Study on hydration reaction of titanium gypsum–titanium slag low clinker cement

-

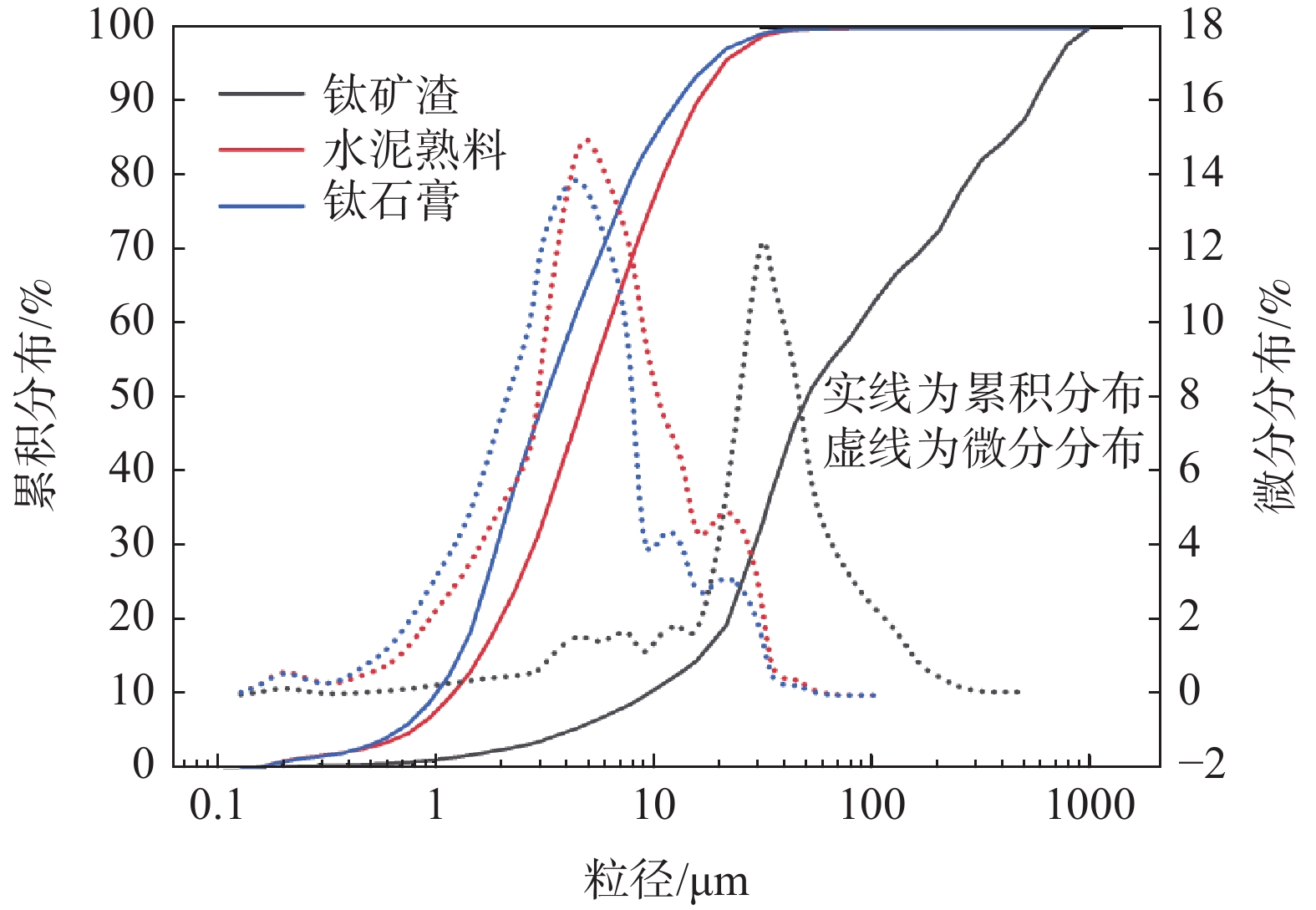

摘要: 为了探究利用钛石膏和钛矿渣制备低熟料水泥的可行性,研究其水化特性。采用钛石膏、钛矿渣、水泥熟料为主要原料,并用硅酸钠做为激发剂,配制10组低熟料水泥。对各组的抗压强度、软化系数、收缩率进行了测试,采用水化热分析、TG-DSC、XRD和SEM等测试方法对水化过程和水化产物进行了研究。结果表明,适当增加钛矿渣或水泥熟料的掺量可以提升水泥的抗压强度和软化系数,并能减小水泥的收缩。硅酸钠可以显著激发水泥的水化反应活性,促使生成更多的C-S(A)-H、AFt、CH等水化产物,从而提高抗压强度和软化系数,但过量掺入硅酸钠会造成收缩率增加。当钛石膏、钛矿渣、熟料和硅酸钠的比例为30∶55∶15∶8时,养护56 d的抗压强度达到51.3 MPa,软化系数为0.74,表现出了较好的力学性能和耐水性。Abstract: In order to explore the feasibility of using titanium gypsum and titanium slag to prepare low clinker cement and study its hydration characteristics, 10 groups of cement were prepared with titanium gypsum, titanium slag and cement clinker as the main raw materials and sodium silicate as the activator. The compressive strength, softening coefficient and shrinkage rate of each group were tested. The hydration process and hydration products were studied by hydration thermal analysis, TG-DSC, XRD and SEM. The results show that appropriate increase of titanium slag or clinker content can improve the compressive strength and softening coefficient of cement, and reduce the shrinkage of cement. Sodium silicate can significantly activate the hydration reactivity of cement, and promote the generation of more C-S(A)-H, AFt and CH, so as to improve the compressive strength and softening coefficient, but excessive incorporation of sodium silicate will cause an increase in shrinkage rate. With the ratio of titanium gypsum, titanium slag, clinker and sodium silicate of 30∶55∶15∶8, the compressive strength reached 51.3 MPa of 56 days after curing and the softening coefficient was 0.74, showing good mechanical properties and water resistance.

-

Key words:

- titanium gypsum /

- titanium slag /

- cement /

- clinker /

- sodium silicate /

- hydration

-

表 1 原材料的XRF分析结果

Table 1. XRF analysis results of raw materials

% 原料 CaO SiO2 TiO2 Al2O3 MgO Fe2O3 SO3 P2O5 Na2O K2O MnO 钛矿渣 26.06 21.76 17.69 13.57 7.13 3.22 2.91 0.05 0.81 0.55 0.45 钛石膏 36.22 2.90 1.20 1.58 1.62 13.56 41.95 0.37 0.10 0.07 0.27 熟料 68.17 18.54 0.67 4.44 1.40 3.57 1.68 0.12 0.31 0.83 0.10 表 2 试验配合比

Table 2. Experimental mix proportion

% 分组 序号 钛石膏 矿渣 熟料 硅酸钠 水灰比 备注 A组 A1 45 50 5 0 30 改变钛石膏与矿渣

比例及硅酸钠掺量A2 25 70 5 0 30 A3 25 70 5 3 30 A4 25 70 5 5 30 A5 25 70 5 8 30 B组 B1 30 60 10 0 30 改变矿渣与熟料

比例及硅酸钠掺量B2 30 55 15 0 30 B3 30 55 15 3 30 B4 30 55 15 5 30 B5 30 55 15 8 30 表 3 失重率统计

Table 3. Weight loss ratio statistics

试验组 各温度段失重率/% 累积失重率/% 30~110 ℃ 500~700 ℃ 700~900 ℃ A2 0.026 1.445 1.312 2.783 A3 0.316 2.271 4.636 7.223 A5 0.318 2.424 4.669 7.411 B2 0.735 3.666 5.181 9.582 B3 1.010 4.439 4.982 10.431 B5 2.755 4.554 4.136 11.445 -

[1] Ma Lei, Sheng Yu, Zhou Junhong, et al. Study on new process of comprehensive utilization and separation of sulfur and calcium of titanium gypsum[J]. Inorganic Chemicals Industry, 2022,54(7):124−128. (马磊, 盛余, 周骏宏, 等. 钛石膏综合利用及硫钙分离新工艺研究[J]. 无机盐工业, 2022,54(7):124−128.Ma Lei, Sheng Yu, Zhou Junhong, et al. Study on new process of comprehensive utilization and separation of sulfur and calcium of titanium gypsum[J]. Inorganic Chemicals Industry, 2022, 54(7): 124-128 [2] Jin Biqiang, Zhang Tingting, Zhu Jingping, et al. The development and research progress of titanium gypsum exploitation and utilization[J]. Multipurpose Utilization of Mineral Resources, 2020,(3):28−32. (靳必强, 张婷婷, 朱静平, 等. 钛石膏的开发利用研究进展[J]. 矿产综合利用, 2020,(3):28−32.Jin Biqiang, Zhang Tingting, Zhu Jingping, et al. The development and research progress of titanium gypsum exploitation and utilization[J]. Multipurpose Utilization of Mineral Resources, 2020(3): 28-32 [3] Zhang Jiufu, Yan Yun, Hu Zhihua, et al. Properties and hydration behavior of Ti-extracted residues-red gypsum based cementitious materials[J]. Construction and Building Materials, 2019,(218):610−617. [4] Yang He. Analysis of the strength mechanism of lime-base activated titanium gypsum composite cementitious material[J]. Iron Steel Vanadium Titanium, 2021,42(3):111−118. (杨贺. 石灰碱激发钛石膏复合胶凝材料强度机理分析[J]. 钢铁钒钛, 2021,42(3):111−118.Yang He. Analysis of the strength mechanism of lime-base activated titanium gypsum composite cementitious material[J]. Iron Steel Vanadium Titanium, 2021, 42(3): 111-118 [5] Du Huihui, Ni Wen, Gao Guangjun, et al. Research on application of vanadium-titanium slag in fabricated precast concrete slab[J]. New Building Materials, 2021,48(10):172−177. (杜惠惠, 倪文, 高广军, 等. 钒钛矿渣在装配式预制板材中的应用研究[J]. 新型建筑材料, 2021,48(10):172−177.Du Huihui, Ni Wen, Gao Guangjun, et al. Research on application of vanadium-titanium slag in fabricated precast concrete slab[J]. New Building Materials, 2021, 48(10): 172-177 [6] Wang Shuai, Lv Shuzhen, Zhao Jie, et al. Preparation of mineral admixture for concrete with high titanium slag[J]. Journal of Southwest University of Science and Technology, 2021,36(1):28−34. (王帅, 吕淑珍, 赵杰, 等. 高钛矿渣制备混凝土用矿物掺合料研究[J]. 西南科技大学学报, 2021,36(1):28−34.Wang Shuai, Lv Shuzhen, Zhao Jie, et al. Preparation of mineral admixture for concrete with high titanium slag[J]. Journal of Southwest University of Science and Technology, 2021, 36(1): 28-34 [7] Omeid Rahmani. An experimental study of accelerated mineral carbonation of industrial waste red gypsum for CO2 sequestration[J]. Journal of CO2 Utilization, 2020,(35):265−671. [8] Chen Feixiang, Shui Zhonghe, Ding Sha, et al. Optimization design research on the mix proportion of persulphated phosphogypsum-slag cement concrete[J]. Journal of Wuhan University of Technology, 2013,35(11):8−13. (陈飞翔, 水中和, 丁沙, 等. 过硫磷石膏矿渣水泥混凝土的配合比优化设计研究[J]. 武汉理工大学学报, 2013,35(11):8−13.Chen Feixiang, Shui Zhonghe, Ding Sha, et al. Optimization design research on the mix proportion of persulphated phosphogypsum-slag cement concrete[J]. Journal of Wuhan University of Technology, 2013, 35(11): 8-13. [9] Zhang Yue, Wang Hongjie, Yang Lin, et al. Influence of phosphogypsum particle size on properties and microstructure of wet-mixed mortar[J]. Bulletin of the Chinese Ceramic Society, 2022,41(8):2836−2843. (张粤, 王宏杰, 杨林, 等. 磷石膏粒径对湿拌砂浆性能及微观结构的影响研究[J]. 硅酸盐通报, 2022,41(8):2836−2843.Zhang Yue, Wang Hongjie, Yang Lin, et al. Influence of phosphogypsum particle size on properties and microstructure of wet-mixed mortar[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(8): 2836-2843. [10] Xie Jianhai, Kang Huning, Xiang Renke, et al. Study on performance of fluorogypsum composite cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2013,32(4):772−775. (谢建海, 亢虎宁, 向仁科, 等. 氟石膏复合胶凝材料的性能研究[J]. 硅酸盐通报, 2013,32(4):772−775.Xie Jianhai, Kang Huning, Xiang Renke, et al. Study on performance of fluorogypsum composite cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2013, 32(4): 772-775 [11] Ma Yuan, Fan Chuangang, Wu You, et al. Preparation and characterization of persulfur titanium gypsum slag cement[J]. Non-metallic Mines, 2016,39(6):41−44. (马远, 樊传刚, 吴悠, 等. 过硫钛石膏矿渣水泥的制备与性能表征[J]. 非金属矿, 2016,39(6):41−44. doi: 10.3969/j.issn.1000-8098.2016.06.013Ma Yuan, Fan Chuangang, Wu You, et al. Preparation and characterization of persulfur titanium gypsum slag cement[J]. Non-metallic Mines, 2016, 39(6): 41-44 doi: 10.3969/j.issn.1000-8098.2016.06.013 [12] Li Jingwei, Wang Wenlong, Xu Dong, et al. Preparation of sulfoaluminate cementitious material using harmful titanium gypsum: material properties and heavy metal immobilization characteristics[J]. Waste Disposal & Sustainable Energy, 2020,2(2):127−137. [13] Zhang Jiufu, Yan Yun, Hu Zhihua. Preparation and characterization of foamed concrete with Ti-extracted residues and red gypsum[J]. Construction and Building Materials, 2018,171:109−119. [14] Li Liangyuan, Shi Zongli, Ai Yongping. Alkaline activation of gypsum-granulated blast furnace slag cementing materials[J]. Journal of the Chinese Ceramic Society, 2008,(3):405−410. (黎良元, 石宗利, 艾永平. 石膏-矿渣胶凝材料的碱性激发作用[J]. 硅酸盐学报, 2008,(3):405−410.Li Liangyuan, Shi Zongli, Ai Yongping. Alkaline activation of gypsum-granulated blast furnace slag cementing materials[J]. Journal of the Chinese Ceramic Society, 2008(3): 405-410 [15] Chen Shikun, Zhang Yajun, Yan Dongming, et al. The influence of Si/Al ratio on sulfate durability of metakaolin-based geopolymer[J]. Construction and Building Materials, 2020,265(2):120735. [16] 郝忠卿, 高阳, 张翛, 等. 碱激发煤液化残渣地聚物力学及微观特性研究[J/OL]. 建筑材料学报: 1-12[2023-02-23].Hao Zhongqing, Gao Yang, Zhang Xiao, et al. Study on the mechanics and microscopic properties of direct coal liquefaction residue based geopolymer activated by alkali activator[J/OL]. Journal of Building Materials, 1-12[2023-02-23] [17] Ivanov K S, Korotkov E A. Effect of sodium silicate slurries on the properties of alkali-activated materials[J]. Inorganic Materials, 2017,53(9):973−979. doi: 10.1134/S0020168517090096 [18] Jiang Yong, Jia Lujun, Wen Mengyuan, et al. Preparation of alkali-activated fly ash /steel slag cementitious materials[J]. Bulletin of the Chinese Ceramic Society, 2019,38(7):2152−2156, 2161. (蒋勇, 贾陆军, 文梦媛, 等. 碱激发粉煤灰/钢渣胶凝材料的制备[J]. 硅酸盐通报, 2019,38(7):2152−2156, 2161.Jiang Yong, Jia Lujun, Wen Mengyuan, et al. Preparation of alkali-activated fly ash /steel slag cementitious materials[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7): 2152-2156, 2161 [19] Zhang Jun, Chen Haoyu, Hou Dongwei. Development of shrinkage and internal moisture in cement paste mortar and concrete at early age[J]. Journal of Building Materials, 2011,14(3):287−292. (张君, 陈浩宇, 侯东伟. 水泥净浆、砂浆及混凝土早期收缩与内部湿度发展分析[J]. 建筑材料学报, 2011,14(3):287−292.Zhang Jun, Chen Haoyu, Hou Dongwei. Development of shrinkage and internal moisture in cement paste mortar and concrete at early age[J]. Journal of Building Materials, 2011, 14(3): 287-292 [20] Gu Yamin, Fang Yonghao. Shrinkage, cracking, shrinkage-reducing and toughening of alkali-activated slag cement-a short review[J]. Journal of the Chinese Ceramic Society, 2012,40(1):76−84. (顾亚敏, 方永浩. 碱矿渣水泥的收缩与开裂特性及其减缩与增韧[J]. 硅酸盐学报, 2012,40(1):76−84.Gu Yamin, Fang Yonghao. Shrinkage, cracking, shrinkage-reducing and toughening of alkali-activated slag cement-a short review[J]. Journal of the Chinese Ceramic Society, 2012, 40(1): 76-84 [21] Cartwright C, Rajabipour F, Radlińska A. Shrinkage characteristics of alkaliactivated slag cements[J]. Journal of Materials in Civil Engineering, 2015, 27(7): B4014007: 1-9. -

下载:

下载: