Study on desulfurization using ammonium bicarbonate and vanadium extraction by acid leaching from calcified vanadium tailings

-

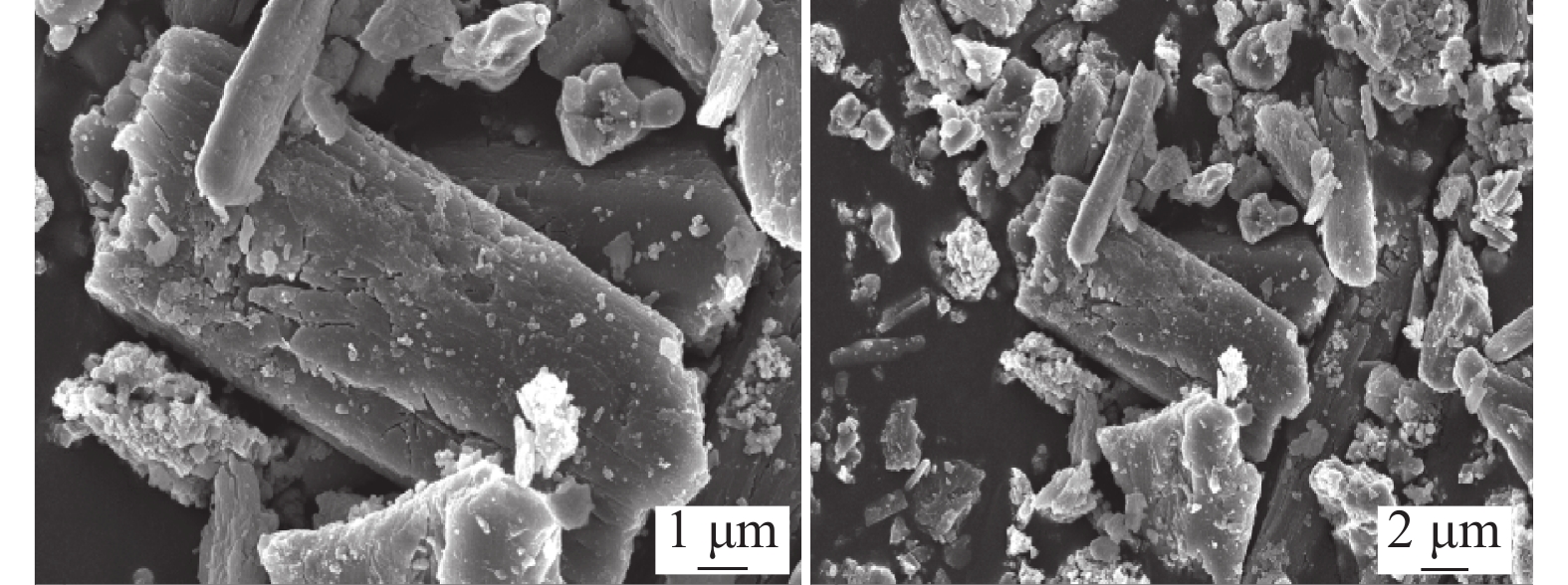

摘要: 针对钙化提钒尾渣难以实现有效提钒利用的现状,提出采用碳酸氢铵脱硫-酸性浸出的工艺对钙化提钒尾渣进行处理。研究了脱硫过程中反应温度、碳酸氢铵加入量、液固比对脱硫效果的影响;酸浸过程中温度、pH、液固比对提钒效果的影响,并采用曲面响应的研究手段进行了条件优化,获得了最佳反应参数。结果表明:在脱硫反应温度为30 ℃,碳酸氢铵用量与脱硫理论值之比为1.4∶1,脱硫液固比(L∶S)=5∶1时,脱硫率为94.58%;在酸浸温度30 ℃,酸浸液固比L∶S=6∶1,酸浸pH=1.0的条件下,尾渣钒的浸出率为56.79%。通过曲面响应试验得到了最佳工艺参数:浸出pH为0.977,浸出温度为39.36 ℃,液固比4.455∶1。在该条件下,钒的浸出率的预测值为56.80%,验证性试验浸出率为56.77%,比预测值仅低0.03个百分点。研究结果表明该工艺操作简单,脱硫率高,提钒效果较好,有利于钙化提钒尾渣的有效利用,具有良好的发展前景。Abstract: In view of the current situation that it is difficult to achieve effective utilization of vanadium from calcified vanadium extraction tailings, a process of desulfurization using ammonium bicarbonate followed by acid leaching was proposed. The effects of reaction temperature, adding amount of ammonium bicarbonate and liquid-solid ratio on desulfurization were studied. In the subsequent process of acid leaching, the effects of leaching temperature, pH value and liquid-solid ratio on the vanadium extraction were also studied. The surface response method was used to optimize the conditions and the best reaction parameters was obtained. The results show that the desulfurization rate reaches 94.58% when the reaction temperature is 30 ℃, the ratio of ammonium bicarbonate to the theoretical value of desulfurization is 1.4∶1 and the ratio of liquid to solid (L∶S) is 5∶1. Under the conditions of acid leaching temperature of 30 ℃, liquid-solid ratio (L∶S) of 6∶1 and pH value of 1.0, the vanadium leaching rate of tailing slag is 56.79%. According to the surface response test results, the optimal process parameters were obtained containing leaching pH value of 0.977, leaching temperature of 39.36 ℃ and liquid-solid ratio of 4.455∶1. Under these conditions, the predicted value of vanadium leaching rate is 56.80%, and the confirmatory experiment shows that the leaching rate is 56.77%, which is only 0.03% lower than the former. This process has the advantages of simple operation, high desulfurization rate and good vanadium extraction effect, which is conducive to the effective utilization of calcified vanadium extraction tailings and has a good development prospect.

-

表 1 钙化提钒尾渣主要成分含量

Table 1. Main composition of calcified vanadium extraction tailings

% S V CaO TFe MgO MnO 6.59 0.865 11.46 25.90 1.48 6.51 表 2 脱硫最佳条件稳定试验结果

Table 2. Stable desulfurization results under optimum conditions

编号 残渣质量/g 钒含量/% 脱硫率/% 1 26.53 0.92 94.62 2 26.51 0.93 94.49 3 26.55 0.93 94.64 平均值 26.53 0.93 94.58 表 3 酸性浸出最佳条件稳定试验结果

Table 3. Stable test results under optimal acid leaching conditions

编号 残渣质量/g 钒含量/% 浸出率/% 1 10.46 0.74 55.77 2 10.41 0.73 57.03 3 10.45 0.73 57.58 平均值 10.44 0.73 56.79 表 4 Box-Behnken设计因素与水平

Table 4. Box-Behnken design factors and levels

水平 因素 A(浸出pH) B(浸出温度/℃) C(液固比) +1 0.8 30 2∶1 0 1.0 40 4∶1 −1 1.2 50 6∶1 表 5 Box-Behnken试验设计与试验结果

Table 5. Box-behnken test design and results

编号 因素 浸出率/% A B C 1 −1 −1 0 40.13 2 1 −1 0 38.61 3 −1 1 0 49.00 4 1 1 0 52.01 5 −1 0 −1 47.61 6 1 0 −1 45.89 7 −1 0 1 52.61 8 1 0 1 43.30 9 0 −1 −1 40.73 10 0 1 −1 51.79 11 0 −1 1 42.45 12 0 1 1 47.97 13 0 0 0 38.47 14 0 0 0 39.70 15 0 0 0 36.99 16 0 0 0 39.70 17 0 0 0 36.68 表 6 回归模型的方差分析结果

Table 6. Variance analysis results of regression model

来源 平方和 自由度 均方 F值 P值 显著性 模型 490.87 9 54.54 27.48 0.0001 显著 残差 13.89 7 1.98 失拟项 5.64 3 1.88 0.9110 0.5109 不显著 纯误差 8.25 4 2.06 总误差 504.76 16 -

[1] Sun Zhaohui. Analysis on new vanadium technologies and prospects of vanadium industry[J]. Iron Steel Vanadium Titanium, 2012,33(1):1−7. (孙朝晖. 钒新技术及钒产业发展前景分析[J]. 钢铁钒钛, 2012,33(1):1−7. doi: 10.7513/j.issn.1004-7638.2012.01.001 [2] Ji Yunbo, Tong Xiong, Ye Guohua. The research status and progress of vanadium extraction[J]. Metallic Ore Dressing Abroad, 2007,44(5):10-13, 37. (姬云波, 童 雄, 叶国华. 提钒技术的研究现状和进展[J]. 国外金属矿选矿, 2007,44(5):10-13, 37. [3] Wu Hanjiang, Zhang Fengshou, Yan Genpeng. Influence of process parameters on residual stress for TC4 alloy aero-engine blade in precision forging[J]. Forging & Stamping Technology, 2020,45(1):9-14. (吴捍疆, 张丰收, 燕根鹏. 工艺参数对TC4合金航空发动机叶片精锻残余应力的影响[J]. 锻压技术, 2020,45(1):9-14. doi: 10.13330/j.issn.1000-3940.2020.01.002 [4] Lü Changxiao, Zhang Ting'an, Zhang Ying, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Chinese Journal of Rare Metals, 2020,44(11):1208−1214. (吕昌晓, 张廷安, 张莹, 等. 从钙化焙烧-酸浸尾渣中综合回收钒的研究[J]. 稀有金属, 2020,44(11):1208−1214. doi: 10.13373/j.cnki.cjrm.xy19020016 [5] 徐兴名, 张林, 王进, 等. 钒渣钙化焙烧熟料的二次酸浸工艺: 中国, CN109097567A[P]. 2018-12-28.Xu Xingming, Zhang Lin, Wang Jin, et al. Secondary acid leaching technology of calcified roasting clinker with vanadium slag: China, CN109097567A[P]. 2018-12-28. [6] 何文艺, 申彪, 李明, 等. 钙化提钒尾渣的提钒方法: 中国, CN109355515B[P]. 2021-03-16.He Wenyi, Shen Biao, Li Ming, et al. The method of vanadium extraction from calcified vanadium tailings: China, CN109355515B[P]. 2021-03-16. [7] 付自碧, 申彪, 叶露, 等. 一种从钙化提钒尾渣中回收钒的方法: 中国, CN114350981A[P]. 2022-04-15.Fu Zibi, Shen Biao, Ye Lu, et al. A method for recovery of vanadium from calcified vanadium extraction tailings: China, CN114350981A[P]. 2022-04-15. [8] 张林. 浓硫酸浸出提钒技术研究[C]//2014全国钒钛学术交流会论文集. 攀枝花: 中国金属学会, 2014: 59-61.Zhang Lin. Research on vanadium extraction technology by concentrated sulfuric acid leaching [C]//Proceedings of 2014 National Vanadium and Titanium Academic Exchange Conference. Panzhihua: The Chinese Society for Meta. , 2014: 59-61. [9] Li Lanjie, Zhang Li, Zheng Shili, et al. Acid leaching of calcined vanadium titanomagnetite with calcium compounds for extraction of vanadium[J]. The Chinese Journal of Process Engineering, 2011,(4):573−578. (李兰杰, 张力, 郑诗礼, 等. 钒钛磁铁矿钙化焙烧及其酸浸提钒[J]. 过程工程学报, 2011,(4):573−578. [10] Zhang Juhua, Zhang Wei, Zhang Li, et al. Effect of acid leaching on the vanadium leaching rate in process of vanadium extraction using calcium roasting[J]. Journal of Northeastern University(Natural Science), 2014,35(11):1574−1578. (张菊花, 张伟, 张力, 等. 酸浸对钙化焙烧提钒工艺钒浸出率的影响[J]. 东北大学学报 (自然科学版), 2014,35(11):1574−1578. [11] Ashvin J, Makadia J, Nanavati I. Optimisation of machining parameters for turning operations based on response surface methodology[J]. Measurement, 2013,46(4):1521−1529. doi: 10.1016/j.measurement.2012.11.026 [12] Liu Bingguo, Peng Jinhui, Wan Rundong, et al. Optimization of preparing V2O5 by calcination from ammonium metavanadate using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2011,21(3):673−678. doi: 10.1016/S1003-6326(11)60764-4 [13] Nie Wenlin, Luo Bin, He Yanbing. Experiment study on optimization of sulfuric acid leaching of titanium from titanium-bearing electric furnace slag by response surface methodology[J]. Mining & Metallurgy, 2021,30(2):83−87. (聂文林, 罗斌, 何雁冰. 响应曲面法优化硫酸浸出钒钛磁铁矿高炉渣试验研究[J]. 矿冶, 2021,30(2):83−87. doi: 10.3969/j.issn.1005-7854.2021.02.013 [14] Zheng Zhaoqiang, Xia Hongying, Peng Jinhui, et al. Process optimization for the preparation of activate carbon from abandoned dregs of gallumt using response surface methodology[J]. Environmental Pollution & Control, 2013,35(3):5−9. (郑照强, 夏洪应, 彭金辉, 等. 响应曲面法优化废弃五倍子药渣制取活性炭的研究[J]. 环境污染与防治, 2013,35(3):5−9. doi: 10.3969/j.issn.1001-3865.2013.03.002 -

下载:

下载: