Two pass laser welding of TC4 titanium alloy and 316L stainless steel with vanadium interlayer

-

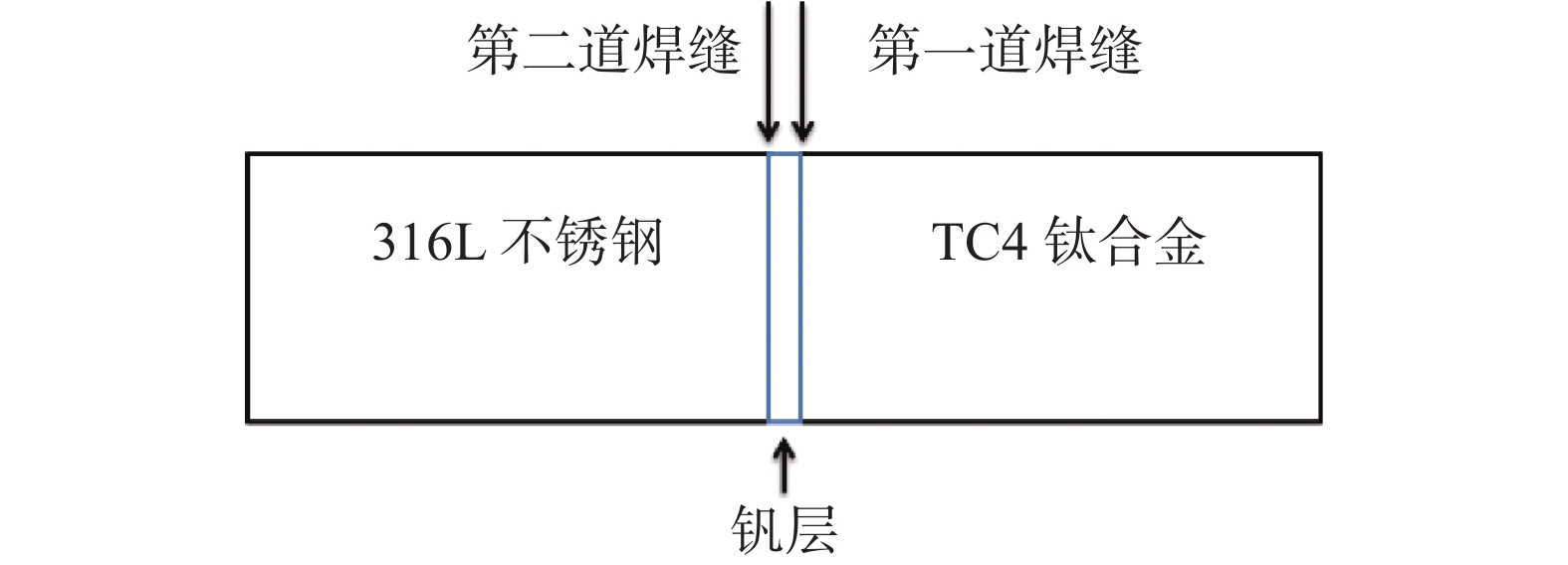

摘要: 采用TC4钛合金和316L不锈钢作为母材,纯钒作为中间层材料,进行了双道激光焊接试验。研究了焊接速度、光束偏移量对焊缝成形、显微组织、力学性能的影响,并进行了分析测试。结果表明:在钛合金一侧的钒中间层可发生一定程度的熔化,但界面近域均为固溶体,对接头的力学性能影响较小。在钒与不锈钢一侧,钒中间层与不锈钢呈钎焊界面,钒发生一定程度的溶解与扩散,形成扩散层。随着钢侧光束偏移量的增加,V/Fe界面扩散层的厚度减小,偏移量为0.3 mm时,界面扩散层厚度达到35.8 μm,此时抗拉强度最高达到406.9 MPa,断裂位置为钒/不锈钢界面处,断口呈韧性断裂特征。

-

关键词:

- 钛合金;不锈钢;双道激光焊接 /

- 钒中间层 /

- 焊接速度 /

- 光束偏移量

Abstract: A two-pass laser welding test was carried out using TC4 titanium alloy and 316L stainless steel as the base material and pure vanadium as the interlayer material. The influence of welding speed and beam offset on weld formation, microstructure, and mechanical properties were studied and analyzed. The results show that the vanadium interlayer on the side of titanium alloy can be melted to a certain extent. Still, all near the interface are the solid solution, and the mechanical properties of the joint are less affected. On the side of stainless steel, the vanadium interlayer is brazed with the stainless steel. Vanadium dissolves and diffuses to some extent, forming a diffusion layer. With the increase of beam offset on the steel side, the thickness of the V/Fe interface diffusion layer decreases. At an offset of 0.3 mm, the thickness of the interfacial diffusion layer reaches 35.8 μm, and the maximum tensile strength reaches 406.9 MPa at this time. The fracture location is at the vanadium/stainless steel interface, and the fracture is characterized by ductile fracture. -

表 1 试验材料化学成分

Table 1. Chemical compositions of TC4 and 316L

% 材料 Fe C Si Ni Cr Mn Mo Al V Ti TC4 0.3 0.1 0.15 0.015 5.5 4.5 余量 316L 余量 ≤0.03 ≤1.0 10.0~14.0 16.0~18.0 ≤2.0 2.0~3.0 表 2 不锈钢/钒焊接界面的元素含量

Table 2. Element content of stainless steel/vanadium welding interface

% 位置 Ti V Cr Fe Ni A 0.06 28.47 11.98 51.61 7.88 B 0.07 14.80 16.54 60.74 7.85 -

[1] 王喆, 肖明颖, 高华兵, 等. 钛合金/钢异种连接接头组织与性能研究进展[J]. 材料工程, 2022, 50(5): 1-9.Wang Zhe, Xiao Mingying, Gao Huabing, et al. Research progress on microstructure and properties of titanium alloy/steel dissimilar joints[J]. Journal of Materials Engineering, 2022, 50(5): 1-9. [2] Liu Fu, Li Shikai, Jiang Peng, et al. Research progress of titanium/steel dissimilar metal welding technology[J]. Journal of Materials Development and Application, 2020,35(2):67−74. (刘夫, 李士凯, 蒋鹏, 等. 钛/钢异种金属焊接技术的研究进展[J]. 材料开发与应用, 2020,35(2):67−74. doi: 10.19515/j.cnki.1003-1545.2020.02.014 [3] Song Tingfeng, Jiang Xiaosong, Mo Defeng, et al. Progress in welding of stainless steel and titanium alloy dissimilar metals[J]. Materials Review, 2015,29(11):81−87. (宋庭丰, 蒋小松, 莫德锋, 等. 不锈钢和钛合金异种金属焊接研究进展[J]. 材料导报, 2015,29(11):81−87. [4] Zhang Y, Zhou J P, Sun D Q, et al. Nd: YAG laser welding of dissimilar metals of titanium alloy to stainless steel without filler metal based on a hybrid connection mechanism[J]. Journal of Materials Research and Technology, 2020,9(2):1662−1672. doi: 10.1016/j.jmrt.2019.12.001 [5] Ananthakumar K, Kumaran S. Plasma assisted diffusion joining of CP-titanium-304L stainless steel: Attributes of temperature and time[J]. Materials Today:Proceedings, 2020,33:3174−3176. doi: 10.1016/j.matpr.2020.04.099 [6] Chu Q, Tong X, Xu S, et al. Interfacial investigation of explosion-welded titanium/steel bimetallic plates[J]. Journal of Materials Engineering and Performance, 2020,29(1):78−86. doi: 10.1007/s11665-019-04535-9 [7] Li S, Chen Y, Zhou X, et al. High-strength titanium alloy/steel butt joint produced via friction stir welding[J]. Materials Letters, 2019,234:155−158. doi: 10.1016/j.matlet.2018.09.094 [8] Tomashchuk I, Sallamand P, Belyavina N, et al. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer[J]. Materials Science and Engineering:A, 2013,585:114−122. doi: 10.1016/j.msea.2013.07.050 [9] Zhang Yifu, Zhang Hua, Su Zhanzhan. Effect of Zr-Ni interlayer on microstructure and properties of laser welded TC4 titanium alloy /304SS stainless steel[J]. Rare Metals, 2020,44(11):1137−1145. (张义福, 张华, 苏展展. Zr-Ni中间层对TC4钛合金/304SS不锈钢激光焊接头组织性能的影响[J]. 稀有金属, 2020,44(11):1137−1145. [10] Yu J, Zhang H, Wang B, et al. Dissimilar metal joining of Q235 mild steel to Ti6Al4V via resistance spot welding with Ni–Cu interlayer[J]. Journal of Materials Research and Technology, 2021,15:4086−4101. doi: 10.1016/j.jmrt.2021.10.039 [11] Tomashchuk I, Grevey D, Sallamand P. Dissimilar laser welding of AISI 316L stainless steel to Ti6–Al4–6V alloy via pure vanadium interlayer[J]. Materials Science and Engineering:A, 2015,622:37−45. doi: 10.1016/j.msea.2014.10.084 [12] Zhang Y, Zhou J, Sun D Q, et al. Two pass laser welding of TC4 titanium alloy to 301L stainless steel via pure V interlayer[J]. Journal of Materials Research and Technology, 2020,9(2):1400−1404. doi: 10.1016/j.jmrt.2019.11.066 -

下载:

下载: