Preparation and properties of calcium silicate sound insulation board from vanadium-titanium iron ore tailings

-

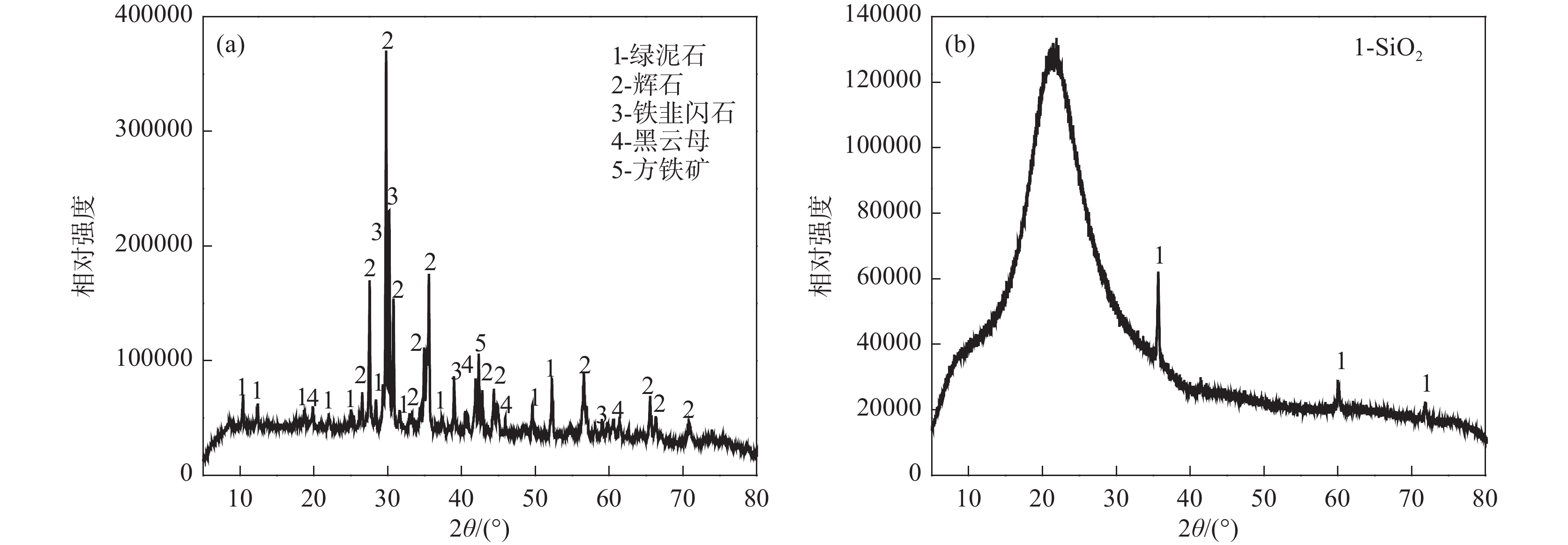

摘要: 为了促进胶凝活性弱的钒钛铁尾矿的综合利用,研究以钒钛铁尾矿为主要原料制备硅酸钙隔声板材。通过粒度分析、力学性能测试等手段,首先研究了钒钛铁尾矿的粉磨特性,而后以钒钛铁尾矿、硅灰、水泥为原料,制备复合胶凝材料,再添加废橡胶粉和钢纤维为增强材料,采用蒸汽养护的方式来制备硅酸钙隔声板材,并探索增强材料以及层结构对硅酸钙隔声板材性能的影响。结果表明,碱熔能有效促进钒钛铁尾矿中硅、铝活性的提高,Si4+和Al3+最高浓度分别为17.27、6.80 mg/L;当复合胶凝材料配合比为钒钛铁尾矿∶水泥∶硅灰=2∶7∶1,胶砂比为1∶3,水胶比为0.5,28 d抗压强度为39.7 MPa。钒钛铁尾矿所制备的硅酸钙隔声板材中,单层隔声板材中单掺钢纤维0.93%时,抗折强度为8.0 MPa;单掺橡胶粉1%(体积分数)时,抗折强度为8.8 MPa;复合添加(钢纤维1.6%,橡胶粉3%)时,其抗折强度为6.1 MPa。分层浇筑不同配料料浆制备的多层结构板材,抗折强度最高值为8.2 MPa。钒钛铁尾矿制备的硅酸钙隔声板材,其抗折强度符合GB/T 7019-2014和JC/T 564.1-2018标准要求。Abstract: In order to promote the comprehensive utilization of vanadium-titanium iron ore tailings (VTIOTs) with weak gelling activity, the preparation of calcium silicate sound insulation board (CSSB) using VTIOTs as the main raw material was investigated. Through particle size analysis, mechanical properties and other testing methods, the grinding characteristics of VTIOTs were studied, then composite cementitious materials (CCM) were prepared with VTIOTs, silica fume and cement, and then CSSB were prepared by steam curing with waste rubber powder and steel fiber as reinforcement materials, and the effects of reinforcement materials and layer structure on the properties of CSSB were explored. The results show that alkali melting can effectively improve the activity of silicon and aluminum in VTIOTs, and the highest concentrations of Si4+and Al3+are 17.27 mg/L and 6.80 mg/L, respectively. When the mix proportion of CCM∶VTIOTs∶cement∶SF = 2∶7∶1, the cement sand ratio = 1∶3, the water cement ratio = 0.5, and the 28-day compressive strength is 39.7 MPa. For the CSSB prepared from VTIOTs, when the volume content of steel fiber or rubber powder in the single layer sound insulation plate is 0.93% or 1%, the flexural strength reaches 8.0 MPa and 8.8 MPa, respectively, while for the dual addition the flexural strength is 6.1 MPa. The maximum flexural strength of multilayer structural plates prepared by pouring slurry with different ingredients in layers is 8.2 MPa. The flexural strength of CSSB prepared from VTIOTs meets the requirements of GB/T 7019-2014 and JC/T 564.1-2018 standard.

-

表 1 原材料化学成分

Table 1. Chemical compositions of the raw materials

% 原料 SiO2 Al2O3 CaO Fe2O3 TiO2 P2O5 MgO K2O Na2O SO3 LOI 钒钛铁尾矿 43.20 7.63 21.93 10.95 0.91 11.26 0.30 0.56 0.09 3.17 硅 灰 93.50 0.94 0.08 0.10 0.81 0.54 0.26 0.24 0.12 3.41 水 泥 4.68 10.95 61.67 0.30 0.34 0.15 2.79 0.06 17.06 2.00 表 2 复合胶凝材料配合比

Table 2. Mix proportion of CCM

试验

编号水泥/g 钒钛铁尾矿/g 硅灰/g 液体与粘合剂

的比率砂与粘合剂

的比率A0 450 0.5 3.0 A1 315 135 0.5 3.0 A2 315 90 45 0.5 3.0 表 3 掺加钢纤维制备硅酸钙隔声板材的配合比

Table 3. The mix ratio of CSSB prepared by mixing steel fibers

试验

编号水泥/g 尾矿粉/g 硅灰/g 尾矿砂/g 水/g 钢纤维

(体积分数)/%S0 560 160 80 1200 160 0 S1 560 160 80 1200 160 0.93 S2 560 160 80 1200 160 1.60 S3 560 160 80 1200 160 2.27 表 4 掺加废橡胶粉制备硅酸钙隔声板材的配合比

Table 4. The mix ratio of CSSB prepared by mixing waste rubber powder

试验编号 水泥/g 尾矿粉/g 硅灰/g 尾矿砂/g 水/g 橡胶粉/% R0 560 160 80 1200 160 0 R1 560 160 80 1200 160 1 R2 560 160 80 1200 160 3 R3 560 160 80 1200 160 5 表 5 掺加钢纤维和废橡胶粉制备硅酸钙隔声板材的配合比

Table 5. The mix ratio of CSSB prepared by mixing steel fiber and waste rubber powder

试验

编号水泥/g 尾矿粉/g 硅灰/g 尾矿砂/g 水/g 钢纤维(体

积分数)%橡胶

粉/ %SR0 560 160 80 1200 160 0 0 SR1 560 160 80 1200 160 0.93 3 SR2 560 160 80 1200 160 1.60 3 SR3 560 160 80 1200 160 2.27 3 SR4 560 160 80 1200 160 0.93 7 SR5 560 160 80 1200 160 1.60 7 SR6 560 160 80 1200 160 2.27 7 表 6 不同层结构硅酸钙隔声板材的配合比

Table 6. The mix ratio of CSSB with different layer structures

试验

编号水泥/g 尾矿

粉/g硅灰/g 尾矿

砂/g水/g 钢纤维(体

积分数)/%橡胶粉/% 1 2 3 L1-0 560 160 80 1200 160 0 0 L2-1 280 80 40 600 80 1.60 0 3 L2-2 280 80 40 600 80 1.60 0 7 L2-3 280 80 40 600 80 2.27 0 3 L2-4 280 80 40 600 80 2.27 0 7 L3-1 186.7 53.3 26.7 400 53.3 1.60 0 3 0 L3-2 186.7 53.3 26.7 400 53.3 1.60 0 7 0 L3-3 186.7 53.3 26.7 400 53.3 2.27 0 3 0 L3-4 186.7 53.3 26.7 400 53.3 2.27 0 7 0 -

[1] Yao G, Wang Q, Su Y W, et al. Mechanical activation as an innovative approach for the preparation of pozzolan from iron ore tailings[J]. Minerals Engineering, 2020,145:106068. doi: 10.1016/j.mineng.2019.106068 [2] Lu Chang, Chen Hongyun, Fu Liangjie, et al. Research progress on the preparation of new building materials using iron tailings[J]. Materials Report, 2021,35(5):5011−5026. (路畅, 陈洪运, 傅梁杰, 等. 铁尾矿制备新型建筑材料的国内外进展[J]. 材料导报, 2021,35(5):5011−5026. doi: 10.11896/cldb.20030178Lu Chang, Chen Hongyun, Fu Liangjie, et al. Research progress on the preparation of new building materials using iron tailings [J]. Materials Report, 2021, 35(5): 5011-5026. doi: 10.11896/cldb.20030178 [3] Chen T, Jian S, Xie X, et al. Research progress on comprehensive utilization of vanadium-titanium magnetite tailings[J]. Conservation and Utilization of Mineral Resources, 2021,41(2):174−178. [4] Shuai Y, Zhang Q, Heng Y, et al. Efficient iron recovery from iron tailings using advanced suspension reduction technology: A study of reaction kinetics, phase transformation, and structure evolution[J]. Journal of Hazardous Materials, 2020,404:124067. [5] Wang W, Ye P F, Zhou X L, et al. Effects of reductant type on coal-based direct reduction of iron ore tailings[J]. Annales de Chimie Science des Matériaux, 2018,42(3):453−466. [6] Shuai Y, Zhou W T, Han Y X, et al. Efficient enrichment of iron concentrate from iron tailings via suspension magnetization roasting and magnetic separation[J]. Journal of Material Cycles and Waste Management, 2020,22(1):1152−1162. [7] Zhai J H, Wang H B, Pan C, et al. Recycling of iron and titanium resources from early tailings: From fundamental work to industrial application[J]. Chemosphere, 2020,242:1−8. [8] Zhang Y, Wang L J, Duan Y D, et al. Preparation and performance of ce-doped far-infrared radiation ceramics by single iron ore tailings[J]. Ceramics International, 2022,48(8):11709−11717. doi: 10.1016/j.ceramint.2022.01.029 [9] Menders B C, Pedroti L G, Fontes M P F, et al. Technical and environmental assessment of the incorporation of iron ore tailings in construction clay bricks[J]. Construction and Building Materials, 2019,227:1−13. [10] Li X G, Wang P Q, Qin J Y, et al. Mechanical properties of sintered ceramsite from iron ore tailings affected by two-region structure[J]. Construction and Building Materials, 2020,240:117919. doi: 10.1016/j.conbuildmat.2019.117919 [11] Santana P H L, Burak D L, Thiengo C C, et al. Jack beans and vetiver grass growth on iron ore tailing sediments from the doce river dam disaster in brazil: Plant growth regulator effects under different edaphic conditions[J]. Journal of Soils and Sediments, 2020,20(2):1−8. [12] Cui X W, Geng Y, Li T, et al. Field application and effect evaluation of different iron tailings soil utilization technologies[J]. Resources, Conservation and Recycling, 2021,173:1−12. [13] Hellen L D C E S A, Athos M L S, Regina M B, et al. Addition of iron ore tailings to increase the efficiency of anaerobic digestion of pig manure: A technical and economic analysis[J]. Biomass and Bioenergy, 2021,148:1−18. [14] Qiu J P, Yang L, Sun X G, et al. Strength characteristics and failure mechanism of cemented super-fine unclassified tailings backfill[J]. Minerals, 2017,58(7):1−13. [15] Coura I R, Carmignano O R D R, Heitmann A P, et al. Use of iron mine tailing as fillers to polyethylene[J]. Scientific Reports, 2021,11(1):1−9. doi: 10.1038/s41598-020-79139-8 [16] Onitiri M A, Akinlabi E T. Effects of particle size and particle loading on the tensile properties of iron-ore-tailing-filled epoxy and polypropylene composites[J]. Mechanics of Composite Materials, 2017,52(6):817−828. doi: 10.1007/s11029-017-9633-4 [17] Carmignano O R, Vieira S S, Teixeira A P C, et al. Iron ore tailings: Characterization and applications[J]. Journal of the Brazilian Chemical Society, 2021,32(10):1895−1911. [18] Chen M X, Lu L C, Wang S D, et al. Investigation on the formation of tobermorite in calcium silicate board and its influence factors under autoclaved curing[J]. Construction and Building Materials, 2017,143:280−288. doi: 10.1016/j.conbuildmat.2017.03.143 [19] Zhan Jiayu, Yang Feihua, Li Wanmin, et al. Hydration characteristics and humidity control performance of calcium silicate board prepared from mine mailing and diatomite[J]. Journal of Wuhan University of Technology (Materials Science), 2020,35(1):147−154. doi: 10.1007/s11595-020-2238-0 -

下载:

下载: