| [1] |

Pietzka M A, Schuster J C. Summary of constitutional data on the aluminum-carbon-titanium system[J]. Journal of Phase Equilibria, 1994,15(4):392-400. doi: 10.1007/BF02647559

|

| [2] |

Tzenov N V, Barsoum M W. Synthesis and characterization of Ti3AlC2[J]. Journal of the American Ceramic Society, 2000,83(4):825-832.

|

| [3] |

Zhang Heng, Wang Libo, Dai Yahui, et al. Preparation and performances of ternary layered ceramic Ti3AlC2/ultrahigh molecular weight polyethylene composites[J]. Acta Materiae Compositae Sinica, 2017,34(6):1177−1184. (张恒, 王李波, 戴亚辉, 等. 三元层状陶瓷Ti3AlC2/超高分子量聚乙烯复合材料的制备及性能[J]. 复合材料学报, 2017,34(6):1177−1184.

|

| [4] |

Li Liang, Chen Yuqi, Ma Shibang, et al. Synthesis of Ti3AlC2 and its electrical transmission performance by thermobaric method using TiH2 as Ti source[J]. Journal of Nanyang Normal University, 2020,19(6):24−27. (李良, 陈玉奇, 马世榜, 等. 以TiH2为Ti源热压法合成Ti3AlC2及其电传输性能研究[J]. 南阳师范学院学报, 2020,19(6):24−27. doi: 10.3969/j.issn.1671-6132.2020.06.005

|

| [5] |

李翀. Ti3AlC2陶瓷材料的SHS/PHIP制备工艺及其性能与应用研究[D]. 哈尔滨: 哈尔滨工程大学, 2007.Li Chong. Ti3AlC2 the preparation process of SHS/PHIP of ceramic materials and its properties and applications[D]. Harbin: Harbin Engineering University, 2007.

|

| [6] |

Wang Qingsong, Dai Li, Zhao Na, et al. Electrical and mechanical properties of discharge plasma sintering Cu/Ti3AlC2[J]. Foshan Ceramics, 2020,30(1):23−26. (王青松, 代历, 赵娜, 等. 放电等离子烧结Cu/Ti3AlC2的电性能及力学性能[J]. 佛山陶瓷, 2020,30(1):23−26.

|

| [7] |

刘可. Ti3AlC2复合材料的离子辐照及摩擦磨损性能研究[D]. 合肥: 合肥工业大学, 2008.Liu Ke. Study on ionic irradiation and friction and wear properties of Ti3AlC2 composites[D]. Hefei: Hefei University of Technology, 2008.

|

| [8] |

Yang Zhanxin, Wu Qiong, Qi Guochao, et al. Study on synthesis of high purity Ti3AlC2 materials by pressureless sintering[J]. Journal of Ceramics, 2019,44(12):41-43. (杨占鑫, 吴琼, 齐国超, 等. 无压烧结制备高纯层状Ti3AlC2材料的研究[J]. 陶瓷学报, 2019,44(12):41-43.

|

| [9] |

Lv Zhenlin, Liu Jingge, Xiao Qiyan, et al. Preparation of Ti3AlC2 ceramics and their friction and wear properties[J]. Journal of the Chinese Ceramic Society, 2012,40(4):503−506. (吕振林, 刘晶歌, 肖琪聃, 等. Ti3AlC2陶瓷的制备及其摩擦磨损性能[J]. 硅酸盐学报, 2012,40(4):503−506.

|

| [10] |

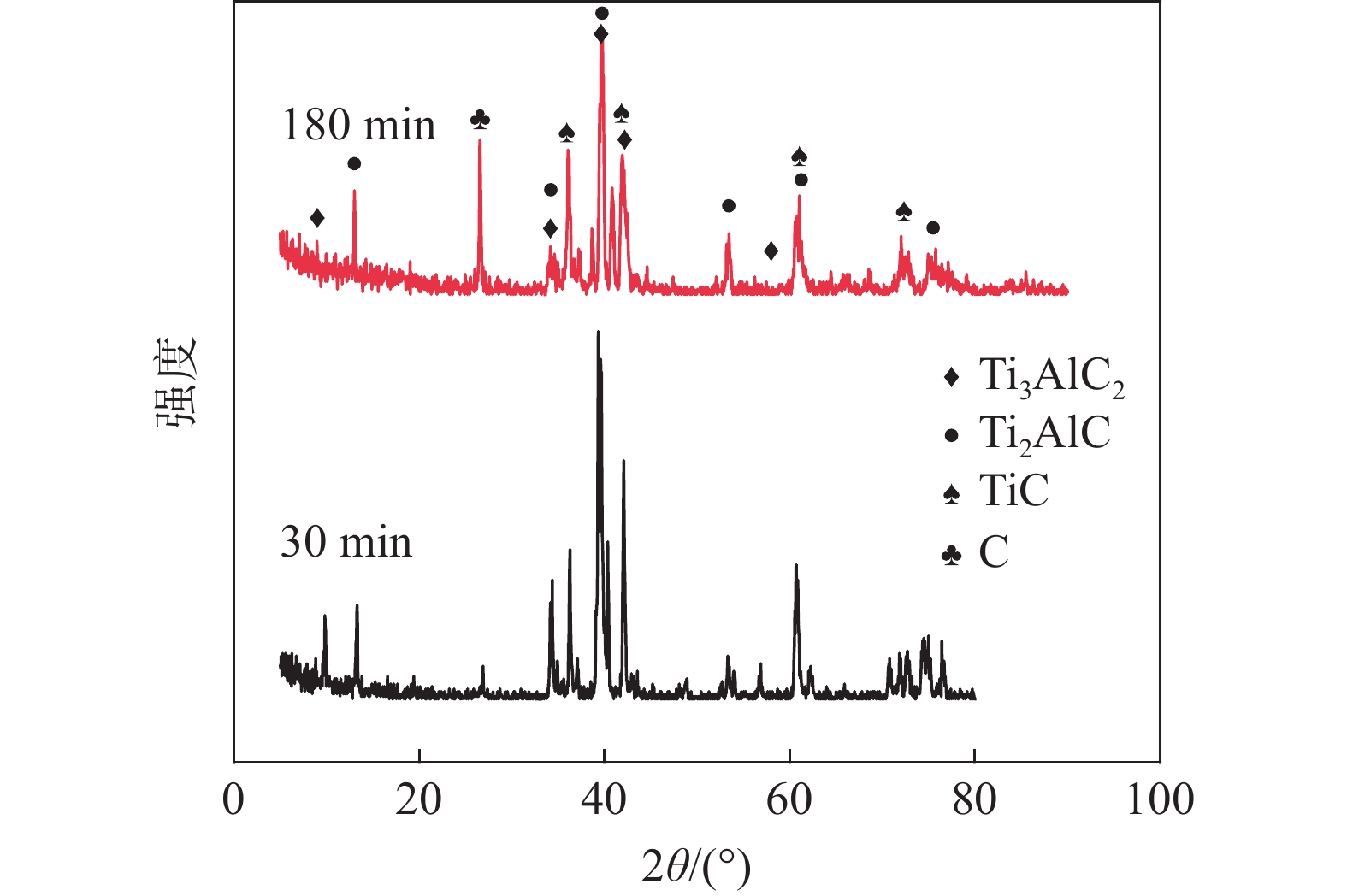

Peng Hang, Dai Shuai, Ni Jie, et al. Preparation of Ti–Al–C ternary layered ceramics by pressureless sintering[J]. Journal of the Chinese Ceramic Society, 2019,47(9):1301−1305. (彭航, 代帅, 倪杰, 等. 无压烧结制备Ti–Al–C系三元层状陶瓷[J]. 硅酸盐学报, 2019,47(9):1301−1305.

|

| [11] |

Li Xikun, Cai Ming, Qi Yanyu, et al. Preparation of Ti3AlC2 ceramics by powder metallurgy[J]. Journal of Shenyang Ligong University, 2020,39(1):24−28,34. (李喜坤, 蔡明, 齐艳雨, 等. 粉末冶金法制备Ti3AlC2陶瓷研究[J]. 沈阳理工大学学报, 2020,39(1):24−28,34. doi: 10.3969/j.issn.1003-1251.2020.01.006

|

| [12] |

Xiao Qiyan, Wu Shan, Sun Jinlei, et al. Study on current-carry friction and wear properties of Ti3AlC2 material[J]. Forging & Stamping Technology, 2015,36(8):1910−1913. (肖琪聃, 吴珊, 孙金磊, 等. Ti3AlC2材料载流摩擦磨损性能的研究[J]. 锻造技术, 2015,36(8):1910−1913.

|

| [13] |

Zhou Weibing, Mei Bingchu, Zhu Jiaoqun, et al. Fabrication of Ti2AlC/Ti3AlC2 ceramics material by hot pressing[J]. Shandong Ceramics, 2003,26(2):6−9. (周卫兵, 梅炳初, 朱教群, 等. 热压烧结工艺制备Ti2AlC/Ti3AlC2陶瓷材料[J]. 山东陶瓷, 2003,26(2):6−9. doi: 10.3969/j.issn.1005-0639.2003.02.002

|

| [14] |

Zhao Zhuoling, Feng Xiaoming, Ai Taotao, et al. Preparation and high-temperature oxidation behavior of Ti3AlC2 material[J]. Bulletin of the Chinese Ceramic Society, 2011,30(1):65−68. (赵卓玲, 冯小明, 艾桃桃, 等. Ti3AlC2材料的制备及其高温抗氧化性能研究[J]. 硅酸盐通报, 2011,30(1):65−68.

|

| [15] |

Wang Xinyu, Wu Lili, Gao Hong, et al. Synthesis of Ti3AlC2 and electrochemical performance of Ti3C2Tx nanosheet electrode[J]. Scientia Sinica(Chimica), 2018,48(3):289−297. (王新宇, 武立立, 高红, 等. Ti3AlC2的制备及Ti3C2Tx薄膜的电化学性能研究[J]. 中国科学:化学, 2018,48(3):289−297.

|

| [16] |

Han Xin, Wang Mingzhi, Liang Baoyan, et al. Fabrication of Ti3AlC2 by mechanical alloying and heat treatment with Sn Aids[J]. Rare Metal Materials and Engineering, 2010,A01:204−207. (韩欣, 王明智, 梁宝岩, 等. Sn做助剂机械合金化+热处理制备Ti3AlC2[J]. 稀有金属材料与工程, 2010,A01:204−207.

|

| [17] |

Liu Kexin, Jin Songzhe. Fabrication of Ti3AlC2 mechanical alloying ceramic materials[J]. Journal of Changchun University of Technology, 2012,33(1):106−110. (刘可心, 金松哲. 机械合金化合成Ti3AlC2导电陶瓷[J]. 长春工业大学学报, 2012,33(1):106−110. doi: 10.3969/j.issn.1674-1374-B.2012.01.024

|

| [18] |

Yang Chen, Jia Shusheng, Jin Songzhe, et al. Research on the fabrication of Ti3AlC2 ceramic materials by mechanical alloying[J]. Rare Metal Materials and Engineering, 2007,36(s3):282−285. (杨晨, 贾树胜, 金松哲, 等. 机械合金化制备Ti3AlC2陶瓷材料的研究[J]. 稀有金属材料工程, 2007,36(s3):282−285.

|

| [19] |

Qian Xukun. The effect of parameters of pressure-assisted combustion synthesis on preparation of Ti3AlC2 bulk[J]. Journal of Lishui University, 2017,39(2):36−41. (钱旭坤. 压力辅助燃烧合成工艺对制备Ti3AlC2块材的影响[J]. 丽水学院报, 2017,39(2):36−41.

|

| [20] |

Wang Xiaohui, Zhou Yanchun. Solid-liquid reaction synthesis of layered machinable Ti3AlC2 ceramic[J]. Journal of Materials Chemistry, 2002,12(3):455−460. (王晓辉, 周彦春. 层状可加工Ti3AlC2陶瓷的固液反应合成[J]. 材料化学学报, 2002,12(3):455−460. doi: 10.1039/b108685e

|

| [21] |

Ai Taotao, Feng Xiaoming, Xu Feng, et al. Fabrication of Ti3AlC2 ceramics by insituhot-pressing technique[J]. Heat Treatment of Metals, 2010,35(12):113−116. (艾桃桃, 冯小明, 徐峰, 等. 原位热压合成Ti3AlC2陶瓷[J]. 金属热处理, 2010,35(12):113−116.

|

下载:

下载: