Analysis of the gear shaft broken teeth of the reducer

-

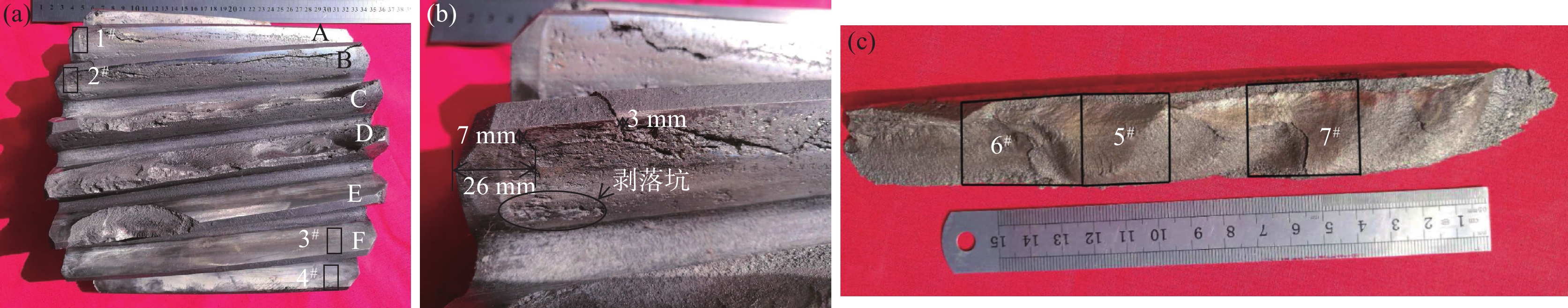

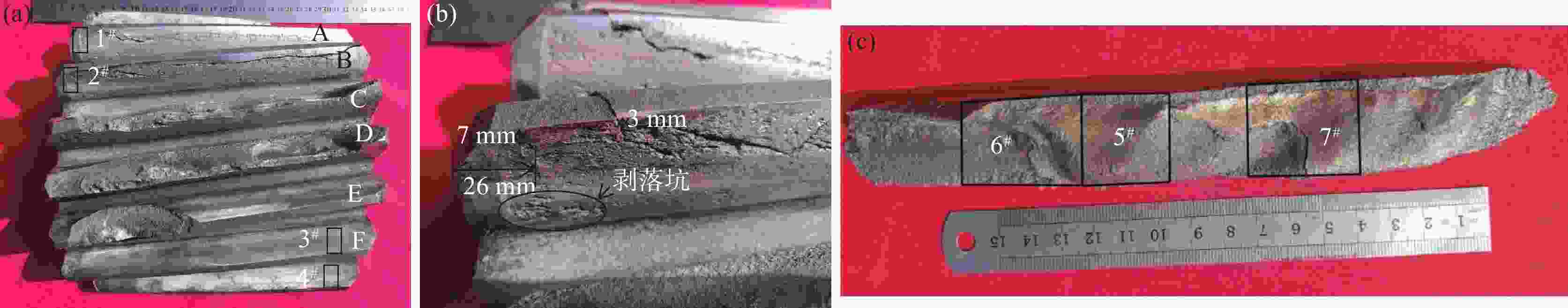

摘要: 针对减速机齿轮轴发生断齿现象,进行了化学成分分析,利用金相分析技术研究了齿轮轴内部微观组织结构以及产生缺陷的原因,采用扫描电镜观察断口形貌特征,以及通过硬度计算方法计算了齿部的硬化层深度,并对齿顶渗碳淬火硬化层进行了数学校验。结果表明,由于齿轮在淬火加热时温度过高,导致齿轮内部出现粗大马氏体及网状碳化物,齿面存在严重的内氧化现象致使齿部材料脆化,进而出现沿晶裂纹和掉块,并且在齿轮轴存在安装偏载且硬度偏低的协同作用下发生断齿现象。Abstract: Aiming at the broken phenomenon of the gear shaft in a reducer, the chemical composition of the gear shaft was analyzed; the internal microstructure of the gear shaft and the causes of defects were studied by metallographic analysis technology. The fracture morphology was observed by scanning electron microscope, and the hardened layer depths of the tooth were calculated by the hardness calculation method, and the carburized and quenched hardened layers on the tooth top were mathematically verified. The results show that the high temperature of the gear during quenching and heating leads to the appearance of coarse martensite and network carbide in the gear. There is a serious internal oxidation phenomenon on the tooth surface, resulting in the embrittlement of the tooth material, and then intergranular cracking and blocks falling. In addition, the phenomenon of broken teeth occurs under the synergistic effect of the eccentric loads and low hardness.

-

Key words:

- gear shaft /

- internal oxidation /

- material embrittlement /

- intergranular crack

-

表 1 齿轮轴的化学成分

Table 1. Composition analysis of the gear shaft

% C Si Mn P S Cr Ni Cu Mo GB/T 3077-2015 0.17~

0.230.17~

0.370.90~

1.20≤0.030 ≤0.030 1.10~

1.40≤0.30 ≤0.30 0.20~

0.30齿轮轴 0.188 0.271 0.895 0.014 0.024 1.13 0.062 0.150 0.214 表 2 1#非金属夹杂物评级

Table 2. Non-metallic inclusion rating of 1# sample 级

试样编号 A B C D DS 1 1.5e 0.5 1.0 1.0 1.0 表 3 齿顶的维氏硬度检测结果

Table 3. Vickers hardness testing results of the tooth tip

试验目的 硬度值(HV1) 硬度点确定/mm 渗碳淬火硬化层

深度592 611 599 601 603 604 607 596 586 582 572 585 齿顶

(a1=0.15,

点间距0.075,

行距0.2)568 567 565 557 566 558 553 561 560 538 543 532 539 528 549 532 526 542 522 504 517 492 500 硬化层

深度校核554 561 559 553 550 543 d1=1.65 529 544 554 546 555 543 d2=1.85 表层

硬度618 630 630 a=0.15 588 593 588 a=0.65 表 4 齿非受力侧面的维氏硬度检测结果

Table 4. Vickers hardness testing results of the non-stress side of the tooth

试验目的 硬度值(HV1) 硬度点确定/mm 渗碳淬火硬化层

深度627 611 608 603 611 591 583 590 585 587 587 593 齿非受压侧(a1=0.15,

点间距0.075,

行距0.2)583 577 576 569 572 570 574 560 567 552 543 546 512 515 538 469 459 硬化层

深度校核545 562 550 550 566 560 d1=1.725 549 505 529 544 530 529 d2=1.925 表层硬度 637 639 630 a=0.15 表 5 6#样沿晶断口晶界上夹杂物能谱分析成分结果

Table 5. Inclusions on the intergranular fracture boundaries of the 6# sample by EDS

% 图6(b) O Si S Ti Cr Mn Fe 1 42.01 0.84 1.00 0.49 55.67 2 13.38 0.46 0.79 1.16 84.21 3 23.68 0.27 0.28 1.05 0.76 73.97 4 28.70 0.64 1.13 0.80 1.13 1.09 5 0.43 1.41 1.00 97.16 表 6 2#样齿顶面内氧化能谱分析成分结果

Table 6. Oxide of tooth tip of the 2# sample by EDS

% 图6(f) O Si Cr Mn Fe 1 26.66 1.88 19.59 11.79 40.08 2 31.67 1.37 34.10 18.27 14.59 3 28.78 1.20 32.95 17.97 19.10 4 20.68 1.19 16.08 9.49 52.56 5 0.58 0.44 1.00 1.38 96.61 -

[1] Zhang Xiaoyun, Zhou Xinjian. Analysis of gear failure in coal-mine machinery[J]. Lubrication Engineering, 2003,(5):54−56. (张潇云, 周新建. 煤矿机械传动齿轮失效形式分析[J]. 润滑与密封, 2003,(5):54−56. doi: 10.3969/j.issn.0254-0150.2003.05.021Zhang Xiaoyun, Zhou Xinjian. Analysis of Gear Failure in Coal-Mine Machinery[J]. Lubrication Engineering, 2003(5): 54-56. doi: 10.3969/j.issn.0254-0150.2003.05.021 [2] Gao Zhansheng, Li Lingling. Failure analysis of the transmission gear[J]. Heat Treatment of Metals, 2019,44(S1):236−239. (高占盛, 李玲玲. 变速箱齿轮断裂分析[J]. 金属热处理, 2019,44(S1):236−239.Gao Zhansheng, Li Lingling. Failure analysis of the transmission gear[J]. Heat Treatment of Metals, 2019, v. 44(S1): 236-239. [3] Wei Jun, Wang Yi, Wu Xizhu, et al. Failure analysis of gear tooth fracture of a transmission[J]. Automobile Parts, 2019,127(1):44−46. (位君, 王义, 吴喜柱, 等. 变速器齿轮断齿失效分析[J]. 汽车零部件, 2019,127(1):44−46. doi: 10.19466/j.cnki.1674-1986.2019.01.010Wei Jun, Wang Yi, Wu Xizhu, et al. Failure Analysis of Gear Tooth Fracture of a Transmission[J]. Automobile Parts, 2019, 127(01): 44-46. doi: 10.19466/j.cnki.1674-1986.2019.01.010 [4] Zhang Xiaoju, Jia Shu, Li Jianlong. Failure analysis on auxiliary middle shaft of transmission[J]. Hot Working Technology, 2015,44(16):241−243. (张晓菊, 贾舒, 李建龙. 变速箱副箱中间轴断齿失效分析[J]. 热加工工艺, 2015,44(16):241−243. doi: 10.14158/j.cnki.1001-3814.2015.16.072Zhang Xiaoju, Jia Shu, Li Jianlong. Failure Analysis on Auxiliary Middle Shaft of Transmission[J]. Hot Working Technology, 2015, 044(016): 241-243. doi: 10.14158/j.cnki.1001-3814.2015.16.072 [5] Song Tingfeng. Choice mine equipment reducer gear material[J]. Coal Mine Machinery, 2011,32(7):104−105. (宋庭锋. 矿用设备齿轮箱齿轮材料的选取[J]. 煤矿机械, 2011,32(7):104−105. doi: 10.3969/j.issn.1003-0794.2011.07.048Song Tingfeng. Choice Mine Equipment Reducer Gear Material[J]. Coal Mine Machinery, 2011, 32(7) : 104-105. doi: 10.3969/j.issn.1003-0794.2011.07.048 [6] Qiu Yajun, Ye Jianyi, Zhang Juanjuan. Influence of network carbide on impact property of steel GCr15[J]. Bearing, 2008,11(4):28−31. (仇亚军, 叶健熠, 张娟娟. GCr15钢网状碳化物对其冲击性能的影响[J]. 轴承, 2008,11(4):28−31. doi: 10.3969/j.issn.1000-3762.2008.04.011Qiu Yajun, Ye Jianyi, Zhang Juanjuan. Influence of Network Carbide on Impact Property of Steel GCr15[J]. Bearing, 2008, 011(04): 28-31. doi: 10.3969/j.issn.1000-3762.2008.04.011 -

下载:

下载: