Numerical simulation of the temperature field in titanium sponge reactor during magnesium thermal production process

-

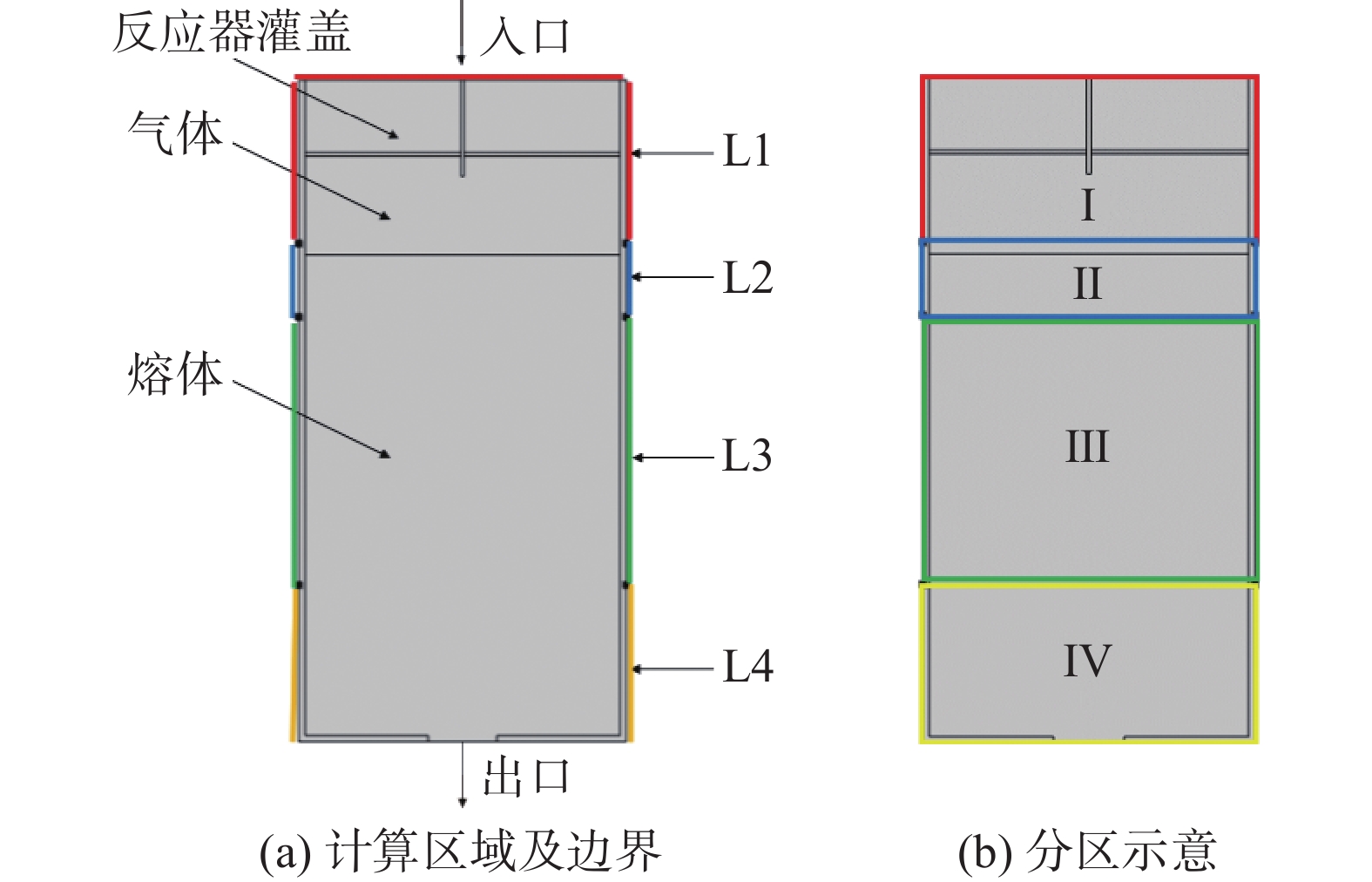

摘要: 以7.5 t“I”炉实际尺寸为基础,建立镁热法生产海绵钛还原炉物理模型,模拟还原过程中炉内温度场分布。研究发现,在TiCl4中心加料工况下,反应器由内向外,在横向和纵向均形成明显的温度梯度,从反应中心区至器壁温度逐渐降低,且上部氩气区域温度明显低于反应区熔体温度。提高TiCl4给料速度,延长连续给料时间均能使反应区最高温度和平均温度呈现上升趋势。对于7.5 t“I”型炉,当料速低于280 kg/h时,反应释放热量低于风冷区的散热量,生产中需要对反应器进行补热,当给料速度从200 kg/h提高至400 kg/h时,3 h内反应区最高温度由986.5 ℃上升至1167.4 ℃。当器壁控制温度由820 ℃降低至750 ℃时,反应中心温度降低约18 ℃,即增大器壁与反应中心温度梯度有利于促进炉内熔体散热。通过建立合理的壁温控制和加料、排料制度,能够避免海绵钛出现硬芯,改善产品质量。Abstract: Based on the size of 7.5 t “I” type furnace, the physical model of titanium sponge reactor was established to simulate the temperature field. Under the center feeding condition of TiCl4, it is found that the temperature gradient is formed both horizontally and vertically from the inside-out of the reactor. The temperature gradually decreases from the center to the wall, and the temperature of upper Ar zone is obviously lower than the melt temperature in the reaction zone. With the increasing feed rate and time of TiCl4, the maximum and average temperature of the reaction zone increase. As to 7.5 t “I” type furnace, when the feed rate is lower than 280 kg/h, heat generation is lower than heat dissipation in the air-cooling zone, hence reactor need be heated by electric furnace. When the feed rate goes from 200 kg/h to 400 kg/h, the maximum temperature in reaction zone increases from 986.5 ℃ to 1167.4 ℃ in 3 hours. When the reactor wall temperature decreases from 820 ℃ to 750 ℃, the temperature of reaction center decreases about 18 ℃, which means that enlarging the temperature gradient between the wall and the reaction center is conducive to promoting the heat dissipation of the melt in the furnace. By establishing reasonable wall temperature control, feeding and discharging system, hard core can be avoided and product quality can be improved.

-

Key words:

- titanium sponge /

- magnesiothermic reduction /

- temperature field /

- numerical simulation

-

表 1 模拟计算所用物质的物性参数

Table 1. Physical parameters of the substance used for simulation calculation

物质名称 导热系数/

[W·(m·K)−1]定压比热容/

[J·(kg·K)−1]密度/

(kg·m−3)动力粘度/

(Pa·s)TiCl4(l) 0.0802 774.37 1758.09 5.76×10−4 TiCl4(g) 0.0077 537.77 5.94 1.23×10−5 Mg(l) 90.7 1344 1538 6.41×10−4 MgCl2(l) 1.7 971 1637 1.62×10−3 Ar(g) 0.05 518 0.627 4.70×10−7 321不锈钢 1.307+0.018×T 279.925+0.275×T 7930 表 2 TiCl4持续加入1 h后反应器内温度状况

Table 2. Temperature of the reactor after continuous feeding of TiCl4 for 1 h

进料速度/

(kg.h−1)Ⅱ区熔体最高

温度/℃Ⅱ区平均

温度/℃Ⅲ区平均

温度/℃200 983.7 803.4 815.1 240 991.4 830.4 818.9 280 996.5 847.9 821.9 300 1006.5 853.0 822.1 350 1054.0 870.2 824.6 400 1132.0 925.5 832.5 表 3 TiCl4持续加入3 h后反应器内温度状况

Table 3. Temperature of the reactor after continuous feeding of TiCl4 for 3 h

进料速度/

(kg·h−1)Ⅱ区熔体最高

温度/℃Ⅱ区平均

温度/℃Ⅲ区平均

温度/℃200 986.5 794.9 818.5 240 994.2 828.7 825.7 280 998.1 847.5 830.4 300 1009.9 854.0 831.0 350 1063.2 875.2 835.6 400 1167.4 945.8 850.5 表 4 不同器壁工况条件下器内最高温度、平均温度

Table 4. Maximum and average temperature of the air-cooling zone at different temperature of the cooling wall

进料速度/(kg·h−1) Ⅱ区最高温度/℃ Ⅲ区平均温度/℃ 750 ℃ 785 ℃ 820 ℃ 750 ℃ 785 ℃ 820 ℃ 200 978.5 986.5 994.6 785.89 794.9 804.0 240 986.5 994.2 1001.9 819.77 828.7 837.7 280 990.6 998.1 1005.5 838.57 847.5 856.4 300 1002.0 1009.9 1017.5 845.09 854.0 862.9 350 1055.6 1063.2 1070.9 866.26 875.2 884.1 400 1159.8 1167.4 1175.1 936.83 945.8 954.8 -

[1] Lütjering G , Williams J C. Titanium[M]. New York: Berlin Heidelberg, 2007: 1-12. [2] Kroll W. The production of ductile titanium[J]. Transaction of the Electrochemical Society, 1940,78:35−47. doi: 10.1149/1.3071290 [3] Sheng Zhuo, Li Kaihua, Li Liang. Inflow process of Fe, Ni, and Cr impurities in Ti sponge during Kroll process[J]. Metallurgical Research & Technology, 2020,117(101):1−7. [4] Ivan, Fedorovich, Chervonyj, et al. Thermodynamic laws of impurities in the titanium sponge inflow during its production[J]. Acta Mechanica Slovaca, 2011,13(4):40−47. [5] Li Jiayin, Wu Weiyan. Titanium production using integrated process of Mg reduction with distillation large scale equipment improvement[J]. Titanium Industry Process, 2010,27(4):25−29. (李家荫, 吴卫岩. 镁热还原蒸馏联合法生产海绵钛—大型设备装备水平的改进[J]. 钛工业进展, 2010,27(4):25−29. doi: 10.3969/j.issn.1009-9964.2010.04.007 [6] 肖志海, 肖自江, 陈德明, 等. 抑制海绵钛生产用反应器拉伸装置及方法: 中国, CN114231757A[P]. 2022-03-25.Xiao Zhihai, Xiao Zijiang, Chen Deming, et al. A device and method for inhibiting stretching of the titanium sponge reactor: China, CN114231757 A[P]. 2022-03-25. [7] Ding Ziwen. Current situation analysis of titanium sponge production equipment[J]. China Metal Bulletin, 2019,(2):118−120. (丁子文. 海绵钛生产装备现状分析[J]. 中国金属通报, 2019,(2):118−120. doi: 10.3969/j.issn.1672-1667.2019.02.074 [8] Wang W, Wu F, Jin H. Enhancement and performance evaluation for heat transfer of air cooling zone for reduction system of sponge titanium[J]. Heat and Mass Transfer, 2017,53(2):465−473. doi: 10.1007/s00231-016-1836-z [9] 盛卓, 李开华, 马占山, 等. 一种海绵钛生产反应器: 中国, CN113373305B[P]. 2022-06-03.Sheng Zhuo, Li Kaihua, Ma Zhanshan, et al. A reactor for titanium sponge production: China, CN113373305B[P]. 2022-06-03. [10] He Yongdong, Chen Deming, Sun Xiaohan, et al. Simulation of temperature field in a 13 t large-scale titanium sponge reduction reactor[J]. Journal of Special Foundry and Non-ferrous Alloys, 2021,41(8):956−960. (贺永东, 陈德明, 孙小涵, 等. 13 t大型海绵钛反应器内部温度场模拟研究[J]. 特种铸造及有色合金, 2021,41(8):956−960. [11] Gao Chengtao, Wu Fuzhong, Wang Wenhao, et al. Analysis of temperature field in molten pool for sponge titanium production by magnesiothermic reduction[J]. Nonferrous Metals(Extractive Metallurgy), 2014,(4):22−25. (高成涛, 吴复忠, 王文豪, 等. 镁热法生产海绵钛还原熔池温度场的分析[J]. 有色金属(冶炼部分), 2014,(4):22−25. [12] Hyun Na Bae, Seon Hyo Kim, Lee Go Gi, et al. Study of thermal behavior in a Kroll reactor for the optimization of Ti sponge production[J]. Materials Science Forum, 2010,654:839−842. [13] 胡小平. 传热传质分析[M]. 长沙: 国防科技大学出版社, 2011.Hu Xiaoping. Analysis of mass and heat transfer[M]. Changsha: National University of Defense Technology Press, 2011. -

下载:

下载: