Mechanism analysis of the production of sublimated sulfur in the tail gas of acidolysis of titanium concentrate

-

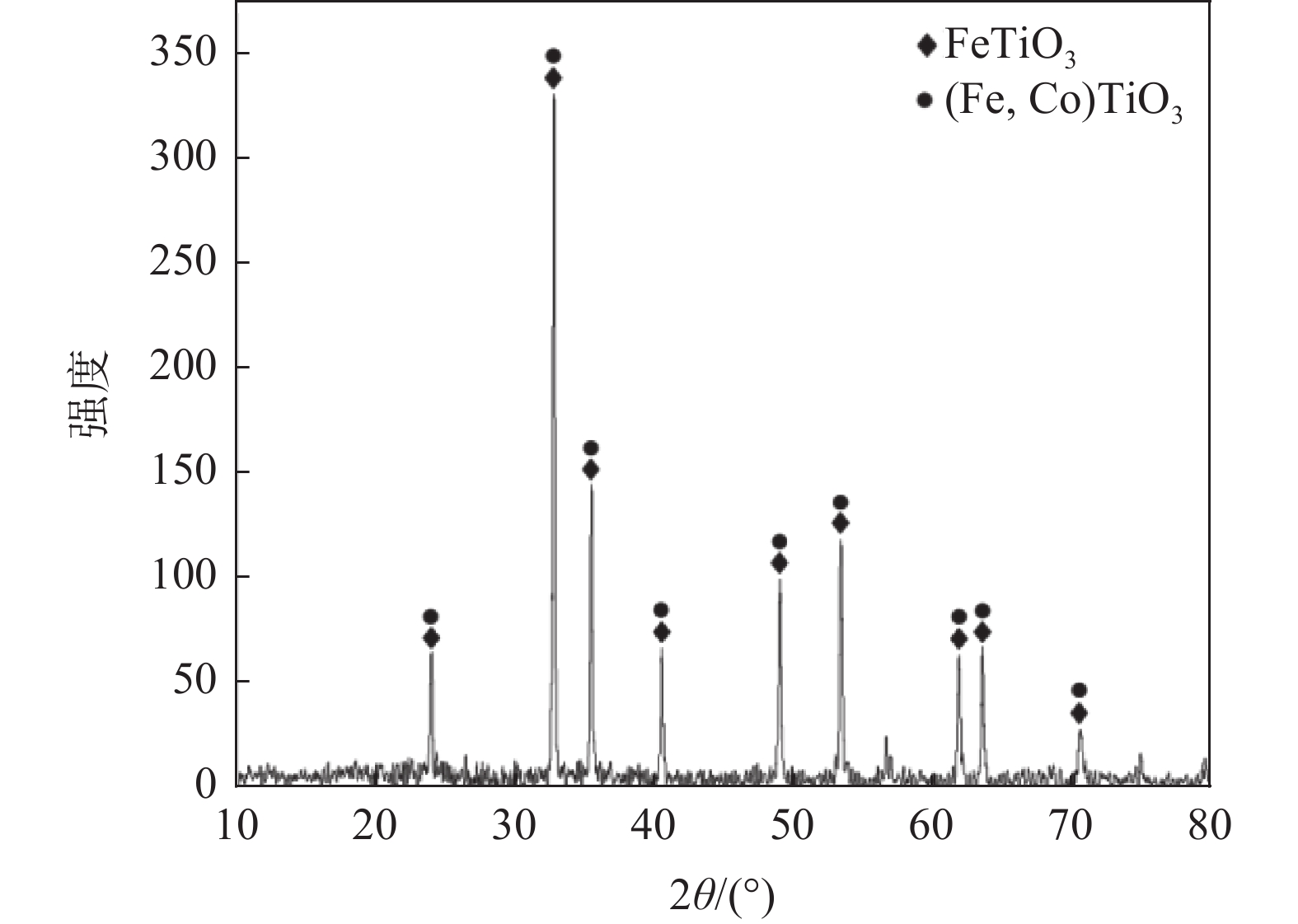

摘要: 针对硫酸法钛白酸解过程中升华硫堵塞管道从而影响钛白粉连续生产的问题,从钛精矿的结构组成分析出发,结合其在酸解过程可能存在的主要化学反应和实际生产中具体的酸解工艺条件,通过计算相关反应的吉布斯自由能变化,绘制酸解反应条件下体系的电位-pH图,探究了酸解尾气中升华硫产生的机理。结果表明,酸解尾气中单质硫应该主要来源于钛精矿中的磁黄铁矿(FeS),磁黄铁矿在酸解的高温(180~220 ℃)、高酸度(pH:−1.51~−1.47)复杂环境下被氧化生成单质硫,待反应结束后冷却凝固形成升华硫。因此在生产中可以从具体工艺入手,在不降低酸解率的情况下改变酸解环境(改变化学电位、降低环境pH值),以此规避或减小升华硫的产生,降低升华硫对硫酸法钛白的影响。Abstract: In order to prevent the continuous production of titanium dioxide from being blocked by sublimated sulfur in the process of titanium dioxide acidolysis by sulflate process, this paper starts from the structural composition analysis of titanium concentrate, combined with the main chemical reactions that may exist in the acidolysis process and the specific acidolysis process conditions in actual production by calculating the change of Gibbs free energy of related reactions. The potentio-pH diagram of the system under the condition of acid hydrolysis was drawn, and the mechanism of the occurrence of sublimated sulfur in the tail gas of acid hydrolysis was explored. The results show that the elemental sulfur in the tail gas of acidolysis mainly come from the pyrrhotite (FeS) in titanium concentrate. The pyrrhotite is oxidized in the complex environment of acid hydrolysis at high temperature (180~220 ℃) and high acidity (pH: −1.51~−1.47) to produce elemental sulfur, which is cooled and solidified to form sublimated sulfur after the reaction. Therefore we can start from the specific process, change the acid hydrolysis environment (change the chemical potential, reduce the environmental pH value) without reducing the acid hydrolysis rate in order to avoid or reduce the occurrence of sublimation sulfur in production, reduce the effect of sublimation sulfur on the sulfate process titanium white.

-

Key words:

- titanium concentrate /

- acid hydrolysis /

- tail gas /

- sublimation sulfur /

- mechanism analysis

-

表 1 钛精矿的主要化学成分

Table 1. Main chemical components of titanium concentrate

% TiO2 TFe SiO2 MgO Al2O3 CaO V2O5 S MnO 46.14 19.65 0.79 1.277 0.06 0.84 0.08 0.14 0.26 表 2 钛精矿的矿物组成

Table 2. Mineral composition of titanium concentrate

% 钛铁矿 绿泥石 钛闪石 透辉石 榍石 磁铁矿 钛铁矿+绿泥石 钛铁矿+石灰 微斜长石 黄铁矿 磁黄铁矿 90.53 2.44 1.77 0.94 0.65 0.58 0.54 0.53 0.39 0.12 0.06 表 3 钛精矿中的元素赋存情况

Table 3. Occurrence of elements in titanium concentrate

% 矿物 Al Ca Fe Mg Mn S Si Ti V 钛铁矿 12.22 11.42 94.94 82.98 79.47 0.00 29.14 97.45 97.48 磁铁矿 3.02 0.00 1.05 0.48 0.00 0.00 0.00 0.14 0.61 钛闪石 16.41 24.18 0.51 2.20 7.18 0.00 14.29 0.56 0.70 绿泥石 37.30 1.42 1.44 6.78 0.00 0.00 19.30 0.15 0.02 榍石 2.27 18.12 0.07 0.02 0.00 0.00 5.39 0.46 0.06 钛铁矿+石灰 0.52 10.21 0.40 0.69 0.00 0.00 0.36 0.47 0.41 微斜长石 9.76 4.11 0.01 0.00 0.00 0.00 5.06 0.00 0.00 钛铁矿+绿泥石 3.06 7.04 0.34 0.00 8.74 0.00 3.44 0.50 0.35 磁黄铁矿 0.00 0.00 0.11 0.00 0.00 24.86 0.00 0.00 0.00 黄铁矿 0.00 0.00 0.17 0.00 0.00 69.52 0.00 0.01 0.00 -

[1] Lu Lu, Zhang Chuanlin, Mi Shaobo. Probing interface structure and cation segregation in (In, Nb) co-doped TiO2 thin films[J]. Materials Characterization, 2022,191:112−164. [2] Jiang M, Zhang M H, Wang L Z, et al. Photocatalytic degradation of xanthate in flotation plant tailings by TiO2/graphene nanocomposites[J]. Chemical Engineering Journal, 2022,431:134104. doi: 10.1016/j.cej.2021.134104 [3] Ji R, Xing L, Yang K X, et al. Defect and interface co-steering ultra-wide microwave absorption and superior thermal conductance of TiO2/Fe/C nanocomposites[J]. Applied Surface Science, 2023,608:155207. doi: 10.1016/j.apsusc.2022.155207 [4] Ziental Daniel, Czarczynska-Goslinska Beata, Mlynarczyk Dariusz T, et al. Titanium dioxide nanoparticles: Prospects and applications in medicine[J]. Nanomaterials, 2020,10(2):387. doi: 10.3390/nano10020387 [5] Paolini R, Borroni D, Pedeferri M, et al. Self-cleaning building materials: The multifaceted effects of titanium dioxide[J]. Construction and Building Materials, 2018,182:126−133. doi: 10.1016/j.conbuildmat.2018.06.047 [6] Yu X, Jin X, Chen X Y, et al. A microorganism bred TiO2/Au/TiO2 heterostructure for whispering gallery mode resonance assisted plasmonic photocatalysis[J]. ACS Nano, 2020,14:13876−13885. doi: 10.1021/acsnano.0c06278 [7] Croce P S, Mousavi A. A sustainable sulfate process to produce TiO2 pigments[J]. Environmental Chemistry Letters, 2013,11(4):325−328. doi: 10.1007/s10311-013-0410-x [8] Zhang L, Hu H P, Liao Z, et al. Hydrochloric acid leaching behavior of different treated Panxi ilmenite concentrations[J]. Hydrometallurgy, 2011: 40-47. [9] Nguyen T H, Lee M S. A review on the recovery of titanium dioxide from ilmenite ores by direct leaching technologies[J]. Mineral Processing and Extractive Metallurgy Review, 2019,40(4):231−247. doi: 10.1080/08827508.2018.1502668 [10] Luo Zhiqiang. Application of continuous acidolysis in TiO2 production by sulfuric acid process[J]. Inorganic Chemicals Industry, 2012,44(3):33−35. (罗志强. 连续酸解技术在硫酸法钛白生产中的应用[J]. 无机盐工业, 2012,44(3):33−35.Luo Zhiqiang. Application of continuous acidolysis in TiO2 production by sulfuric acid process[J]. Inorganic Chemicals Industry, 2012, 44(3): 33-35. [11] Qu Yichen, Zhang Yingying. Study on continuous acidification technology of titanium dioxide by sulfuric acid method[J]. Research and Development, 2019,45(7):153−154. (曲以臣, 张盈盈. 硫酸法钛白粉中连续酸解技术研究[J]. 化工设计通讯, 2019,45(7):153−154. doi: 10.3969/j.issn.1003-6490.2019.07.101Qu Yichen, Zhang Yingying. Study on continuous acidification technology of titanium dioxide by sulfuric acid method[J]. Research and Development, 2019, 45(7): 153-154. doi: 10.3969/j.issn.1003-6490.2019.07.101 [12] Jia Linie, Liang Bin, Lü Li, et al. Beneficiation of titania by sulfuric acid pressure leaching of Panzhihua ilmenite[J]. Hydrometallurgy, 2014,59:92−98. [13] Li Zenghe, Wang Zhencui, Li Ge. Preparation of nano-titanium dioxide from ilmenite using sulfuric acid-decomposition by liquid phase method[J]. Powder Technology, 2016,287:256−263. doi: 10.1016/j.powtec.2015.09.008 [14] Wang Haibo, Luo Zhiqiang, Wu Xiaoping, et al. Study on the S content of titanium slag acid hydrolysis tail gas[J]. Iron Steel Vanadium Titanium, 2020,41(4):92−96. (王海波, 罗志强, 吴小平, 等. 钛渣酸解尾气S含量研究[J]. 钢铁钒钛, 2020,41(4):92−96.Wang Haibo, Luo Zhiqiang, Wu Xiaoping, et al. Study on the S content of titanium slag acid hydrolysis tail gas[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 92-96. -

下载:

下载: