Study on the effect of coke particle size on titanium slag smelting

-

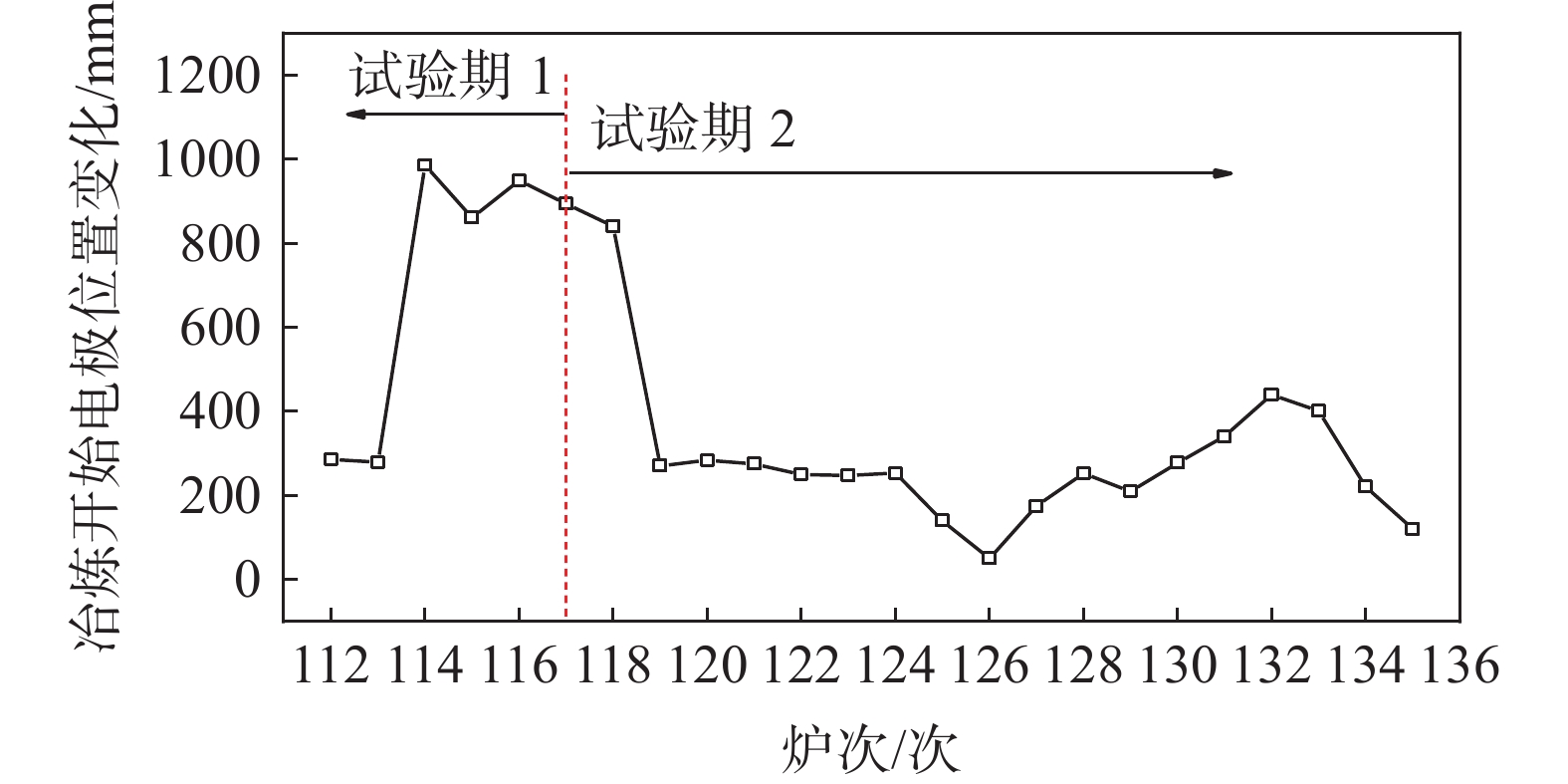

摘要: 根据颗粒在流体中自由沉降运动特点,通过理论计算得到连续加料冶炼钛渣条件下被带出焦炭颗粒粒径最大值为0.06 mm。结合工业上应用情况,得到试验用焦炭粒度范围2~8 mm。基于此,考察了焦炭粒度对钛渣冶炼的影响,结果表明,在功率不变条件下,焦炭粒度偏大、反应相对滞后引起冶炼过程烟气温度、CO浓度波动大,冶炼初期存在电极位置快速上升等问题,导致吨渣焦耗、百吨料耗时、吨渣电耗比基准期分别多24 kg、0.18 h、52.07 kWh;相较而言,功率由17.67 MW/h提升至18.14 MW/h(提升0.47 MW/h)时,热力学和动力学条件得到改善,促进焦炭充分反应,消除炉内残碳量,使冶炼更加稳定,同时吨渣焦耗、吨渣电耗比“未提升功率的试验期”分别降低了26 kg、128.12 kWh;焦炭粒度分布变窄且均匀,有利于钛渣冶炼过程和质量稳定控制,而功率提升可有效降低焦炭粒度相对偏大对钛渣冶炼的不利影响。Abstract: According to the characteristics of free settling movement of particles in the fluid, the theoretical calculation results show that the maximum size of coke particles taken out under the condition of continuous feeding smelting titanium slag is 0.06 mm. Combined with the industrial application, the size range of coke for test is 2~8 mm. Based on this, the influence of coke particle size on titanium slag smelting was investigated. The results show that under the condition of constant power, the flue gas temperature and CO concentration fluctuate greatly in the smelting process, and the electrode position rises rapidly at the beginning of smelting, which is caused by the large coke particle size and relatively delayed reaction. As a result, the consumption per ton of slag coke, the time consumption per hundred tons of material, and the power consumption per ton of slag are respectively 24 kg, 0.18 h, 52.07 kWh more than the reference period. By contrast, the power is increased from 17.67 MW/h to 18.14 MW/h (increased by 0.47 MW/h), thermodynamic and kinetic conditions are improved, coke is fully reacted, carbon residue in the furnace is eliminated, and smelting is more stable. At the same time, coke consumption per ton of slag and power consumption per ton of slag are reduced by 26 kg and 128.12 kWh respectively compared with "unraised power test period". The narrow and uniform coke particle size distribution is conducive to the titanium slag smelting process and quality stability control, while the increase of power can effectively reduce the adverse effect of relatively large coke particle size on titanium slag smelting.

-

Key words:

- titanium slag , smelting /

- coke /

- lower limit of particle size /

- power consumption

-

表 1 酸溶性钛渣的成分指标

Table 1. The component index of acid-soluble titanium slag

% ∑TiO2 TiO2 FeO Ti3O5 74.55 57.03 5.78 16.35 表 2 钛精矿主要化学成分

Table 2. Main chemical composition of titanium concentrate

% TiO2 FeO Fe2O3 SiO2 CaO MgO S 47.73 36.33 5.33 2.53 0.765 3.58 0.18 表 3 焦炭成分及粒度指标

Table 3. Coke composition and grain size index

% 类别 Fcd Ad Vd S 占比 +8 mm +2 mm~8 mm −2 mm 基准期 83.95 14.49 1.41 0.74 7.04 52.50 40.46 试验期 83.53 14.94 1.40 0.70 5.50 90.57 3.93 表 4 纯气体和混合气体流量及体积百分数指标

Table 4. Flow and volume percent indexes of pure gas and mixed gas

气体 流量/(m3·h−1) 体积百分数/ % 摩尔质量/(g·mol−1) CO 1636.72 81.86 28 CH4 26.58 1.33 16 CO2 86.14 4.31 44 N2 250.00 12.50 28 混合气体 1999.44 100.00 28.53 表 5 纯气体和混合气体粘度

Table 5. Viscosity of pure gas and mixed gas

气体组分 C K 温度范围/K 高温下气体

粘度/(Pa·s)CO 145.4424 15.21555 273~1300 4.93×10−5 CO2 276.2054 16.72158 238~973 4.06×10−5 CH4 166.3868 10.14328 77~1050 2.84×10−5 N2 192.8608 15.53529 871~1552 5.44×10−5 O2 237.9236 19.15405 758~1700 6.93×10−5 H2 151.8340 7.396744 321~1060 2.11×10−5 混合气体 4.93×10−5 表 6 钛渣电炉主要技术参数

Table 6. Main technical parameters of titanium slag electric furnace

变压器容量/MW 炉膛直径/mm 挂渣层厚度/mm 电极直径/mm 出渣口数量/个 出铁口数量/个 煤气回收工艺 25.5 9800 1000 1000 1 1 干法除尘 表 7 电极位置标准差及标准差的方差

Table 7. Standard deviation of electrode position and variance of standard deviation

类别 标准差平均值/mm 标准差的方差/mm2 基准期 349.49 5340.54 试验期1 331.13 4043.09 试验期2 325.92 1743.48 表 8 烟气温度及CO浓度

Table 8. Flue gas temperature and CO concentration

类别 烟气温度 CO浓度 平均值

/ ℃标准差

平均值标准差

的方差平均值

/%标准差

平均值标准差

的方差基准期 331.20 55.54 56.51 33.78 13.91 2.50 试验期1 335.72 50.10 157.49 31.68 12.76 3.32 试验期2 326.29 41.96 33.39 34.60 12.61 1.97 表 9 主要冶炼指标

Table 9. Main smelting indexes

类别 吨渣焦耗/t 功率/(MW·h−1) 百吨料耗时/h 吨渣电耗/kWh 基准期 0.143 17.64 7.15 2287.46 试验期1 0.167 17.67 7.33 2339.53 试验期2 0.141 18.14 6.80 2211.41 -

[1] Han Fengxia, Lei Ting, Zhou Lin, et al. Ratio of anthracite to ilmenite of titanium slag smelted by 30MVA DC arc furnace[J]. Chinese Journal of Rare Metals, 2012,36(2):298−303. (韩丰霞, 雷霆, 周林. 30MVA直流电弧炉冶炼钛渣配碳比研究[J]. 稀有金属, 2012,36(2):298−303.Han Fengxia, Lei Ting, Zhou Lin, et al. Ratio of anthracite to ilmenite of titanium slag smelted by 30 MVA DC arc furnace[J]. Chinese Journal of Rare Metals, 2012, 36(2): 298-303. [2] Ma Xiang, Han Fengxia, Lei Ting. Factor of reductant carbon during titanium slag smelting in closed direct current arc furnace[J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2013,38(5):6−10. (马翔, 韩丰霞, 雷霆. 密闭直流电弧炉钛渣生产还原剂碳因素分析[J]. 昆明理工大学学报(自然科学版), 2013,38(5):6−10.Ma Xiang, Han Fengxia, Lei Ting. Factor of reductant carbon during titanium slag smelting in closed direct current arc furnace[J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2013, 38(5): 6-10. [3] Xiao Jun. Study on the influence of different reductants on titanium slag of Panzhihua titanium concentrate smelting[J]. China Nonferrous Metallurgy, 2018,47(2):35−38. (肖军. 不同还原剂对攀枝花钛精矿冶炼钛渣影响研究[J]. 中国有色冶金, 2018,47(2):35−38.Xiao Jun. Study on the influence of different reductants on titanium slag of Panzhihua titanium concentrate smelting[J]. China Nonferrous Metallurgy, 2018, 47(2): 35-38. [4] Qiu Shuxing, Xiao Jun, Li Kaimao, et al. Impact of Panjiang coke on titanium slag smelting with Panzhihua titanium concentrate[J]. China Nonferrous Metallurgy, 2022,51(2):24−29. (邱淑兴, 肖军, 李凯茂, 等. 盘江焦炭对攀枝花钛精矿冶炼钛渣影响研究[J]. 中国有色冶金, 2022,51(2):24−29.Qiu Shuxing, Xiao Jun, Li Kaimao, et al. Impact of Panjiang coke on titanium slag smelting with Panzhihua titanium concentrate[J]. China Nonferrous Metallurgy, 2022, 51(2): 24-29. [5] Li Jie, Song Canyang, Li Xiaojing, et al. Research and application of combustibility and reactivity of pulverized coal injected in blast furnace[J]. China Metallurgy, 2019,29(1):8−13. (李杰, 宋灿阳, 李小静, 等. 高炉喷吹煤粉燃烧性与反应性的研究与应用[J]. 中国冶金, 2019,29(1):8−13.Li Jie, Song Canyang, Li Xiaojing, et al. Research and application of combustibility and reactivity of pulverized coal injected in blast furnace[J]. China Metallurgy, 2019, 29(1): 8-13. [6] Gu Longjian, Li Chongchao, Liang Surong, et al. Effect of different carburizing agents on carburizing and its influence on steel quality[J]. Iron Steel Vanadium Titanium, 1992,13(2):18−26. (古隆建, 礼重超, 梁素荣, 等. 不同增碳剂增碳效果及对钢质量影响的研究[J]. 钢铁钒钛, 1992,13(2):18−26.Gu Longjian, Li Chongchao, Liang Surong, et al. Effect of different carburizing agents on carburizing and its influence on steel quality[J]. Iron Steel Vanadium Titanium, 1992, 13(2): 18-26. [7] Correspondent. Antway helps Shenhua Ningxia coal to liquids project with an annual output of 4 million t/a run at full capacity[J]. Chemical Fertilizer Design, 2018,56(2):14. (本刊通讯员. 安特威助力神华宁煤年产400万t/a煤制油项目满负荷运行[J]. 化肥设计, 2018,56(2):14.Correspondent. Antway helps Shenhua Ningxia coal to liquids project with an annual output of 4 million t/a run at full capacity[J]. Chemical Fertilizer Design, 2018, 56(2): 14. [8] Li Kaimao. Discussion on recycling of gas from titanium slag electric furnace[J]. Light Metals, 2014,(12):39−41. (李凯茂. 钛渣电炉煤气回收利用的探讨[J]. 轻金属, 2014,(12):39−41.Li Kaimao. Discussion on recycling of gas from titanium slag electric furnace[J]. Light Metals, 2014(12): 39-41. [9] Ma Peisheng, Jiang Biyun, Zhang Jianhou. Critical assessment of viscosity and its correlation with temperature for gaseous substances under normal pressure[J]. Journal of Chemical Industry and Engineering (China), 1981,(3):193−205. (马沛生, 江碧云, 张建侯. 气体常压粘度数据的评定和对温度的关联[J]. 化工学报, 1981,(3):193−205.Ma Peisheng, Jiang Biyun, Zhang Jianhou. Critical assessment of viscosity and its correlation with temperature for gaseous substances under normal pressure[J]. Journal of Chemical Industry and Engineering (China), 1981 (3): 193-205. [10] Tian Linan. Viscosity calculation of pure gas, gas mixture and liquid[J]. Chemical Fertilizer Design, 1997,(6):9−13. (田立楠. 纯气体、混合气体及液体粘度的计算[J]. 化肥设计, 1997,(6):9−13.Tian Linan. Viscosity calculation of pure gas, gas mixture and liquid[J]. Chemical Fertilizer Design, 1997(6): 9-13. [11] Li Kaimao. Economic analyzing on slag grade and power consumption for smelting Panzhihua titanium concentrates[J]. Light Metals, 2015,(10):46−50. (李凯茂. 攀枝花钛精矿冶炼钛渣的经济品位及电耗分析[J]. 轻金属, 2015,(10):46−50.Li Kaimao. Economic analyzing on slag grade and power consumption for smelting Panzhihua titanium concentrates[J]. Light Metals, 2015(10): 46-50. -

下载:

下载: