Research on microstructure evolution of GH5188 alloy during plastic processing

-

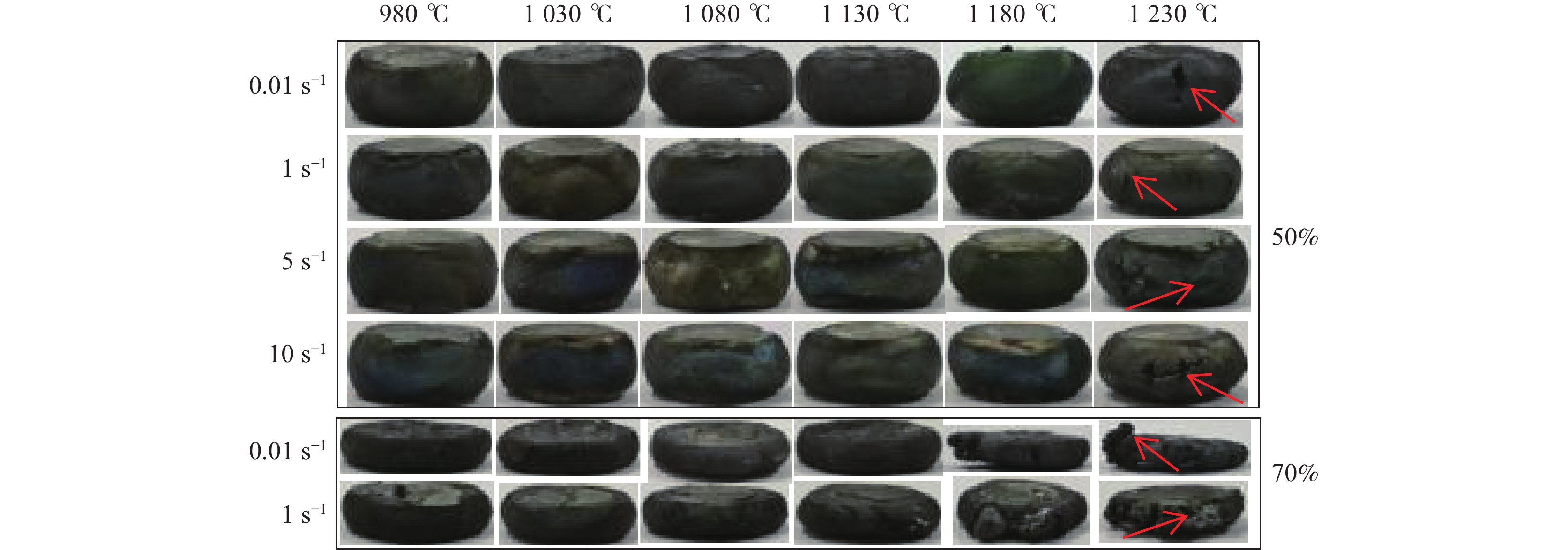

摘要: 利用Gleeble-3800热模拟试验机对GH5188高温合金进行了热变形行为及组织传递规律研究,在等温压缩试验中,获得了变形温度在980~1230 ℃,应变速率0.01~10 s−1,变形量10%~70%范围内GH5188高温合金的应力值,探究了不同温度和应变速率条件下的应力变化规律,建立了GH5188合金的本构关系模型,提出了优化的锻造工艺参数。结果表明,变形温度越高,流变应力越低,应变速率越大,流变应力越大;合金变形量不超过70%,锻造温度不超过1230 ℃,在1080~1180 ℃温度区间进行多次镦拔时,能够实现铸态组织的破碎细化;随着变形量的增加,在保温过程中合金更容易达到完全再结晶状态,且晶粒尺寸细化,然而,在持续保温过程中,晶粒尺寸则会逐渐长大。Abstract: The Gleeble-3800 thermal simulation testing machine was used to investigate the thermal deformation behavior and structure transfer law of GH5188 superalloy. In the isothermal compression test, the relevant data of stress in the range of deformation temperature of 980~1230 ℃, strain rate of 0.01~10 s−1, and the deformation amount of 10%~70% was obtained. And the effect of different temperatures and rates on the stress of GH5188 superalloywas discussed. Furthermore, the constitutive relation model of GH5188 alloy was established, and the optimized forging process parameters were proposed. Deformation behaviors show that the flow stress decrease with the increase of deformation temperature, but increase with the increase of flow stress. Microstructural observation indicates that the as-cast structure can be broken and refined when the deformation of the alloy does not exceed 70% and the forging temperature exceed 1230 ℃. When the upsetting is performed multiple times in the temperature range of 1080~1180 ℃, it is easier for the alloy to reach a fully recrystallized state and the recrystallized grain size refines during the heat preservation process as the amount of deformation increases, while the size of recrystallized grains will grow significantly as the holding time increases.

-

图 4 不同变量之间的线性拟合

Figure 4. Linear fit plot between different variables

(a)$ \mathrm{ln}\dot{\epsilon } $-$ \mathrm{ln}\sigma $;(b)$ \mathrm{ln}\dot{\epsilon } $-$ \mathrm{\sigma } $;(c)$ \mathrm{ln}\dot{\epsilon } $-$ \mathrm{ln}\left[\mathrm{sinh}\left(\alpha \sigma \right)\right] $;(d)$ \mathrm{ln}\left[\mathrm{sinh}\left(\alpha \sigma \right)\right] $-T−1

图 7 GH5188合金单道次变形20%和40%保温不同时间的显微组织

Figure 7. Microstructure of GH5188 alloy deformed in a single pass with 20% and 40% reduction and held for different time

(a) 1 180 ℃-0.1 s−1-20%-0 s ; (b)1 180 ℃-0.1 s−1-20%-30 s ;(c)1 180 ℃-0.1 s−1-20%-60 s ; (d)1 180 ℃-0.1 s−1-20%-5 min ; (e)1 180 ℃-0.1 s−1-40%-0 s ; (f)1 180 ℃-0.1 s−1-40%-30 s ; (g)1 180 ℃-0.1 s−1-40%-60 s ; (h)1 180 ℃-0.1 s−1-40%-5 min

表 1 GH5188棒材化学成分

Table 1. Chemical composition of GH5188 superalloy bar

% C Cr Ni Co W Fe B La Mn Si P S Al Bi Pb Ti 0.078 21.023 21.447 余量 13~16 0.497 0.0029 <0.4 0.837 0.430 0.0070 <0.001 0.054 <0.001 <0.005 0.012 -

[1] Shao Weidong, Tong Chaoshan, Zhuang Wei. Composition design, microstructure and properties of new cobalt-based superalloy[J]. Mechanical Engineering Materials, 2005,29(9):41-44. (邵卫东, 童潮山, 庄伟. 新型钴基高温合金成分设计及其组织与性能[J]. 机械工程材料, 2005,29(9):41-44.Shao Weidong, Tong Chaoshan, Zhuang Wei. Composition design, microstructure and properties of new cobalt-based superalloy[J]. Mechanical Engineering Materials, 2005, 29(9): 4. [2] Wang Zhongyuan, Zhang Weiqiang, Xin Xin, et al. Microstructure and homogenization process of GH188 alloy[J]. Journal of Shenyang University of Science and Technology, 2011,30(6):12-16. (王中原, 张伟强, 信昕, 等. GH188合金的微观组织和均匀化工艺[J]. 沈阳理工大学学报, 2011,30(6):12-16.Wang Zhongyuan, Zhang Weiqiang, Xin Xin, et al. Microstructure and homogenization process of GH188 alloy[J]. Journal of Shenyang University of Science and Technology, 2011, 30(6): 5. [3] Dong Yunpeng, Wang Chaoyuan, Song Xiaojun, et al. Research on rheological behavior of GH5188 alloy[J]. Forging Technology, 2013,38(6):116-121. (东赟鹏, 王超渊, 宋晓俊, 等. GH5188合金流变行为研究[J]. 锻压技术, 2013,38(6):116-121.Dong Yunpeng, Wang Chaoyuan, Song Xiaojun, et al. Research on rheological behavior of GH5188 alloy [J]. Forging Technology, 2013, 38(6): 16. [4] Yao Zhihao, Dong Jianxin, Zhang Maicang. Microstructure control and prediction during hot deformation of GH738 superalloy II. Validation and application of microstructure evolution model[J]. Acta Metallurgical Sinica, 2011,47(12):1581-1590. (姚志浩, 董建新, 张麦仓. GH738高温合金热变形过程显微组织控制与预测 II. 组织演化模型验证与应用[J]. 金属学报, 2011,47(12):1581-1590.Yao Zhihao, Dong Jianxin, Zhang Maicang. Microstructure control and prediction during hot deformation of GH738 superalloy II. Validation and application of microstructure evolution model[J]. Acta Metallurgical Sinica, 2011, 47(12): 10. [5] Yuan Zhizhong, Cui Shugang, Luo Rui, et al. High-temperature constitutive model and microstructure evolution of 57Ni-22Cr-14W-2Mo superalloy[J]. Chinese Journal of Plasticity Engineering, 2020,(11):151−158. (袁志钟, 崔树刚, 罗锐, 等. 57Ni-22Cr-14W-2Mo高温合金的高温本构模型及微观组织演化[J]. 塑性工程学报, 2020,(11):151−158. doi: 10.3969/j.issn.1007-2012.2020.11.023Yuan Zhizhong, Cui Shugang, Luo Rui, et al. High-temperature constitutive model and microstructure evolution of 57 Ni-22 Cr-14 W-2 Mo superalloy[J]. Chinese Journal of Plasticity Engineering, 2020, (11): 151-158 doi: 10.3969/j.issn.1007-2012.2020.11.023 [6] Zhou Haiping, Zhang Hongbin, Liu Jie, et al. Prediction of hot deformation flow stress of nickel-based superalloy based on dynamic recrystallization kinetic equation (English)[J]. Rare Metal Materials and Engineering, 2018,(11):3329−3337. (周海萍, 张弘斌, 刘杰, 等. 基于动态再结晶动力学方程的镍基高温合金热变形流变应力预测(英文)[J]. 稀有金属材料与工程, 2018,(11):3329−3337.Zhou Haiping, Zhang Hongbin, Liu Jie, et al. Prediction of hot deformation flow stress of nickel-based superalloy based on dynamic recrystallization kinetic equation (English) [J]. Rare Metal Materials and Engineering, 2018, (11): 3329-3337. [7] Yang Qingbo, Deng Yanjun, Yang Mou, et al. The effect of Al3Zr particles on the hot deformation behavior and processing map of AlCuLi-based alloys at high temperatures[J]. The Chinese Journal of Nonferrous Metals:English Edition, 2020,30(4):872-882. (杨庆波, 邓燕君, 杨谋, 等. 高温下Al3Zr颗粒对AlCuLi基合金的热变形行为以及加工图的影响[J]. 中国有色金属学报:英文版, 2020,30(4):872-882.Yang Qingbo, Deng Yanjun, Yang Mou, et al. The effect of Al3 Zr particles on the hot deformation behavior and processing map of AlCuLi-based alloys at high temperatures[J]. The Chinese Journal of Nonferrous Metals: English Edition, 2020, 30(4): 11. [8] Kong Yonghua, Chang Pengpeng, Li Qian, et al. Hot deformation characteristics and processing map of nickel-based C276 superalloy[J]. Journal of Alloys & Compounds, 2015,622:738−744. [9] Zhang Dongxu, Wen Zhixun, Yue Zhufeng. Research on hot deformation behavior and constitutive model of GH3230 superalloy[J]. Rare Metals, 2014,(6):986−992. (张冬旭, 温志勋, 岳珠峰. GH3230高温合金热变形行为及本构模型研究[J]. 稀有金属, 2014,(6):986−992. doi: 10.13373/j.cnki.cjrm.2014.06.008Zhang Dongxu, Wen Zhixun, Yue Zhufeng. Research on hot deformation behavior and constitutive model of GH3230 superalloy[J]. Rare Metals, 2014, (6): 986-992 doi: 10.13373/j.cnki.cjrm.2014.06.008 [10] Li Sha, Miao Huajun, Jin Xianzhe, et al. Research on hot deformation behavior and microstructure evolution of new nickel-based superalloy GH4700[J]. Casting Technology, 2013,34(8):953-957. (李莎, 苗华军, 金宪哲, 等. 新型镍基高温合金GH4700热变形行为及组织演变研究[J]. 铸造技术, 2013,34(8):953-957.Li Sha, Miao Huajun, Jin Xianzhe, et al. Research on hot deformation behavior and microstructure evolution of new nickel-based superalloy GH4700 [J]. Casting Technology, 2013, 34(8): 5. [11] Li Fulin, Fu Rui, Feng Di, et al. Study on hot deformation behavior of nickel-based wrought superalloy CDS&W FGH96[J]. Rare Metals, 2015,39(3):201-206. (李福林, 付锐, 冯涤, 等. 镍基变形高温合金CDS&W FGH96热变形行为研究[J]. 稀有金属, 2015,39(3):201-206.Li Fulin, Fu Rui, Feng Di, et al. Study on hot deformation behavior of nickel-based wrought superalloy CDS&W FGH96 [J]. Rare Metals, 2015, 39(3): 6. [12] Wu Zhigang, Li Defu, Guo Shengli, et al. Effect of deformation conditions on dynamic recrystallization of GH625 alloy under high temperature deformation[J]. Rare Metals, 2010, 34,(6):833-838. (吾志岗, 李德富, 郭胜利, 等. 变形条件对GH625合金高温变形动态再结晶的影响[J]. 稀有金属, 2010, 34,(6):833-838.Wu Zhigang, Li Defu, Guo Shengli, et al. Effect of deformation conditions on dynamic recrystallization of GH625 alloy under high temperature deformation [J]. Rare Metals, 2010(6): 6. [13] Wang Zhongtang, Deng Yonggang, Zhang Shihong. Critical conditions for dynamic recrystallization of superalloy Inconel 690 based on work hardening rate[J]. Journal of Materials Heat Treatment, 2014,35(7):193−197. (王忠堂, 邓永刚, 张士宏. 基于加工硬化率的高温合金Inconel 690动态再结晶临界条件[J]. 材料热处理学报, 2014,35(7):193−197.Wang Zhongtang, Deng Yonggang, Zhang Shihong. Critical conditions for dynamic recrystallization of superalloy Inconel 690 based on work hardening rate[J]. Journal of Materials Heat Treatment, 2014(7): 5. [14] Guo Shengli, Li Defu, Pen Haijia, et al. Hot deformation and processing maps of Inconel 690 superalloy[J]. Journal of Nuclear Materials, 2011,410(1-3):52−58. doi: 10.1016/j.jnucmat.2010.12.309 [15] Chen Xiaomin, Wen Dongxu. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation-science direct[J]. Materials & Design, 2014,57(5):568−577. [16] Wu Kai, Liu Guoquan, Hu Benfu, et al. Hot compressive deformation behavior of a new hot isostatically pressed Ni–Cr–Co based powder metallurgy superalloy[J]. Materials & Design, 2011,32(4):1872−1879. -

下载:

下载: