| [1] |

Li Jie, Li Zhi, Yan Minghao. Development of high alloy ultra high strength steel[J]. Materials Engineering, 2007,4:61−65. (李杰, 李志, 颜鸣嗥. 高合金超高强度钢的发展[J]. 材料工程, 2007,4:61−65. doi: 10.3969/j.issn.1001-4381.2007.08.015

|

| [2] |

Garrison W M. Ultrahigh-strength steels for aerospace applications[J]. JOM, 1990,42(5):20−24. doi: 10.1007/BF03220942

|

| [3] |

Little C D, Machmeier P M. High strength fracture resistant weldable steels: USA Patent, 4, 076, 525[P]. 1978.

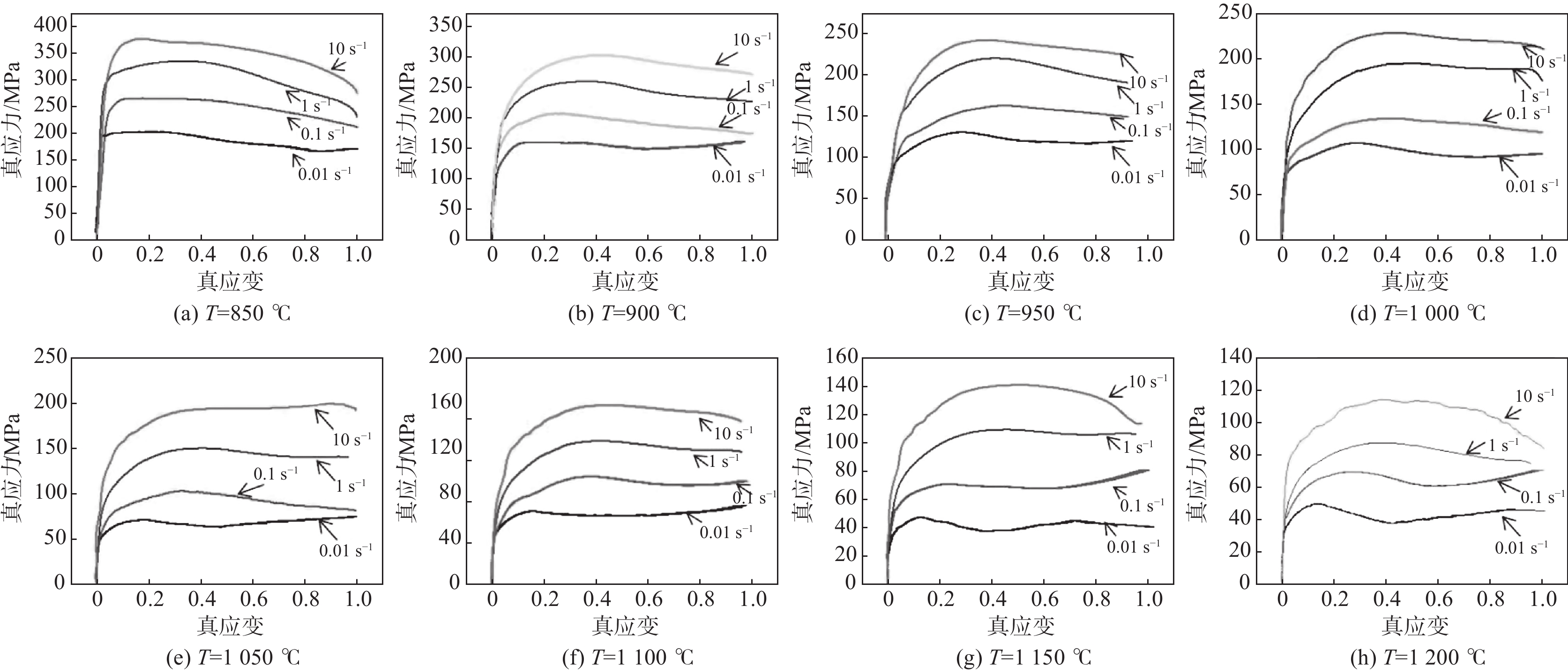

|

| [4] |

Hemphill R M, Wert D E. High strength, high fracture toughness alloy: USA Patent, 5, 268, 044[P] . 1993.

|

| [5] |

Caffrey T J. Combined strength and toughness characterize new aircraft alloy[J]. Advanced Materials & Processes, 1992,142(3):47−50.

|

| [6] |

Zhao Zhenye. Study on secondary hardening in ultra-high strength steel[J]. Journal of Aeronautical Materials, 2002,22(4):46−55. (赵振业. 超高强度钢中的二次硬化现象研究[J]. 航空材料学报, 2002,22(4):46−55. doi: 10.3969/j.issn.1005-5053.2002.04.010

|

| [7] |

刘文义. 7085铝合金热加工力学行为及微观组织演变规律研究[D]. 重庆: 重庆大学, 2014.Liu Wenyi. Research on mechanical property and microstructure evolution in hot working of 7085 aluminum alloy[D]. Chongqing: Chongqing University, 2014.

|

| [8] |

张世伟, 杨明, 梁益龙, 等, 20 CrNi2 Mo 钢高温变形的本构方程与动态再结晶行为[J]. 钢铁, 2017, 52(8): 97-106.Zhang Shiwei, Yang Ming, Liang Yilong, et al. Constitutive equation and dynamic recrystallization behavior of 20CrNi2Mo steel during high temperature deformation[J]. Iron &Steel, 2017, 52 (8): 97-106.

|

| [9] |

Stewart G R, Jonas J J, Montheillet F. Kinetics and critical con-ditions for the initiation of dynamic recrystallization in 304 stainless steel[J]. ISIJ International, 2004,44(9):1581. doi: 10.2355/isijinternational.44.1581

|

| [10] |

Lee Y C, Hwang E, Shih Y P. A combined approach to fuzzy model identification[J]. Systems Man & Cybernetics IEEE Transactions on, 1994,24(5):736−744.

|

| [11] |

Chen Xuewen, Xiao Xiao, Huang Tao, et al. Thermal deformation behavior and constitutive equation of CR8 steel[J]. Journal of Material Heat Treatment, 2017,38(11):120−124. (陈学文, 肖晓, 皇涛, 等. Cr8钢的热变形行为及本构方程[J]. 材料热处理学报, 2017,38(11):120−124.

|

| [12] |

Liu Yong, Zhao Haitao, Chen Hongwei, et al. DIN 1.2738 analysis of hot deformation and hot working diagram of plastic mold steel[J]. Special Steel, 2020,41(1):16−20. (刘泳, 赵海涛, 陈红卫, 等. DIN 1.2738塑料模具钢热变形及热加工图分析[J]. 特殊钢, 2020,41(1):16−20. doi: 10.3969/j.issn.1003-8620.2020.01.004

|

| [13] |

侯丹丹. AerMet100 超高强度钢高温变形行为研究[D]. 秦皇岛: 燕山大学, 2015: 10-13.Hou Dandan. Research on high temperature deformation behavior of AerMet100 ultra high strength steel[D]. Qinhuangdao: Yanshan University, 2015: 10-13.

|

| [14] |

Takuda H, Fujimoto H, Hatta N. Modeling of flowing stress of Mg-Al-Zn alloys at elevated temperatures[J]. Journal of Materials Processig Technology, 1998,80-81(8):513−516.

|

| [15] |

Zener C, Hollomon J H. Problems in non-elasticdeformation of metals[J]. J. Appl. Phys, 1946,17(2):38−43.

|

| [16] |

Jonas J J, Sellars C M, Pegart W J M. Strength and structure under hot working conditions[J]. Tegar Int Metall Reviews, 1969,14(130):1−24.

|

下载:

下载: