Effects of pre-strain on tensile mechanical properties of commercially pure titanium TA2 welded joint

-

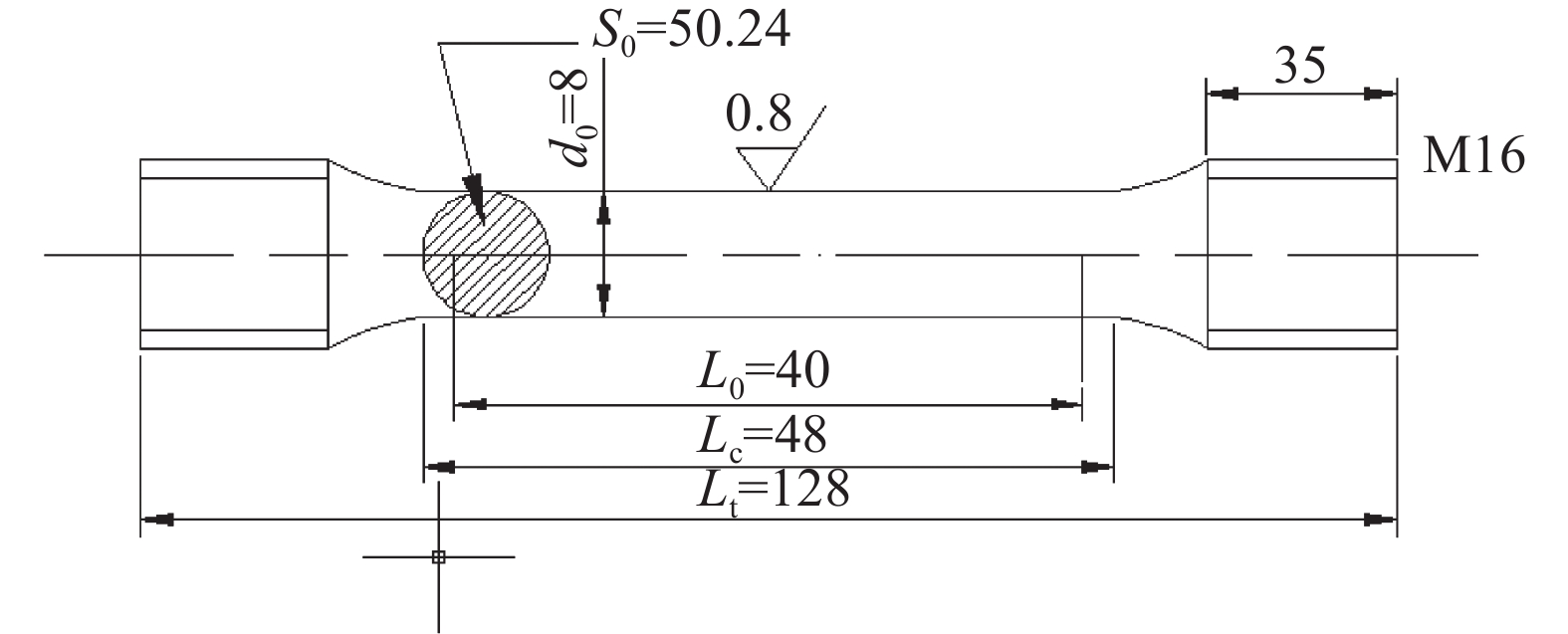

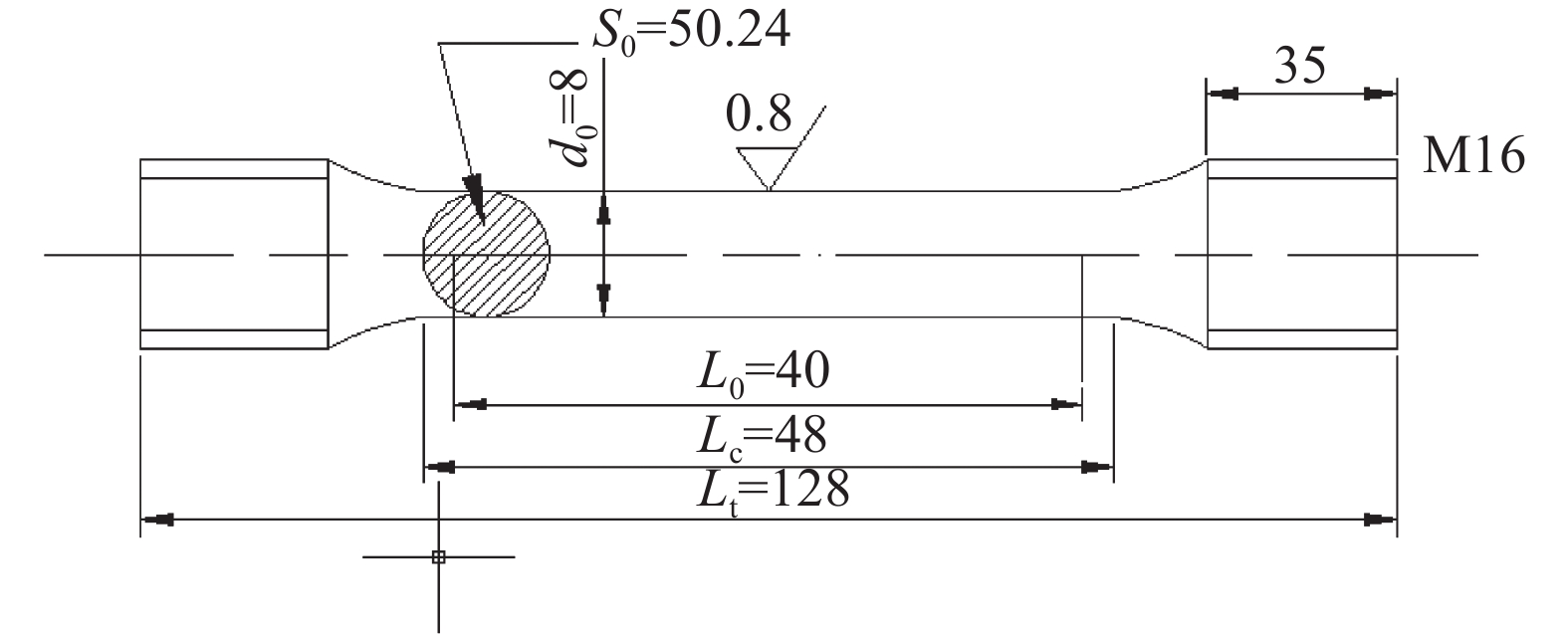

摘要: 以工业纯钛TA2焊接接头为研究对象,开展了预应变后的室温拉伸力学性能测试。结果表明,预应变后应力应变曲线上升,屈服强度及抗拉强度随着预应变量的增加而增加。综合考虑预应变量及应变速率影响,建立了预应变后材料强度的经验表达式。根据Hollomon本构方程,研究了预应变后应变速率敏感性指数及应变强化指数的变化,确定了预应变试样的拉伸本构方程。断口观察表明,预应变后材料延伸率下降,断口收缩率及韧窝尺寸均下降。Abstract: In this paper, room temperature tensile mechanical properties of commercially pure titanium TA2 welded joint after pre-straining were studied. The results show that stress-strain curves rises and yield strength and tensile strength increase with the degree of pre-strain. With considering effects of pre-strain and strain rate, the empirical expression for the strength of the material after pre-strain was developed. According to Hollomon constitutive equation, the variations of strain rate sensitivity index and strain hardening exponent were analyzed. Meanwhile, the tensile constitutive equation for the pre-strained samples was determined. The observation of fracture surface indicates that the reduction of fracture surface and the size of dimples decreases after pre-straining due to the decrease of elongation of the material.

-

Key words:

- TA2 /

- welded joint /

- tensile properties /

- pre-strain /

- constitutive equation

-

表 1 不同预应变下不同应变的应变速率敏感性指数m

Table 1. Strain rate sensitivity index m at different strain points under different pre-strains

应变/% 应变速率敏感指数m 预应变ε=2% 预应变ε=4% 1 0.0149 0.0336 2 0.0126 0.0308 3 0.0122 0.0293 4 0.0169 0.028 均值 0.0141 0.0304 表 2 不同预应变下不同应变速率的应变硬化指数n

Table 2. Strain hardening index n under different pre-strains and different strain rates

应变速率/s−1 应变硬化指数n 预应变ε=2% 预应变ε=4% 0.005 0.0644 0.036 0.0005 0.0578 0.0274 0.00005 0.067 0.0175 均值 0.063 0.027 表 3 不同预应变下不同应变速率的强度系数K值

Table 3. Strengthening coefficient K values under different strain rates and pre-strains

应变速率/s−1 K值 预应变ε=2% 预应变ε=4% 0.005 675.78 697.8 0.0005 693.79 704.7 0.00005 677.79 707.92 均值 682.5 703.46 -

[1] Chen Y, Zheng S, Zhou J, et al. Influence of H2S interaction with prestrain on the mechanical properties of high-strength X80 steel[J]. International Journal of Hydrogen Energy, 2016,41(24):10412−10420. doi: 10.1016/j.ijhydene.2016.01.144 [2] Zhang Xiaoyong, Bi Zongyue, Gao Huilin, et al. Prestrain embrittlement of X80 large deformation pipeline steel[J]. Welded Pipe and Tube, 2013,8:12−16. (张骁勇, 毕宗岳, 高惠临, 等. X80大变形管线钢的预应变脆化[J]. 焊管, 2013,8:12−16. doi: 10.3969/j.issn.1001-3938.2013.06.002Zhang Xiaoyong, Bi Zongyue, Gao Huilin, et al. Prestrain embrittlement of X80 large deformation pipeline steel[J]. Welded Pipe and Tube, 2013, 8: 12-16 doi: 10.3969/j.issn.1001-3938.2013.06.002 [3] Hu Hanjiang, Zhao Aimin, Yin Zhukai, et al. Effect of pre-strain on mechanical properties and hardening behavior of TRIP steel[J]. Transactions of Materials and Heat Treatmet, 2016,37(5):128−132. (胡汉江, 赵爱民, 印珠凯, 等. 预应变对TRIP钢力学性能及硬化行为的影响[J]. 材料热处理学报, 2016,37(5):128−132. doi: 10.13289/j.issn.1009-6264.2016.05.022Hu Hanjiang, Zhao Aimin, Yin Zhukai, et al. Effect of pre-strain on mechanical properties and hardening behavior of TRIP steel[J]. Transactions of Materials and Heat Treatmet, 2016, 37(5): 128-132 doi: 10.13289/j.issn.1009-6264.2016.05.022 [4] Mao Bowen, Sun Xiaoyu, Wang Wurong, et al. Effect of pre-strain and strain rates on mechanical properties of HC340LA high strength low alloy steel[J]. Journal of Plasticity Engineering, 2014,1:7−12. (毛博文, 孙晓屿, 王武荣, 等. 预应变和应变速率对HC340LA低合金高强钢力学性能的影响[J]. 塑性工程学报, 2014,1:7−12. doi: 10.3969/j.issn.1007-2012.2014.06.002Mao Bowen, Sun Xiaoyu, Wang Wuyong, et al. Effect of pre-strain and strain rates on mechanical properties of HC340 LA high strength low alloy steel[J]. Journal of Plasticity Engineering, 2014, 1: 7-12 doi: 10.3969/j.issn.1007-2012.2014.06.002 [5] Ma Z C, Zhao H W, Hu X L, et al. Influences of tensile pre-strain and bending pre-deflection on bending and tensile behaviors of an extruded AZ31B magnesium alloy[J]. Materials and Design, 2014,64(14):566−572. [6] Liu Xiaoning, Yang Fan, Liu Ceng, et al. Pre-strain effect evaluation of austenitic stainless steel[J]. Journal of Mechanical Strength, 2019,41(1):104−109. (刘小宁, 杨帆, 刘岑, 等. 奥氏体不锈钢预应变效果评价[J]. 机械强度, 2019,41(1):104−109. doi: 10.16579/j.issn.1001.9669.2019.01.018Liu Xiaoning, Yang Fan, Liu Ceng, et al. Pre-strain effect evaluation of austenitic stainless steel[J]. Journal of Mechanical Strength, 2019, 41(1): 104-109 doi: 10.16579/j.issn.1001.9669.2019.01.018 [7] Zheng Jinyang, Li Yaxian, Xu Ping. Influence factors of mechanical property for strain strengthening austenitic stainless steel[J]. Journal of PLA University of Science and Technology(Natural Science Edition), 2011,5:512−519. (郑津洋, 李雅娴, 徐平. 应变强化用奥氏体不锈钢力学性能影响因素[J]. 解放军理工大学学报, 2011,5:512−519.Zheng Jinyang, Li Yaxian, Xu Ping. Influence factors of mechanical property for strain strengthening austenitic stainless steel[J]. Journal of PLA University of Science and Technology(Natural Science Edition), 2011, 5: 512-519 [8] Han Yu, Zhou Wei, Xu Ye. Study on the deformation law of cold-stretching for austenitic stainless steel pressure vessel[J]. Journal of Mechanical Strength, 2022,44(2):409−415. (韩豫, 周微, 徐晔. 应变强化奥氏体不锈钢压力容器的变形规律研究[J]. 机械强度, 2022,44(2):409−415. doi: 10.16579/j.issn.1001.9669.2022.02.021Han Yu, Zhou Wei, Xu Ye. Study on the deformation law of cold-stretching for austenitic stainless steel pressure vessel[J]. Journal of Mechanical Strength, 2022, 44(2): 409-415 doi: 10.16579/j.issn.1001.9669.2022.02.021 [9] Chen Xiaoning, Zhou Jijun. Study on strain strengthened bearing capacity of austenitic stainless steel pressure vessels[J]. China Plant Engineering, 2017,4:173−174. (陈小宁, 周吉军. 奥氏体不锈钢压力容器的应变强化承载能力研究[J]. 中国设备工程, 2017,4:173−174. doi: 10.3969/j.issn.1671-0711.2017.19.080Chen Xiaoning, Zhou Jijun. Study on strain strengthened bearing capacity of austenitic stainless steel pressure vessels[J]. China Plant Engineering, 2017, 4: 173-174 doi: 10.3969/j.issn.1671-0711.2017.19.080 [10] Xu Guodong, Wang Guisheng. Development of titanium and its industry[J]. Chinese Journal of Rare Metals, 2009,33:903−912. (许国栋, 王桂生. 钛金属和钛产业的发展[J]. 稀有金属, 2009,33:903−912. doi: 10.3969/j.issn.0258-7076.2009.06.028Xu Guodong, Wang Guisheng. Development of titanium and its industry[J]. Chinese Journal of Rare Metals, 2009, 33: 903-912 doi: 10.3969/j.issn.0258-7076.2009.06.028 [11] Chang Le, Peng Jian, Zhou Changyu, et al. Fields-backofen and a modified Johnson-Cook model for CP-Ti at ambient and intermediate temperature[J]. Rare Metal Materials and Engineering, 2017,46(7):1803−1809. doi: 10.1016/S1875-5372(17)30170-4 [12] Lu L, Li J, Su C Y, et al. Research on fatigue crack growth behavior of commercial pure titanium base metal and weldment at different temperatures[J]. Theoretical and Applied Fracture Mechanics, 2019,100:215−224. doi: 10.1016/j.tafmec.2019.01.017 [13] Zhao Qing, Chang Le, Zheng Yixiang, et al. Tensile mechanical properties and constitutive model of commercial pure titanium TA2 welded joints at medium-low temperature[J]. Iron Steel Vanadium Titanium, 2022,43(5):81−89. (赵青, 常乐, 郑逸翔, 等. TA2工业纯钛焊接接头中低温拉伸力学性能及本构模型[J]. 钢铁钒钛, 2022,43(5):81−89. doi: 10.7513/j.issn.1004-7638.2022.05.012Zhao Qing, Chang Le, Zheng Yixiang, et al. Tensile mechanical properties and constitutive model of commercial pure titanium TA2 welded joints at medium-low temperature[J]. Iron Steel Vanadium Titanium, 2022, 43(5): 81-89 doi: 10.7513/j.issn.1004-7638.2022.05.012 [14] Chang L, Zhou C Y, He X H. The Effects of prestrain and subsequent annealing on tensile properties of CP-Ti[J]. Metals, 2017,7:99. doi: 10.3390/met7030099 -

下载:

下载: