Study on microstructure transformation behavior of Ti-Nb microalloyed high-speed guardrail steel under continuous cooling

-

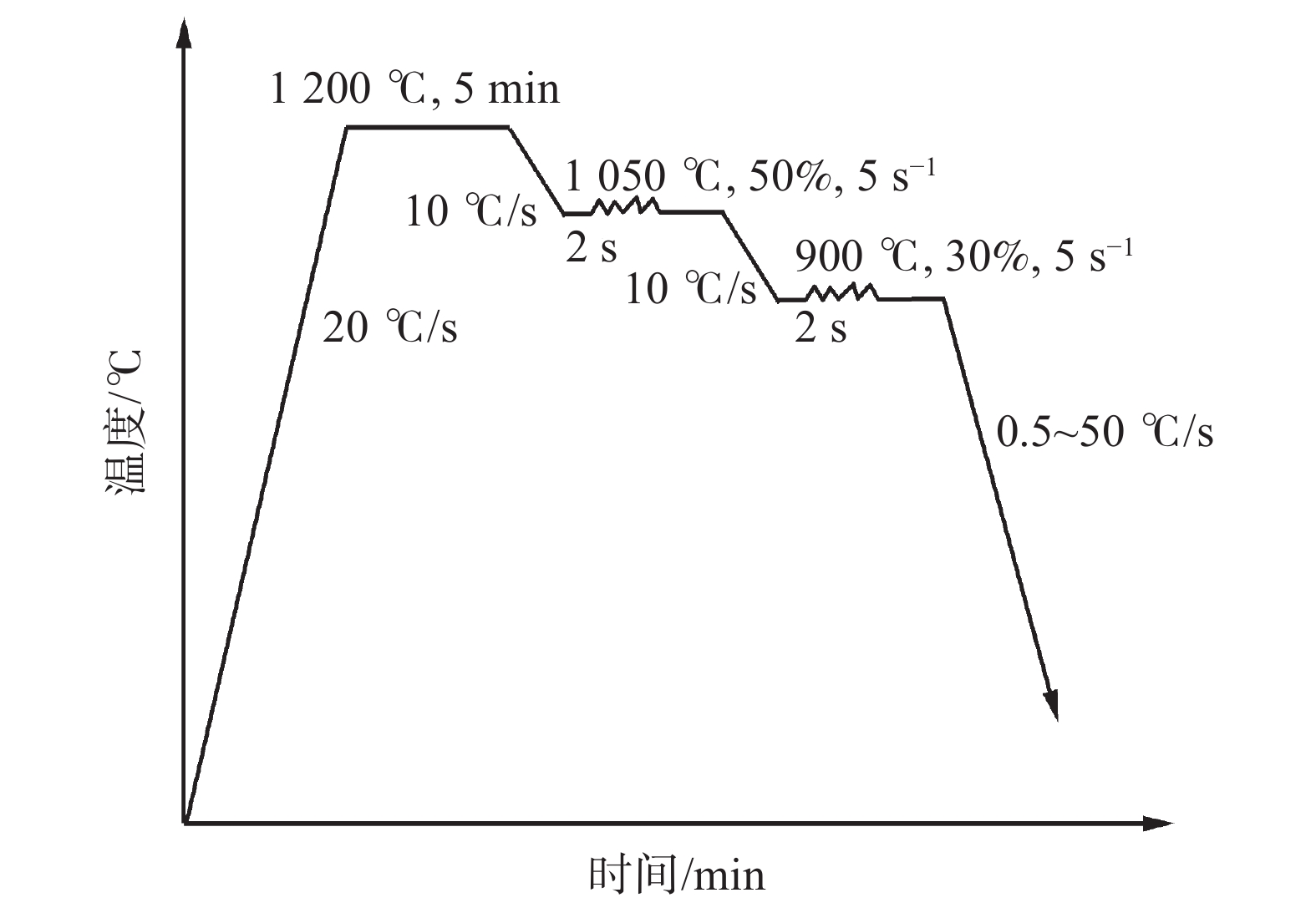

摘要: 利用热模拟试验机、OM、TEM等试验设备,研究了Ti-Nb微合金化高速护栏钢的连续冷却组织转变规律,建立了试验钢的CCT曲线。研究结果表明:当冷速为0.5 ℃/s时,试验钢中的奥氏体发生铁素体-珠光体相变;当冷速大于1 ℃/s时,开始发生贝氏体相变;当冷速为10~20 ℃/s时,既发生铁素体-贝氏体相变又发生马氏体相变;当冷速≥30 ℃/s时,发生贝氏体-马氏体的相变。随着冷速的增加,试验钢的硬度也随之增大。在不同冷速下钢中均存在(Ti, Nb)C析出物,且在钢中呈弥散分布,在低冷速条件下,钢中析出物的体积分数较大,尺寸较小,具有一定的析出强化效果。Abstract: The thermal simulation testing machine, OM, TEM and other experimental equipment were used to study the continuous cooling transformation behavior of Ti-Nb microalloyed high-speed guardrail steel in the experiment. The results show that when the cooling rate is 0.5 ℃/s, the austenite of the test steel emerges ferrite-pearlite phase transformation. When the cooling rate is greater than 1 ℃/s, the bainite phase transformation begins to occur. At the cooling rate of 10~20 ℃/s, both ferrite-bainite phase transformation and martensite phase transformation come out. While the bainite-martensite phase transformation appears when the cooling rate rises to 30 ℃/s. As the cooling rate increases, the hardness of the test steel also improves. There exists (Ti, Nb) dispersed precipitates in the steel at different cooling rates. In the condition of low cooling rate, the volume fraction of the precipitates in the steel is larger, and the size is smaller, which has a certain precipitation strengthening effect.

-

Key words:

- high-speed guardrail steel /

- Ti-Nb microalloying /

- CCT curve /

- hardness

-

表 1 试验钢的主要化学成分

Table 1. The target composition of the steel

% C Si Mn Ti Nb N Cr S P 0.050~0.070 0.10~0.30 1.40~1.60 0.10~0.15 ≤0.01 ≤0.005 0.30~0.50 ≤0.005 ≤0.010 表 2 试验钢不同冷却速度下的相变温度和组织类型

Table 2. The transformation points and microstructures of the steel at different cooling rates

冷却速率/(℃·s−1) 转变温度/℃ 组织 A→F+P A→F+P+B A→F+B A→F+B+M A→B+M 开始 结束 开始 结束 开始 结束 开始 结束 开始 结束 0.5 802 650 F+P 1 792 589 F+P+B 5 760 513 F +B 10 696 509 F+B+M 20 699 466 F+B+M 30 646 412 B+M 50 624 395 B+M -

[1] Shi Zhongran, Chai Xiyang, Chai Feng, et al. The mechanism of intragranular ferrite formed on Ti-rich(Ti, V) (C, N) precipitates in the coarse heat affected zone of a V-N-Ti microalloyed steel[J]. Materials Letters, 2016,175(14):266−270. [2] Xu Yang, Zhang Weina, Sun Mingxue, et al. The blocking effects of interphase precipitation on dislocations’ movement in Nb/Ti micro-alloyed steels[J]. Materials Letters, 2015,139(15):177−181. [3] Chen Jun, Lv Mengyang, Tang Shuai, et al. Microstructure, mechanical proper-ties and interphase precipitation behaviors in V-Ti microalloyed steel[J]. Acta Metall. Sin., 2014,50:524−530. (陈俊, 吕梦阳, 唐帅, 等. V-Ti 微合金钢的组织性能及相间析出行为[J]. 金属学报, 2014,50:524−530. [4] Phaniraj M P, Shin Youngmin, Lee Joonho, et al. Development of high strength hot rolled low carbon copper-bearing steel containing nanometer sized carbides[J]. Mater. Sci. Eng., 2015,A633:1−8. [5] Li Xiaolin, Wang Zhaodong. Interphase precipitation behaviors of nanometer-sized carbides in a Nb-Ti-bearing low- carbon microalloyed steel[J]. Acta Metall. Sin., 2015,51:417−424. (李小琳, 王昭东. 含 Nb-Ti 低碳微合金钢中纳米碳化物的相间析出行为[J]. 金属学报, 2015,51:417−424. [6] Zhang Ke, Li Zhaodong, Sui Fengli, et al. Effect of cooling rate on the tissue transformation and mechanical properties of Ti-V-Mo composite microalloyed steel[J]. Acta Metall. Sin., 2018,54(1):31−38. (张可, 李昭东, 隋凤利, 等. 冷却速率对Ti-V-Mo复合微合金钢组织转变及力学性能的影响[J]. 金属学报, 2018,54(1):31−38. [7] Gan Xiaolong, Han Bin, Tan Wen, et al. Continuous cooling transition curves of Ti-Nb composite microalloyed high-strength steel[J]. Thermal Processing Technology, 2015,44(24):79−81. (甘晓龙, 韩斌, 谭文, 等. Ti-Nb复合微合金化高强钢连续冷却转变曲线[J]. 热加工工艺, 2015,44(24):79−81. [8] Mecozzi M G, Sietsma J, Van Der Zwaag S. Analysis of γ→α transformation in a Nb micro-alloyed C-Mn steel by phase field modeling[J]. Acta Mater, 2006,54:1431−1440. doi: 10.1016/j.actamat.2005.11.014 [9] Yang Gengwei, Mao Xinping, Zhao Gang, et al. Organizational properties and strengthening mechanism of Ti microalloyed high-strength hot-rolled strip steel[J]. Journal of Iron and Steel Research, 2016,28(12):75−80. (杨庚蔚, 毛新平, 赵刚, 等. Ti微合金化高强度热轧带钢组织性能及强化机理[J]. 钢铁研究学报, 2016,28(12):75−80. [10] Song Siying, Tian Junyu, Fan Lei, et al. Dynamic and static CCT curves of Q460 for high performance building[J]. Journal of Wuhan University of Science and Technology, 2021,44(6):406−414. (宋思颖, 田俊羽, 樊雷, 等. 高性能建筑结构用钢Q460的动态和静态CCT曲线研究[J]. 武汉科技大学学报, 2021,44(6):406−414. [11] He Xianling, Yang Gengwei, Mao Xinping, et al. Influence of Nb on the phase transformation pattern and tissue properties of Ti-Mo microalloyed steel by continuous cooling[J]. Acta Metall. Sin., 2017,53(6):648−656. (何仙灵, 杨庚蔚, 毛新平, 等. Nb对Ti-Mo微合金钢连续冷却相变规律及组织性能的影响[J]. 金属学报, 2017,53(6):648−656. [12] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006: 27.Yong Qilong. The second phase in steel materials [M]. Beijing: Metallurgical Industry Press, 2006: 27. [13] Misra R D K, Nathani H, Hartmann J E, et al. Microstructural evolution in a new 770 MPa hot rolled Nb-Ti microalloyed steel[J]. Materials Science and Engineering A, 2005,394:339−352. doi: 10.1016/j.msea.2004.11.041 -

下载:

下载: