Study on preparation of super sulfate cement by titanium slag and phosphogypsum

-

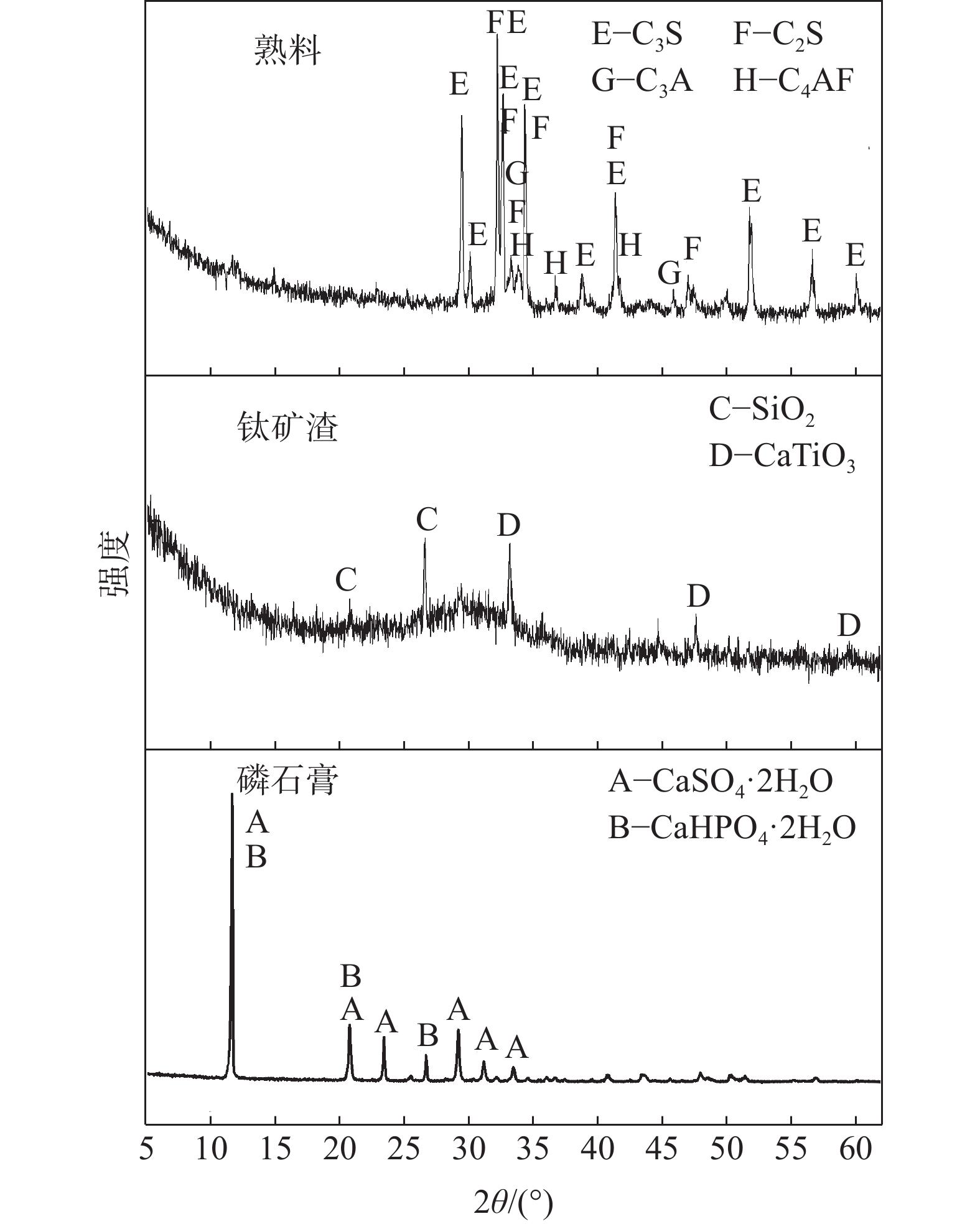

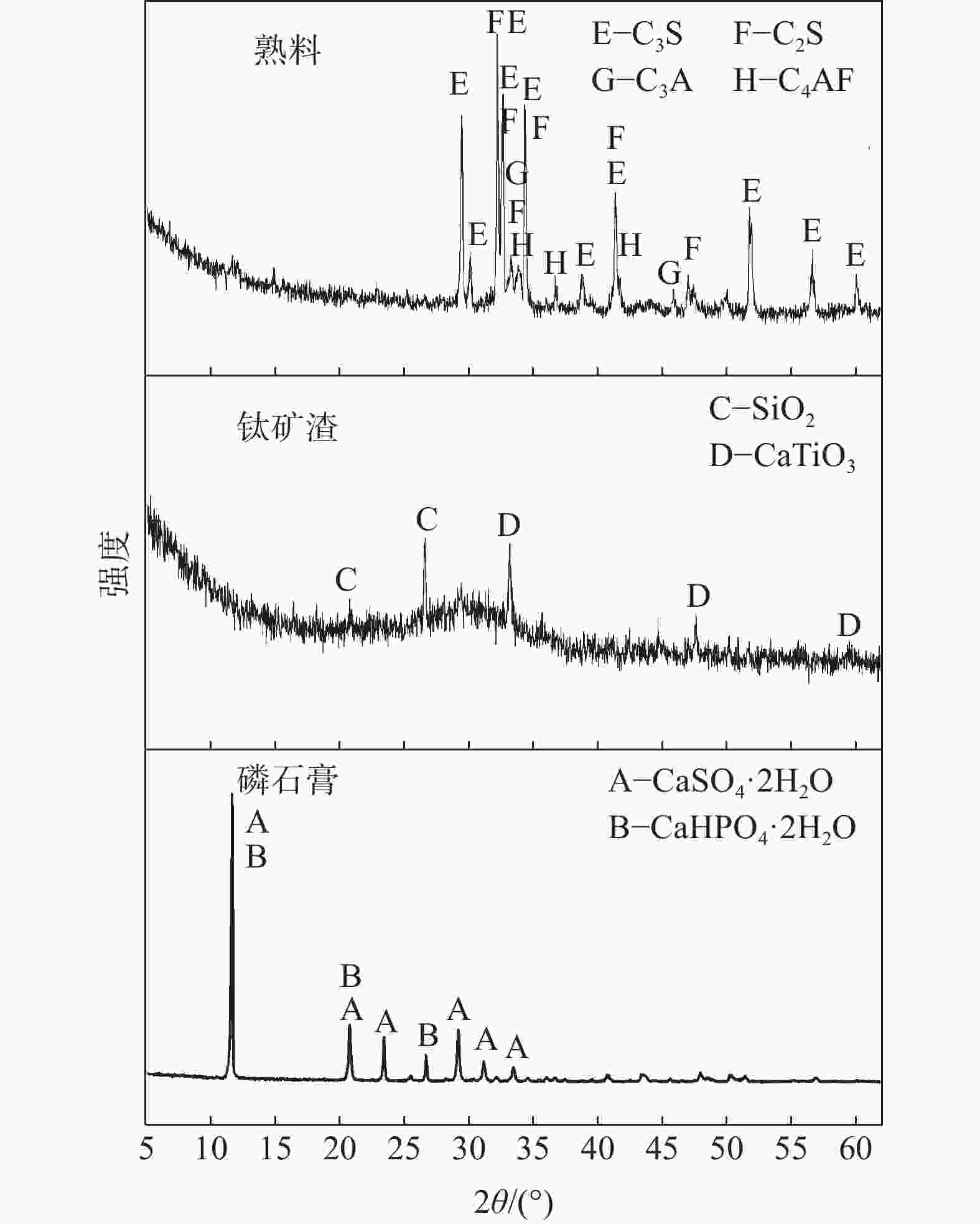

摘要: 采用磷石膏、钛矿渣、熟料和硅酸钠配制了10组超硫酸盐水泥,对基体的抗压强度、水化放热、水化产物进行了研究,并对纤维增强后的抗折强度、拉伸强度和抗冲击强度进行测试。结果表明,熟料和钛矿渣均能有效提升超硫酸盐水泥的抗压强度,并能促进水化放热和二次水化反应。较优的水泥配比为磷石膏∶钛矿渣∶熟料∶硅酸钠=25∶60∶13∶2,此时抗压强度达到42.1 MPa。玄武岩纤维可显著提高超硫酸盐水泥的抗折强度和抗冲击强度,表现为:当掺入0.3% 6 mm纤维时,试件的抗折强度提升了27.0%;掺入0.6%的12 mm纤维时,抗冲击强度提高了120.3%。拉伸试验结果表明,玄武岩纤维对提升水泥的极限拉伸强度不利,但能提高水泥的拉伸应变能力。Abstract: Ten groups of super sulfate cement (SSC) were prepared by phosphogypsum, titanium slag, clinker and sodium silicate. The compressive strength, hydration heat release and hydration products of the matrix were studied, and the flexural strength, tensile strength and impact strength after fiber reinforcement were tested. The results show that both clinker and titanium slag can effectively improve the compressive strength of SSC, and promote hydration exothermic and secondary hydration reaction. The optimal cement ratio is phosphogypsum 25%, titanium slag 60%, clinker 13%, sodium silicate 2%, and the compressive strength reaches 42.1 MPa. Basalt fiber can significantly improve the flexural strength and impact strength of SSC. Specifically, with an addition of 0.3% 6-mm fiber, the flexural strength of the specimen increases by 27.0%. The impact strength increases by 120.3% when 0.6% 12-mm fiber is added. The tensile test results show that basalt fiber is disadvantageous to the improvement of the ultimate tensile strength of cement, but can enhance the tensile strain capacity of cement.

-

Key words:

- super sulfate cement /

- titanium slag /

- phosphogypsum /

- basalt fiber /

- flexural strength /

- tensile strength

-

表 1 原材料的XRF分析结果

Table 1. XRF analysis results of raw materials

% 成分 CaO SiO2 TiO2 Al2O3 MgO Fe2O3 SO3 P2O5 Na2O K2O MnO 钛矿渣 27.06 28.76 16.69 12.57 7.13 3.22 2.31 0.05 0.81 0.75 0.45 磷石膏 36.48 10.48 0.22 1.52 0.37 0.95 46.83 1.97 0.09 0.27 熟料 68.17 18.54 0.67 4.44 1.40 3.57 1.68 0.12 0.31 0.83 0.10 表 2 试验配合比

Table 2. Experimental mix proportion

% 组号 磷石膏 钛矿渣 熟料 硅酸钠 水灰比 PS1 5 90 3 2 45 PS2 25 70 3 2 45 PS3 45 50 3 2 45 PS4 65 30 3 2 45 PS5 85 10 3 2 45 PK1 25 70 3 2 45 PK2 25 65 8 2 45 PK3 25 60 13 2 45 PK4 25 55 18 2 45 PK5 25 50 23 2 45 -

[1] Liu Shuhua, Wang Lu, Yu Baoying. Review on hydration mechanism and engineering application of supersulfate cement[J]. China Concrete, 2018,(10):46−51. (刘数华, 王露, 余保英. 超硫酸盐水泥的水化机理及工程应用综述[J]. 混凝土世界, 2018,(10):46−51. doi: 10.3969/j.issn.1674-7011.2018.10.008 [2] Dvorkin L, Nihaeva L. Modified supersulfated cements[J]. Zaštita Materijala, 2021,62(4):340−348. doi: 10.5937/zasmat2104340D [3] Wang Liang, Zhou Yang, Peng Zechuan, et al. Study on the strength and carbonation resistance of desulfurized gypsum-based supersulfate cement concrete[J]. China Concrete and Cement Products, 2022,(3):85−90. (王亮, 周扬, 彭泽川, 等. 脱硫石膏基超硫酸盐水泥混凝土强度和抗碳化性能研究[J]. 混凝土与水泥制品, 2022,(3):85−90. [4] Wu Q, Xue Q, Yu Z. Research status of super sulfate cement[J]. Journal of Cleaner Production, 2021,294:126228. doi: 10.1016/j.jclepro.2021.126228 [5] Chen Yu, Ji Junrong, Zhou Zhou, et al. Influencing factors and enhancement methods of early strength of supersulfated cement[J]. Bulletin of the Chinese Ceramic Society, 2021,40(5):1413−1419. (陈宇, 季军荣, 周洲, 等. 超硫酸盐水泥早期强度影响因素及提高途径[J]. 硅酸盐通报, 2021,40(5):1413−1419. doi: 10.16552/j.cnki.issn1001-1625.2021.05.001 [6] Chen Yitao, Ge Xuexiang, Li Jie, et al. Preparation and mechanical properties of concrete of titanium gypsum persulfate cement & coal gangue[J]. Journal of Anhui University of Technology(Natural Science), 2021,38(4):373−378. (陈儀涛, 葛雪祥, 李杰, 等. 钛石膏基过硫酸盐水泥煤矸石混凝土的制备及力学性能[J]. 安徽工业大学学报(自然科学版), 2021,38(4):373−378. [7] Gao Y X, Xiang J Y, Wang J, et al. Study on mechanical properties of microbead modified super sulfate cement concrete[C]//The 10th International Symposium on High Performance Concrete-Innovation & Utilization. Beijing: Trans Tech Publications Ltd, 2014. [8] Nguyen H A, Chang T P, Chen C T, et al. Engineering and creep performances of green super-sulfated cement concretes using circulating fluidized bed combustion fly ash[J]. Construction and Building Materials, 2022,346:128274. doi: 10.1016/j.conbuildmat.2022.128274 [9] Yu B Y, Wang J, Gao Y X, et al. Studies on key technology and toughness of super sulfate cement-based compound materials[J]. Applied Mechanics and Materials, 2014,665:151−154. doi: 10.4028/www.scientific.net/AMM.665.151 [10] Wu Shuanglei, Ji Junrong, Zhou Weijie, et al. Effect and mechanism of sodium lactate on strength of supersulfate cement[J]. Bulletin of the Chinese Ceramic Society, 2022,41(9):3008−3015. (武双磊, 季军荣, 周威杰, 等. 乳酸钠对超硫酸盐水泥强度的影响及作用机理[J]. 硅酸盐通报, 2022,41(9):3008−3015. doi: 10.3969/j.issn.1001-1625.2022.9.gsytb202209004 [11] Du Huihui, Ni Wen, Gao Guangjun, et al. Research on application of vanadium-titanium slag in fabricated precast concrete slab[J]. New Building Materials, 2021,48(10):172−177. (杜惠惠, 倪文, 高广军, 等. 钒钛矿渣在装配式预制板材中的应用研究[J]. 新型建筑材料, 2021,48(10):172−177. doi: 10.3969/j.issn.1001-702X.2021.10.037 [12] Wang Shuai, Lv Shuzhen, Zhao Jie, et al. Preparation of mineral admixture for concrete with high titanium slag[J]. Journal of Southwest University of Science and Technology, 2021,36(1):28−34. (王帅, 吕淑珍, 赵杰, 等. 高钛矿渣制备混凝土用矿物掺合料研究[J]. 西南科技大学学报, 2021,36(1):28−34. doi: 10.3969/j.issn.1671-8755.2021.01.005 [13] Liu Shuxian, Su Yan, Yang Min, et al. Experimental study on preparation of the steel slag and slag composite cementitious material and its gelling activity inspiration[J]. Metal Mine, 2022,(11):252−258. (刘淑贤, 苏严, 杨敏, 等. 钢渣-矿渣复合胶凝材料的制备及胶凝活性激发试验研究[J]. 金属矿山, 2022,(11):252−258. [14] Zhou Miaoqin. Tao Xue. Liao Xun, et al. Production and discharge of phosphogypsum and research progress on its resource utilization[J]. Yunnan Chemical Technology, 2022,49(12):4−8. (周妙琴, 陶雪, 廖迅, 等. 磷石膏产排情况及资源化利用研究进展[J]. 云南化工, 2022,49(12):4−8. doi: 10.3969/j.issn.1004-275X.2022.12.02 [15] Rutherford P M, Dudas M J, Samek R A. Environmental impacts of phosphogypsum[J]. Science of the Total Environment, 1994,149(1-2):1−38. doi: 10.1016/0048-9697(94)90002-7 [16] Chernysh Y, Yakhnenko O, Chubur V, et al. Phosphogypsum recycling: a review of environmental issues, current trends, and prospects[J]. Applied Sciences, 2021,11(4):1575. doi: 10.3390/app11041575 [17] Jiang Yong, Li Liangjing, Li Wei, et al. Properties of calcined phosphogypsum composite modified cementitious materials[J]. Sichuan Building Materials, 2021,47(6):1−3. (蒋勇, 李靓婧, 李伟, 等. 煅烧磷石膏复合改性胶凝材料的性能[J]. 四川建材, 2021,47(6):1−3. doi: 10.3969/j.issn.1672-4011.2021.06.001 [18] Wu Lei, Zhao Zhiman, Zhu Weimin, et al. Effect of chopped basalt fiber on the bending strength of phosphogypsum[J]. Non-Metallic Mines, 2017,40(6):9−11. (吴磊, 赵志曼, 朱伟民, 等. 短切玄武岩纤维对磷石膏抗折强度影响研究[J]. 非金属矿, 2017,40(6):9−11. doi: 10.3969/j.issn.1000-8098.2017.06.003 [19] Li Nianhua, Liu Yuankun, Cui Zhenghao, et al. Properties and applications of basalt fibers[J]. Synthetic Fiber in China, 2022,51(12):16−23. (李年华, 刘元坤, 崔正浩, 等. 玄武岩纤维的性能及其应用[J]. 合成纤维, 2022,51(12):16−23. [20] Victor C Li. Engineered cementitious composites (ECC)[M]. Springer, 2019: 43-44. [21] Curosu I, Mechtcherine V, Forni D, et al. Performance of various strain hardening cement-based composites (SHCC) subject to uniaxial impact tensile loading[J]. Cement and Concrete Reseach, 2017,(102):16−28. [22] 陈鹏飞. 玄武岩纤维和聚丙烯纤维混凝土抗冲击性能研究与数值分析[D]. 青岛: 青岛理工大学, 2021.Chen Pengfei. Research and numerical analysis on impact resistance of basalt fiber and polypropylene fiber reinforced concrete[D]. Qingdao: Qingdao University of Technology, 2021. -

下载:

下载: