Laboratory study on improving recovery rate of pyrite concentrate in titanium separation process in Panxi region

-

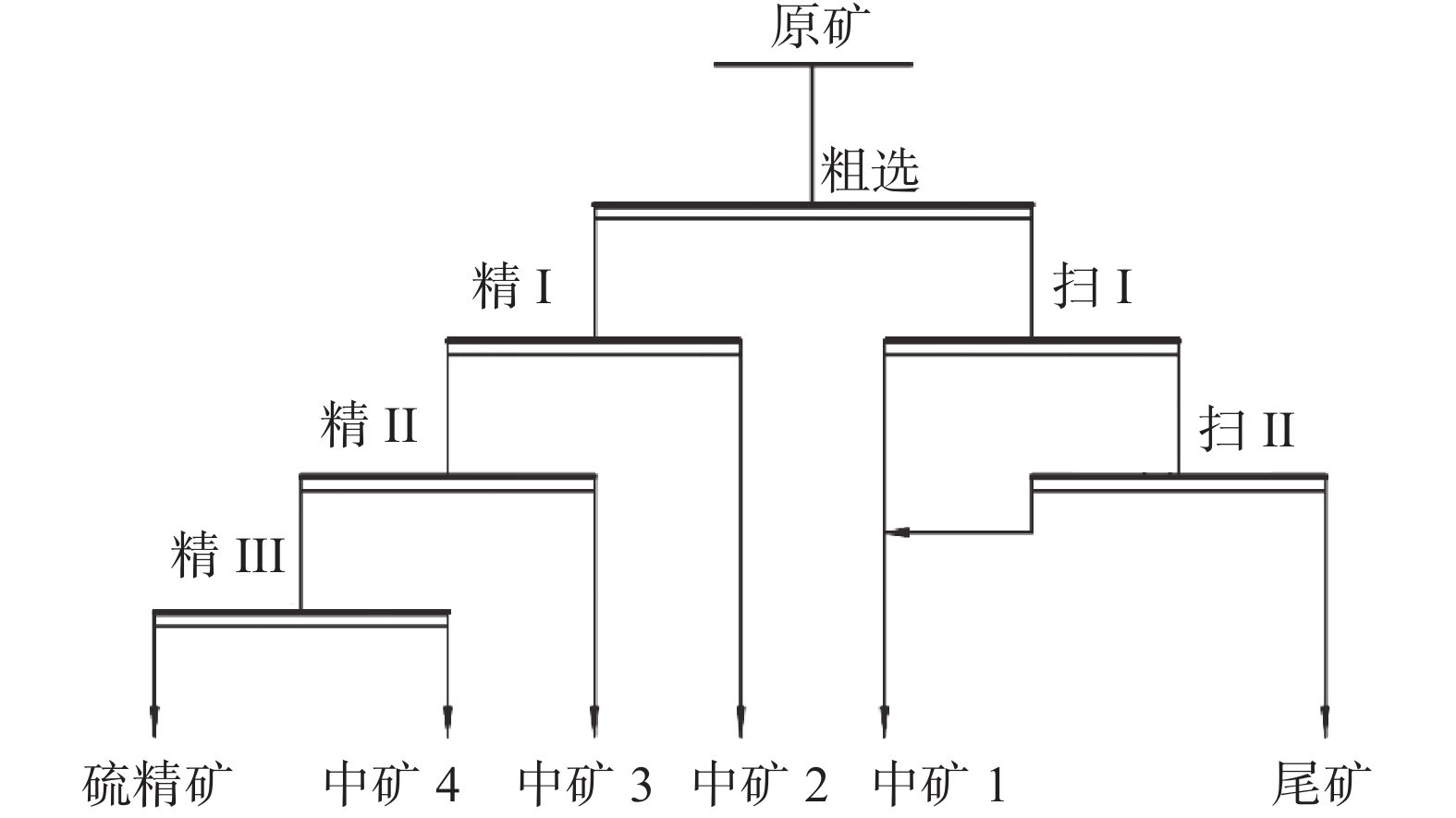

摘要: 针对攀西地区某选钛浮选斜板沉砂采用常规“先浮硫再硫钴富集”工艺及常规药剂“丁基黄药+2#油”回收硫化物时,硫钴回收率低、不利于后续硫钴浮选分离等问题,采用“一粗两扫三精”浮选流程,并添加微细粒硫钴矿物高效辅助捕收剂EMC-50、起泡剂EMP-02和抑制剂EM515等进行了实验室优化研究。试验表明,添加新药剂后能获得产率2.00%、S品位36.37%、Co品位0.36%、S回收率83.53%的硫精矿,硫精矿的回收率较当前采用常规药剂的提高了3.21个百分点,单位硫精矿药剂成本降低111元/t。新药剂的使用将有利于提高攀西硫精矿的综合利用价值。Abstract: In the case of sanding of a titanium flotation inclined plate in Panxi area, the conventional process of “first floating sulfur and then enriching cobalt sulphide” and the recovery of sulphides with the conventional reagent “Butyl xanthate +2# oil” were adopted, the low recovery of cobalt sulphide is unfavorable to the subsequent flotation separation of cobalt sulphide, the flotation process of “one roughing, two sweeping and three refining” was optimized by adding high efficient auxiliary collector EMC-50, foaming agent EMP-02 and inhibitor EM515.The results showed that sulfur concentrate with yield of 2.00% , S grade of 36.37% , Co grade of 0.36% and S recovery of 83.53% could be obtained by adding new reagent, the recovery of pyrite concentrate is 3.21% higher than that of conventional reagent, and the reagent cost per unit pyrite concentrate is 111 yuan/t lower. The use of new reagents will be beneficial to improve the comprehensive utilization value of Panxi pyrite concentrate.

-

Key words:

- vanadium-titanium magnetite /

- titanium separation /

- sulfur concentrate /

- recovery /

- grade

-

表 1 试样化学多元素分析结果

Table 1. Chemical element analysis of samples

% S Co Ni Cu TFe TiO2 Mn CaO MgO Al2O3 SiO2 P Zn Y 0.87 0.022 0.033 0.021 17.12 11.25 0.30 4.61 19.06 6.11 31.69 0.035 0.016 0.001 表 2 主要矿物含量及单体解离度测定结果

Table 2. Determination of main mineral content and monomer dissociation degree

% 项目 铁钛

氧化物金属硫化物 脉石

矿物磁黄

铁矿黄铁矿 含钴镍黄铁矿 黄铜矿 硫钴镍

铁矿闪锌矿 矿物含量 17.27 1.99 0.05 0.05 0.03 0.01 偶见 80.60 单体解离度 88.57 91.31 91.43 79.69 59.93 69.29 63.94 99.08 表 3 辅助捕收剂用量条件试验结果

Table 3. Results of conditional test on the amount of auxiliary collector

辅助捕收剂用量/(g·t−1) 产品 产率/% S品位/% S回收率/% 粗选:10

扫Ⅰ:5

扫Ⅱ:2.5硫粗精矿 3.19 23.25 84.63 中矿1 2.64 1.64 4.94 尾矿 94.17 0.097 10.43 给矿 100.00 0.87 100.00 粗选:20

扫Ⅰ:10

扫Ⅱ:5硫粗精矿 3.25 24.53 88.77 中矿1 1.34 3.46 5.18 尾矿 95.40 0.057 6.05 给矿 100.00 0.88 100.00 粗选:30

扫Ⅰ:15

扫Ⅱ:7.5硫粗精矿 3.95 20.89 92.30 中矿1 1.44 2.21 3.57 尾矿 94.61 0.039 4.13 给矿 100.00 0.88 100.00 粗选:40

扫Ⅰ:20

扫Ⅱ:10硫粗精矿 7.03 11.67 94.37 中矿1 2.32 1.21 3.23 尾矿 90.64 0.023 2.40 给矿 100.00 0.87 100.00 表 4 抑制剂对比试验结果

Table 4. Results of conditional tests for inhibitors

抑制剂种类及用量/(g·t−1) 产品 产率/% S品位/% S回收率/% 不加抑制剂 硫精矿 43.28 29.92 61.97 中矿4 24.73 21.53 25.47 中矿3 8.00 17.37 6.66 中矿2 23.99 5.13 5.90 给矿 100.00 20.89 100.00 硫酸

精选Ⅰ:50

精选Ⅱ:40

精选Ⅲ:20硫精矿 42.08 35.97 72.60 中矿4 21.24 18.01 18.34 中矿3 7.34 12.95 4.55 中矿2 29.34 3.20 4.51 给矿 100.00 20.85 100.00 EM515

精选Ⅰ:40

精选Ⅱ:30

精选Ⅱ:20硫精矿 39.80 39.21 75.27 中矿4 25.43 13.50 16.56 中矿3 5.22 18.37 4.61 中矿2 29.56 2.50 3.56 给矿 100.00 20.83 100.00 表 5 开路浮选试验结果

Table 5. Test results of spiral gravity separation concentration

% 产品 产率 S品位 S回收率 硫精矿 1.20 39.17 54.26 中矿4 0.33 24.32 9.26 中矿3 0.75 18.55 16.06 中矿2 3.84 2.88 12.77 中矿1 3.86 0.83 3.70 尾矿 90.02 0.038 3.95 给矿 100.00 0.87 100.00 表 6 新药剂应用后与选厂当前生产的硫精矿指标对比

Table 6. Comparison of sulfur concentrate index between the application of the new agent and the current production of the concentrator

% 项目 产率 S品位 Co品位 S回收率 备注 新药剂应用后 2.00 36.37 0.36 83.53 按照9折核算 选厂当前生产 1.95 35.91 0.35 80.32 差值 0.05 0.46 0.01 3.21 表 7 本次研究与选厂当前生产的药剂用量与成本对比

Table 7. Comparison of dosage and cost between this study and the current production of the concentrator

用量/(g·t−1) 成本(元·t−1) 本次研究 选厂当前生产 本次研究 选厂当前生产 硫酸 730.00 6750.00 0.33 3.04 丁基黄药 240.00 500.00 1.92 4.00 EMC-50 52.50 0 1.42 0 2#油 0 180 0 1.44 EMP-02 55.00 0 0.22 0 EM515 120.00 0 2.37 0 合计 1197.50 7430.00 6.26 8.48 ★注:年药剂使用量与药剂成本之积除以年原矿处理量。 -

[1] 杨耀辉, 赵开乐. 攀西钒钛磁铁矿伴生钴资源回收技术研究[M]. 成都: 中国地质科学院矿产综合利用研究所, 2021.Yang Yaohui, Zhao Kaile. Study on recovery technology of associated cobalt resources of Panxi vanadium titanium magnetite [M]. Chengdu: Institute of Multipurpose Utilization of Mineral Resources, Chinese Academy of Geological Sciences, 2021. [2] Deng Jie, Zhang Yuan, Liu Feiyan. Recovery of cobalt and sulfur from the iron ore tailing of vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section), 2015,(2):30−34. (邓杰, 张渊, 刘飞燕. 钒钛磁铁矿选铁尾矿中硫钴资源综合回收研究[J]. 有色金属(选矿部分), 2015,(2):30−34.Deng Jie, Zhang Yuan, Liu Feiyan. Recovery of cobalt and sulfur from the iron ore tailing of vanadium-titanium magnetite [J]. Nonferrous Metals(Mineral Processing Section), 2015(2): 30-34. [3] Wang Hongbin, Li Jin, Zhang Guohua. Efficient recovery of ilmenite from vanadium bearing titanomagnetite in Panxi[J]. Iron Steel Vanadium Titanium, 2020,41(3):23−29. (王洪彬, 李金, 张国华. 攀西钒钛磁铁矿中钛铁矿高效回收工艺研究[J]. 钢铁钒钛, 2020,41(3):23−29. doi: 10.7513/j.issn.1004-7638.2020.03.003Wang Hongbin, Li Jin, Zhang Guohua. Efficient recovery of ilmenite from vanadium bearing titanomagnetite in Panxi [J]. Iron Steel Vanadium Titanium, 2020, 41(3): 23-29. doi: 10.7513/j.issn.1004-7638.2020.03.003 [4] Wang Hongbin. Study on efficient recovery process of fine grained ilmenite in Panxi area[J]. Iron Steel Vanadium Titanium, 2017,38(1):27−30. (王洪彬. 攀西细粒级钛铁矿高效回收工艺研究[J]. 钢铁钒钛, 2017,38(1):27−30.Wang Hongbin. Study on efficient recovery process of fine grained ilmenite in Panxi area[J]. Iron Steel Vanadium Titanium, 2017, 38(1): 27-30. [5] 戴向东. 攀枝花硫钴粗精矿精选新技术的研究[D]. 昆明: 昆明理工大学, 2001.Dai Xiangdong. Study on new technology of concentrate of cobalt sulphide crude concentrate in Panzhihua [D] . Kunming: Kunming University of Science and Technology, 2001. [6] Dong Lihui, Shi Wenyu. Study on the comprehensive recovery of sulfur and cobalt from the tailings of vanadium titanium magnetite with iron separation[J]. Technology Wind, 2018,(26):1. (董礼辉, 师文裕. 钒钛磁铁矿选铁尾矿中硫钴资源综合回收研究[J]. 科技风, 2018,(26):1.Dong Lihui, Shi Wenyu. Study on the comprehensive recovery of sulfur and cobalt from the tailings of vanadium titanium magnetite with iron separation[J]. Technology Wind, 2018(26): 1 [7] Deng Jie, Zhang Yuan, Liu Feiyan. Comprehensive utilization of primacy sulfur cobalt concentrate in west Panzhihua vanadium-titanium magnetite[J]. Modern Minging, 2014,(1):41−44. (邓杰, 张渊, 刘飞燕. 攀西钒钛磁铁矿中硫钴粗精矿综合利用研究[J]. 现代矿业, 2014,(1):41−44. doi: 10.3969/j.issn.1674-6082.2014.01.012Deng Jie, Zhang Yuan, Liu Feiyan. Comprehensive tilization of primacy sulfur cobalt concentrate in west Panzhihua vanadium-titanium magnetite[J]. Modern Minging, 2014(1): 41-44 doi: 10.3969/j.issn.1674-6082.2014.01.012 -

下载:

下载: