Influence of phosphorus on the properties of Fe-Mn damping alloy

-

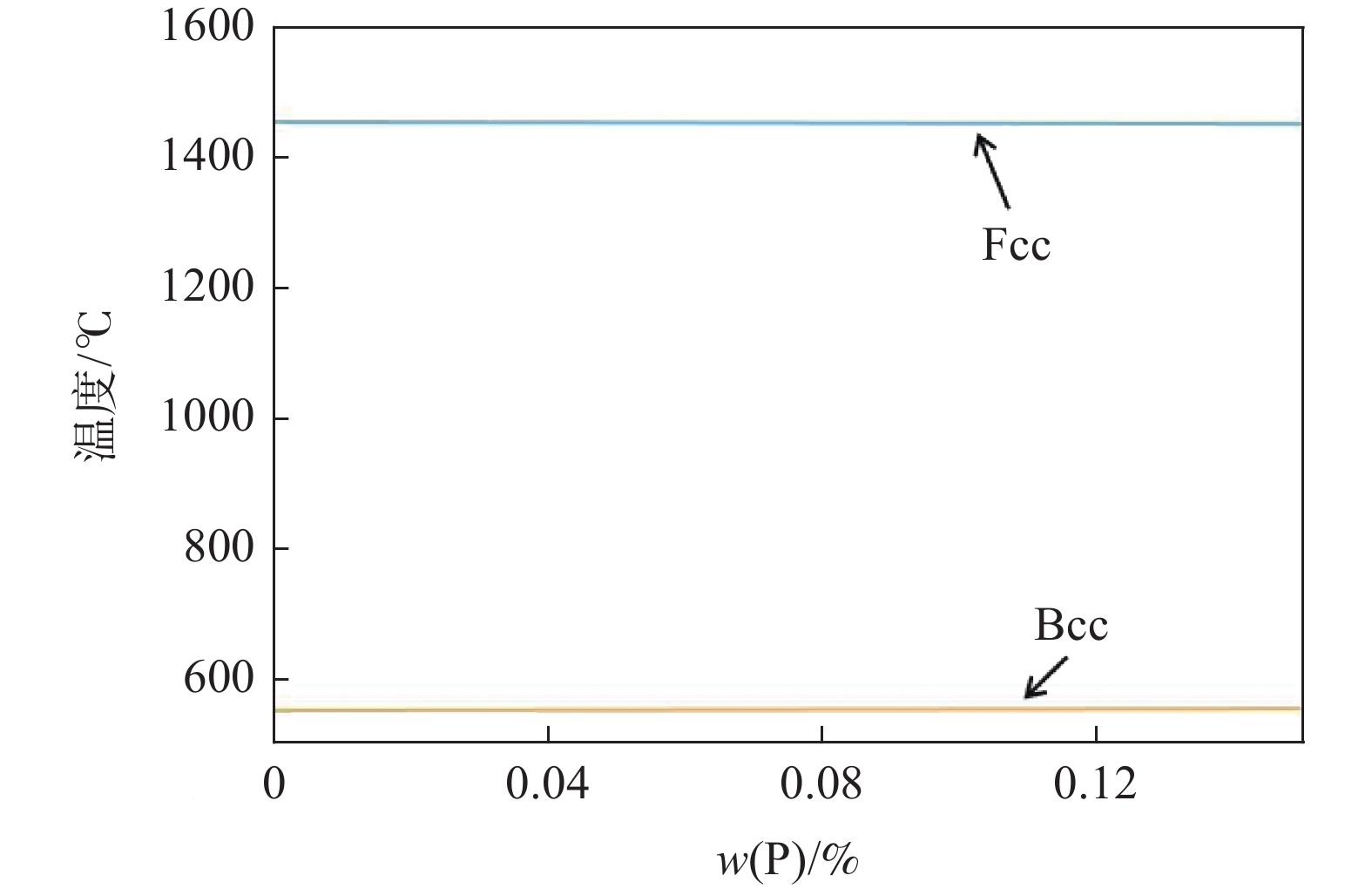

摘要: Fe-Mn基阻尼合金是近些年来发现的一种新型金属阻尼材料。以Fe-Mn基阻尼合金为研究对象,对经不同固溶温度(800、900、1000 ℃)处理后的Fe-Mn、Fe-Mn-P阻尼合金的力学性能、耐蚀性能、阻尼性能进行了测试,利用EBSD进行了显微组织结构表征。结果表明:磷元素添加提高了阻尼合金的屈服强度,有利于提高合金的耐腐蚀性能,但极大地恶化了阻尼合金的低温韧性,降低了阻尼合金的阻尼性能。在800 ℃固溶状态下,Fe-Mn-P合金阻尼性能最佳,随着固溶温度的升高,Fe-Mn-P阻尼合金强度降低,阻尼性能降低;ε/ε和ε/γ界面密度是影响Fe-Mn-P阻尼合金阻尼性能的重要因素。Abstract: Fe-Mn damping alloy is a new type of metal damping material discovered in recent years. This paper takes Fe-Mn damping alloy as the research object. The mechanical properties, corrosion resistance and damping properties of the alloy were tested, and the microstructure was characterized by EBSD. The addition of phosphorus increases the yield strength of the damping alloy, which is beneficial to improve the corrosion resistance, but greatly deteriorates the low-temperature toughness and reduces the damping. With the increase of solid solution treatment temperature, the strength and damping of Fe-Mn-P damping alloy decrease; the damping of Fe-Mn-P alloy is the best at 800 ℃. ε/ε and ε/γ interface density is an important factor affecting the damping of Fe-Mn-P alloy.

-

Key words:

- damping alloy /

- phosphorus /

- solid solution treatment temperature /

- strength /

- interface density /

- damping

-

表 1 试验用阻尼合金化学成分

Table 1. Chemical compositions of the experimental damping alloy

% 编号 C Mn P S Fe Fe-Mn 0.0050 15.89 0.0050 0.0055 Bal. Fe-Mn-P 0.0080 16.00 0.0790 0.0065 Bal. 表 2 经不同固溶温度处理后阻尼合金力学性能

Table 2. Mechanical properties of damping alloys treated at different solution temperatures

编号 固溶温

度/℃屈服强

度/MPa抗拉强

度/MPa断后伸长

率/%AKV2

(−20 ℃)/JFe-Mn 1000 358 685 52.0 176 Fe-Mn-P 1000 382 740 48.5 16 Fe-Mn-P 900 383 744 46.0 10 Fe-Mn-P 800 390 761 46.0 10 -

[1] Song G Y, Mo L. Summary of kinds and features of damping alloys[J]. Noise and Vibration Control, 2010,30(4):37−38. [2] Baik S H. High damping Fe-Mn martensitic alloys for engineering applications[J]. Nuclear Engineering & Design, 2000,198(3):241−252. [3] Kim Jung-Chul, Han Dong-Woon, Seung-Han Baik, et al. Effects of alloying elements on martensitic transformation behavior and damping capacity in Fe-17Mn alloy[J]. Materials Science and Engineering A, 2004,378:323−327. doi: 10.1016/j.msea.2003.11.075 [4] Jee K K, Jang W Y, Baik S H, et al. Damping mechanism and application of Fe-Mn based alloys[J]. Materials Science & Engineering A, 1999,273:538−542. [5] Jun J H, Lee Y K, Choi C S. Damping mechanisms of Fe-Mn alloy with (γ+ɛ) dual phase structure[J]. Materials Science and Technology, 2000,16(4):389−392. doi: 10.1179/026708300101507974 [6] Jun J H, Choi C S. The influence of Mn content on microstructure and damping capacity in Fe-(17~23)%Mn alloys[J]. Materials Science & Engineering A, 1998,252(1):133−138. [7] Huang S. Study on the damping mechanism of Fe-Mn alloy[J]. Rare Metal Materials and Engineering, 2007,36:683−687. [8] 黄姝珂, 李宁, 文玉华, 等. 运用位错运动理论分析Fe-Mn合金的减振机理[C]//第六届中国功能材料及其应用学术会议论文集(10). 武汉: 中国仪器仪表学会仪表功能材料学会, 2007.Huang Shuke, Li Ning, Wen Yuhua, et al. Study of damping mechanism of Fe-Mn alloy using dislocation-moving theory[C]//Proceedings of the 6th China Conference on Functional Materials and Their Application(10). Wuhan: Instrument Functional Materials Society of China Instrument and Control Society, 2007. [9] Wang Shihong, Li Jian, Chai Feng, et al. Influence of solution temperature on γ→ε transformation and damping capacity of Fe-19 Mn alloy[J]. Acta Metallurgica Sinica, 2020,56(9):10. (王世宏, 李健, 柴锋, 等. 固溶温度对Fe-19Mn合金的γ→ε相变和阻尼性能的影响[J]. 金属学报, 2020,56(9):10. [10] Kim J C, Han D W, Back J H, et al. Effects of Cr and Ni on damping capacity and corrosion resistance of Fe-17%Mn alloy[J]. Journal of the Korea Foundry Society, 2005,25(2):73−79. [11] Wen Y, Qian B, Wu B. Effects of Cr on stacking-fault energy and damping capacity of Fe-Mn[J]. Materials Science & Technology, 2017,33:1019−1025. [12] Yu Qian. Review and prospect of weathering steel[J]. Journal of Iron and Steel Research, 2007,19(11):4. (于千. 耐候钢发展现状及展望[J]. 钢铁研究学报, 2007,19(11):4. doi: 10.13228/j.boyuan.issn1001-0963.2007.11.001 [13] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.Yong Qilong. Second phase in steel materials[M]. Beijing: Metallurgical Industry Press, 2006. [14] Fu Guiqin, Zhu Miaoyong. Phosphorus segregation on steel grain boundary[J]. Ansteel Technology, 2006,(3):5. (付贵勤, 朱苗勇. 磷元素在钢中的晶界偏聚[J]. 鞍钢技术, 2006,(3):5. doi: 10.3969/j.issn.1006-4613.2006.03.002 [15] Ma Zhizhen, Wan Lanfeng. Influence of hot rolling process on non-equilibrium grain boundary segregation of phosphorus by Gleeble thermal simulation[J]. Iron & Steel, 2016,51(2):5. (马植甄, 万兰凤. Gleeble模拟热轧工艺对磷非平衡晶界偏聚的影响[J]. 钢铁, 2016,51(2):5. doi: 10.13228/j.boyuan.issn0449-749x.20150161 [16] Takayama S, Ogura T, Fu S C, et al. The calculation of transition temperature changes in steels due to temper embrittlement[J]. Metall. Trans., 1980,11(9):1513−1530. doi: 10.1007/BF02654515 [17] Huang S K, Li N, Wen Y H, et al. Effect of Si and Cr on stacking fault probability and damping capacity of Fe-Mn alloy[J]. Materials Science & Engineering A, 2008,479(1-2):223−228. [18] Chang Wanshun, Chen Xuequn, Li Guomin. Research of the mechanism of phosphor segregation effects to the steel’s corrosion resistance[J]. Equipment Environment Engineering, 2004,(2):31−34. (常万顺, 陈学群, 李国民. 磷偏析对钢耐蚀性影响的机理[J]. 装备环境工程, 2004,(2):31−34. doi: 10.3969/j.issn.1672-9242.2004.05.008 [19] Lee Y K, Jun J H, Choi C S. Damping capacity in Fe-Mn binary alloys[J]. Transactions of the Iron & Steel Institute of Japan, 1997,37(10):1023−1030. [20] Ma Ruzhang, Wang Shiliang. γ→ε Martensitic transformation in ferromanganese alloys[J]. Transactions of Metal Heat Treatment, 1982,(2):30−52. (马如璋, 王世亮. 铁锰合金中γ→ε马氏体相变[J]. 金属热处理学报, 1982,(2):30−52. [21] Shin S, Kwon M, Cho W, et al. The effect of grain size on the damping capacity of Fe-17%Mn[J]. Materials Science and Engineering:A, 2017,683:187−194. doi: 10.1016/j.msea.2016.10.079 -

下载:

下载: