| [1] |

Sidhu S S, Singh H, Gepreel A H. A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials[J]. Materials Science and Engineering C:Materials for Biological Applications, 2020,121(11):111661.

|

| [2] |

Yang Jiahui, Zhang Yifan, Wu Junxia, et al. Research progress of biomedical titanium alloy[J]. Rare Metals and Cemented Carbides, 2021,49(5):29−34,40. (杨佳惠, 张一凡, 武俊霞, 等. 生物医用钛合金研究进展[J]. 稀有金属与硬质合金, 2021,49(5):29−34,40.Yang Jiahui, Zhang Yifan, Wu Junxia, et al. Research progress of biomedical titanium alloy[J]. Rare Metals and Cemented Carbides, 2021, 49(5): 29-34, 40.

|

| [3] |

Zhang L C, Chen L Y. A review on biomedical titanium alloys: Recent progress and prospect[J]. Advanced Engineering Materials, 2019,21:1801215. doi: 10.1002/adem.201801215

|

| [4] |

Liu Jianqiao, Liu Jia, Tang Yujin, et al. Research progress in titanium alloy in the field of orthopaedic implants[J]. Journal of Materials Engineering, 2021,49(8):11−25. (刘剑桥, 刘佳, 唐毓金, 等. 钛合金在骨科植入领域的研究进展[J]. 材料工程, 2021,49(8):11−25. doi: 10.11868/j.issn.1001-4381.2020.000380Liu Jianqiao, Liu Jia, Tang Yujin, et al. Research progress in titanium alloy in the field of orthopaedic implants[J]. Journal of Materials Engineering, 2021, 49(8): 11-25. doi: 10.11868/j.issn.1001-4381.2020.000380

|

| [5] |

Chen L Y, Cui Y W, Zhang L C. Recent development in beta titanium alloys for biomedical applications[J]. Metals, 2020,10:1139. doi: 10.3390/met10091139

|

| [6] |

Rodriguez-Contreras A, Punset M, Calero J, et al. Powder metallurgy with space holder for porous titanium implants: A review[J]. Journal of Materials Science and Technology, 2021,76(17):21.

|

| [7] |

Zhang Erlin, Wang Xiaoyan, Han Yong. Research status of biomedical porous Ti and its alloy in China[J]. Acta Metallurgica Sinica, 2017,53(12):1555−1567. (张二林, 王晓燕, 憨勇. 医用多孔Ti及钛合金的国内研究现状[J]. 金属学报, 2017,53(12):1555−1567. doi: 10.11900/0412.1961.2017.00324Zhang Erlin, Wang Xiaoyan, Han Yong. Research status of biomedical porous Ti and its alloy in China[J]. Acta Metallurgica Sinica, 2017, 53(12): 1555-1567. doi: 10.11900/0412.1961.2017.00324

|

| [8] |

Zhao C, Liang K, Tan J, et al. Bioactivity of porous titanium with hydrogen peroxide solution with or without tantalum chloride treatment at a low temperature[J]. Biomedical Materials, 2013,8(2):025006. doi: 10.1088/1748-6041/8/2/025006

|

| [9] |

Fujibayashi S, Neo M, Kim H M, et al. Osteoinduction of porous bioactive titanium metal[J]. Biomaterials, 2004,25(3):443−450. doi: 10.1016/S0142-9612(03)00551-9

|

| [10] |

Lin Xiao, Ge Jun, Wu Shuilin, et al. Advances in metallic biomaterials with both osteogenic and anti-infection properties[J]. Acta Metallurgica Sinica, 2017,53(10):1284−1302. (林潇, 葛隽, 吴水林, 等. 兼具成骨和抗感染性能的医用金属材料研究进展[J]. 金属学报, 2017,53(10):1284−1302. doi: 10.11900/0412.1961.2017.000269Lin Xiao, Ge Jun, Wu Shuilin, et al. Advances in metallic biomaterials with both osteogenic and anti-infection properties[J]. Acta Metallurgica Sinica, 2017, 53(10): 1284-1302. doi: 10.11900/0412.1961.2017.000269

|

| [11] |

Chen Q, Thouas G A. Metallic implant biomaterials[J]. Materials Science and Engineering R, 2015,87:1−57. doi: 10.1016/j.mser.2014.10.001

|

| [12] |

Vincent M, Hartemann P, Engels-Deutsch M. Antimicrobial applications of copper[J]. International Journal of Hygiene & Environmental Health, 2016,219:585−591.

|

| [13] |

Akbarpour M R, Mirabad H M, Hemmati A, et al. Processing and microstructure of Ti-Cu binary alloys: A comprehensive review[J]. Progress in Materials Science, 2022,127:100933. doi: 10.1016/j.pmatsci.2022.100933

|

| [14] |

Liu J, Li F, Liu C, et al. Effect of Cu content on the antibacterial activity of titanium–copper sintered alloys[J]. Materials Science & Engineering C:Materials for Biological Applications, 2014,35(1):392−400.

|

| [15] |

Zhang E, Zheng L, Liu J, et al. Influence of Cu content on the cell biocompatibility of Ti-Cu sintered alloys[J]. Materials Science & Engineering C:Materials for Biological Applications, 2015,36(8):148−157.

|

| [16] |

Zhang E, Li S, Ren J, et al. Effect of extrusion processing on the microstructure, mechanical properties, biocorrosion properties and antibacterial properties of Ti-Cu sintered alloys[J]. Materials Science & Engineering C:Materials for Biological Applications, 2016,69:760−768.

|

| [17] |

Liu R, Ma Z, Kunle Kolawole S, et al. In vitro study on cytocompatibility and osteogenesis ability of Ti–Cu alloy[J]. Journal of Materials Science:Materials in Medicine, 2019,30(7):75. doi: 10.1007/s10856-019-6277-z

|

| [18] |

Kikuchi M, Takahashi M, Okuno O. Elastic moduli of cast Ti-Au, Ti-Ag, and Ti-Cu alloys[J]. Dental Materials, 2006,22(7):641−646. doi: 10.1016/j.dental.2005.05.015

|

| [19] |

Alshammari Y, Yang F, Bolzoni L. Low-cost powder metallurgy Ti-Cu alloys as a potential antibacterial material[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2019,95:232−239. doi: 10.1016/j.jmbbm.2019.04.004

|

| [20] |

Mai Ping, Cui Xumei, Zhao Chaoyong, et al. Effect of sintering process on microstructure and mechanical properties of porous Ti-5Cu alloy[J]. Iron Steel Vanadium Titanium, 2019,40(3):46−53. (麦萍, 崔旭梅, 赵朝勇, 等. 烧结工艺对多孔Ti-5Cu合金微观结构和力学性能的影响[J]. 钢铁钒钛, 2019,40(3):46−53.Mai Ping, Cui Xumei, Zhao Chaoyong, et al. Effect of sintering process on microstructure and mechanical properties of porous Ti-5 Cu alloy[J]. Iron Steel Vanadium Titanium, 2019, 40(3): 46-53.

|

| [21] |

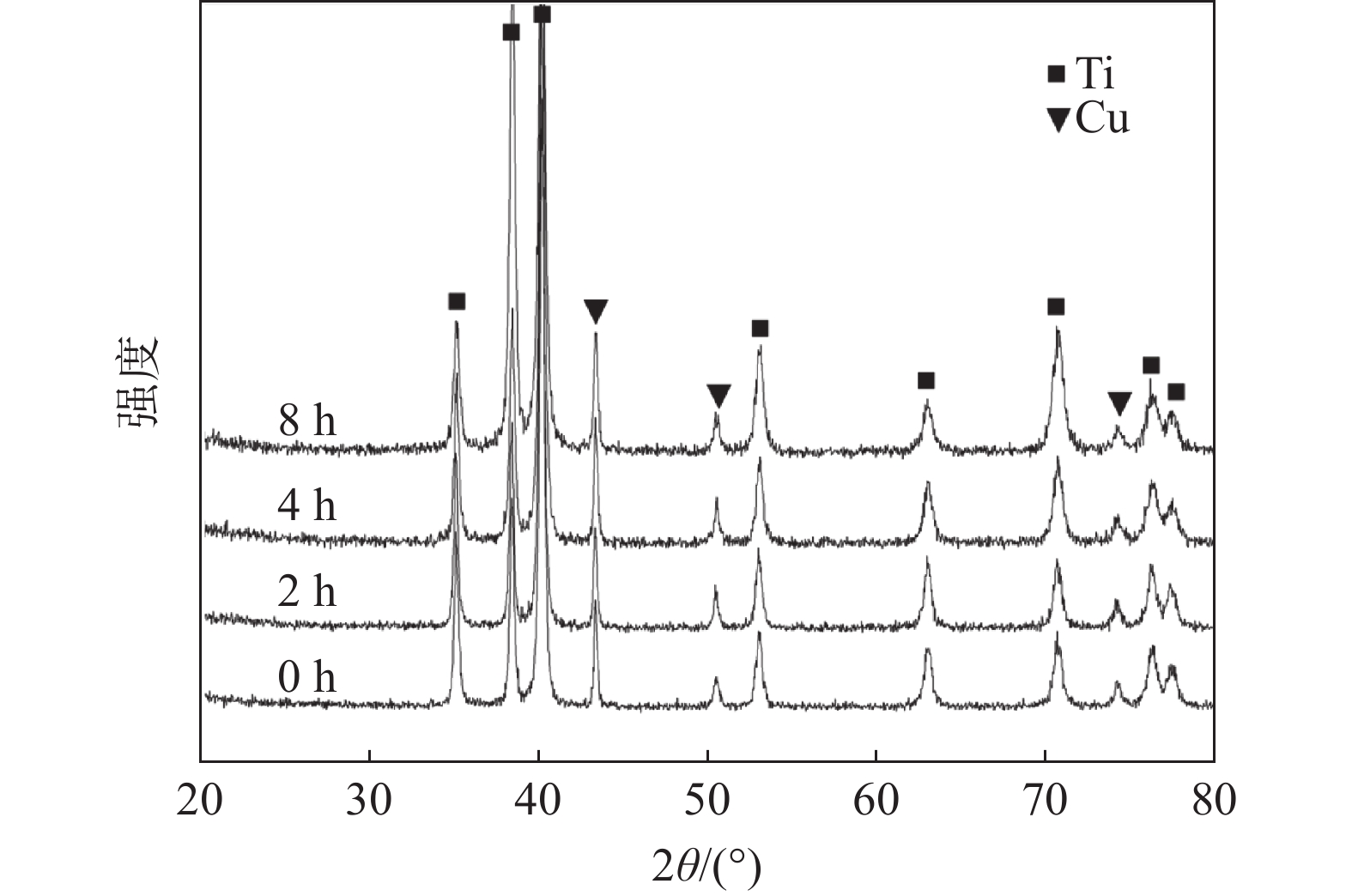

Wang X P, Xu L J, Chen Y Y, et al. Effect of milling time on microstructure of Ti35Nb2.5Sn/10HA biocomposite fabricated by powder metallurgy and sintering[J]. Transactions of Nonferrous Metals Society of China, 2012,22(3):608−612. doi: 10.1016/S1003-6326(11)61221-1

|

| [22] |

Zhao Chaoyong, Zhang Xuefeng, Zhang Lei, et al. Preparation and mechanical properties of porous Ti-5Ag alloy[J]. Iron Steel Vanadium Titanium, 2018,39(2):49−55. (赵朝勇, 张雪峰, 张磊, 等. 多孔Ti-5Ag合金的制备及力学性能研究[J]. 钢铁钒钛, 2018,39(2):49−55. doi: 10.7513/j.issn.1004-7638.2018.02.008Zhao Chaoyong, Zhang Xuefeng, Zhang Lei, et al. Preparation and mechanical properties of porous Ti-5 Ag alloy[J]. Iron Steel Vanadium Titanium, 2018, 39(2): 49-55. doi: 10.7513/j.issn.1004-7638.2018.02.008

|

| [23] |

Nouri A, Hodgson P D, Wen C. Effect of ball-milling time on the structural characteristics of biomedical porous Ti–Sn–Nb alloy[J]. Materials Science and Engineering C:Materials for Biological Applications, 2011,31(5):921−928. doi: 10.1016/j.msec.2011.02.011

|

| [24] |

唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙: 中南大学出版社, 2009.Tang Renzheng, Tian Rongzhang. Binary alloy phase diagrams and crystal structure of intermediate phase[M]. Changsha: Central South University Press, 2009.

|

| [25] |

Hou L G, Li L I, Zheng Y F. Effects of ball milling time on porous Ti–3Ag alloy and its apatite-inducing abilities[J]. Transactions of Nonferrous Metals Society of China, 2013,23(5):1356−1366. doi: 10.1016/S1003-6326(13)62604-7

|

| [26] |

Weiner S, Wagner H D. The material bone: Structure-mechanical function relations[J]. Annual Review of Materials Science, 1998,28(1):271−298. doi: 10.1146/annurev.matsci.28.1.271

|

| [27] |

Alvarez K, Nakajima H. Metallic scaffolds for bone regeneration[J]. Materials, 2009,2(3):790−832. doi: 10.3390/ma2030790

|

| [28] |

Pattanayak D K, Matsushita T, Doi K, et al. Effects of oxygen content of porous titanium metal on its apatite-forming ability and compressive strength[J]. Materials Science and Engineering C:Materials for Biological Applications, 2009,29(6):1974−1978. doi: 10.1016/j.msec.2009.03.014

|

| [29] |

Gibson L J. The mechanical behaviour of cancellous bone[J]. Journal of Biomechanics, 1985,18(5):317−328. doi: 10.1016/0021-9290(85)90287-8

|

下载:

下载: