Study on the corrosion behavior of a 600 MPa corrosion-resistant steel barin a chloride environment

-

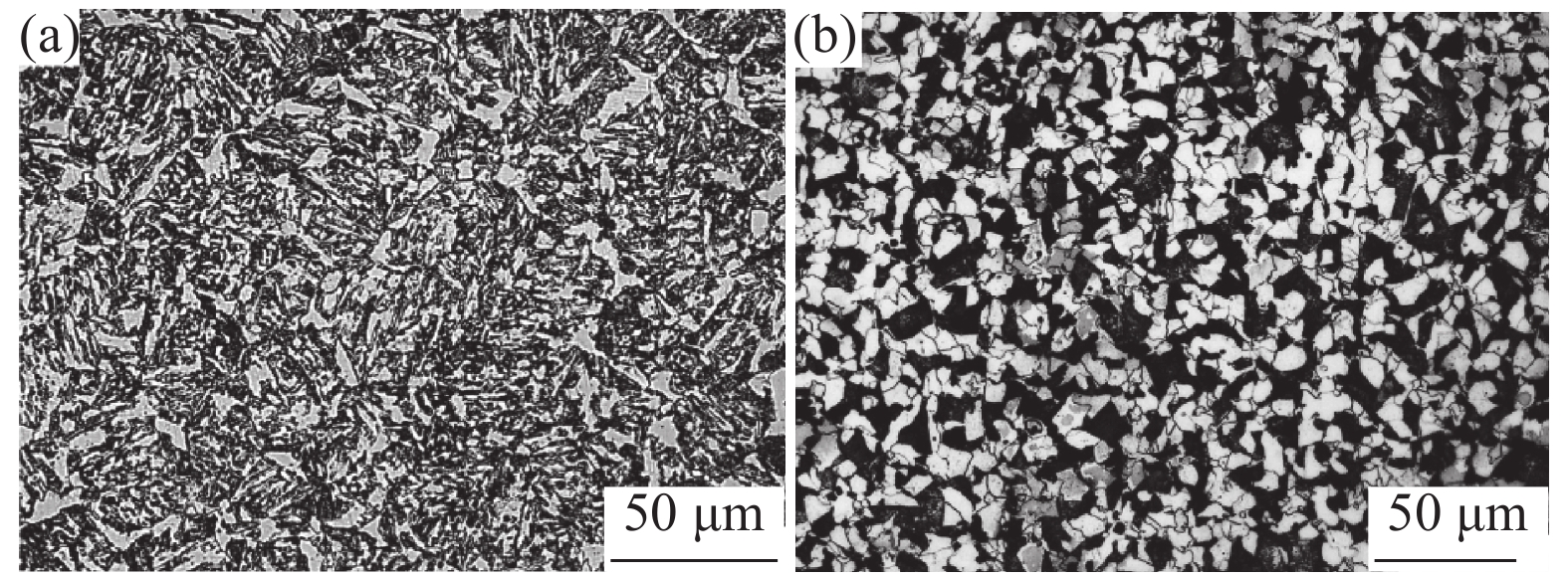

摘要: 以普通600 MPa级高强抗震钢筋HRB600E和经过合金调控后的同级别耐蚀钢筋为试验对象,通过周期浸润试验、电化学试验、表面分析技术和物相分析技术研究了氯盐环境下Cr、V对600 MPa级耐蚀钢筋腐蚀行为。结果表明,耐蚀合金的加入促进基体中贝氏体组织产生,减缓了铁素体阳极腐蚀进程;V、Cr元素的协同作用能够阻碍Cl−下渗,有效延缓锈层生长速度,360 h周期浸润后耐蚀钢筋腐蚀速率下降;Cr-V体系元素调控下耐蚀钢筋电化学性质自腐蚀电位提升,钝化后电位正移,腐蚀电流密度下降;耐蚀钢筋钝化后交流阻抗值显著提升,在混凝土碱性环境中耐腐蚀性能优异;合金元素调控改善了钢筋腐蚀产物的物相组成,耐蚀钢筋后期腐蚀产物中α-FeOOH及γ-FeOOH 占比更高,且内锈层有尖晶石结构产物FeCr2O4富集,增加了内锈层的致密度和稳定性。

-

关键词:

- 600 MPa级耐蚀钢筋 /

- 腐蚀行为 /

- 耐蚀性能 /

- 氯离子腐蚀 /

- Cr-V体系

Abstract: The effect of Cr and V elements on the corrosion behavior of the ordinary 600 MPa grade high-strength seismic steel bar HRB600E and the same grade corrosion-resistant steel bar after alloy regulation was studied by the cyclic immersion tests, electrochemical tests, surface analysis, and phase analysis in a chloride environment. The results show that the addition of corrosion-resistant alloy promotes the formation of bainite in the matrix and slows down the corrosion process of the ferrite anode. The synergistic effect of V and Cr elements can hinder the infiltration of Cl−, effectively delaying the growth rate of the rust layer, and the corrosion rate of corrosion-resistant steel bars decreases after 360 hours of cyclic immersion. Under the control of Cr-V elements, the self-corrosion potential of the electrochemical properties of corrosion-resistant steel bars increases, while the potential shifts positively after passivation, and the corrosion current density decreases. The AC impedance value of the corrosion-resistant steel bar is significantly improved after passivation, and it shows excellent corrosion resistance in the alkaline environment of concrete. The regulation of alloying elements improves the phase composition of corrosion products of the steel bars. The proportion of α-FeOOH and γ-FeOOH in the later corrosion products of the corrosion-resistant steel bars is higher and the internal rust layer is enriched with spinel-structured product FeCr2O4, which increases the density and stability of the internal rust layer. -

表 1 试验钢化学成分

Table 1. Chemical compositions of HRB600cE and HRB600E bar

% 钢种 C Si Mn S P Cr Mo+Ni+Cu V Nb Fe HRB600cE ≤0.20 0.50 1.15 ≤0.004 ≤0.018 0.75~1.10 ≥1.10 ≤0.10 余量 HRB600E 0.26 0.70 1.54 ≤0.008 ≤0.025 ≤0.15 ≤0.012 表 2 锈层致密处元素组成

Table 2. Chemical compositions of the compact rust

牌号 浸润时长/h 元素占比/% O Cr V Fe Cl HRB600cE 144 5.321 0.421 0.254 93.684 0.320 360 30.835 0.158 0.301 67.726 0.980 HRB600E 144 12.822 0.023 84.341 2.267 360 27.942 0.331 69.033 2.182 表 3 HRB600cE与HRB600E极化曲线拟合结果

Table 3. Fitting results of the polarization curves of HRB600cE and HRB600E

钢筋状态 Ecorr/mV icorr/(μA·cm−2) Ep/mV HRB600cE原始态 683 1.34 0 HRB600cE钝化后 623 0.78 29 HRB600E原始态 765 4 0 HRB600E钝化后 734 3.32 0 -

[1] Ye Zhanchun, Guan Chunlong. Study on corrosion resistance and wear resistance of new vanadium-containing weather proof steel for building[J]. Iron Steel Vanadium Titanium, 2019,40(4):116−120. (叶占春, 关春龙. 含钒新型建筑耐候钢的耐蚀及耐磨性能研究[J]. 钢铁钒钛, 2019,40(4):116−120. doi: 10.7513/j.issn.1004-7638.2019.04.022Ye Zhanchun, Guan Chunlong. Study on corrosion resistance and wear resistance of new vanadium-containing weather proof steel for building[J]. Iron Steel Vanadium Titanium, 2019, 40(4): 116-120. doi: 10.7513/j.issn.1004-7638.2019.04.022 [2] Luo Yihua, Huang Yao, Yang Xuefeng, et al. Effect of P elements on mechanical properties and corrosion resistance of high strength weathering steel used in transmission tower[J]. Iron Steel Vanadium Titanium, 2019,40(1):142−147. (罗义华, 黄耀, 杨雪锋, 等. P元素对耐候高强钢铁塔力学性能和腐蚀性能的影响[J]. 钢铁钒钛, 2019,40(1):142−147. doi: 10.7513/j.issn.1004-7638.2019.01.025Luo Yihua, Huang Yao, Yang Xuefeng, et al. Effect of P elements on mechanical properties and corrosion resistance of high strength weathering steel used in transmission tower[J]. Iron Steel Vanadium Titanium, 2019, 40(1): 142-147. doi: 10.7513/j.issn.1004-7638.2019.01.025 [3] Du Fengyin, Jin Zuquan, Zhao Tiejun, et al. Electrochemical chloride extraction from corrosion-resistant steel bar-reinforced concrete[J]. International Journal of Electrochemical Science, 2018,13:7076−7094. doi: 10.20964/2018.07.79 [4] Xie Qiong, Shi Peiyang, Liu Chengjun, et al. Experimental studies on corrosion behaviour of ferritic stainless steel in HCl based solution[J]. Iron Steel Vanadium Titanium, 2015,36(4):114−118. (解琼, 史培阳, 刘承军, 等. 铁素体不锈钢在盐酸基溶液中的加速腐蚀行为研究[J]. 钢铁钒钛, 2015,36(4):114−118. doi: 10.7513/j.issn.1004-7638.2015.04.020Xie Qiong, Shi Peiyang, Liu Chengjun, et al. Experimental studies on corrosion behaviour of ferritic stainless steel in HCl based solution [J]. Iron Steel Vanadium Titanium, 2015, 36(4): 114-118. doi: 10.7513/j.issn.1004-7638.2015.04.020 [5] Zhou Yu, Ye Yinghua, Xi Jie, et al. Experiment of properties deterioration of air- entrained concrete in seawater-aggressive and freeze-thaw environment[J]. Concrete, 2011,(12):18−20. (周煜, 叶英华, 袭杰, 等. 海水侵蚀环境与冻融交替作用下引气混凝土性能劣化试验[J]. 混凝土, 2011,(12):18−20. doi: 10.3969/j.issn.1002-3550.2011.12.006Zhou Yu, Ye Yinghua, Xi Jie, et al. Experiment of properties deterioration of air- entrained concrete in seawater-aggressive and freeze-thaw environment[J]. Concrete, 2011(12): 18-20. doi: 10.3969/j.issn.1002-3550.2011.12.006 [6] Bao Huiming, Zhao Xuewen, Xiong Xin, et al. Study of sisal fiber concrete 's anti- erosion property in marine environment[J]. Concrete, 2012,(6):23−24. (包惠明, 赵学文, 熊鑫, 等. 海洋环境下剑麻纤维混凝土抗侵蚀试验研究[J]. 混凝土, 2012,(6):23−24. doi: 10.3969/j.issn.1002-3550.2012.06.008Bao Huiming, Zhao Xuewen, Xiong Xin, et al. Study of sisal fiber concrete 's anti- erosion property in marine environment[J]. Concrete, 2012(6): 23-24. doi: 10.3969/j.issn.1002-3550.2012.06.008 [7] Qin Fangcheng, Qi Haiquan, Meng Zhengbing, et al. Advances in high corrosion resistant rebar for ocean engineering[J]. Materials Reports, 2022,36(6):158−164. (秦芳诚, 亓海全, 孟征兵, 等. 海洋工程高抗蚀筋材研究进展[J]. 材料导报, 2022,36(6):158−164.Qin Fangcheng, Qi Haiquan, Meng Zhengbing, et al. Advances in high corrosion resistant rebar for ocean engineering[J]. Materials Reports, 2022, 36(6): 158-164. [8] Sun Lijuan, Liu Bingwei, Sun Yongjuan. Influence of seawater erosion on the mechanical properties and chloride ion transport of fiber concrete[J]. Concrete, 2022,(6):24−28. (孙丽娟, 刘兵伟, 孙永娟. 海水侵蚀对纤维混凝土力学性能和氯离子传输性能的影响[J]. 混凝土, 2022,(6):24−28. doi: 10.3969/j.issn.1002-3550.2022.06.005Sun Lijuan, Liu Bingwei, Sun Yongjuan. Influence of seawater erosion on the mechanical properties and chloride ion transport of fiber concrete[J]. Concrete, 2022(6): 24-28. doi: 10.3969/j.issn.1002-3550.2022.06.005 [9] Liu Tao, Chen Yongfeng, Zhu Libin, et al. Effect of alloy adjustment on corrosion resistance of steel rebar[J]. Journal of Iron and Steel Research, 2022,34(2):156−161. (刘涛, 陈永峰, 朱利斌, 等. 合金调控对钢筋耐蚀性能的影响[J]. 钢铁研究学报, 2022,34(2):156−161.Liu Tao, Chen Yongfeng, Zhu Libin, et al. Effect of alloy adjustment on corrosion resistance of steel rebar[J]. Journal of Iron and Steel Research, 2022, 34(2): 156-161. [10] Ai Zhiyong, Sun Wei, Jiang Jinyang. Recent status of research on corrosion of low alloy corrosion resistant steel and analysis on existing eroblems[J]. Corrosion Science and Protection Technology, 2015,27(6):525−536. (艾志勇, 孙伟, 蒋金洋. 低合金耐蚀钢筋锈蚀研究现状及存在的问题分析[J]. 腐蚀科学与防护技术, 2015,27(6):525−536.Ai Zhiyong, Sun Wei, Jiang Jinyang. Recent status of research on corrosion of low alloy corrosion resistant steel and analysis on existing eroblems[J]. Corrosion Science and Protection Technology, 2015, 27(6): 525-536. [11] 田玉琬. 海工用高强耐蚀钢筋的腐蚀机理及阻锈剂研究[D]. 北京: 北京科技大学, 2021.Tian Yuwan. Study on corrosion mechanism of the high-strength corrosion-resistance steel reinforcement and inhibitor in marine structures [D]. Beijing: University of Science and Technology Beijing, 2021. [12] Chen Huande, Ma Han, Zhang Yu, et al. Microstructure and tensile properties of 00Cr10MoV corrosion resistant rebar for ocean engineering[J]. Transaction of Materials and Heat Treament, 2019,40(5):103−108. (陈焕德, 麻晗, 张宇, 等. 海洋工程用00Cr10MoV耐蚀钢筋的组织及拉伸性能[J]. 材料热处理学报, 2019,40(5):103−108.Chen Huande, Ma Han, Zhang Yu, et al. Microstructure and tensile properties of 00 Cr10 MoV corrosion resistant rebar for ocean engineering[J]. Transaction of Materials and Heat Treament, 2019, 40(5): 103-108. [13] 甘玲. 高强耐蚀钢筋在氯盐环境下的腐蚀行为[D]. 马鞍山: 安徽工业大学, 2017.Gan Ling. Corrosion behavior of high-strength corrosion resistant rebar in a solution of chlorine salt[D]. Ma, anshan: Anhui University of Technology, 2017. [14] Chen Xinhua, Dong Junhua, Han Enhou, et al. Effect of Cu-Mn on the corrosion performance of carbon steels in wet/ dry environments[J]. Materials Protection, 2007,40(10):19−22,93-94. (陈新华, 董俊华, 韩恩厚, 等. 干湿交替环境下Cu、Mn合金化对低合金钢腐蚀行为的影响[J]. 材料保护, 2007,40(10):19−22,93-94. doi: 10.3969/j.issn.1001-1560.2007.10.006Chen Xinhua, Dong Junhua, Han Enhou, et al. Effect of Cu-Mn on the corrosion performance of carbon steels in wet/ dry environments [J]. Materials Protection, 2007, 40(10): 19-22, 93-94. doi: 10.3969/j.issn.1001-1560.2007.10.006 -

下载:

下载: