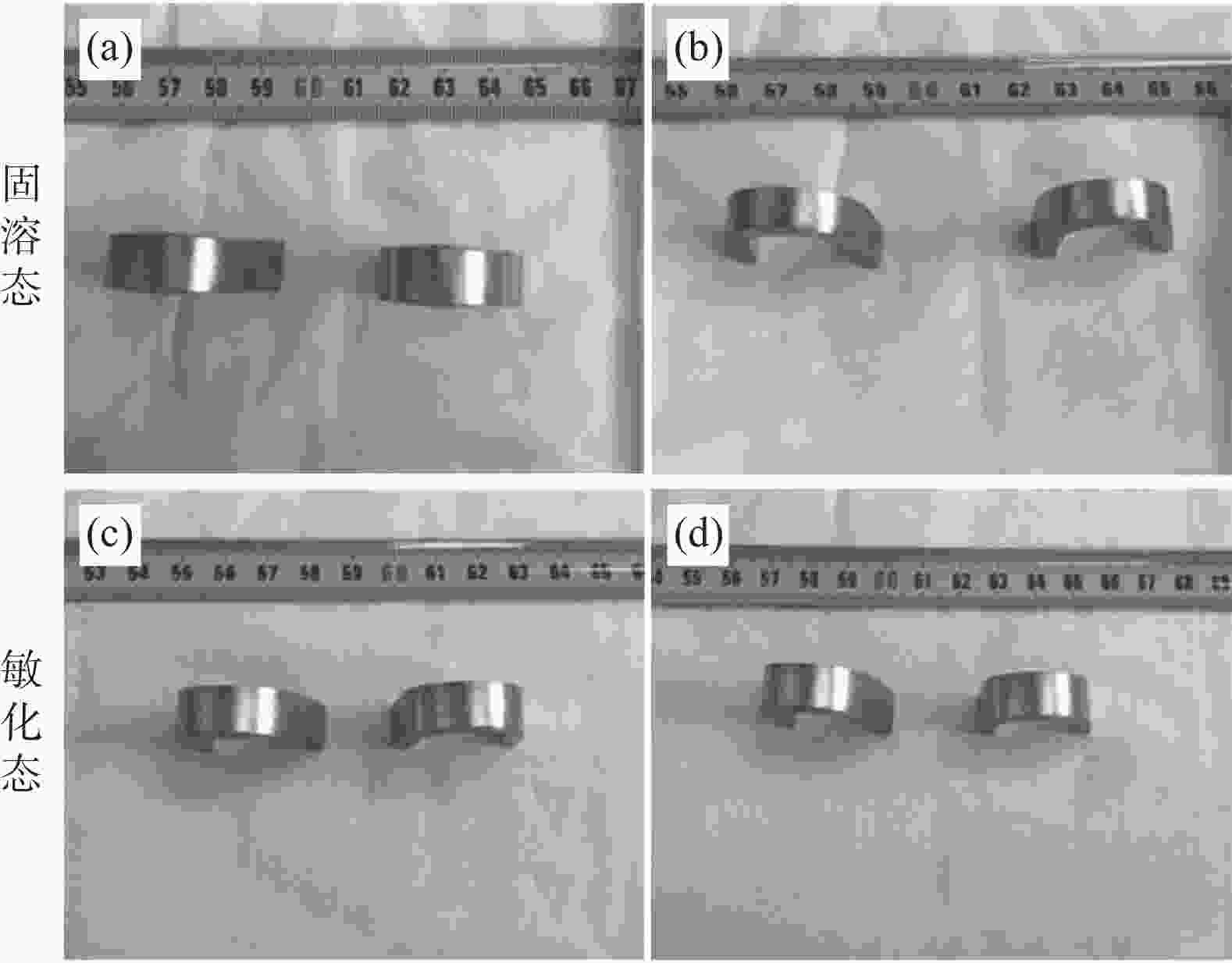

摘要: 316H不锈钢是我国四代先进钠冷快堆热交换器主体结构材料,获得C、N等关键微量元素的合理控制限是实现其国产化制造的前提。但是ASTM标准对316H合金中C的要求控制范围较宽,难以兼顾合金的耐晶间腐蚀和焊接性能,尤其对C极易出现偏析的大尺寸管板、法兰等部件。此外,该标准也并未给出N的控制范围。试验研究了C、N含量对合金的晶粒度、室温和580 ℃拉伸性能、室温冲击韧性和耐晶间腐蚀性能的影响。结果表明,C含量在0.04%~0.06%变化时,316H不锈钢晶粒度、拉伸性能、冲击韧性变化并不明显。尽管该范围的C含量合金热轧板材具有良好的耐晶间腐蚀性,但随着C含量的增加,合金腐蚀速率有所提高。N含量在0.05%~0.07%变化时,316H不锈钢晶粒度、拉伸性能、冲击性能变化并不明显,耐晶间腐蚀速率随着N含量的增加有降低的趋势。基于上述结果,综合分析并确定了工程化制造的大尺寸316H不锈钢部件C和N含量的推荐控制限,即C 0.04%~0.05%,N 0.06%~0.07%。Abstract: 316H austenitic stainless steel is used as the main structural material of the Chinese fourth-generation advanced sodium-cooled fast reactor heat exchanger. The premise of realizing domestic production is to obtain the reasonable control limit of the key trace-elements such as C and N. However, the ASTM standard shows a wide range of control of C element in 316H alloy, which makes it difficult to balance the intergranular corrosion resistance and welding performance of the alloy, especially for large-size tube sheet, flange and other parts where C element is prone to segregate. Besides, the ASTM standard doesn’t give the control range of N. In this paper, the influence of the C, N contents on the microstructure and properties, such as the grain size, tensile properties under room temperature or 580 °C, the room-temperature impact toughness and the intergranular corrosion resistance were investigated by the tensile and impact testing machines, combined with other testing methods such as OM and intergranular corrosion performance testing. The findings demonstrate that there are slight changes in grain size, tensile properties, and impact toughness of the alloys with C (0.04%~0.06%) or with N (0.05% to 0.07%). Although the hot-rolled alloy plates with the C contents of 0.04% to 0.06% generally show good intergranular corrosion resistance, the corrosion rate increases with the increasing C content. The rate of the intergranular corrosion resistance tends to decrease with the increase of the N content. Based on the results, the recommended control limits of the C and N content of the engineered 316H stainless steel parts are determined.

-

Key words:

- 316H austenitic stainless steel /

- sodium-cooled fast reactor /

- heat exchanger /

- C content /

- N congtent /

- microstructure /

- properties

-

表 1 316H试验钢化学成分

Table 1. Chemical compositions of the 316H steels

% 炉号 C Si Mn Ni Cr Mo Al P S B Co V N H O B1 0.045 0.45 1.47 11.99 17.52 2.58 <0.02 <0.005 <0.0005 <0.001 <0.02 <0.02 0.068 0.0005 0.0012 B2 0.048 0.43 1.49 12.01 17.53 2.59 0.019 <0.005 <0.0005 <0.001 <0.005 <0.005 0.066 0.0004 0.0005 B3 0.058 0.43 1.48 12.02 17.53 2.60 0.045 <0.005 <0.0005 <0.001 <0.005 <0.005 0.068 0.0004 0.0005 B4 0.045 0.41 1.49 12.03 17.51 2.60 0.036 <0.005 <0.0005 <0.001 <0.005 <0.005 0.045 0.0005 0.0007 表 2 不同C含量的316H不锈钢固溶态和敏化态经腐蚀后单位面积腐蚀速率

Table 2. Corrosion rate per unit area of 316H stainless steel with different C content in solid solution and sensitized state after corrosion

状态 样品号 w(C)/% 单位面积腐蚀速率/(g·h−1·mm−2) 固溶态 B1 0.045 1.40E-07 B2 0.048 1.44E-07 B3 0.058 1.54E-07 敏化态 B1 0.045 1.71E-07 B2 0.048 1.90E-07 B3 0.058 1.97E-07 表 3 N含量对316H试样的室温、580 ℃拉伸性能影响

Table 3. Effect of N content on the tensile properties of 316H austenitic stainless steel at room temperature and 580 ℃

样品号 w(N)/% Rm/MPa Rp0.2/MPa Z/% A/% 室温 580 ℃ 室温 580 ℃ 室温 580 ℃ 室温 580 ℃ B4 0.045 602 427 306 174 87 82 63 44 B1 0.068 626 436 302 181 88 84 65 44 表 4 不同N含量的316H固溶态和敏化态经腐蚀后单位面积腐蚀速率

Table 4. Corrosion rate per unit area of 316H with different N content in solid solution and sensitized state after corrosion

状态 样品号 w(N)/% 单位面积腐蚀速率/(g·h−1·mm−2) 固溶态 B4 0.045 1.49E-07 B1 0.068 1.40E-07 敏化态 B4 0.045 1.78E-07 B1 0.068 1.71E-07 -

[1] Xu Mi. Present situation and prospect of fast reactor technology development in China[J]. Engineering Sciences, 2008,(1):70. (徐銤. 我国快堆技术发展的现状和前景[J]. 中国工程科学, 2008,(1):70. [2] Michiuchi M, Kokawa H, Wang Z J, et al. Twin-induced grain boundary engineering for 316 austenitic stainless steel[J]. Acta Materialia, 2006,54(19):5179. doi: 10.1016/j.actamat.2006.06.030 [3] Li Xiaobing, Gao Ming, Li Haoze, et al. Effect of residual hydrogen content on the tensile properties and crack propagation behavior of a type 316 stainless steel[J]. International Journal of Hydrogen Energy, 2019,44:25054. doi: 10.1016/j.ijhydene.2019.07.131 [4] Gao Yan, Zhang Chunlei, Xiong Xiahua, et al. Intergranular corrosion susceptibility of a novel super 304H stainless steel[J]. Engineering Failure Analysis, 2012,24:26. doi: 10.1016/j.engfailanal.2012.03.004 [5] Wang Wei. Effect of nitrogen on microstructure of cold deformed high nitrogen austenitic stainless steel[J]. Ransactions of Metal Heat Treatment, 2010,31(7):59. (王威. 氮对冷变形高氮奥氏体不锈钢微观结构的作用[J]. 材料热处理学报, 2010,31(7):59. [6] Sumita M, Hanawa T, Teoh S H. Development of nitrogen-containing nical-free austenitic stainless steels for metallic biomaterials-review[J]. Materials Science and Engineering C, 2004,24:753. doi: 10.1016/j.msec.2004.08.030 [7] Wu Yongjun. Study on improving intergranular corrosion resistance of 00Cr21Ni6Mn9N stainless steel tube[J]. Special Steel Technology, 2008,(2):15. (吴勇军. 改善00Cr21Ni6Mn9N不锈钢管晶间腐蚀性能的研究[J]. 特钢技术, 2008,(2):15. [8] Briant C L, Mulford R A, Hall E L. Sensitization of austenitic stainless steels, I. Controlled purity alloys[J]. Corrosion, 1982,38(9):468. doi: 10.5006/1.3577362 -

下载:

下载: