Study on the microstructure and properties of the transition region of IN625/TC4 bimetallic structure by laser melting deposition with Cu interlayer

-

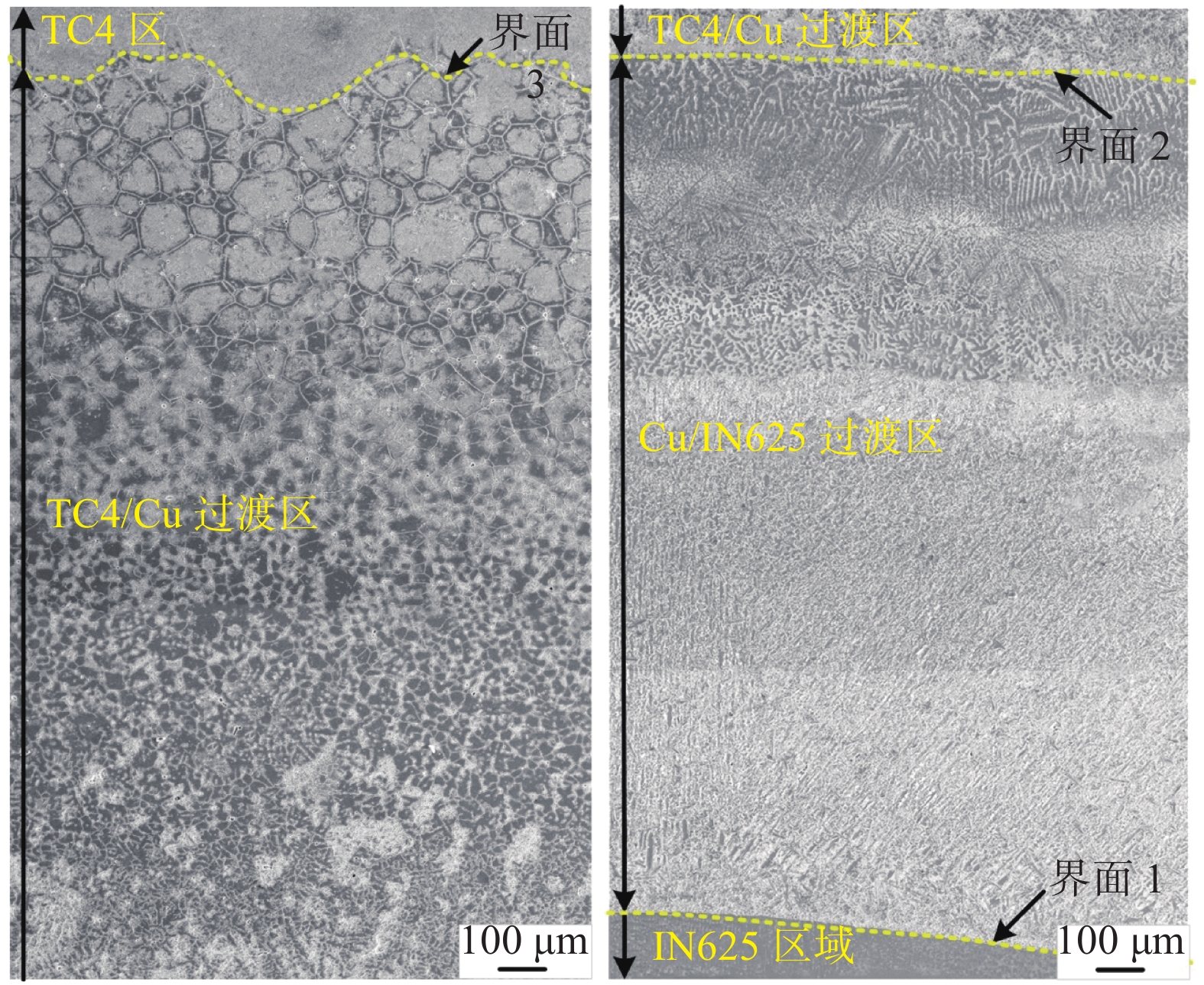

摘要: 由具有优异高温性能的IN625镍基高温合金和轻质高强度的TC4钛合金构成的双金属结构在航空航天领域中具有广阔的应用前景,然而,由于两种金属的物理化学性质差异较大,直接制造IN625/TC4双金属结构时,不可避免地在过渡区形成裂纹等冶金缺陷,因此IN625/TC4双金属结构的有效连接一直是行业研究的热点与难点。采用激光熔化沉积技术,通过添加Cu夹层制备了无裂纹等冶金缺陷的IN625/TC4双金属结构,研究了其过渡区的显微组织与力学性能。结果表明,Cu夹层激光熔化沉积IN625/TC4双金属结构过渡区内部的相组成主要为:γ-Ni、γ-Cu、(Cr, Mo)、Ti2Cu、TiCu、TiNi3、α-Ti及β-Ti;室温拉伸结果表明,添加Cu夹层的IN625/TC4双金属结构的抗拉强度约为228.9 MPa,断裂位置位于Cu/IN625过渡区附近,断口形貌表现为准解理断裂特性。Abstract: The bimetallic structure composed of IN625 nickel-based high-temperature alloy with excellent high-temperature properties and lightweight and high-strength TC4 titanium alloy has broad application prospects in the aerospace field. However, due to the large differences in physical and chemical properties of the two metals, the direct fabrication of IN625/TC4 bimetallic structure inevitably results in the formation of metallurgical defects such as cracks in the transition region, so the effective connection of IN625/TC4 bimetallic structure has been a hot spot and a difficult area of research in the industry. In this work, laser melting deposition technology was used to prepare IN625/TC4 bimetallic structure without cracks and other metallurgical defects by adding Cu interlayer, and studied the microstructure and mechanical properties of the transition region. The results show that the phase composition inside the transition region of the IN625/TC4 bimetallic structure deposited by laser melting with Cu interlayer is mainly γ-Ni, γ-Cu, (Cr, Mo), Ti2Cu, TiCu, TiNi3, α-Ti and β-Ti. Tensile results at room temperature indicate that the tensile strength of the IN625/TC4 bimetallic structure with Cu interlayer is about 228.9 MPa. The fracture location is near the Cu/IN625 transition region, and the fracture morphology shows quasi-dissociative fracture characteristics.

-

图 5 Cu夹层双金属结构室温拉伸试验

(a)以Cu 为夹层的IN625/TC4双金属结构拉伸断口形貌;(b)为图5(a)中方色框内部的放大;(c)EDS点扫描;(d)试样拉伸性能

Figure 5. Room temperature tensile test of bimetallic structure using Cu interlayer

表 1 主要工艺参数

Table 1. Mian process parameters

材料 激光功

率/W扫描速度/

(mm·min−1)送粉速度/

(g·min−1)层厚/

mm层数 IN625 1800 720 8.4 0.6 44 Cu 2100 720 8.9 0.6 1 TC4 2400 720 4.8 0.6 44 表 2 Cu/IN625过渡区EDS点扫描结果

Table 2. EDS scanning results at Cu/IN625 transition region

% 微区 Ni Cr Mo Nb Fe Ti Al V Cu 物相 1 47.68 1.75 0.06 0.33 0.83 24.01 1.17 0.10 24.07 (Ni, Cu)ss 2 7.79 54.32 20.21 0.26 0.99 6.74 3.25 2.11 4.33 (Cr, Mo) 3 21.2 3.03 1.02 0.77 0.52 63.71 7.23 2.39 0.13 TiNi3 4 5.77 3.45 2.5 0.35 1.97 40.23 4.23 1.69 39.81 TiCu 5 38.65 1.29 0.18 0.49 0.18 5.43 3.56 2.33 47.88 (Ni, Cu)ss 6 4.32 3.44 0.15 0.79 0.21 56.4 5.08 0.30 29.30 Ti2Cu 表 3 TC4/Cu过渡区EDS点扫描结果

Table 3. EDS point scanning results at TC4/Cu transition region

% 微区 Ni Cr Mo Nb Fe Ti Al V Cu 物相 1 8.01 6.39 1.79 0.69 0.73 65.02 8.13 2.83 6.41 β-Ti 2 2.27 0.83 0.11 0.05 0.17 82.81 10.73 1.20 1.83 α-Ti 3 9.89 2.81 0.07 0.08 1.23 56.81 1.00 1.88 26.23 Ti2Cu 4 4.93 1.90 0.20 0.06 0.61 80.49 5.69 3.03 3.08 β-Ti 5 1.39 0.33 0.11 0.01 0.22 85.08 10.30 1.50 1.05 α-Ti 6 8.61 2.46 0.45 0.10 0.41 76.34 5.79 1.95 3.89 β-Ti -

[1] Pm A, Hy B, Abp A. Microstructure evolution of Inconel 625 alloy during single-track laser powder bed fusion[J]. Additive Manufacturing, 2022,55:102824. doi: 10.1016/j.addma.2022.102824 [2] Chen Y, Xu M, Zhang T, et al. Grain refinement and mechanical properties improvement of Inconel 625 alloy fabricated by ultrasonic-assisted wire and arc additive manufacturing[J]. Journal of Alloys and Compounds, 2022,910:164957. doi: 10.1016/j.jallcom.2022.164957 [3] Pang X, Xiong Z, Sun J, et al. Enhanced strength-ductility synergy in laser additive manufactured TC4 titanium alloy by grain refinement[J]. Materials Letters, 2022,326:132949. doi: 10.1016/j.matlet.2022.132949 [4] Zhou X, Xu D, Geng S, et al. Mechanical properties, corrosion behavior and cytotoxicity of Ti-6Al-4V alloy fabricated by laser metal deposition[J]. Materials Characterization, 2021,179:111302. doi: 10.1016/j.matchar.2021.111302 [5] Zhao H, Liu Z, Yu C, et al. Finite element analysis for residual stress of TC4/Inconel718 functionally gradient materials produced by laser additive manufacturing[J]. Optics & Laser Technology, 2022,152:108146. [6] Wu D, Song C, Di T, et al. Intermetallic regulation mechanism of inconel718/Ti6A14V composite by novel follow-up ultrasonic assisted laser additive manufacturing[J]. Composites, Part B. Engineering, 2022,15(235):109736. [7] Shang C, Wang C, Li C, et al. Eliminating the crack of laser 3D printed functionally graded material from TA15 to Inconel718 by base preheating[J]. Optics & Laser Technology, 2020,126:106100. [8] Xia Y, Lei J, Chen H. Effects of circular oscillating laser on microstructure and mechanical property of nickel-based superalloy by laser melting deposition[J]. Optics & Laser Technology, 2022,155:108361. [9] Hao Y, Huang Y, Zhao K, et al. Research on the microstructure and mechanical properties of doubled annealed laser melting deposition TC11 titanium alloy[J]. Optics & Laser Technology, 2022,150:107983. [10] Gao Z, Wang L, Lyu F, et al. Temperature variation and mass transport simulations of invar alloy during continuous-wave laser melting deposition[J]. Optics & Laser Technology, 2022,152:108163. [11] Gu D, Shi X, Poprawe R, et al. Material-structure-performance integrated laser-metal additive manufacturing[J]. Science, 2021,372(6545):1487. doi: 10.1126/science.abg1487 [12] Benedetti M, Klarin J, Johansson F, et al. Study of the compression behaviour of Ti6Al4V trabecular structures produced by additive laser manufacturing[J]. Materials, 2019,12(9):1471. doi: 10.3390/ma12091471 [13] Safronov V A, Gusarov A, Gusarov V, et al. Distortions and residual stresses at layer-by-layer additive manufacturing by fusion[J]. Journal of Manufacturing Science and Engineering:Transactions of the ASME, 2017,139(3):031017. doi: 10.1115/1.4034714 [14] Liu Z, Lu S, Tang H, et al. Characterization and decompositional crystallography of the massive phase grains in an additively-manufactured Ti-6Al-4V alloy[J]. Materials Characterization, 2017,127:146−152. doi: 10.1016/j.matchar.2017.01.012 [15] Onuike B, Heer B, Bandyopadhyay A. Additive manufacturing of Inconel 718-Copper alloy bimetallic structure using laser engineered net shaping (LENS)[J]. Additive Manufacturing, 2018,21:133−140. doi: 10.1016/j.addma.2018.02.007 [16] Domack M S, Baughman J M. Development of nickel‐titanium graded composition components[J]. Emerald Group Publishing Limited, 2005,11:655−668. [17] Shang C, Xu G, Wang C, et al. Laser deposition manufacturing of bimetallic structure from TA15 to inconel 718 via copper interlayer[J]. Materials Letters, 2019,252(1):342−344. [18] Zoeram A S, Mousavi S. Effect of interlayer thickness on microstructure and mechanical properties of as welded Ti6Al4V/Cu/NiTi joints[J]. Materials Letters, 2014,133(15):5−8. [19] 王辰阳. 激光增材制造TC4/Inconel 718双金属结构过渡区组织性能的研究[D]. 沈阳, 沈阳工业大学, 2021.Wang Chenyang. Study on microstructures and mechanical properties of TC4-INconel718 bimetallic structure gradient transition zone prepared by laser melting deposition[D]. Shenyang: Shengyang University of Technology, 2021. -

下载:

下载: