Innovative design of automatic casting process for continuous casting ladle based on TRIZ theory

-

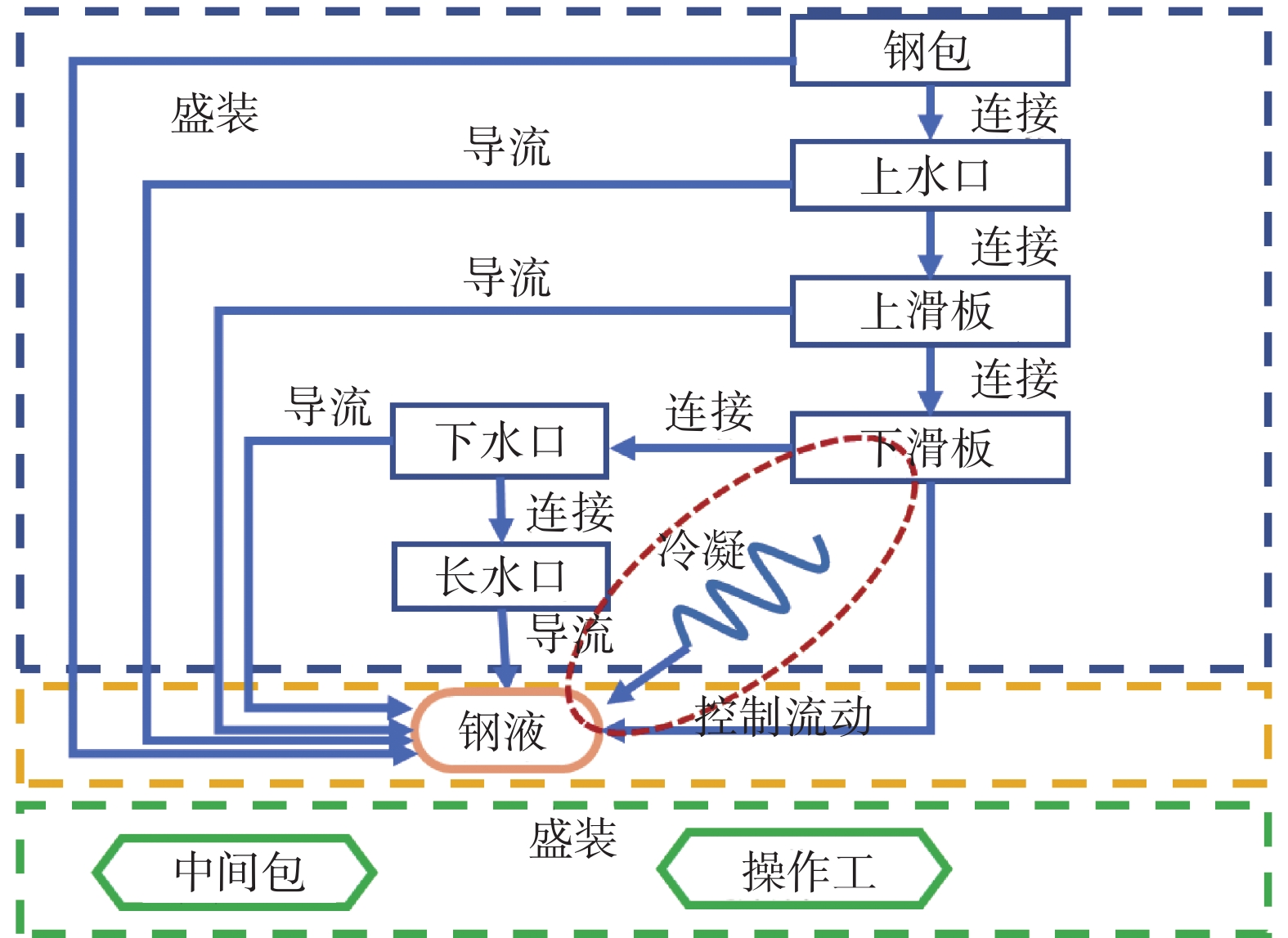

摘要: 基于TRIZ理论,建立了连铸钢包开浇系统的功能模型,通过因果链原因分析法,确定了产生问题的关键原因;充分应用技术冲突、物理冲突、物质-场模型以及效应等工具对连铸钢包开浇工艺进行了改进,产生了8种创新解。针对某厂80 t钢包具体情况,通过方案对比优选出最佳方案,即采用真空复合滑板控流结构。实施后取得了良好的效果,钢包自动开浇率达到97%以上,虽然与采用传统的引流砂开浇工艺的自开率基本持平,但是降低了钢中大颗粒夹杂物产生量,有效解决了传统引流砂开浇工艺带来的引流砂污染钢液的顽疾。Abstract: Based on TRIZ theory, the function model of ladle pouring system had been established, and the key causes of the problem had been determined by causal chain analysis. By fully applying the tools of technical conflict, physical conflict, material-field model and effect, the start-up process of continuous casting ladle was improved, eight kinds of innovative solutions were produced, and the optimal scheme was determined by scheme comparison. The scheme adopts vacuum composite flow control skateboard and achieves good process effect. The automatic casting rate of the ladle can reach more than 97%. Although it is basically the same as the self-opening rate of the traditional drainage sand casting process, the new scheme can reduce the amount of large particle inclusions in the steel and effectively solve the drainage sand pollution caused by the traditional drainage sand casting process.

-

Key words:

- continuous casting /

- ladle /

- automatic pouring /

- skateboard /

- TRIZ theory

-

表 1 方案比选

Table 1. Scheme comparison results

编号 方案详情 A B C D 方案评价 方案1 增加滑板厚度 10 10 10 5 8.5 方案2 低熔点高密度的液体金属“防凝剂” 8 9 9 7 8.2 方案3 低熔点高密度金属防凝剂回收循环利用 8 8 8 7 7.7 方案4 通过对水口内钢水(S1)增加电磁加热(S改进的超系统)来调节钢水温度,防止冷凝 6 6 7 6 6.3 方案5 将钢包底部原有的底吹氩透气塞与钢包下滑板组合在一起,形成包底吹氩和滑动水口一体化设计,通过下滑板上嵌入的透气塞向钢水上水口内吹入氩,使得钢包上水口内低温钢水与钢包内高温钢水实现机械混合,将原有的静态热能场替换成机械场,从而改善系统功能 9 9 8 7 8.1 方案6 下滑板镶嵌石棉板等保温材料 9 9 10 8 9 方案7 内部中空结构的下滑板 9 9 10 9 9.3 方案8 内部真空结构的下滑板 9 9 10 10 9.6 -

[1] Deng Zhiyin, Peng Peng, Zhu Miaoyong. State of art in study on sintering of ladle filler sands and improvement of ladle free-opening rate[J]. Iron and Steel, 2022,57(1):1−12. (邓志银, 彭朋, 朱苗勇. 钢包引流砂烧结与钢包自动开浇率提升研究进展[J]. 钢铁, 2022,57(1):1−12. [2] Kono T, Fukuhisa Y. Improvement of opening ratio without burning by oxygen on ladle sliding nozzles[J]. Taikabutsu, 1978,(5):638−642. [3] Zhong Kai, Wang Cong, Zhang Qidong, et al. Research and practice on improving free-opening rate of covered ladle[J]. China Metallurgy, 2019,29(3):36−42. (钟凯, 王崇, 张启东, 等. 提高加盖钢包自开率的研究与实践[J]. 中国冶金, 2019,29(3):36−42. doi: 10.13228/j.boyuan.issn1006-9356.20180283 [4] Kobayashi Y, Todoroki H, Kirihara F, et al. Sintering behavior of silica filler sands for sliding zozzle in a ladle[J]. ISIJ International, 2014,54(8):1823−1829. doi: 10.2355/isijinternational.54.1823 [5] Deng Z, Glaser B, Bombeck M A, et al. Mechanism study of the blocking of ladle well due to sintering of filler sand[J]. Steel Research International, 2016,87(4):484−493. doi: 10.1002/srin.201500118 [6] Deng Z, Glaser B, Bombeck M A, et al. Effects of temperature and holding time on the sintering of ladle filler sand with liquid steel[J]. Steel Research International, 2016,87(7):921−929. doi: 10.1002/srin.201500277 [7] Wang Bo, Zou Ping, Sun Xiubing, et al. Source analysis and control of large inclusions in Q195 hot rolled strip[J]. China Metallurgy, 2021,31(8):60−65. (王博, 邹平, 孙秀兵, 等. Q195热轧带钢大型夹杂物来源分析及控制[J]. 中国冶金, 2021,31(8):60−65. [8] Li Wengqiang, Li Yan, Wang Jie, et al. The process model to aid innovation of products conceptual design[J]. Expert Systems with Applications, 2010,37(5):3574−3587. doi: 10.1016/j.eswa.2009.10.034 [9] Yang Yousheng, Tang Shunjun, Wang Xiaodong, et al. Deep-sea water hydraulic solenoid valves based on TRIZ theory[J]. Journal of Mechanical Engineering, 2019,55(16):205−212. (杨友胜, 唐顺军, 王晓东, 等. 基于 TRIZ 理论的深海水液压电磁阀[J]. 机械工程学报, 2019,55(16):205−212. doi: 10.3901/JME.2019.16.205 [10] Zhong Xingli, Lu Yijia, Ai Yu, et al. Design of eco-friendly stockyard based on TRIZ theory[J]. China Metallurgy, 2023,33(1):139−146. (钟星立, 路益嘉, 艾宇, 等. 基于TRIZ 理论的环保原料场设计[J]. 中国冶金, 2023,33(1):139−146. [11] Yang C J, Chen J L. Forecasting the design of eco-products by integrating TRIZ evolution patterns with CBR and simple LCA methods[J]. Expert Systems with Applications, 2012,39(3):2884−2892. doi: 10.1016/j.eswa.2011.08.150 [12] Liu Xiaoyong, Wu Xiaoling, Li Rongli, et al. Research on product sensorial design method based on conflict resolution theory of TRIZ[J]. Journal of Machine Design, 2021,38(10):136−144. (刘小勇, 吴小玲, 李荣丽, 等. 基于TRIZ冲突解决原理的产品感知设计方法研究[J]. 机械设计, 2021,38(10):136−144. doi: 10.13841/j.cnki.jxsj.2021.10.020 [13] Chou J R. An ideation method for generating new product ideas using TRIZ, concept mapping, and fuzzy linguistic evaluation techniques[J]. Advanced Engineering Informatics, 2014,28(4):441−454. doi: 10.1016/j.aei.2014.06.006 [14] Wang Wei, Li Xindi, Nie Zifeng. Innovative design of agricultural machinery's automatic loading following system based on TRIZ theory[J]. Journal of Machine Design, 2022,39(2):101−106. (王伟, 李昕迪, 聂子丰. 基于TRIZ理论的农机自动装载跟随系统创新设计[J]. 机械设计, 2022,39(2):101−106. doi: 10.13841/j.cnki.jxsj.2022.02.017 [15] Moehrle M G. TRIZ-based technology roadmap ping[M]. Springer Berlin Heidelberg, 2013. [16] Li Miao, Ming Xinguo, He Lina, et al. A TRIZ-based trimming method for patent design around[J]. Computer-Aided Design, 2015,62:20−30. doi: 10.1016/j.cad.2014.10.005 [17] Cao Lei, Shi Yongliang, Ma Baozhen, et al. The application of TRIZ theory in improving the harm of drainage sand to molten steel[J]. Refractories, 2021,55(6):517−521. (曹磊, 石永亮, 马保振, 等. TRIZ理论在改善引流砂对钢液危害中的应用[J]. 耐火材料, 2021,55(6):517−521. -

下载:

下载: