Investigation of multiphase transport behaviors in a FTSR mold during electromagnetic continuous casting process

-

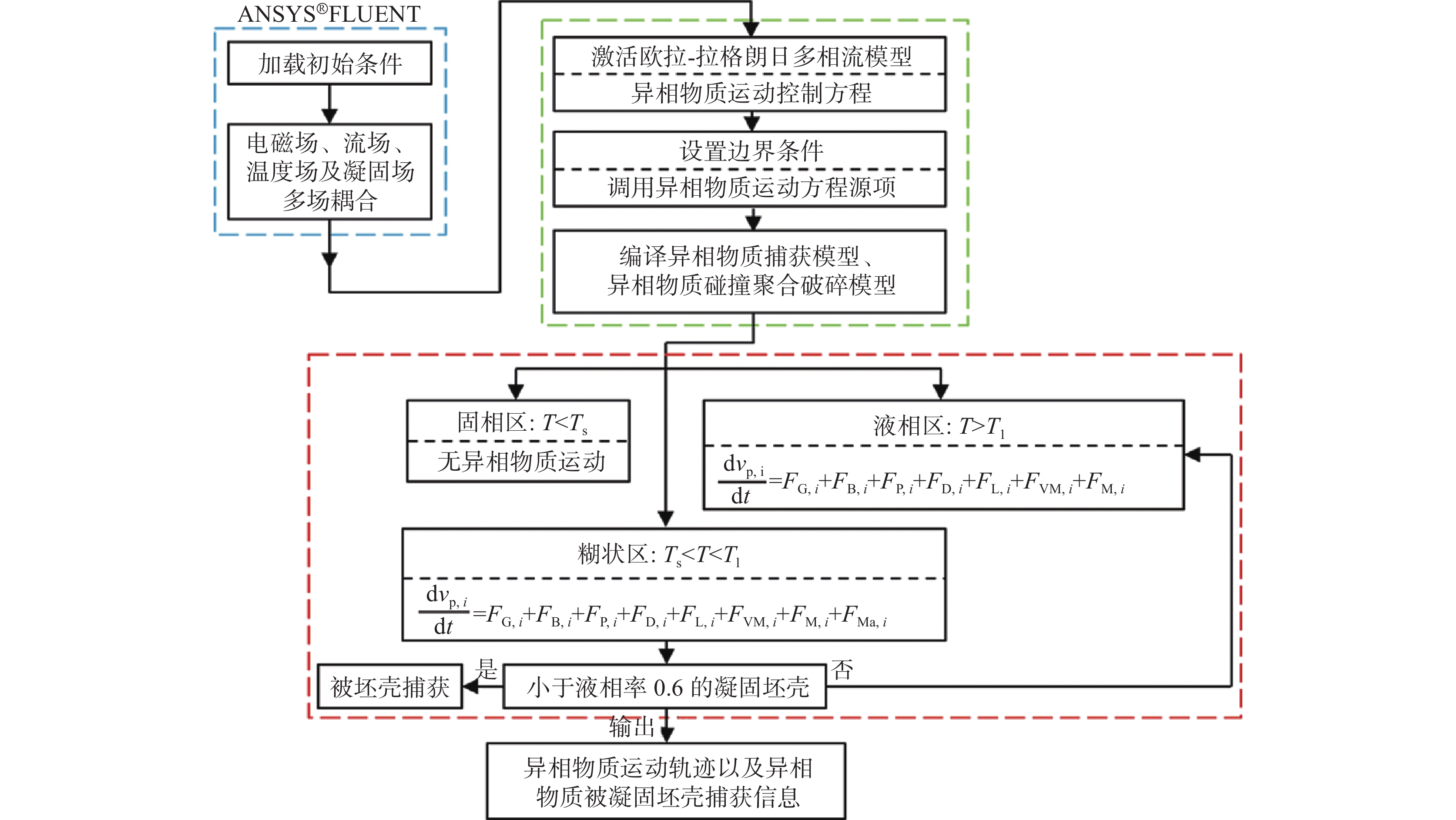

摘要: 为研究薄板坯连铸全幅一段电磁制动冶金效果,以漏斗形FTSR结晶器为研究对象,利用建立的三维多场数学模型,模拟全幅一段电磁制动作用下电磁参数变化对FTSR结晶器钢液流动、传热凝固及夹杂物迁移行为的影响。结果表明,施加全幅一段电磁制动后,结晶器内钢液温度分布的均匀性提高,钢液流股对熔池的穿透深度减小,这不仅利于下回流钢液夹带的夹杂物上浮去除,还促使上回流钢液将热量输送到弯月面区,避免弯月面处熔渣凝固而形成渣圈。此外,通过适当增加磁感应强度,可降低钢液表面流速,控制上吐出孔处液面波动。当磁感应强度达到0.3 T时,钢液表面最大流速降低至0.27 m/s,上吐出孔处液面峰值降低至7.3 mm。Abstract: For the research object of flexible thin slab rolling (FTSR) funnel-shaped mold, a three-dimensional (3-D) multi-field coupling mathematical model was established for describing the electromagnetic braking (EMBr) continuous casting process. To investigate the metallurgical effect of Ruler-EMBr device, the effects of various electromagnetic parameters on the behaviors of molten steel flow, heat transfer, solidification, and inclusions motion in the FTSR mold were discussed. The results indicate that the application of Ruler-EMBr can improve the uniformity of molten steel temperature distribution and reduce the penetration depth of downward backflow in the FTSR mold. This is beneficial to the floating removal of inclusions entrained in the downward backflow. Moreover, it is also conducive to the upward backflow to transport more heat to the meniscus region, avoiding slag solidification and slag rim formation. The parametric study also shows that the molten steel surface velocity can be reduced and the surface fluctuation at the upper ports of submerged entry nozzle (SEN) can be controlled with the increase of magnetic flux density appropriately. When the magnetic flux density reaches to 0.3 T, the maximum molten steel surface velocity decreases to 0.27 m/s, and the surface peak value at the upper ports of SEN decreases to 7.3 mm.

-

表 1 FTSR结晶器计算参数

Table 1. Computational parameters of FTSR mold

结晶器尺寸/

mm × mm结晶器长度/mm 结晶器计算域/mm 漏斗最大

开度/mm漏斗区长度/mm 水口浸入深度/mm 拉坯速度/(m∙min‒1) 1500 × 70 1200 4000 165 1200 225 4.5 钢液密度/(kg∙m‒3) 钢液黏度/(Pa∙s) 钢液电导率/(S∙m‒1) 磁感应强度/T 固相线温度/K 液相线温度/K 过热度/K 7020 0.0062 7.14 × 105 0.15、0.2、0.3、0.5 1763 1 803 25 导热系数/(W∙m‒1∙K‒1) 比热容/(J∙kg‒1∙K‒1) 凝固潜热/(kJ∙kg‒1) 热扩散系数/K‒1 夹杂物比热容/(J∙kg‒1∙K‒1) 夹杂物密度/(kg∙m‒3) 夹杂物粒径/μm 27[3] 700[3] 272[3] 0.0001[25] 860 5000[24] 50 表 2 FTSR结晶器不同网格节点数的误差统计结果

Table 2. Statistic results of error with different grid node numbers in the FTSR mold

网格 网格节点数 $ {{{T}}_{{{{M}}_{{i}}}}} $/mm $ {\delta _{{T}}} = {{\left| {{{{T}}_{{{{M}}_{{i}}}}} - {{{T}}_{{{{M}}_1}}}} \right|} \mathord{\left/ {\vphantom {{\left| {{{\text{T}}_{{{\text{M}}_{\text{i}}}}} - {{\text{T}}_{{{\text{M}}_1}}}} \right|} {{{\text{T}}_{{{\text{M}}_1}}}}}} \right. } {{{{T}}_{{{{M}}_1}}}}} $ M1 540,000 12.64 0 M2 860,000 12.56 0.63% M3 1300,000 12.51 1.03% -

[1] Yang Yadi, Zhao Jing, Cui Jianzheng. Numerical simulation on interfacial behavior and mixing phenomena in three-phase argon-stirred ladles[J]. Iron Steel Vanadium Titanium, 2021,42(5):138−148. (杨亚迪, 赵晶, 崔剑征. 三相氩气搅拌钢包内界面行为及混合现象的数值模拟[J]. 钢铁钒钛, 2021,42(5):138−148. doi: 10.7513/j.issn.1004-7638.2021.05.022Yang Yadi, Zhao Jing, Cui Jianzheng. Numerical simulation on interfacial behavior and mixing phenomena in three-phase argon-stirred ladles[J]. Iron Steel Vanadium Titanium, 2021, 42(5): 138-148. doi: 10.7513/j.issn.1004-7638.2021.05.022 [2] Vakhrushev A, Wu M, Ludwig A, et al. Numerical investigation of shell formation in thin slab casting of funnel-type mold[J]. Metall. Mater. Trans. B, 2014,45(3):1024−1037. doi: 10.1007/s11663-014-0030-2 [3] Liu H, Yang C, Zhang H, et al. Numerical simulation of fluid flow and thermal characteristics of thin slab in the funnel-type molds of two casters[J]. ISIJ Int., 2011,51(3):392−401. doi: 10.2355/isijinternational.51.392 [4] Zhang L S, Zhang X F, Wang B, et al. Numerical analysis of the influences of operational parameters on the braking effect of EMBr in a CSP funnel-type mold[J]. Metall. Mater. Trans. B, 2014,45(1):295−306. doi: 10.1007/s11663-013-9948-z [5] Tian X Y, Li B W, He J C. Electromagnetic brake effects on the funnel shape mold of a thin slab caster based on a new type magnet[J]. Metall. Mater. Trans. B, 2009,40(4):596−604. doi: 10.1007/s11663-009-9246-y [6] Thunman M, Eckert S, Hennig O. Study on the formation of open-eye and slag entrainment in gas stirred ladle[J]. Steel Res. Int., 2007,78(12):849−856. doi: 10.1002/srin.200706297 [7] Hwang Y S, Cha P R, Nam H S, et al. Numerical analysis of the influences of operational parameters on the fluid flow and meniscus shape in slab caster with EMBr[J]. ISIJ Int., 1997,37(7):659−667. doi: 10.2355/isijinternational.37.659 [8] Zhu Miaoyong, Cai Zhaozhen. Heat transfer behavior and homogenous solidification control for high-speed continuous casting slab mold[J]. Chinese Journal of Engineering, 2022,44(4):703−711. (朱苗勇, 蔡兆镇. 高速连铸结晶器内凝固传热行为及其均匀性控制[J]. 工程科学学报, 2022,44(4):703−711. doi: 10.3321/j.issn.1001-053X.2022.4.bjkjdxxb202204021Zhu Miaoyong, Cai Zhaozhen. Heat transfer behavior and homogenous solidification control for high-speed continuous casting slab mold[J]. Chinese Journal of Engineering, 2022, 44(4): 703-711. doi: 10.3321/j.issn.1001-053X.2022.4.bjkjdxxb202204021 [9] Zhu Miaoyong. Some considerations for new generation of high-efficiency continuous casting technology development[J]. Iron and Steel, 2019,54(8):21−36. (朱苗勇. 新一代高效连铸技术发展思考[J]. 钢铁, 2019,54(8):21−36. doi: 10.13228/j.boyuan.issn0449-749x.20190213Zhu Miaoyong. Some considerations for new generation of high-efficiency continuous casting technology development[J]. Iron and steel, 2019, 54(8): 21-36. doi: 10.13228/j.boyuan.issn0449-749x.20190213 [10] Liu Z, Vakhrushev A, Wu M, et al. Effect of an electrically-conducting wall on transient magnetohydrodynamic flow in a continuous-casting mold with an electromagnetic brake[J]. Metals, 2018,8(8):609−623. doi: 10.3390/met8080609 [11] Schurmann D, Glavinic´ I, Willers B, et al. Impact of the electromagnetic brake position on the flow structure in a slab continuous casting mold: An experimental parameter study[J]. Metall. Mater. Trans. B, 2020,51(1):61−78. doi: 10.1007/s11663-019-01721-x [12] Wang Y F, Zhang L F. Fluid flow-related transport phenomena in steel slab continuous casting strands under electromagnetic brake[J]. Metall. Mater. Trans. B, 2011,42(6):1319−1351. doi: 10.1007/s11663-011-9554-x [13] Jin K, Vanka S P, Thomas B G. Large eddy simulations of the effects of EMBr and SEN submergence depth on turbulent flow in the mold region of a steel caster[J]. Metall. Mater. Trans. B, 2017,48(1):162−178. doi: 10.1007/s11663-016-0801-z [14] Sarkar S, Singh V, Ajmani S K, et al. Effect of double ruler magnetic field in controlling meniscus flow and turbulence intensity distribution in continuous slab casting mold[J]. ISIJ Int., 2016,56(12):2181−2190. doi: 10.2355/isijinternational.ISIJINT-2016-313 [15] Thomas B G, Singh R, Vanka S P, et al. Effect of single-ruler electromagnetic braking (EMBr) location on transient flow in continuous casting[J]. JMSP, 2015,15(1):93−104. [16] Yin Y B, Zhang J M. Mathematical modeling on transient multiphase flow and slag entrainment in continuously casting mold with double-ruler EMBr through LES+VOF+DPM method[J]. ISIJ Int., 2021,61(3):853−864. doi: 10.2355/isijinternational.ISIJINT-2020-592 [17] Sarkar S, Singh V, Ajmani S K, et al. Effect of argon injection in meniscus flow and turbulence intensity distribution in continuous slab casting mold under the influence of double ruler magnetic field[J]. ISIJ Int., 2018,58(1):68−77. doi: 10.2355/isijinternational.ISIJINT-2017-448 [18] Hernandez S G, Guzman C H G, Davila R M, et al. Modeling study of EMBr effects on the detrimental dynamic distortion phenomenon in a funnel thin slab mold[J]. Crystals, 2020,10(11):958−976. doi: 10.3390/cryst10110958 [19] Li Z, Zhang L T, Ma D Z, et al. A narrative review: the electromagnetic field arrangement and the “braking” effect of electromagnetic brake (EMBr) technique in slab continuous casting[J]. Metall Res Technol., 2021,118(2):218−234. doi: 10.1051/metal/2021016 [20] Cai Zhaozhen, Zhu Miaoyong. Simulation of thermal behavior during steel solidification in slab continuous casting mold[J]. Acta Metallurgica Sinica, 2011,47(6):678−687. (蔡兆镇, 朱苗勇. 板坯连铸结晶器内钢凝固过程热行为研究[J]. 金属学报, 2011,47(6):678−687.Cai Zhaozhen, Zhu Miaoyong. Simulation of thermal behavior during steel solidification in slab continuous casting mold[J]. Acta Metallurgica Sinica, 2011, 47(6): 678-687. [21] Gong Jiarui, Liu Zhongqiu, Wu Yingdong, et al. Transient movement and capture behavior of dispersed argon bubbles in continuous casting mold[J]. Journal of Iron and Steel Research, 2022,34(5):461−469. (宫佳睿, 刘中秋, 吴颖东, 等. 连铸结晶器内弥散氩气泡的瞬态运动和捕捉行为[J]. 钢铁研究学报, 2022,34(5):461−469.Gong Jiarui, Liu Zhongqiu, Wu Yingdong, et al. Transient movement and capture behavior of dispersed argon bubbles in continuous casting mold[J]. Journal of Iron and Steel Research, 2022, 34(5): 461-469. [22] Tian Guichang, Ji Chenxi, Gao Rongzheng, et al. Physical simulation of influence of mold nozzle structure on mold flux entrapment[J]. Steelmaking, 2021,37(6):38−44,58. (田贵昌, 季晨曦, 高荣正, 等. 连铸结晶器内水口结构对卷渣行为影响的物理模拟[J]. 炼钢, 2021,37(6):38−44,58.Tian Guichang, Ji Chenxi, Gao Rongzheng, et al. Physical simulation of influence of mold nozzle structure on mold flux entrapment[J]. Steelmaking, 2021, 37(6): 38-44, 58. [23] Deok K, Woo K, Kee C. Numerical simulation of the coupled turbulent flow and macroscopic solidification in continuous casting with electromagnetic brake[J]. ISIJ Int., 2000,40(7):670−676. doi: 10.2355/isijinternational.40.670 [24] 刘中秋. 连铸结晶器内多相非均匀传递机制的多尺度模拟[D]. 沈阳: 东北大学, 2015.Liu Zhongqiu. Multi-scale modeling of multiphase and inhomogeneous transmission mechanisms in continuous casting mold [D]. Shenyang: Northeastern University, 2015. [25] Aboutalebi M, Hasan M, Guthrie R. Coupled turbulent flow, heat, and solute transport in continuous casting processes[J]. Metall. Mater. Trans. B, 1995,26(4):731−744. doi: 10.1007/BF02651719 [26] Lait J, Brimacombe J, Weinberg F. Mathematical modeling of heat flow in the continuous casting of steel[J]. Ironmaking & Steelmaking, 1974,1(2):90−97. [27] Xu L, Wang E, Karcher C, et al. Numerical simulation of the effects of horizontal and vertical EMBr on jet flow and mold level fluctuation in continuous casting[J]. Metall. Mater. Trans. B, 2018,49(5):2779−2793. doi: 10.1007/s11663-018-1342-4 -

下载:

下载: