Preparation of Zr-doped BaTiO3 dielectric ceramics by solution combustion synthesis and its energy storage performance

-

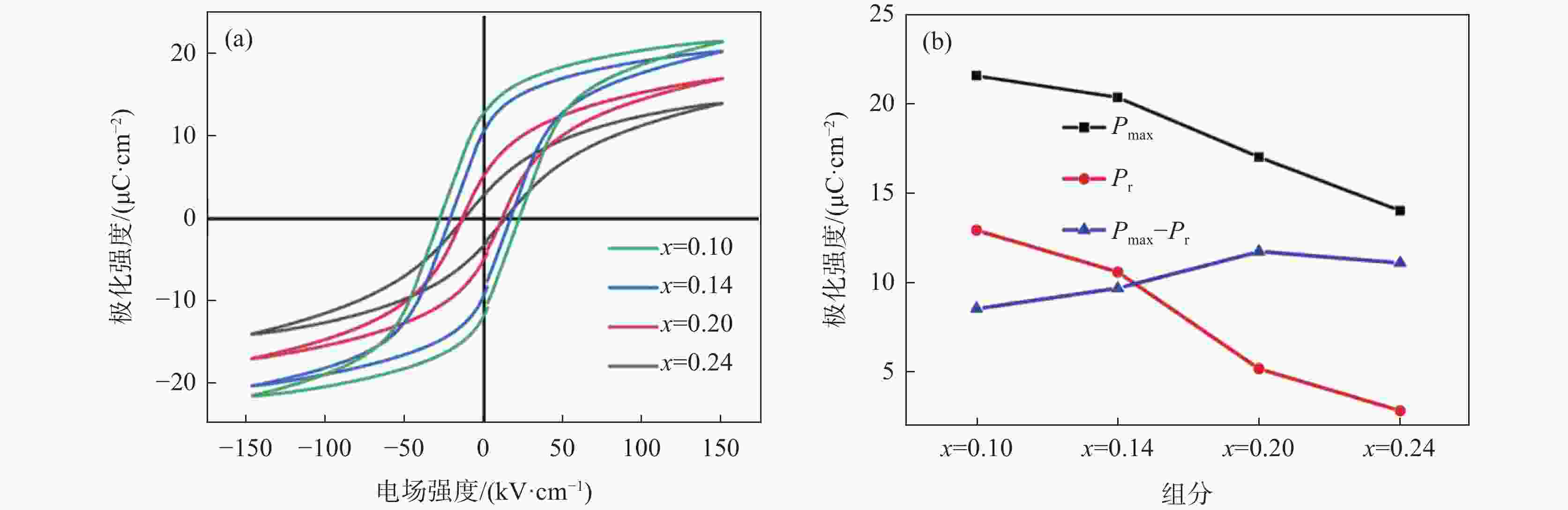

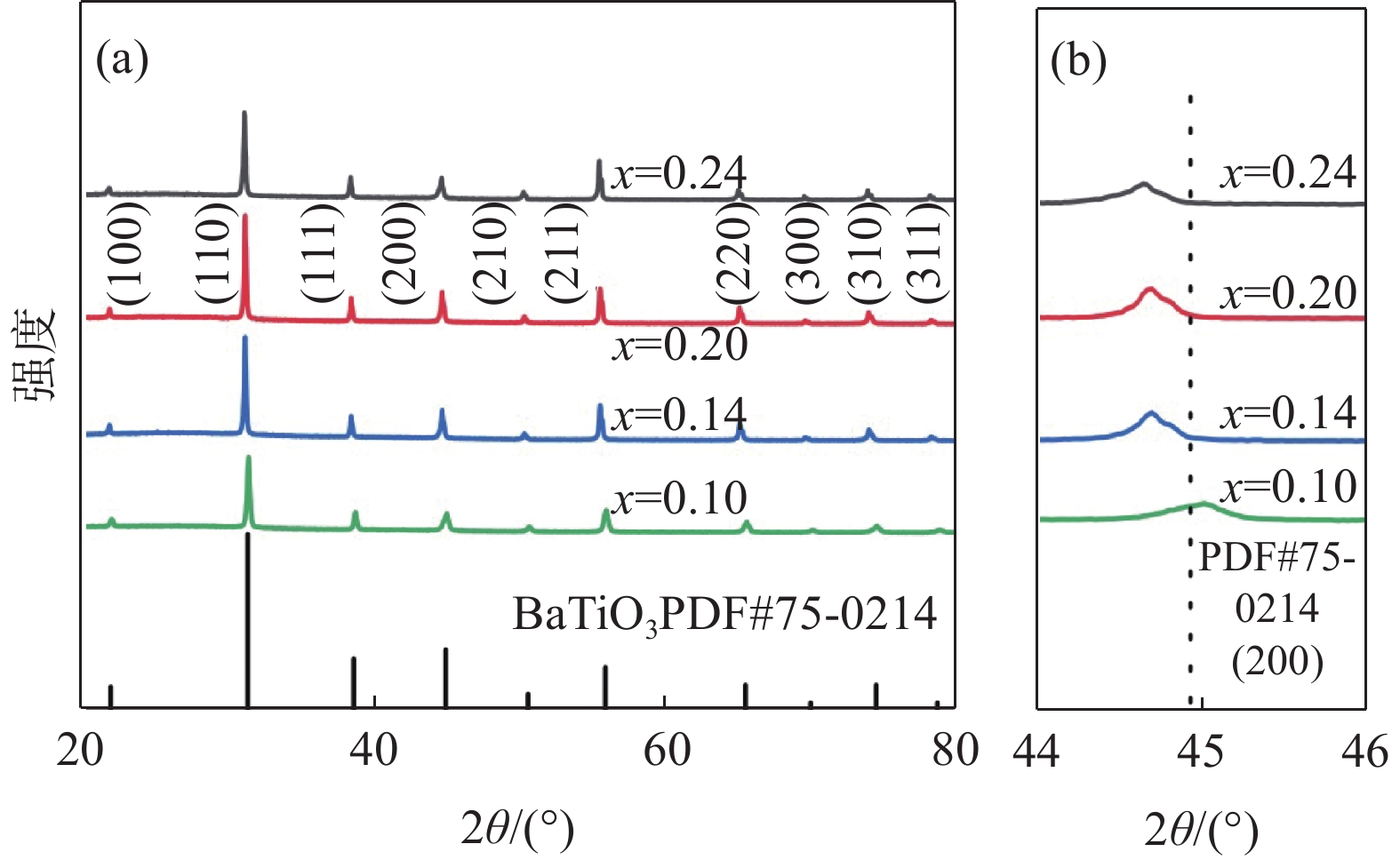

摘要: 介电陶瓷电容器具有超高的功率密度和超快的充放电速度,在能量回收系统、脉冲大功率领域等具有重要的应用前景。以硝酸钡、钛酸丁酯、硝酸氧锆、甘氨酸以及硝酸为原料,柠檬酸为络合剂,硝酸锰为助烧剂,采用溶液燃烧法制备了Zr掺杂的 BaTi(1-x)ZrxO3(BTZx)介电陶瓷。分别采用 X 射线衍射仪和扫描电子显微镜对BTZx介电陶瓷样品进行了物相和微观形态分析。利用精密阻抗分析仪和铁电分析仪研究了BTZx 介电陶瓷样品的介电和储能性能。研究结果表明,Zr4+的引入细化了陶瓷晶粒,提高了击穿强度,增加了离子混乱度,有效减小了剩余极化。当x=0.20时,获得优异的储能性能: 在350 kV/cm下,可释放能量密度和储能效率分别达到 1.60 J/cm3 和 88.5%。Abstract: Dielectric ceramic capacitors have important application prospects in energy recovery systems and pulse power fields due to their ultrahigh power density and ultrafast charging- discharging speed. In this paper, Zr-doped BaTi(1-x)ZrxO3 (BTZx) dielectric ceramics were prepared by solution combustion synthesis with barium nitrate, butyl titanate, zirconium nitrate, glycine and nitric acid as raw materials, citric acid as complexing agent and manganese nitrate as sintering aid. The crystalline structure and microscopic morphologies of BTZx dielectric ceramic samples were analyzed by X-ray diffractometer and scanning electron microscope, respectively. The dielectric and energy storage properties of the BTZx dielectric ceramic samples were investigated using a precision impedance analyzer and a ferroelectric analyzer. The results show that the introduction of Zr4+ refines the ceramic grains, improves the breakdown strength, increases the ionic disorder, and effectively reduces the remanent polarization. When x=0.20, excellent energy storage performance is obtained: at 350 kV/cm, the recoverable energy density and energy storage efficiency reach 1.60 J/cm3 and 88.5%, respectively.

-

图 6 (a) BTZ0.20在不同电场条件下的单极电滞回线; (b)不同电场条件下的极化特性; (c) 不同电场下BTZ0.20的储能特性

Figure 6. (a) Variations of the unipolar P-E loops of BTZ0.20 with different electric fields; (b) The polarization characteristics of BTZ0.20 under different electric fields; (c) Energy storage properties of BTZ0.20 under different electric fields

-

[1] Wang Ge, Lu Zhilun, Li Yong, et al. Electroceramics for high-energy density capacitors: Current status and future perspectives[J]. Chemical Reviews, 2021,121(10):6124−6172. doi: 10.1021/acs.chemrev.0c01264 [2] Letao Yanga, Xi Konga, Fei Li, et al. Perovskite lead-free dielectrics for energy storage applications[J]. Progress in Materials Science, 2019,102:72−108. doi: 10.1016/j.pmatsci.2018.12.005 [3] Sun Zixiong , Wang Zhuo , Tian Ye , et al. Progress, outlook, and challenges in lead-free energy-storage ferroelectrics [J]. Advanced Electronic Materials, 2019: 1900698. [4] Yao Zhonghua, Song Zhe, Hao Hua, et al. Homogeneous/Inhomogeneous-structured dielectrics and their energy-storage performances[J]. Advanced Materials, 2017,29(20):1601727. doi: 10.1002/adma.201601727 [5] Haribabu Palneedi, Mahesh Peddigari, Geon-Tae Hwang, et al. High-performance dielectric ceramic films for energy storage capacitors: Progress and outlook[J]. Advanced Functional Materials, 2018,28:1803665. doi: 10.1002/adfm.201803665 [6] Yuan Qibin, Chen Mi, Zhan Shili, et al. Ceramic-based dielectrics for electrostatic energy storage applications: Fundamental aspects, recent progress, and remaining challenges[J]. Chemical Engineering Journal, 2022,446:136315. doi: 10.1016/j.cej.2022.136315 [7] Zeng Fanzhou, Cao Minghe, Zhang Lin, et al. Microstructure and dielectric properties of SrTiO3 ceramics by controlled growth of silica shells on SrTiO3 nanoparticles[J]. Ceramics International, 2017,43:7710−7716. doi: 10.1016/j.ceramint.2017.03.073 [8] Wang Fenglin, Zhang Weijun, Mao Haijun, et al. Research progress on temperature-stable BaTiO3-based complex perovskite MLCC dielectrics[J]. Materials Reports, 2022,36(1):57−63. (汪丰麟, 张为军, 毛海军, 等. 温度稳定型BaTiO3基复合钙钛矿型介质材料研究进展[J]. 材料导报, 2022,36(1):57−63. [9] Yan Guiwei, Ma Minggang, Li Chengbo, et al. Enhanced energy storage property and dielectric breakdown strength in Li+ doped BaTiO3 ceramics[J]. Journal of Alloys and Compounds, 2021,857:158021. doi: 10.1016/j.jallcom.2020.158021 [10] Si Xie, Yang Bai, Fei Han, et al. Distinct effects of Ce doping in A or B sites on the electrocaloric effect of BaTiO3 ceramics[J]. Journal of Alloys and Compounds, 2017,724:163−168. doi: 10.1016/j.jallcom.2017.07.012 [11] 徐源. 锆钛酸钡陶瓷的制备及改性研究[D]. 汉中: 陕西理工大学, 2019.Xu Yuan. Preparation and modification of zirconium titanate ceramics[D]. Hanzhong: Shaanxi University of Technology, 2019. -

下载:

下载: