Effect of deoxidizer on non-metallic inclusions in M50NiL steel

-

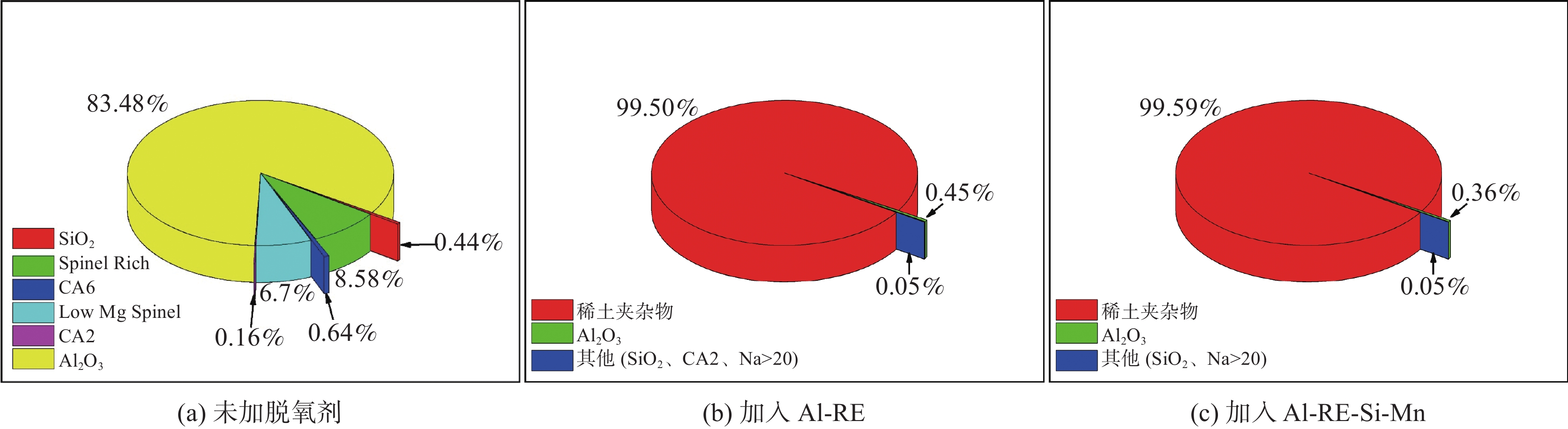

摘要: 在航空发动机用轴承钢M50NiL的真空冶炼过程中使用不同脱氧剂进行脱氧 , 重点研究了不同脱氧剂类型对钢中夹杂物形貌、类型、尺寸及数量密度的影响。结果表明,未添加脱氧剂时,钢中夹杂物主要为Al2O3和铝镁尖晶石;使用Al-RE作为脱氧剂后,钢中夹杂物的主要类型为稀土夹杂物;而使用Al-RE-Si-Mn作为脱氧剂后,钢中夹杂物类型、尺寸及分布特征与Al-RE脱氧剂基本相当。稀土元素的加入能明显改善钢中夹杂物的类型及形貌,使主要夹杂物类型由带有棱角且形状不规则的富Al2O3型夹杂物转变为近球形的稀土夹杂物,同时降低了钢中夹杂物的最大尺寸,以及大尺寸的Al2O3夹杂物数量,但过量的稀土使得钢中出现了稀土夹杂物的团聚。

-

关键词:

- M50NiL钢 /

- 脱氧剂 /

- Al-RE /

- Al-RE-Si-Mn /

- 非金属夹杂物

Abstract: Different deoxidizers were used for deoxidation in the vacuum smelting process of aero-engine bearing steel M50NiL, and the influence of different deoxidizer types on the morphology, type, size and number density of inclusions in the steel were studied. The results indicate that without adding deoxidizer, the inclusions in steel are mainly Al2O3 and Al-Mg spinel. After using Al-RE as deoxidizer, the main types of inclusions in steel are rare earth inclusions. When Al-RE-Si-Mn is used as deoxidizer, the type, size and distribution characteristics of inclusions in steel are basically similar to those of Al-RE deoxidizer. The addition of rare earth elements can significantly improve the type and morphology of inclusions in steel, where the main inclusion types are transformed from Al2O3-rich inclusions with angular and irregular shapes to nearly spherical rare earth inclusions, while reduce the maximum size of inclusions in steel and the number of large-sized Al2O3 inclusions. However, excessive addition of rare earth causes the agglomeration of rare earth inclusions in steel.-

Key words:

- M50NiL steel /

- deoxidizer /

- Al-RE /

- Al-RE-Si-Mn /

- non-metallic inclusions

-

表 1 M50NiL钢主要化学成分

Table 1. Main chemical composition of M50NiL steel

% C Cr Mo Ni V Fe 0.11~0.15 4~4.25 4~4.5 3.2~3.6 1.13~1.33 Bal. 表 2 冶炼原料中的铝元素含量

Table 2. Aluminum content in smelting raw materials

% 纯Fe 金属Cr Mo条 金属V Ni板 0.0216 <0.0005 <0.0005 0.10 <0.0005 表 3 不同试验钢中主要夹杂物类型的尺寸分布

Table 3. Size distribution of main inclusions in different test steels

脱氧剂类型 Al2O3夹杂粒级占比/% 稀土夹杂粒级占比/% 0~2 μm 2~10 μm >10 μm 0~2 μm 2~10 μm >10 μm 未加脱氧剂 80.8 18.1 1.0 加Al-RE 29.9 65.1 5.0 54.9 44.8 0.4 加Al-RE-Si-Mn 31.3 64.1 4.7 68.0 31.8 0.2 -

[1] Bhattacharyya Abir, Subhash Ghatu, Arakere Nagaraj. Evolution of subsurface plastic zone due to rolling contact fatigue of M50NiL case hardened bearing steel[J]. Int J Fatigue, 2014,59:102−113. doi: 10.1016/j.ijfatigue.2013.09.010 [2] Wang Fangfang, Zhou Chungen, Zheng Lijing, et al. Corrosion resistance of carbon ion-implanted M50NiL aerospace bearing steel[J]. Prog Nat Sci:Mater Int, 2017,27(5):615−621. doi: 10.1016/j.pnsc.2017.07.003 [3] Wang P, Wang B, Liu Y, et al. Effects of inclusion types on the high-cycle fatigue properties of high-strength steel[J]. Scripta Mater, 2022,206:114232. doi: 10.1016/j.scriptamat.2021.114232 [4] Cerullo Michele, Tvergaard Viggo. Micromechanical study of the effect of inclusions on fatigue failure in a roller bearing[J]. International Journal of Structural Integrity, 2015,6(1):124−141. doi: 10.1108/IJSI-04-2014-0020 [5] Bhadeshia H K D H. Steels for bearings[J]. Prog Mater Sci, 2012,57(2):268−435. doi: 10.1016/j.pmatsci.2011.06.002 [6] Pan Tao, Yang Zhigang, Bai Bingzhe, et al. Study on thermal stress and strain energy in γ-Fe matrix around inclusion caused by thermal coefficient difference[J]. Acta Metallurgica Sinica, 2003,(10):1037−1042. (潘涛, 杨志刚, 白秉哲, 等. 钢中夹杂物与奥氏体基体热膨胀系数差异导致的热应力和应变能研究[J]. 金属学报, 2003,(10):1037−1042. doi: 10.3321/j.issn:0412-1961.2003.10.005Pan Tao, Yang Zhigang, Bai Bingzhe, et al. Study on thermal stress and strain energy in γ-Fe matrix around inclusion caused by thermal coefficient difference[J]. Acta Metallurgica Sinica, 2003 (10): 1037-1042. doi: 10.3321/j.issn:0412-1961.2003.10.005 [7] 栾心汉. 小电炉炼钢[M]. 西安: 陕西科学技术出版社, 1982.Luan Xinhan. A small electric furnace makes steel[M]. Xi, an: Shaanxi Science and Technology Press, 1982. [8] Gu Chao, Bao Yanping, Gan Peng, et al. An experimental study on the impact of deoxidation methods on the fatigue properties of bearing steels[J]. Steel Research International, 2018,89(9):1800129. doi: 10.1002/srin.201800129 [9] Xiao Wei, Wang Min, Bao Yanping. The research of low-oxygen control and oxygen behavior during RH process in silicon-deoxidization bearing steel[J]. Metals, 2019,9(8):812. doi: 10.3390/met9080812 [10] Zheng Hongyan, Guo Shuqiang, Qiao Mengran, et al. Study on the modification of inclusions by Ca treatment in GCr18Mo bearing steel[J]. Advances in Manufacturing, 2019,7(4):438−447. doi: 10.1007/s40436-019-00266-1 [11] Hsu Chinchuan, Chung Hohua. Analysis of influence of aluminum content on inclusion characteristic and fatigue life of bearing steel using statistics of extreme values[J]. Advanced Materials Research, 2014,939:11−18. doi: 10.4028/www.scientific.net/AMR.939.11 [12] Xiao Wei, Bao Yanping, Gu Chao, et al. Ultrahigh cycle fatigue fracture mechanism of high-quality bearing steel obtained through different deoxidation methods[J]. International Journal of Minerals, Metallurgy and Materials, 2021,28(5):804−815. doi: 10.1007/s12613-021-2253-y [13] Wang Le, Liu Liu, Yao Tonglu, et al. New process development of refining clean bearing steel with low cost[J]. Steelmaking, 2018,34(3):67−72. (王乐, 刘浏, 姚同路, 等. 低成本轴承钢洁净冶炼新工艺的开发[J]. 炼钢, 2018,34(3):67−72.Wang Le, Liu Liu, Yao Tonglu, et al. New process development of refining clean bearing steel with low cost[J]. Steelmaking, 2018, 34(3): 67-72. [14] Yang Chaoyun, Luan Yikun, Li Dianzhong, et al. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel[J]. Journal of Materials Science & Technology, 2019,35(7):1298−1308. [15] Wu Hua, Yan Su, Yang You, et al. Influence of inclusions on fatigue properties of 18Mn2SiVB non-quenched steel[J]. Heat Treat Met, 2006,(3):88−90. (吴化, 闫肃, 杨友, 等. 18Mn2SiVB非调质钢中夹杂物对其疲劳性能的影响[J]. 金属热处理, 2006,(3):88−90. doi: 10.3969/j.issn.0254-6051.2006.03.024Wu Hua, Yan Su, Yang You, et al. Influence of inclusions on fatigue properties of 18 Mn2 SiVB non-quenched steel[J]. Heat Treat Met, 2006 (3): 88-90. doi: 10.3969/j.issn.0254-6051.2006.03.024 [16] 邓爱军. 高铁用轴承钢冶金过程的关键技术研究[D]. 马鞍山: 安徽工业大学, 2019.Deng Aijun. Research on the key technology of metallurgical process of bearing steel for high-speed rail[D]. Ma'anshan: Anhui University of Technology, 2019. [17] GB/T 10561-2005. 钢中非金属夹杂物含量的测定标准评级图显微检验法[S].GB/T 10561-2005. Standard grading chart microscopic inspection method for determination of non-metallic inclusion content in steel[S]. -

下载:

下载: