Review on technology developments of titanium-steel clad plates based on global patent analysis

-

摘要: 基于全球钛钢复合板专利申请态势,对钛钢复合板关键技术的发展变化进行深入分析,结果显示,中、日是钛钢复合板主要技术来源国,日本起步相对较早,但中国后来者居上,专利申请数量全球排名第一;钛钢复合板加工工艺是专利布局热点,其中直接轧制法专利数量最多;专利技术功效以降低成本和提高结合强度为主。基于以上分析结果,从专利的视角,为国内企业的技术创新和产品开发提出相关建议。Abstract: The development of key technologies of titanium-steel clad plates is reviewed based on a comprehensive mining of global patent applications. The results show that China and Japan are the major technology sources of titanium-steel clad plates. While Japan started earlier, China later rank first in patent applications in the world. Titanium-steel clad plate processing technologies are research hot spots, among which the direct rolling process route holds the largest share in a patent portfolio. The aims of the patented technologies is primarily to reduce the cost and improve the bonding strength. Based on the above findings, some suggestions about technological innovation and product development are proposed from a patent strategic perspective.

-

Key words:

- titanium-steel clad plates /

- patent analysis

-

表 1 钛钢复合板全球专利布局情况

Table 1. Global patent layout of titanium-steel composite plate

当前申请(专利权)人区域 专利数量/件 中国 465 日本 142 德国 12 韩国 6 法国 3 美国 2 其他地区 2 表 2 钛钢复合板各技术分支专利申请数量情况

Table 2. The number of patent applications for each technical branch of titanium-steel composite plate

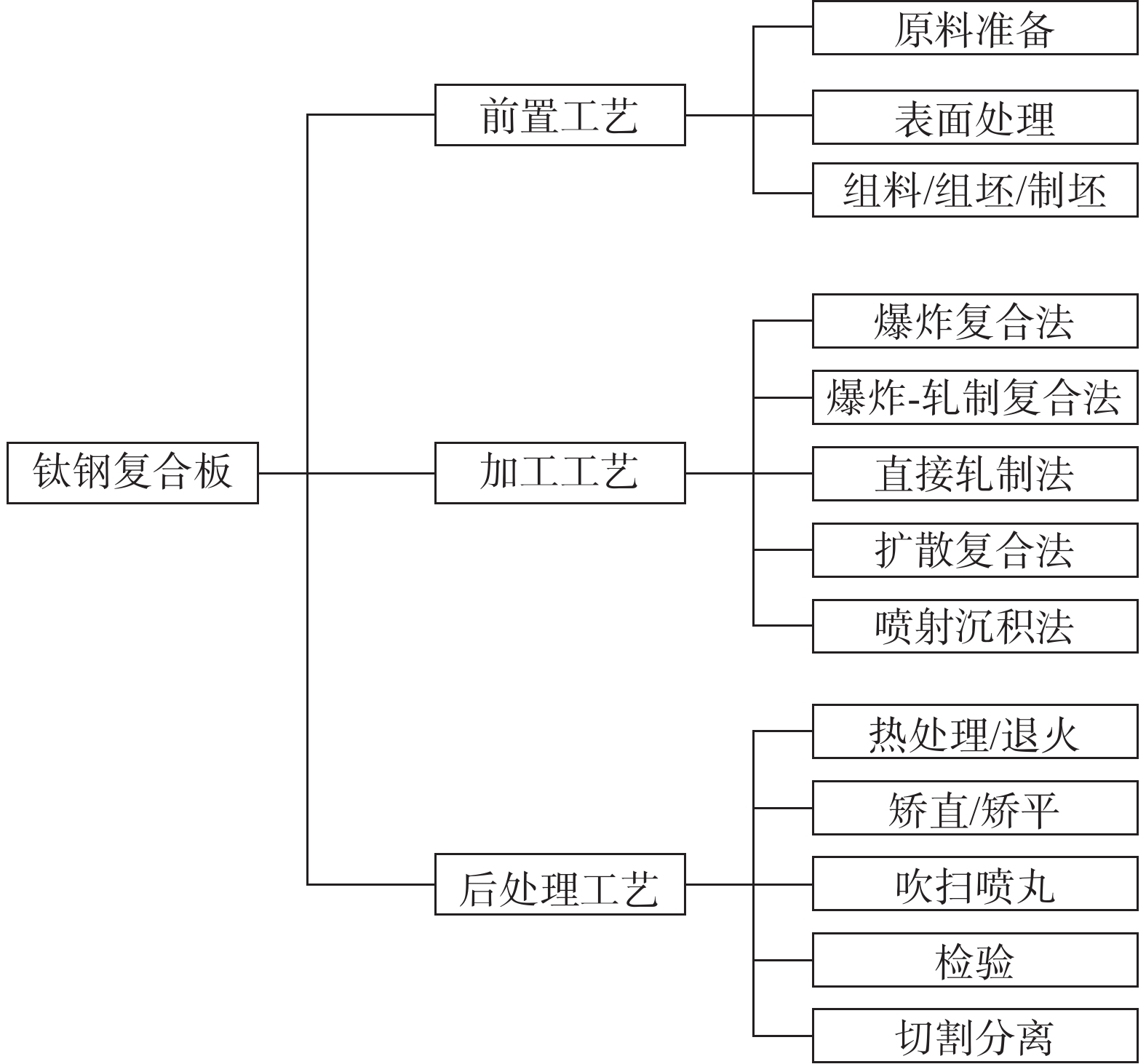

工艺名称 处理方式 数量 前置工艺 表面处理 38 组料/组坯/制坯 137 原料准备 96 加工工艺 爆炸复合法 90 直接轧制法 248 爆炸-轧制复合法 35 扩散复合法 13 喷射沉积法 8 后处理 退火 137 矫直/矫平 39 吹扫抛丸 38 检验 47 切割分离 64 成品表面处理 37 表 3 钛钢复合板加工工艺主要申请人(前5名)

Table 3. Main applicants for titanium-steel composite plate processing (Top 5)

加工工艺 主要申请人(TOP5) 专利申请/件 爆炸复合法 安徽宝泰 12 西安天力 9 旭化成 8 宝鸡钛程 8 南京斯迈柯 4 直接轧制法 住友金属 26 攀钢集团 22 日本制铁 21 日本钢管 16 宝山钢铁 11 扩散焊接法 旭化成 4 兰州理工大学 1 太原理工大学 1 日本制铁 1 三菱重工 1 爆炸-轧制复合法 西安天力 4 中国石油天然气 2 宝鸡石油钢管 2 晋西工业 2 北京科技大学 2 喷射沉积法 宝山钢铁 2 日新制钢株式会社 2 新日本制铁 2 宝鸡石油钢管 1 中国科学院金属研究院 1 表 4 部分专利的退火加热温度范围

Table 4. Annealing temperature ranges of some patents

序号 公开(公告)号 申请人 加热温度/ ℃ 保温时长/min 1 CN102794607B 西安天力金属复合材料股份有限公司 500~650 60~300 2 CN103320717B 南京钢铁股份有限公司 450~650 10~120 3 CN110202249B 太原钢铁(集团)有限公司 540 60 4 CN106269963B 广汉程明新材料科技有限公司 500~700 5 CN109304367B

瓯锟科技温州有限公司680~700 30~120 表 5 钛钢复合板技术功效

Table 5. Technical efficiency comparison of titanium-steel composite plate

技术/功效 降低生产成本 提高界面强度 提高结合强度 提高表面质量 提高生产安全性 提高生产率 前置工艺 组料 117 73 60 30 29 24 原料准备 68 37 65 19 21 6 表面处理 32 26 21 9 12 4 加工工艺 直接轧制法 172 99 129 41 32 54 爆炸复合法 55 41 50 13 24 11 扩散焊接法 6 8 10 0 2 2 喷射沉积法 8 5 5 3 1 0 爆炸-轧制复合法 28 20 20 11 9 9 后处理 切割分离 49 36 42 12 18 10 成品表面处理 31 26 19 8 12 4 吹扫抛丸 27 21 21 4 12 5 热处理 106 70 73 36 21 39 矫直 33 18 26 17 17 4 检验 40 24 16 14 21 2 焊接 27 26 10 2 5 6 应用领域 17 11 1 5 10 2 -

[1] Chen Xingzhang. Review of laminar composite metal material manufacturing technique[J]. Nonferrous Metal Materials and Engineering, 2017,38(2):63−66. (陈兴章. 层状金属复合材料技术创新及发展趋势综述[J]. 有色金属材料与工程, 2017,38(2):63−66.Chen Xingzhang. Review of laminar composite metal material manufacturing technique[J]. Nonferrous Metal Materials and Engineering, 2017, 38(2): 63-66. [2] Bai Yuliang, Liu Xuefeng, Wang Wenjing, et al. Current status and research trends in processing and application of titanium/steel composite plate[J]. Chinese Journal of Engineering, 2021,43(1):85−96. (白于良, 刘雪峰, 王文静, 等. 钛/钢复合板及其制备应用研究现状与发展趋势[J]. 工程科学学报, 2021,43(1):85−96.Bai Yuliang, Liu Xuefeng, Wang Wenjing, et al.Current status and research trends in processing and application of titanium/steel composite plate[J]. Chinese Journal of Engineering, 2021, 43(1): 85-96. [3] Li Junhan, Sun Ning, Ma Lan, et al. Progress in preparation technology and application of titanium-steel composite sheets[J]. World Nonferrous Metals, 2020,(14):34−36. (李俊翰, 孙宁, 马兰, 等. 钛钢复合板的制备技术进展及应用[J]. 世界有色金属, 2020,(14):34−36. doi: 10.3969/j.issn.1002-5065.2020.14.015Li Junhan, Sun Ning, Ma Lan, et al. Progress in preparation technology and application of titanium-steel composite sheets[J]. World Nonferrous Metals, 2020(14): 34-36. doi: 10.3969/j.issn.1002-5065.2020.14.015 [4] Yang Wenyue, Sun Qian, Li Bing, et al. Study on inhomogeneity of interface microstructure and mechanical properties in explosive welding of titanium-steel clad[J]. Pressure Vessel Technology, 2021,38(12):15−21. (杨文月, 孙倩, 李冰, 等. 钛钢爆炸焊接结合界面组织及力学性能不均匀性研究[J]. 压力容器, 2021,38(12):15−21. doi: 10.3969/j.issn.1001-4837.2021.12.003Yang Wenyue, Sun Qian, Li Bing, et al. Study on inhomogeneity of interface microstructure and mechanical properties in explosive welding of titanium-steel clad[J]. Pressure Vessel Technology, 2021, 38(12): 15-21. doi: 10.3969/j.issn.1001-4837.2021.12.003 [5] Zhang Hangyong, Zang Wei, Guo Longchuang. Microstructure and mechanical properties of interface for titanium/steel clad tube sheet prepared by explosive welding[J]. Iron Steel Vanadium Titanium, 2019,40(6):48−51. (张杭永, 臧伟, 郭龙创. 爆炸焊接法制备的钛/钢复合管板界面组织与力学性能分析[J]. 钢铁钒钛, 2019,40(6):48−51. doi: 10.7513/j.issn.1004-7638.2019.06.010Zhang Hangyong, Zang Wei, Guo Longchuang. Microstructure and mechanical properties of interface for titanium/steel clad tube sheet prepared by explosive welding[J]. Iron Steel Vanadium Titanium, 2019, 40(6): 48-51. doi: 10.7513/j.issn.1004-7638.2019.06.010 [6] Shen Chunyu, Fan Keshe, Li Ying, et al. Research on residual stress distribution in explosive welding titanium steel clad plate[J]. China Chemical Industry Equipment, 2019,21(4):31−35. (沈春豫, 樊科社, 李莹, 等. 爆炸焊接钛/钢复合板残余应力分布状态研究[J]. 中国化工装备, 2019,21(4):31−35.Shen Chunyu, Fan Keshe, Li Ying, et al. Research on residual stress distribution in explosive welding titanium steel clad plate[J]. China Chemical Industry Equipment, 2019, 21(4): 31-35. [7] Tian Shiwei, Jiang Haitao, Liu Jixiong, et al. Rheological behavior and hot rolling process of titanium / steel clad plate[J]. Materials Reports, 2019,33(24):4141−4146. (田世伟, 江海涛, 刘继雄, 等. 钛钢复合板双金属的流变行为及轧制制备[J]. 材料导报, 2019,33(24):4141−4146. doi: 10.11896/cldb.18120063Tian Shiwei, Jiang Haitao, Liu Jixiong, et al. Rheological behavior and hot rolling process of titanium / steel clad plate[J]. Materials Reports, 2019, 33(24): 4141-4146. doi: 10.11896/cldb.18120063 [8] Huang Zhao, He Weijun, Chen Zejun. Interface structure and failure behavior of TA2/stainless steel/Q235 composite plate[J]. Transactions of Materials and Heat Treatment, 2021,42(11):11−19. (黄钊, 何维均, 陈泽军. TA2/不锈钢/Q235复合板的界面结构和失效行为[J]. 材料热处理学报, 2021,42(11):11−19.Huang Zhao, He Weijun, Chen Zejun. Interface structure and failure behavior of TA2/stainless steel/Q235 composite plate[J]. Transactions of Materials and Heat Treatment, 2021, 42(11): 11-19. [9] Yang Yun, Ding Wenhong, Wu Mengxian, et al. Influence of interfacial microstructure control on bonding strength of titanium-steel composite plate[J]. Hot Working Technology, 2023,(7):56−61. (杨赟, 丁文红, 吴梦先, 等. 界面组织调控对钛/钢复合板结合强度的影响[J]. 热加工工艺, 2023,(7):56−61.Yang Yun, Ding Wenhong, Wu Mengxian, et al. Influence of interfacial microstructure control on bonding strength of titanium-steel composite plate[J]. Hot Working Technology, 2023(7): 56-61. [10] Bai Yuliang, Li Jingkun, Liu Xuefeng, et al. Effect of induction heating temperature on the interface of cold−hot-rolled titanium/steel composite plates[J]. Chinese Journal of Engineering, 2020,42(12):1639−1646. (白于良, 李晶琨, 刘雪峰, 等. 感应加热温度对冷-热轧制成形钛/钢复合板界面的影响[J]. 工程科学学报, 2020,42(12):1639−1646.Bai Yuliang, Li Jingkun, Liu Xuefeng, et al. Effect of induction heating temperature on the interface of cold−hot-rolled titanium/steel composite plates[J]. Chinese Journal of Engineering, 2020, 42(12): 1639-1646. [11] Liu Xuefeng, Bai Yuliang, Li Jingkun, et al. Influence factors of interfacial bonding strength of cold rolled titanium / steel laminated composite plates[J]. Journal of Materials Engineering, 2020,48(7):119−126. (刘雪峰, 白于良, 李晶琨, 等. 冷轧成形钛/钢层状复合板界面结合强度的影响因素[J]. 材料工程, 2020,48(7):119−126.Liu Xuefeng, Bai Yuliang, Li Jingkun, et al. Influence factors of interfacial bonding strength of cold rolled titanium / steel laminated composite plates[J]. Journal of Materials Engineering, 2020, 48(7): 119-126. [12] Zhu Kunliang, Zhu Peixian, Zhou Shenggang, et al. Performance of Ti-Fe composite prepared by hot-pressing diffusion welding method[J]. Hot Working Technology, 2014,43(20):69−71,76. (朱坤亮, 竺培显, 周生刚, 等. 热压扩散焊接法制备钛-钢复合材料及性能研究[J]. 热加工工艺, 2014,43(20):69−71,76.Zhu Kunliang, Zhu Peixian, Zhou Shenggang, et al. Performance of Ti-Fe composite prepared by hot-pressing diffusion welding method[J]. Hot Working Technology, 2014, 43(20): 69-71, 76. [13] Hu Jie, Xie Rong, Du Xunbai. Processing technology of titanium steel clad plate and its application in ship and ocean engineering[J]. Jiangsu Ship, 2016,33(6):6−8,12. (胡杰, 谢荣, 杜训柏. 钛钢复合板加工技术及其在船海工程中的应用[J]. 江苏船舶, 2016,33(6):6−8,12.Hu Jie, Xie Rong, Du Xunbai. Processing technology of titanium steel clad plate and its application in ship and ocean engineering[J]. Jiangsu Ship, 2016, 33(6): 6-8, 12. [14] Wang Kuan, Zhu Haiping, Song Zhenli, et al. Review on characteristics of interface of titanium clad steel plate[J]. Journal of Functional Materials, 2017,48(4):4025−4032. (王宽, 朱海平, 宋振莉, 等. 钛钢复合板界面特征研究述评[J]. 功能材料, 2017,48(4):4025−4032.Wang Kuan, Zhu Haiping, Song Zhenli, et al. Review on characteristics of interface of titanium clad steel plate[J]. Journal of Functional Materials, 2017, 48(4): 4025-4032. -

下载:

下载: