Experimental study on special strength curve of rebound method for concrete evaluation of high-titanium slag concrete

-

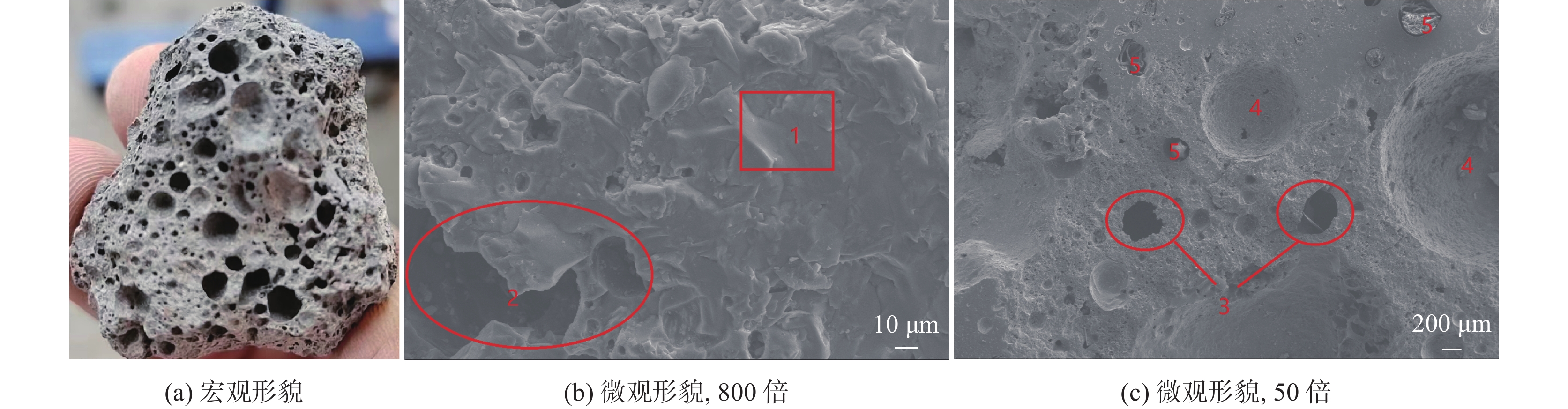

摘要: 在“碳达峰、碳中和”背景下,攀枝花地区推广应用高钛型高炉渣作为粗、细骨料制备混凝土。为提高回弹法检测高钛型高炉渣混凝土强度的准确度,运用高钛型高炉渣粗、细骨料制备强度等级为C20、C25、C30、C35、C40、C45、C50、C55、C60、C65、C70,边长为150 mm的高钛型高炉渣混凝土立方体试块,饱水养护7 d后自然养护21 d,再将其放入室内加速碳化箱加速碳化0、3、7、14、28 d,进行回弹—抗压—碳化深度测定试验。根据《回弹法检测混凝土抗压强度技术规程》(JGJ/T23-2011)推定混凝土强度值与实际抗压强度对比,分析回弹值、碳化深度与实际抗压强度值之间的关系,研究表明:直接运用《规程》测定混凝土回弹强度值普遍低于实际抗压强度值,差值较大,结果过于保守;在《规程》测定值基础上加10 MPa快速判定高钛型高炉渣混凝土回弹强度,精度高于《规范》推定値;基于回弹值、实际强度关系,结合碳化程度修正,运用最小二乘法拟合建立了精度更高的回弹法测定攀西地区高钛型高炉渣混凝土抗压强度的地区测强曲线

$ f_{cu,i}^c = {\text{0}}{\text{.380 3}}R_{\text{m}}^{{\text{1}}{\text{.362 7}}} \cdot {\text{1}}{{\text{0}}^{{{( - 0}}{\text{.008 3}}{{{d}}_{\text{m}}}{\text{)}}}} $ 。Abstract: Under the background of “achieving peak carbon dioxide emission and carbon neutrality,” high-titanium furnace slag is widely used as coarse and fine aggregate to prepare concrete in Panzhihua city of China. The purpose of this paper is to improve the accuracy of strength detection of high titanium slag concrete by springback method. Coarse and fine aggregates of high-titanium blast furnace slag are used to make high-titanium blast furnace slag concrete cubic blocks with strength grade of C20, C25, C30, C35, C40, C45, C50, C55, C60, C65, C70 and side length of 150 mm. Saturated with water for 7 days and then naturally cured for 21 days, then these test blocks were put into the indoor accelerated carbonization box to accelerate carbonization for 0 days, 3 days, 7 days, 14 days and 28 days, respectively, and the rebound-compression-carbonization depth tests are carried out. According to “Technical Specification for Inspecting of Concrete Compressive Strength by Rebound Method” (JGJ/T23-2011), this paper compares the presumed concrete strength value and the actual compressive strength to analyze the relationship between the rebound value, carbonation depth and the actual compressive strength value, the rebound strength of concrete measured by direct use of the “Rules” is generally lower than the actual compressive strength, the difference is large, the result is too conservative. On the basis of the values measured in the above-mentioned “Specification,” 10 MPa is added for the rapid determination of the springback strength of high-titanium furnace slag concrete with a precision higher than that of the “Specification.” In this paper, based on the relationship between rebound value, actual strength and carbonization degree correction, we established the regional strength curve of high-titanium blast furnace slag concrete compressive strength of Panxi area with higher accuracy by using the least square method fitting$f_{cu,i}^c = {\text{0}}{\text{.380 3}}R_{\text{m}}^{{\text{1}}{\text{.362 7}}} \cdot {\text{1}}{{\text{0}}^{-{\text{( 0}}{\text{.008 3}}{{{d}}_{\text{m}}}{\text{)}}}}$ . -

表 1 高钛型高炉渣成分及含量

Table 1. Composition and content of high-titanium blast furnace slag

% F Na2O MgO Al2O3 SiO2 SO3 K2O CaO TiO2 V2O5 MnO Fe2O3 其他 0.1 0.8 10 12 22 0.5 0.5 28 20 0.6 0.9 1.3 3.3 -

[1] Huang Shuanghua, Chen Wei, Sun Jinkun. The application of high titanium slag in concrete materials[J]. New Building Materials, 2006,11:71−73. (黄双华, 陈伟, 孙金坤, 等. 高钛高炉渣在混凝土材料中的应用[J]. 新型建筑材料, 2006,11:71−73. doi: 10.3969/j.issn.1001-702X.2006.11.025 [2] Wang Jie, Zhao Bijian, Zhang Guiyu. Development and application of high-titanium slag series building materials[J]. New Building Materials, 2002,(2):35−36. (王杰, 赵碧建, 张桂玉. 高钛渣系列建材产品的开发及应用[J]. 新型建筑材料, 2002,(2):35−36. [3] Jiang Haimin, Mou Tingmin, Ding Qingjun. Study on the working performance of high titanium heavy slag concrete[J]. Concrete, 2011,(5):125−127. (江海民, 牟廷敏, 丁庆军. 高钛重矿渣混凝土的工作性能研究[J]. 混凝土, 2011,(5):125−127. [4] Sun Jinkun, Chen Wei, Li Yingmin, et al. Experiment and analysis of bond properties between complex high titanium heavy slag concrete(CHTHSC) and reinforcement[J]. Sichuan Building Science, 2010,36(4):216−219. (孙金坤, 陈伟, 李英民, 等. 复高钛重矿渣混凝土与钢筋粘结性能试验研究[J]. 四川建筑科学研究, 2010,36(4):216−219. doi: 10.3969/j.issn.1008-1933.2010.04.057 [5] Wang Jie, Xu Xiaoqian, Huang Shuanghua. Experiment research on normal section flexural performance of flexural member by high titanium blast furnace slag[J]. Construction Technology, 2015,(s1):513−515. (汪杰, 徐晓倩, 黄双华. 高钛型高炉渣受弯构件正截面抗弯性能研究[J]. 施工技术, 2015,(s1):513−515. [6] Wang Jie. Experimental analysis on recycled concrete with high titanium heavy slag and bond properties of steel bars[J]. Revista de la Facultad de Ingeniería, 2017,32(10):204−210. [7] Zhou Wenbo, Ke Changming, Zhang Qin, et al. Application of Pangang blast-furnace slag in construction industry[J]. Multipurpose Utilization of Mineral Resources, 2007,(3):35−37. (周文波, 柯昌明, 张芹, 等. 攀钢高炉渣在建筑行业中的应用[J]. 矿产综合利用, 2007,(3):35−37. doi: 10.3969/j.issn.1000-6532.2007.03.010 [8] Du Huihui, Ni Wen, Gao Guangjun. Experimental study on preparation of C40 concrete with industrial solid wastes from high-titanium blast furnace slag[J]. Material Review, 2020,34(24):24055−24060. (杜惠惠, 倪文, 高广军. 水淬高钛高炉渣制备C40全固废混凝土试验研究[J]. 材料导报, 2020,34(24):24055−24060. [9] Deng P , Sun Y , Liu Y , et al. Revised rebound hammer and pull-out test strength curves for fiber-reinforced concrete[J]. Advances in Civil Engineering, 2020, (3): 8263745.1-8263745.12. [10] Yuan Wei, Yang Renfeng, Yu Jianyou, et al. Experimental study on special testing strength curve for compressive strength evaluation by rebound method[J]. Advances in Materials Science and Engineering, 2021: 8413010. [11] Kocáb D, Misák P, Cikrle P. Characteristic curve and its use in determining the compressive strength of concrete by the rebound hammer test[J]. Materials, 2019,12(17):2705. doi: 10.3390/ma12172705 [12] 中华人民共和国行业标准. JGJ/T23-2011. 回弹法检测混凝土抗压强度技术规程[S]. 北京: 中国建筑工业出版社, 2011.Industrial Standard of the People's Republic of China. JGJ/T23-2011. Technical specification for inspection of concrete compressive strength by rebound method [S]. Beijing: China Architecture and Building Press, 2011. [13] Hannachi S, Guetteche M N. Review of the rebound hammer method estimating concrete compressive strength on site[C]//Proceedings of International Conference on Architecture and Civil Engineering (ICAACE'14). Dubai: 2014: 118-127. [14] Liu Hanyong, Zhao Shangchuan, Wang Jiansheng. Study on special strength curve of rebound method for concrete evaluation of Oujiang river bridge[J]. China Civil Engineering Journal, 2015,48(1):41−48. (刘汉勇, 赵尚传, 王建生. 瓯江大桥混凝土回弹法专用测强曲线研究[J]. 土木工程学报, 2015,48(1):41−48. doi: 10.15951/j.tmgcxb.2015.01.005 [15] Yang Yao, Mao Haiyong, Zhang Hongbo, et al. Experimental study on testing compressive strength of concrete by rebound method in Luzhou area[J]. Sichuan Building Science, 2020,46(1):77−82. (杨曜, 毛海勇, 张洪波, 等. 泸州地区回弹法检测混凝土抗压强度试验研究[J]. 四川建筑科学研究, 2020,46(1):77−82. doi: 10.19794/j.cnki.1008-1933.2020.0013 [16] Guan Pinwu, Guo Jing, Yu Zheng, et al. Experimental study of concrete strength-measuring curve by rebound method for Henan district[J]. Sichuan Building Science, 2018,44(6):1−7. (管品武, 郭靖, 余政, 等. 河南地区回弹法检测混凝土测强曲线的试验研究[J]. 四川建筑科学研究, 2018,44(6):1−7. doi: 10.19794/j.cnki.1008-1933.2018.06.001 [17] Liu Lixian, Zhao Yanfeng, Lv Long, et al. Study of concrete strength-measuring curve by rebound method for Kunming district[J]. Building Science, 2015,31(9):65−69. (刘利先, 赵岩枫, 吕龙, 等. 昆明地区回弹法检测混凝土抗压强度测强曲线的研究[J]. 建筑科学, 2015,31(9):65−69. doi: 10.13614/j.cnki.11-1962/tu.2015.09.012 [18] Zhu Yuewu, Qiu Ping. Research on inspecting of regional concrete compressive strength by rebound method in Shenzhen[J]. Architecture Technology, 2014,45(4):346−348. (朱跃武, 邱平. 深圳地区回弹法检测混凝土抗压强度试验研究[J]. 建筑技术, 2014,45(4):346−348. doi: 10.13731/j.issn.1000-4726.2014.04.015 [19] GB/T 50082-2009. 普通混凝土长期性能和耐久性能试验方法标准[S]. 北京: 中国建筑工业出版社, 2009.GB/T 50082-2009. Standard for test method of long-term performance and durability of ordinary concrete [S]. Beijing: China Architecture and Building Press, 2009. [20] Wang Jie, Li Gen, Liang Yuehua, et al. Experimental study on the prediction model of carbonization depth in high Ti-bearing blast furnace slag concrete[J]. Iron Steel Vanadium Titanium, 2022,43(2):101−106. (汪杰, 李根, 梁月华, 等. 高钛型高炉渣混凝土碳化深度试验研究[J]. 钢铁钒钛, 2022,43(2):101−106. [21] GB/T 50081-2002. 普通混凝土力学性能试验方法标准[S]. 北京: 中国建筑工业出版社, 2003.GB/T 50081-2002. Ordinary concrete mechanics performance test method standard[S]. Beijing: China Architecture and Building Press, 2003. -

下载:

下载: