Control and research on original lump carbides and their inheritance of continuous casting bearing steel billets

-

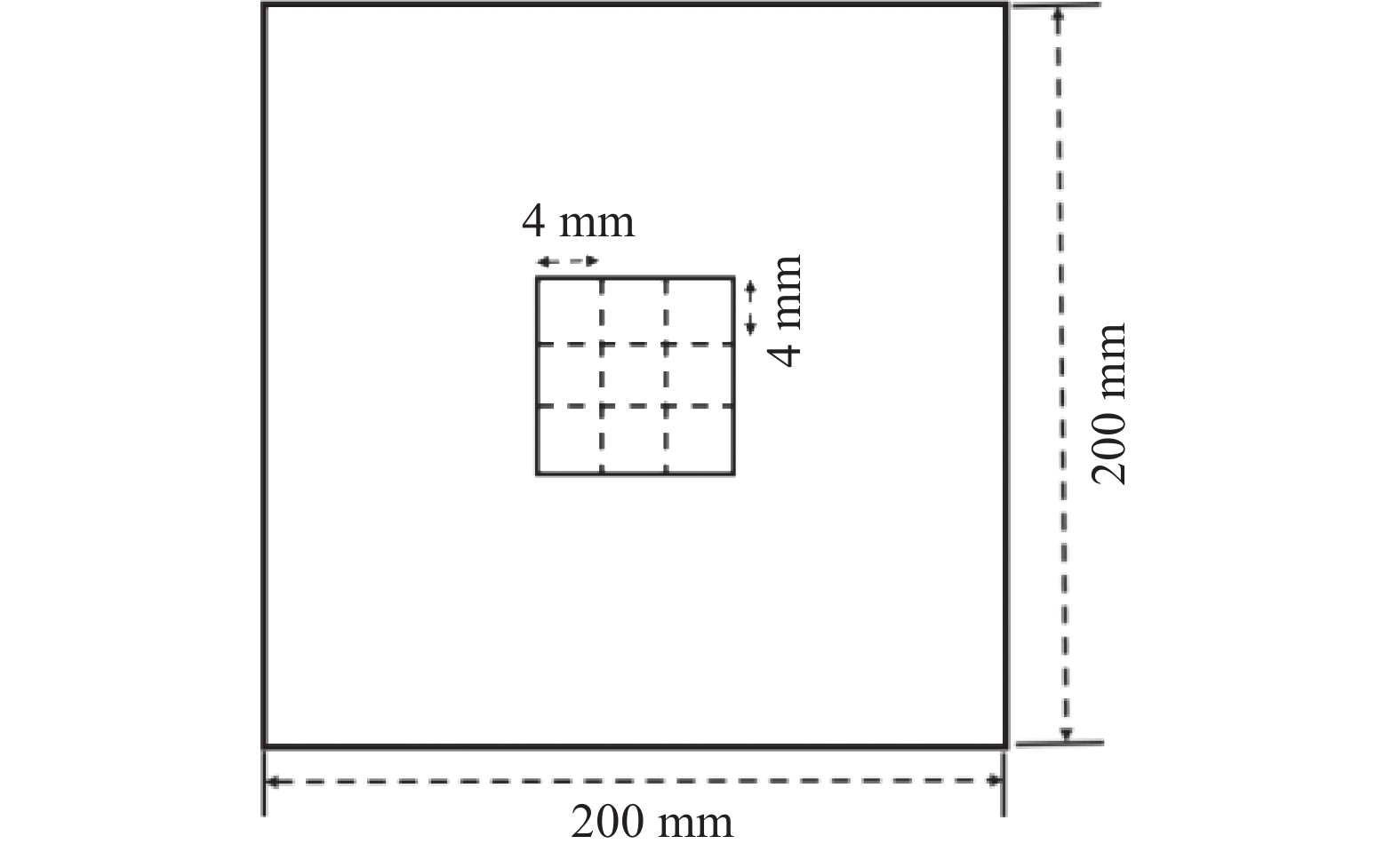

摘要: 通过Image-Pro Plus软件及金相法对GCr15轴承钢连铸坯在不同的连铸因子(过热度、拉速、二冷强度、电磁搅拌条件)下原始块状碳化物的形态、分布及碳偏析指数间的关系进行研究。结果表明,铸坯碳化物按分布、形态分为三类,沿铸坯晶粒边界集中连续、大面积分布的第一类碳化物;沿晶界分布、以“细长枝条态”向晶粒内无规律延伸的第二类碳化物;以单独形态分布在晶界处、边界圆润光滑、分散分布的第三类碳化物,其中断续分布或单独分布的铸坯块状碳化物经过现有轧制加热工艺处理后,液析碳化物级别均为0~0.5级,以此指导连铸最佳配合工艺参数是拉速0.95 m/min,过热度为20~25 ℃、冷却强度为0.35 L/kg、末端电磁搅拌为350 A、7 Hz。Abstract: The morphology, distribution and relationship between the original bulk carbides and carbon segregation index of GCr15 bearing steel continuous casting billets under different continuous casting factors (superheat, drawing speed, secondary cooling strength, electromagnetic stirring conditions) were investigated by Image-Pro Plus software and metallographic method. The results show that the heritability of the original bulk carbide of different types of billets, intermittently distributed or individually distributed billet bulk carbide after the existing rolling heating process, the liquid precipitation carbide level is 0-0.5, which guides the best matching process parameters for continuous casting is the drawing speed 0.95 m/min, superheating degree 20-25 ℃, cooling intensity 0.35 L/kg, end electromagnetic stirring 350 A/7 Hz.

-

Key words:

- bearing steel /

- continuous casting /

- billets /

- original lump carbides /

- form /

- inheritance

-

表 1 连铸试验工艺参数

Table 1. Process parameters of continuous casting test

试验

号试验

内容冷却强度/

(L·kg−1)过热度/

℃拉速/

(m·min−1)末端电磁搅拌 电流/A 频率/Hz 1 过热度 0.35 ≥30 0.95 350 8 2 0.35 25~30 0.95 350 8 3 0.35 20~25 0.95 350 8 4 拉速 0.35 20~25 0.85 350 8 5 0.35 20~25 0.95 350 8 6 0.35 20~25 1.15 350 8 7 冷却

强度0.45 20~25 0.95 350 8 8 0.35 20~25 0.95 350 8 9 0.28 20~25 0.95 350 8 10 末端电

磁搅拌0.35 20~25 0.95 350 4 11 0.35 20~25 0.95 350 8 12 0.35 20~25 0.95 350 12 表 2 现加热炉工艺参数

Table 2. The current process parameters of the heating furnace

预热段 加热段 均热段 温度/℃ 保温时间/ h 温度/℃ 保温时间/ h 温度/℃ 保温时间/ h ≤850 1.0 850~1220 1.5 1220~1250 2 表 3 不同连铸参数下成品棒材液析基本情况

Table 3. Basic situation of the liquid separation bar under different continuous casting parameters

序号 成品棒材液析检验级别/级 过热度组 拉速组 冷却强度组 末端电磁搅拌组 ≥30 ℃ 25~30 ℃ 20~25 ℃ 0.85 m/min 0.95 m/min 1.15 m/min 0.45 L/kg 0.35 L/kg 0.28 L/kg Ⅰ Ⅱ Ⅲ 试样1 2.5 1.0 0.5 2.0 0.5 1.0 2.0 1.5 0.5 1.5 0.5 0.5 试样2 2.0 0.5 0 2.0 0 1.0 2.0 1.0 0 2.0 0.5 0.5 试样3 2.0 1.0 0 2.0 0 0.5 2.0 1.5 0 1.5 0.5 0.5 试样4 2.5 0.5 0.0 2.0 0.5 0.5 1.5 1.0 0.5 1.0 0.5 0.5 注:末端电磁搅拌制度Ⅰ指350 A、4 Hz;Ⅱ指350 A、8 Hz;Ⅲ指350 A、12 Hz。 -

[1] 钟顺思, 王昌生. 轴承钢[M]. 北京: 冶金工业出版社, 2000.Zhong Shunsi, Wang Changsheng. Bearing steel[M]. Beijing: Metallurgical Industry Press, 2000. [2] Zhou Deguang. Formation mechanism and influencing factors of carbon segregation in bearing steel continuous casting billets[J]. Journal of University of Science and Technology Beijing, 1999,(2):21−23. (周德光. 轴承钢连铸坯碳偏析的形成机理和影响因素[J]. 北京科技大学学报, 1999,(2):21−23.Zhou Deguang. Formation mechanism and influencing factors of carbon segregation in bearing steel continuous casting billets[J]. Journal of University of Science and Technology Beijing, 1999(2): 21-23. [3] Liu Yubin, Ye Zhihai, Jiao Hongwei. Causes and preventive measures of liquid segregation defects in bearing steel[J]. Heilongjiang Metallurgy, 2005,(3):5−6. (刘玉斌, 叶志海, 矫宏伟. 轴承钢液析缺陷产生原因及预防措施[J]. 黑龙江冶金, 2005,(3):5−6.Liu Yubin, Ye Zhihai, Jiao Hongwei. Causes and preventive measures of liquid segregation defects in bearing steel[J]. Heilongjiang Metallurgy, 2005(3): 5-6. [4] Liu Jing, Han Jingtao, Xi Junliang, et al. Heating temperature of GCr15 bearing steel and dissolution and diffusion of carbides[J]. Metal Heat Treatment, 2008,33(10):87−89. (刘靖, 韩静涛, 席军良, 等. GCr15轴承钢加热温度与碳化物的溶解扩散[J]. 金属热处理, 2008,33(10):87−89. doi: 10.13251/j.issn.0254-6051.2008.10.027Liu Jing, Han Jingtao, Xi Junliang, et al. Heating temperature of GCr15 bearing steel and dissolution and diffusion of carbides[J]. Metal Heat Treatment, 2008, 33(10): 87-89. doi: 10.13251/j.issn.0254-6051.2008.10.027 [5] Ding Liquan, Fan Zhijin, Fang Defa. Control technology of carbide precipitation in GCr15 bearing steel[J]. Wuhan Iron and Steel Technology, 2013,51(2):27−30. (丁礼权, 范植金, 方德法. GCr15轴承钢液析碳化物的控制工艺[J]. 武钢技术, 2013,51(2):27−30.Ding Liquan, Fan Zhijin, Fang Defa. Control technology of carbide precipitation in GCr15 bearing steel[J]. Wuhan Iron and Steel Technology, 2013, 51(2): 27-30. [6] Kong Xianghua, Liu Jianzun, Liu Zailong, et al. Influence of high temperature deformation treatment on liquid carbide of GCr15 bearing steel[J]. Journal of Heat Treatment of Materials, 2014,35(7):173−176. (孔翔华, 刘建尊, 刘在龙, 等. 高温变形处理对GCr15轴承钢液析碳化物的影响[J]. 材料热处理学报, 2014,35(7):173−176. doi: 10.13289/j.issn.1009-6264.2014.07.031Kong Xianghua, Liu Jianzun, Liu Zailong, et al. Influence of high temperature deformation treatment on liquid carbide of GCr15 bearing steel[J]. Journal of Heat Treatment of Materials, 2014, 35(7): 173-176. doi: 10.13289/j.issn.1009-6264.2014.07.031 [7] Sun Zhengwei, Wang Jinhai, Lu Guangyong. Influence of initial rolling deformation on carbide precipitation in bearing steel[J]. Shandong Metallurgy, 2013,35(3):44−46. (孙正炜, 王金海, 卢光勇. 轧制初期变形量对轴承钢碳化物液析的影响[J]. 山东冶金, 2013,35(3):44−46. doi: 10.3969/j.issn.1004-4620.2013.03.017Sun Zhengwei, Wang Jinhai, Lu Guangyong. Influence of initial rolling deformation on carbide precipitation in bearing steel[J]. Shandong Metallurgy, 2013, 35(3): 44-46. doi: 10.3969/j.issn.1004-4620.2013.03.017 [8] Chang Lizhong, Gao Gang, Shi Xiaofang, et al. Effect of magnesium on liquor carbides in GCr15 bearing steel[J]. Journal of Process Engineering, 2019,19(2):362−369. (常立忠, 高岗, 施晓芳, 等. 镁对GCr15轴承钢中液析碳化物的影响[J]. 过程工程学报, 2019,19(2):362−369. doi: 10.12034/j.issn.1009-606X.218227Chang Lizhong, Gao Gang, Shi Xiaofang, et al. Effect of magnesium on liquor carbides in GCr15 bearing steel[J]. Journal of Process Engineering, 2019, 19(2): 362-369. doi: 10.12034/j.issn.1009-606X.218227 [9] 王伟. 过热度对轴承钢连铸方坯内部质量的影响研究[D]. 重庆: 重庆大学, 2017.Wang Wei. Study on influence of superheat on internal quality of bearing steel continuous casting billet[D]. Chongqing: Chongqing University, 2017. [10] Qin Fengting. Research on process parameters of electromagnetic stirring at the end of 240 mm×240 mm continuous casting billet on bearing steel[J]. Speacial Steel, 2020,41(4):6−10. (秦凤婷. GCr15轴承钢240 mm×240 mm连铸坯末端电磁搅拌工艺参数研究[J]. 特殊钢, 2020,41(4):6−10. doi: 10.3969/j.issn.1003-8620.2020.04.002Qin Fengting. Research on process parameters of electromagnetic stirring at the end of 240 mm×240 mm continuous casting billet on bearing steel[J]. Speacial Steel, 2020, 41(4): 6-10. doi: 10.3969/j.issn.1003-8620.2020.04.002 [11] Guo Xin, Wang Haida, Chen Lie, et al. Influence of electromagnetic stirring technology on internal segregation quality of high carbon chromium bearing steel[J]. Special Steel Technology, 2021,27(2):22−26. (郭鑫, 王海达, 陈列, 等. 末端电磁搅拌技术对高碳铬轴承钢内部偏析质量的影响[J]. 特钢技术, 2021,27(2):22−26. doi: 10.16683/J.CNKI.ISSN1674-0971.2021.2024Guo Xin, Wang Haida, Chen Lie, et al. Influence of electromagnetic stirring technology on internal segregation quality of high carbon chromium bearing steel[J]. Special Steel Technology, 2021, 27(2): 22-26. doi: 10.16683/J.CNKI.ISSN1674-0971.2021.2024 [12] Li Po, Fan Yujing, Zhang Cheng, et al. Influence of pulling speed fluctuation on internal quality of bearing steel 250 mm×280 mm continuous casting billet[J]. Special Steel, 2017,38(5):22−26. (李颇, 范宇静, 张程, 等. 拉速波动对GCr15轴承钢250 mm×280 mm连铸坯内部质量的影响[J]. 特殊钢, 2017,38(5):22−26. doi: 10.3969/j.issn.1003-8620.2017.05.006Li Po, Fan Yujing, Zhang Cheng, et al. Influence of pulling speed fluctuation on internal quality of bearing steel 250 mm×280 mm continuous casting billet[J]. Special Steel, 2017, 38(5): 22-26. doi: 10.3969/j.issn.1003-8620.2017.05.006 [13] Wang Yingzhong, Zhang Xingzhong. Research on continuous casting technology of bearing steel billet[J]. Journal of Iron and Steel Research, 2002,14(5):16−20. (王英忠, 张兴中. 轴承钢大方坯连铸工艺研究[J]. 钢铁研究学报, 2002,14(5):16−20. doi: 10.3321/j.issn:1001-0963.2002.05.004Wang Yingzhong, Zhang Xingzhong. Research on continuous casting technology of bearing steel billet[J]. Journal of Iron and Steel Research, 2002, 14(5): 16-20. doi: 10.3321/j.issn:1001-0963.2002.05.004 [14] Dong Zhongqi, Chen Min, Chen Rui, et al. Influence of high temperature diffusion process regime on carbide precipitation in GCr15 billet[J]. Bearing, 2011,41(7):25−28. (董中奇, 陈敏, 陈锐, 等. 高温扩散工艺制度对GCr15钢坯碳化物析出的影响[J]. 轴承, 2011,41(7):25−28. doi: 10.3969/j.issn.1000-3762.2011.07.010Dong Zhongqi, Chen Min, Cheng Rui, et al. Influence of high temperature diffusion process regime on carbide precipitation in GCr15 billet[J]. Bearing, 2011, 41(7): 25-28. doi: 10.3969/j.issn.1000-3762.2011.07.010 [15] Lu Zhifang, Zhang Zhiguang, Zhao Zhengzheng, et al. Influence of superheat on internal structure of the bearing steel[J]. Chinese Journal of Engineering, 2016,38(z1):45−49. (逯志方, 张治广, 赵铮铮, 等. 过热度对轴承钢内部组织的影响[J]. 工程科学学报, 2016,38(z1):45−49.Lu Zhifang, Zhang Zhiguang, Zhao Zhengzheng, et al. Influence of superheat on internal structure of the bearing steel[J]. Chinese Journal of Engineering, 2016, 38(1): 45-49. [16] Zhang Tao, Cheng Guoguang, Hou Yuyang. Effect of superheat on macrosegregation of GCr15SiMn bearing steel ingot during solidification[J]. China Metallurgy, 2020,30(9):60−66. (张涛, 成国光, 侯雨阳. 过热度对GCr15SiMn轴承钢钢锭宏观偏析的影响[J]. 中国冶金, 2020,30(9):60−66.Zhang Tao, Cheng Guoguang, Hou Yuyang. Effect of superheat on macrosegregation of GCr15 SiMn bearing steel ingot during solidification[J]. China Metallurgy, 2020, 30(9): 60-66. [17] He Wenqing, Wang Bao, Wang Fuming, et al. Causes and preventive measures of center segregation of bloom bearing steel[J]. Iron and Steel, 2009,44(8):39−41. (何庆文, 王宝, 王福明, 等. 大方坯轴承钢中心偏析的成因及预防措施[J]. 钢铁, 2009,44(8):39−41. doi: 10.3321/j.issn:0449-749X.2009.08.009He Wenqing, Wang Bao, Wang Fuming, et al. Causes and preventive measures of center segregation of bloom bearing steel[J]. Iron and Steel, 2009, 44(8): 39-41. doi: 10.3321/j.issn:0449-749X.2009.08.009 [18] 许洪波. 改善轴承钢碳化物不均匀性的工艺研究[D]. 沈阳: 东北大学, 2008.Xu Hongbo. Study on the technology of improving carbide inhomogeneity of bearing steel[D]. Shenyang: Northeastern University, 2008. [19] Singh A K. Numerical study of effect of cooling rate on double diffusive convection and macrosegregation in iron carbon system[J]. ISIJ International, 2001,41(12):1481−1487. doi: 10.2355/isijinternational.41.1481 [20] Jing Tonghong, Sun Hongying, Zhang Ruijun, et al. Basic law of macroscopic carbon segregation in bearing steel continuous casting billets[J]. China Metallurgy, 2008,18(7):19−24. (靳同红, 孙红英, 张瑞军, 等. GCrl5轴承钢连铸坯宏观碳偏析的基本规律[J]. 中国冶金, 2008,18(7):19−24. doi: 10.3969/j.issn.1006-9356.2008.07.005Jing Tonghong, Sun Hongying, Zhang Ruijun, et al. Basic law of macroscopic carbon segregation in bearing steel continuous casting billets[J]. China Metallurgy, 2008, 18(7): 19-24. doi: 10.3969/j.issn.1006-9356.2008.07.005 -

下载:

下载: