Biomass pyrolysis product-enhanced selective reduction-magnetic separation of iron sand

-

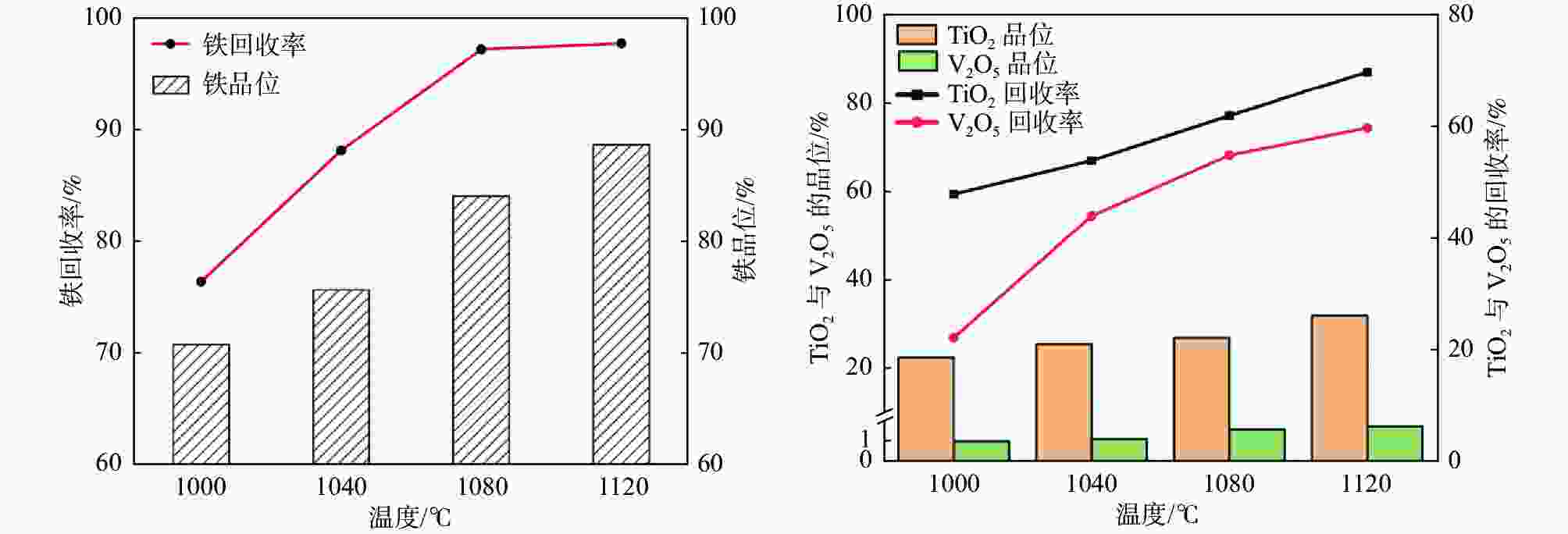

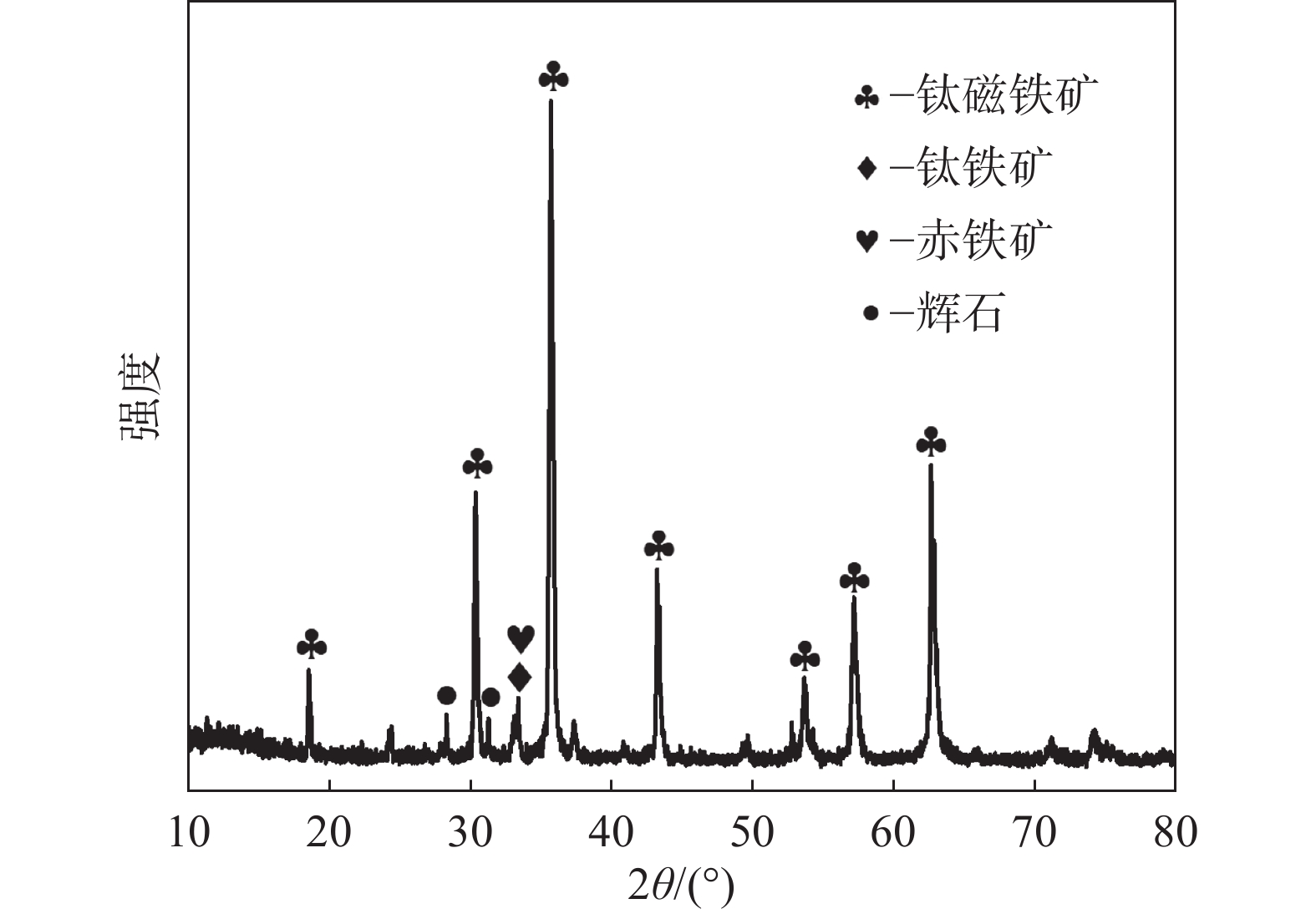

摘要: 以清洁、碳中性、高活性、可再生的生物质作为还原剂,通过密封性气塞限制热解产物的逃逸,对海砂矿内配生物质直接还原行为进行了研究,研究表明,限制生物质热解产生热解产物(CO、H2、CO2、H2O 、CxHyOz)的逃逸,在反应罐内迅速形成了60 kPa的压力,有利于H2、CO的参与还原。其中焦油具有更高的活性,且保障了后期H2的来源,促进了海砂矿的低温快速还原。在还原温度1120 ℃、还原80 min的条件下,可获得金属化率为97.81%、铁回收率为97.81%的铁粉,以及TiO2回收率为69.98%和V2O5回收率59.93%的富钛渣。Abstract: Using clean, carbon neutral, highly reactive and renewable biomass as a reducing agent, limiting the escape of pyrolysis products by hermetic gas plugs, the direct reduction behavior of the biomass allotted within the iron sand was studied. The results show that a pressure of 60 kPa is rapidly developed in the reaction tank as a result of limiting the escape of pyrolysis products (CO、H2、CO2、H2O 、CxHyOz) from biomass pyrolysis, which facilitates the participation of H2, CO in the reduction. The tar has higher activity and guarantees the source of H2 in the later stage, which promotes the rapid reduction of iron sand at low temperature. Under the conditions of reduction temperature of 1120 °C and reduction for 80 min, the iron powder with 97.81% metallization and 97.81% Fe recovery can be obtained, as well as the titanium-rich slag with a TiO2 recovery of 69.98% and a V2O5 recovery of 59.93%.

-

Key words:

- iron sand /

- rapid direct reduction by low temperature /

- biomass /

- pyrolysis products

-

表 1 海砂矿化学成分

Table 1. Chemical composition of iron sand

% TFe FeO Fe2O3 TiO2 V2O5 SiO2 Al2O3 CaO MgO MnO Na2O K2O S P 烧失 54.27 29.08 45.27 10.88 0.68 4.01 3.67 0.48 3.68 0.44 0.079 0.020 0.059 0.027 0.29 表 2 海砂矿粒度组成

Table 2. Iron sand particle size composition

粒度/μm 粒级含量/% +212 22.22 150~212 23.30 75~150 52.14 45~75 1.78 −45 0.56 合计 100 表 3 还原剂分析

Table 3. Analysis of reducing agents

% 生物质工业分析 生物质元素分析 水分 挥发分 固定碳 灰分 C H O N Cl 5.55 80.13 12.61 1.71 48.57 6.09 43.82 0.18 0.014 表 4 生物质灰分分析

Table 4. Analysis of ash content of biomass

% SiO2 Al2O3 CaO MgO Na2O K2O Cl 16.13 3.34 61.60 7.16 0.83 2.94 0.013 -

[1] Bai Fenglong, He Yongjun, Li Jun. Exploration, mining and sustainable development of sea sand resources in China[J]. Mineral Deposits, 2010,29(S1):771−772. (白凤龙, 何拥军, 李军. 中国海砂资源勘查、开采与可持续发展[J]. 矿床地质, 2010,29(S1):771−772. doi: 10.16111/j.0258-7106.2010.s1.557Bai Fenglong, He Yongjun, Li Jun. Exploration, mining and sustainable development of sea sand resources in China[J]. Mineral Deposits, 2010, 29(S1): 771-772. doi: 10.16111/j.0258-7106.2010.s1.557 [2] Li Xingyun. Study on the exploitation, utilization and ownership management of sea sand resources at home and abroad[J]. Co-Operative Economy & Science, 2018,(24):49−51. (李杏筠. 国内外海砂资源开采利用与权属管理探讨[J]. 合作经济与科技, 2018,(24):49−51. doi: 10.3969/j.issn.1672-190X.2018.24.018Li Xingyun. Study on the exploitation, utilization and ownership management of sea sand resources at home and abroad[J]. Co-Operative Economy & Science, 2018(24): 49-51. doi: 10.3969/j.issn.1672-190X.2018.24.018 [3] Sun Lijun, Lv Xianjun, Chen Ping, et al. Experimental study on the mineralogical characteristics and processing technique of beach placer[J]. Mining Research and Development, 2010,30(2):62−65. (孙丽君, 吕宪俊, 陈平, 等. 某海滨砂矿的矿物学特征与选矿试验研究[J]. 矿业研究与开发, 2010,30(2):62−65. doi: 10.13827/j.cnki.kyyk.2010.02.013Sun Lijun, Lu Xianjun, Chen Ping, et al. Experimental study on the mineralogical characteristics and processing technique of beach placer[J]. Mining Research and Development, 2010, 30(2): 62-65. doi: 10.13827/j.cnki.kyyk.2010.02.013 [4] Liu Zhangzheng, Cao Zhicheng, Peng Cheng, et al. Study on direct reduction of sea sand ore containing vanadium and titanium by rotary hearth furnace[J]. Conservation and Utilization of Mineral Resources, 2020,40(4):52−57. (刘长正, 曹志成, 彭程, 等. 钒钛海砂矿转底炉直接还原研究[J]. 矿产保护与利用, 2020,40(4):52−57. doi: 10.13779/j.cnki.issn1001-0076.2020.07.008Liu Zhangzheng, Cao Zhicheng, Peng Cheng, et al. Study on direct reduction of sea sand ore containing vanadium and titanium by rotary hearth furnace[J]. Conservation and Utilization of Mineral Resources, 2020, 40(04): 52-57. doi: 10.13779/j.cnki.issn1001-0076.2020.07.008 [5] Yan Fangxing, Zhang Qifu, Cao Chaozhen, et al. Experimental study on direct reduction of vanadium and titanium-bearing sea sand ore pellets in gas-based shaft furnace[J]. Iron Steel Vanadium Titanium, 2020,41(4):7−11. (闫方兴, 章启夫, 曹朝真, 等. 气基竖炉用含钒钛海滨砂矿球团直接还原试验研究[J]. 钢铁钒钛, 2020,41(4):7−11. doi: 10.7513/j.issn.1004-7638.2020.04.002Yan Fangxing, Zhang Qifu, Cao Chaozhen, et al. Experimental study on direct reduction of vanadium and titanium-bearing sea sand ore pellets in gas-based shaft furnace[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 7-11. doi: 10.7513/j.issn.1004-7638.2020.04.002 [6] Hu Bing, Xie Zhicheng, Huang Zhucheng, et al. A new process for rapid direct reduction by low temperature of marine placer containing vanadic titanomagnetite[J]. Sintering and Pelletizing, 2020,45(6):16−22. (胡兵, 谢志诚, 黄柱成, 等. 钒钛磁铁海砂矿低温快速直接还原新工艺[J]. 烧结球团, 2020,45(6):16−22. doi: 10.13403/j.sjqt.2020.06.078Hu Bing, Xie Zhicheng, Huang Zhucheng, et al. A new process for rapid direct reduction by low temperature of marine placer containing vanadic titanomagnetite[J]. Sintering and Pelletizing, 2020, 45(6): 16-22. doi: 10.13403/j.sjqt.2020.06.078 [7] Hu Chengfei, Yi Lingyun, Zhang Nan, et al. Mechanism for reduction-separation of indonesia iron sand intensified by pre-oxidation treatment[J]. Mining and Metallurgical Engineering, 2021,41(6):161−166. (胡程飞, 易凌云, 张楠, 等. 预氧化强化印尼海砂矿还原分离及机理研究[J]. 矿冶工程, 2021,41(6):161−166. doi: 10.3969/j.issn.0253-6099.2021.06.039Hu Chengfei, Yi Lingyun, Zhang Nan, et al. Mechanism for reduction-separation of indonesia iron sand intensified by pre-oxidation treatment[J]. Mining and Metallurgical Engineering, 2021, 41(6): 161-166. doi: 10.3969/j.issn.0253-6099.2021.06.039 [8] Taylor P R, Shuey S A, Vidal E E, et al. Extractive metallurgy of vanadium-containing titaniferous magnetite ores: a review[J]. Mining, Metallurgy & Exploration, 2006,23(2):80−86. [9] Ghiyats Muhammad Faris, Maksum Ahmad, Soedarsono Johny Wahyuadi. Preliminary study on the use of rice husk as a reducing agent in iron sand reduction[J]. IOP Conference Series:Materials Science and Engineering, 2019,553:12036. doi: 10.1088/1757-899X/553/1/012036 [10] Geng Chao, Sun Tichang, Yang Huifen, et al. Effect of additives on titanium and iron separation from beach titanomagnetite by direct reduction followed by magnetic separation[J]. The Chinese Journal of Nonferrous Metals, 2017,27(8):1720−1728. (耿超, 孙体昌, 杨慧芬, 等. 添加剂对海滨钛磁铁矿直接还原磁选钛铁分离的影响[J]. 中国有色金属学报, 2017,27(8):1720−1728. doi: 10.19476/j.ysxb.1004.0609.2017.08.23Geng Chao, Sun Tichang, Yang Huifen, et al. Effect of additives on titanium and iron separation from beach titanomagnetite by direct reduction followed by magnetic separation[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1720-1728. doi: 10.19476/j.ysxb.1004.0609.2017.08.23 [11] Liu Songli, Bai Chenguang. Technology research and development trend of direct reduction[J]. Journal of Iron and Steel Research, 2011,23(3):1−5. (刘松利, 白晨光. 直接还原技术的进展与展望[J]. 钢铁研究学报, 2011,23(3):1−5. doi: 10.13228/j.boyuan.issn1001-0963.2011.03.009Liu Songli, Bai Chenguang. Technology research and development trend of direct reduction[J]. Journal of Iron and Steel Research, 2011, 23(3): 1-5. doi: 10.13228/j.boyuan.issn1001-0963.2011.03.009 [12] Maurício C Bagatini, Tao Kan, Tim J Evans, et al. Iron ore reduction by biomass volatiles[J]. Journal of Sustainable Metallurgy, 2021,(prepublish):215−226. [13] Huang Zhucheng, Cai Wei, Yi Lingyun, et al. Conversion characteristics of biomass gasification using vanadium titanomagnetite as oxygen carrier[J]. The Chinese Journal of Nonferrous Metals, 2020,30(12):2980−2988. (黄柱成, 蔡威, 易凌云, 等. 钒钛磁铁矿为氧载体的生物质气化转化特性[J]. 中国有色金属学报, 2020,30(12):2980−2988. doi: 10.11817/j.ysxb.1004.0609.2020-36481Huang Zhucheng, Cai Wei, Yi Lingyun, et al. Conversion characteristics of biomass gasification using vanadium titanomagnetite as oxygen carrier[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(12): 2980-2988. doi: 10.11817/j.ysxb.1004.0609.2020-36481 [14] Guo Dabin, Hu Mian, Pu Chengxi, et al. Kinetics and mechanisms of direct reduction of iron ore-biomass composite pellets with hydrogen gas[J]. International Journal of Hydrogen Energy, 2015,40(14):4733−4740. doi: 10.1016/j.ijhydene.2015.02.065 [15] Chen Wenxuan, Liu Peng, Li Xueqin, et al. Research progress of catalytic cracking catalysts for biomass tar[J]. China Forest Products Industry, 2022,59(3):41−48. (陈文轩, 刘鹏, 李学琴, 等. 生物质焦油催化裂解催化剂的研究进展[J]. 林产工业, 2022,59(3):41−48.Chen Wenxuan, Liu Peng, Li Xueqin, et al. Research progress of catalytic cracking catalysts for biomass tar[J]. China Forest Products Industry, 2022, 59(3): 41-48. -

下载:

下载: