Evolution mechanism of inclusions in GH4169 produced by vacuum induction melting

-

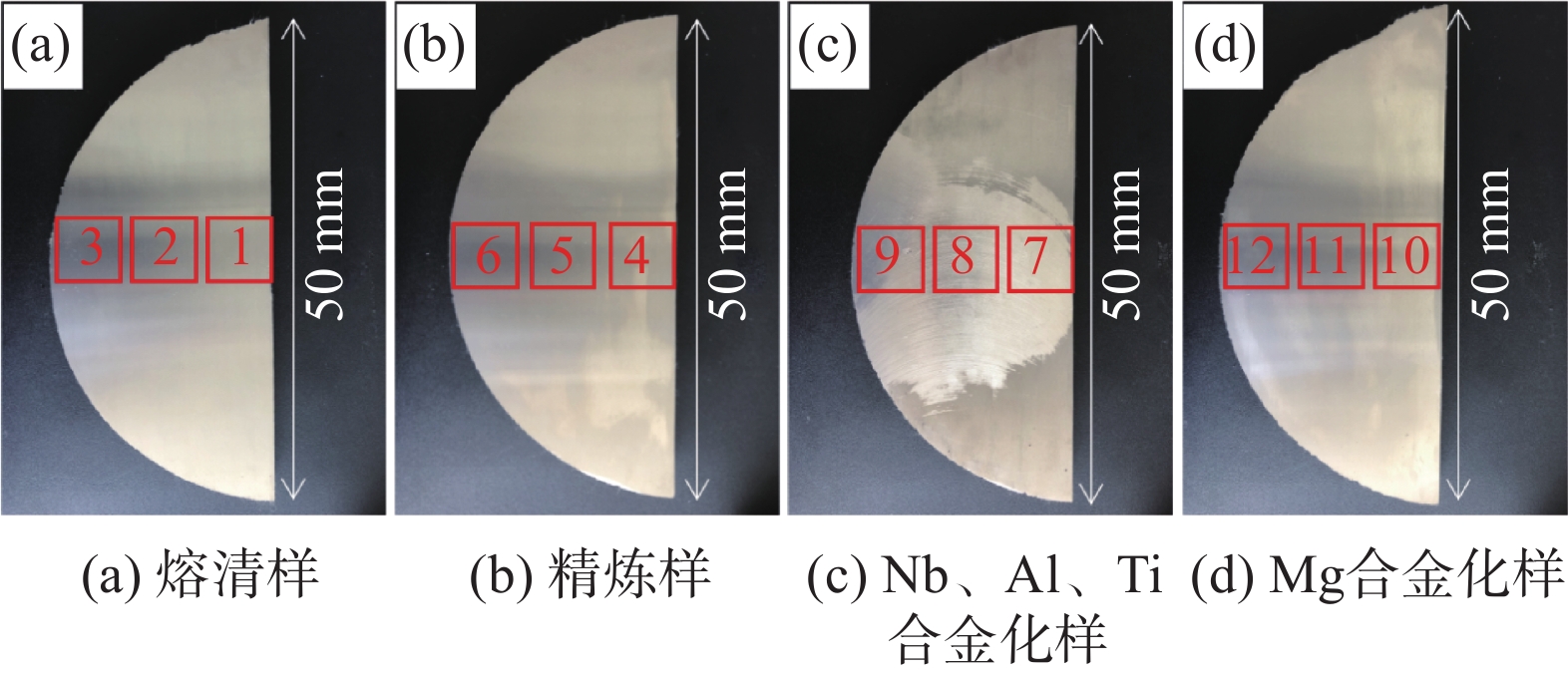

摘要: 高温合金中夹杂物是影响合金冶金质量和使用性能的主要因素,因此研究了GH4169镍基高温合金真空感应(VIM)熔炼制备过程中夹杂物的演变机制。采用真空感应炉对GH4169合金进行冶炼,通过ASPEX型自动扫描电镜分析检测夹杂物的物相组成、尺寸形貌及成分,并分析夹杂物的形成机理、来源及演变机制。结果表明,真空熔炼GH4169合金主要生成五种类型夹杂物:Al2O3、MgAl2O4和MgO单层夹杂物,MgAl2O4-Ti(C,N)-NbC和MgO-Ti(C,N)-NbC多层复合夹杂物。Al2O3在熔化期形成,MgAl2O4在精炼期形成,加入Nb、Al、Ti合金化后形成MgAl2O4-Ti(C,N)-NbC夹杂,加入Mg合金化后生成MgO和MgO-Ti(C,N)-NbC夹杂。随冶炼过程的进行,夹杂物的数量密度先增加后减少,在精炼期夹杂物数量密度达到峰值211.42个/mm2,精炼期结束后,夹杂物数量减少,出钢前夹杂物数量密度46.57个/mm2。Abstract: Inclusion had been considered as main factor affecting metallurgical quality and mechanical property of Ni-based superalloys. In this work the evolution mechanism of inclusions during the preparation of GH4169 Ni-based superalloy by vacuum induction melting (VIM) was studied. A method of ASPEX automatic scanning electron microscope was utilized to characterize the inclusions in GH4169 Ni-based superalloy prepared by vacuum induction melting (VIM). The phases, compositions, morphologies, formation mechanism and evolution mechanism of the inclusions were analyzed. The results indicate that the inclusions of single phase in GH4169 include mainly Al2O3、MgAl2O4 and MgO. The inclusions of composite phases include mainly MgAl2O4-Ti(C,N)-NbC and MgO-Ti(C,N)-NbC. Al2O3 forms during melting period, MgAl2O4 forms during refining period, and MgAl2O4-Ti(C,N)-NbC forms after alloying with Nb, Al and Ti, and MgO and MgO-Ti(C,N)-NbC form after alloying with Mg. As smelting process going, the number density of inclusions firstly increases and then decreases, and the number density of inclusions reaches a peak value of 211.42/mm2 during the refining period. After the refining period, the number of inclusions decreases, and the number density of inclusions before pouring is 46.57/mm2.

-

Key words:

- GH4169 alloy /

- vacuum induction melting /

- inclusions /

- evolution mechanism

-

表 1 GH4169高温合金的化学成分

Table 1. Chemical composition of GH4169 superalloy

% Ni Cr Mo Nb Al Ti Mg C Fe 50.0~55.0 17.0~20.0 2.8~3.2 5.0~5.5 0.5~0.7 0.8~1.5 ≤0.05 ≤0.08 余量 -

[1] Ivanoff T A, Watt T J, Taleff E M. Characterization of solidification microstructures in vacuum arc remelted nickel alloy 718[J]. Metallurgical and Materials Transactions B, 2019,50(2):700−715. doi: 10.1007/s11663-019-01530-2 [2] Rao G A, Prasad K S, Srinias M, et al. Characterisation of hot isostatically pressed nickel base superalloy Inconel 718[J]. Materials Science and Technology, 2003,19(3):313−321. doi: 10.1179/026708303225010605 [3] Whitmore L, Ahmadi M R, Guetaz L, et al. The microstructure of heat-treated nickel-based superalloy 718 plus[J]. Materials Science and Engineering A, 2014,610(29):39−45. [4] 高小勇. FGH96粉末高温合金母合金的纯净化技术研究[D]. 北京: 北京科技大学, 2020.Gao Xiaoyong. Research on purification technology for the master ally of FGH96 powder superalloy[D]. Beijing: University of Science and Technology Beijing, 2020. [5] Wang Chong, Zeng Yanping, Xie Xishan. Influence of characteristic inclusion parameters on crack initiation and propagation ultra-high strength steels for aerospace application under tensile and low cyclic fatigue loading[J]. Journal of University of Science and Technology Beijing, 2009,31(5):557−562. (王冲, 曾燕屏, 谢锡善. 拉伸与低周疲劳载荷作用下夹杂物特征参数对航空用超高强度钢中裂纹萌生与扩展的影响[J]. 北京科技大学学报, 2009,31(5):557−562.Wang Chong, Zeng Yanping, Xie Xishan. Influence of characteristic inclusion parameters on crack initiation and propagation ultra-high strength steels for aerospace application under tensile and low cyclic fatigue loading[J]. Journal of University of Science and Technology Beijing, 2009, 31(5): 557-562. [6] Wang Di, Yang Shufeng, Qu Jinglong, et al. Distribution of inclusions on surface of GH4169 ESR ingot[J]. Iron and Steel, 2021,56(2):155−161. (王迪, 杨树峰, 曲敬龙, 等. GH4169电渣重熔铸锭表层夹杂物分布规律[J]. 钢铁, 2021,56(2):155−161.Wang Di, Yang Shufeng, Qu Jinglong, et al. Distribution of inclusions on surface of GH4169 ESR ingot[J]. Iron and Steel, 2021, 56(02): 155-161. [7] Kong Haohao, Yang Shufeng, Qu Jinglong, et al. Type and distribution of inclusion GH4169 nickel based superalloy[J]. Acta Astronautica Sinica, 2020,41(4):304−311. (孔豪豪, 杨树峰, 曲敬龙, 等. GH4169铸锭中夹杂物的类型及分布规律[J]. 航空学报, 2020,41(4):304−311.Kong Haohao, Yang Shufeng, Qu Jinglong, et al. Type and distribution of inclusion GH4169 nickel based superalloy[J]. Acta Astronautica Sinica, 2020, 41(4): 304-311. [8] 石安君. 超重力对IN718合金熔液凝固及夹杂物机制影响的基础研究[D]. 北京: 北京科技大学, 2021.Shi Anjun. Effect of supergravity on solidification and inclusion behavior of IN718 superalloy[D]. Beijing: University of Science and Technology Beijing, 2021. [9] Shi Chengbin, Chen Xichun, Guo Hanjie, et al. Control of MgO center dot Al2O3 spinel inclusions during protective gas electroslag remelting of die steel[J]. Metallurgical and Materials Transactions B, 2013,44(2):378−389. doi: 10.1007/s11663-012-9780-x [10] Mu Haoyuan, Zhang Tongsheng, Fruehan Richard, et al. Reduction of CaO and MgO slag components by Al in liquid Fe[J]. Metallurgical and Materials Transactions B, 2018,49B(4):1665−1674. [11] Gui Mingxi, Xu Qingbin. Mechanism of MgO thermit reduction reaction[J]. Foreign Refractories, 2006,31(5):45−50. (桂明玺, 徐庆斌. MgO的Al热还原反应的机理[J]. 国外耐火材料, 2006,31(5):45−50.Gui Mingxi, Xu Qingbin. Mechanism of MgO thermit reduction reaction[J]. Foreign Refractories, 2006, 31(5): 45-50. [12] Tora A, Zhou Fei, Wu Ming H, et al. Characterization of non-metallic inclusions in superelastic NiTi tubes[J]. Journal of Materials Engineering and Performance, 2009,18(5/6):448−458. [13] Wei Wenqing, Liu Bingqiang, Jiang Junsheng, et al. Effect of heat treatment on microstructure and mechanical behavior of Nb-35Ti-4C alloy[J]. Rare Metal Materials and Engineering, 2017,46(3):777−782. (魏文庆, 刘炳强, 姜军生, 等. 热处理对Nb-35Ti-4C合金微观组织和力学机制的影响[J]. 稀有金属材料与工程, 2017,46(3):777−782.Wei W Q, Liu B Q, Jiang J S, et al. Effect of heat treatment on microstructure and mechanical behavior of Nb-35 Ti-4 C alloy[J]. Rare Metal Materials and Engineering, 2017, 46(3): 777-782. [14] Yuan Chao, Guo Jianting, Li Gusong, et al. Effect mechanism and control of nitrogen in cast superalloys[J]. The Chinese Journal of Nonferrous Metals, 2011,21(4):14. (袁超, 郭建亭, 李谷松, 等. 铸造高温合金中氮的影响机理与控制[J]. 中国有色金属学报, 2011,21(4):14.Yuan Chao, Guo Jianting, Li Gusong, et al. Effect mechanism and control of nitrogen in cast superalloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 14. [15] Wang Ning, Gao Jinguo, Yang Shulei, et al. Numerical simulation of inclusions movement in vacuum induction melting[J]. China Metallurgy, 2021,31(12):20−26. (王宁, 高锦国, 杨曙磊, 等. 真空感应熔炼中夹杂物运动机制数值模拟[J]. 中国冶金, 2021,31(12):20−26.Wang Ning, Gao Jinguo, Yang Shulei, et al. Numerical simulation of inclusions movement in vacuum induction melting[J]. China Metallurgy, 2021, 31(12): 20-26. -

下载:

下载: