| [1] |

Ma Liyuan, Wang Zengwu, Fan Jing, et al. Summary of《China cardiovascular health and disease report 2021》[J]. Chinese Journal of Interventional Cardiology, 2022,30(7):487−496. (马丽媛, 王增武, 樊静, 等. 中国心血管健康与疾病报告2021概要[J]. 中国介入心脏病学杂志, 2022,30(7):487−496.Ma Liyuan, Wang Zengwu, Fan Jing, et al. Summary of《China cardiovascular health and disease report 2021》[J]. Chinese Journal of Interventional Cardiology, 2022, 30(7): 487-496

|

| [2] |

Daemen J, Boersma E, Flather M, et al. Long-term safety and efficacy of percutaneous coronary intervention with stenting and coronary artery bypass surgery for multivessel coronary artery disease: a meta-analysis with 5-year patient-level data from the ARTS, ERACI-II, MASS-II, and SoS trials[J]. Circulation, 2008,118(11):1146−1154. doi: 10.1161/circulationaha.107.752147

|

| [3] |

Serruys P W, Jaegere P D, Kiemeneij F, et al. A Comparison of balloon-expandable-stent implantation with balloon angioplasty in patients with coronary artery disease[J]. New England Journal of Medicine, 1994, 331: 489 - 495.

|

| [4] |

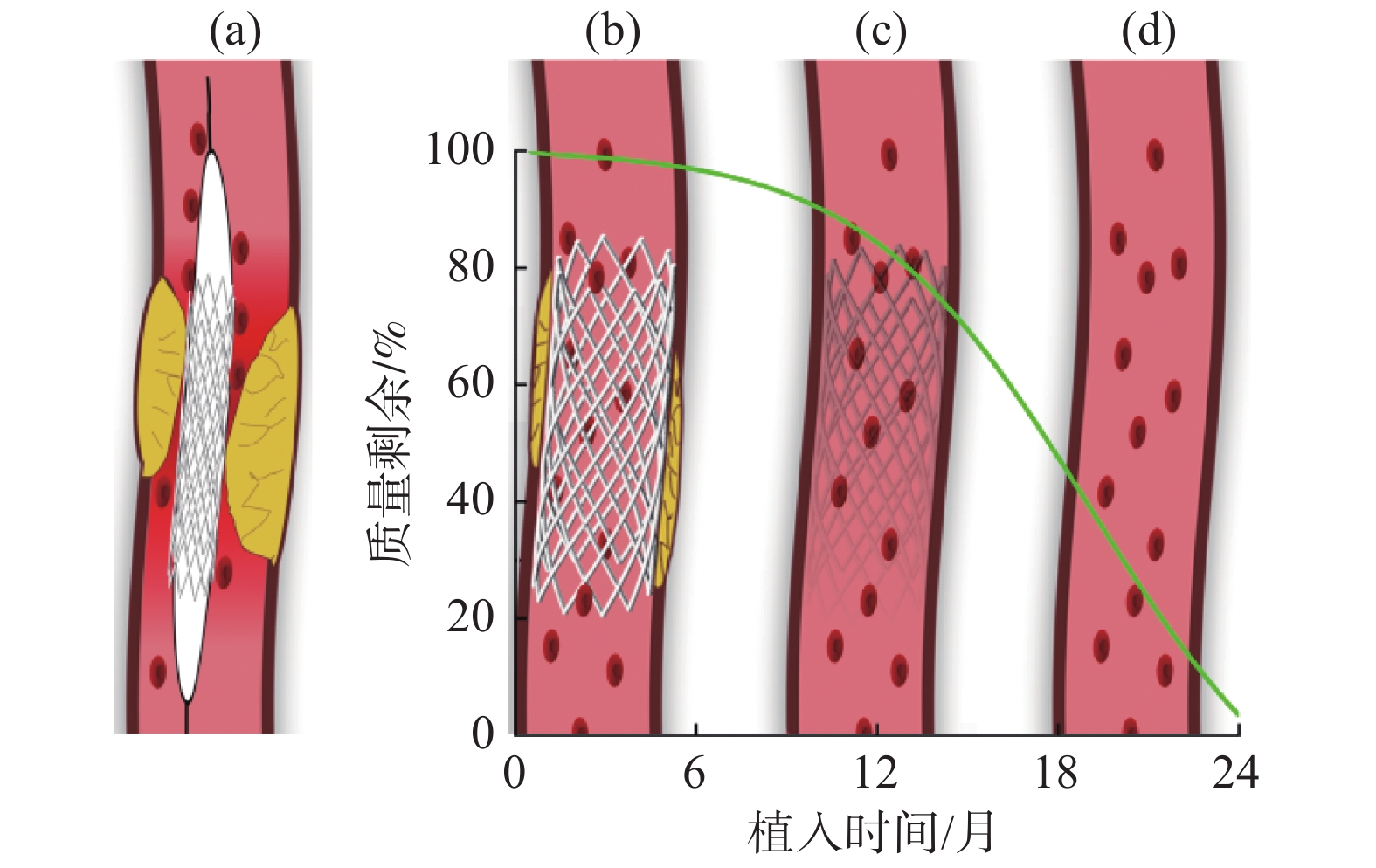

Onuma Y, Serruys P W. Bioresorbable scaffold: the advent of a new era in percutaneous coronary and peripheral revascularization[J]. Circulation, 2011,123(7):779−797. doi: 10.1161/CIRCULATIONAHA.110.971606

|

| [5] |

Zheng Y F, Gu X N, Witte F. Biodegradable metals[J]. Materials Science and Engineering, 2014,77:1−34. doi: 10.1016/j.mser.2014.01.001

|

| [6] |

Loffredo S, Hermawan H, Vedani M, et al. 20 - Absorbable metals for cardiovascular applications[M]. Niinomi M, ed. Metals for Biomedical Devices (Second Edition). Woodhead Publishing, 2019: 523-543.

|

| [7] |

Liu Y, Zheng Y F, Chen X H, et al. Fundamental theory of biodegradable metals—definition, criteria, and design[J]. Advanced Functional Materials, 2019,29(18):1805402. doi: 10.1002/adfm.201805402

|

| [8] |

Chen Q Z, Thouas G A. Metallic implant biomaterials[J]. Materials Science and Engineering, 2015,87:1−57. doi: 10.1016/j.mser.2014.10.001

|

| [9] |

Underwood E J. Trace elements in human and animal nutrition[J]. Soil Science, 1963, 95(4): 287.

|

| [10] |

Schinhammer M, Hanzi A C, Loffler J F, et al. Design strategy for biodegradable Fe-based alloys for medical applications[J]. Acta Biomaterialia, 2010,6(5):1705−1713. doi: 10.1016/j.actbio.2009.07.039

|

| [11] |

Peuster M, Wohlsein P, Brügmann M, et al. A novel approach to temporary stenting: Degradable cardiovascular stents produced from corrodible metal - Results 6-18 months after implantation into New Zealand white rabbits[J]. Heart, 2001,86(5):563−569. doi: 10.1136/heart.86.5.563

|

| [12] |

Peuster M, Hesse C, Schloo T, et al. Long-term biocompatibility of a corrodible peripheral iron stent in the porcine descending aorta[J]. Biomaterials, 2006,27(28):4955−4962. doi: 10.1016/j.biomaterials.2006.05.029

|

| [13] |

Ron W, Rajbabu P, Richard B, et al. Short-term effects of biocorrodible iron stents in porcine coronary arteries[J]. Journal of Interventional Cardiology, 2008,21(1):15−20. doi: 10.1111/j.1540-8183.2007.00319.x

|

| [14] |

Obayi C S, Tolouei R, Mostavan A, et al. Effect of grain sizes on mechanical properties and biodegradation behavior of pure iron for cardiovascular stent application[J]. Biomatter, 2016,6(1):959874. doi: 10.4161/21592527.2014.959874

|

| [15] |

Moravej M, Purnama A, Fiset M, et al. Electroformed pure iron as a new biomaterial for degradable stents: In vitro degradation and preliminary cell viability studies[J]. Acta Biomaterialia, 2010,6(5):1843−1851. doi: 10.1016/j.actbio.2010.01.008

|

| [16] |

Qi Y, Li X, He Y, et al. Mechanism of acceleration of iron corrosion by a polylactide coating[J]. ACS Applied Materials & Interfaces, 2019,11(1):202−218. doi: 10.1021/acsami.8b17125

|

| [17] |

Gorejova R, Orinakova R, Macko J, et al. Electrochemical behavior, biocompatibility and mechanical performance of biodegradable iron with PEI coating[J]. Journal of Biomedical Materals Research Part A, 2022,110(3):659−671. doi: 10.1002/jbm.a.37318

|

| [18] |

Cheng J, Huang T, Zheng Y F. Relatively uniform and accelerated degradation of pure iron coated with micro-patterned Au disc arrays[J]. Materials Science and Engineering:C, 2015,48:679−687. doi: 10.1016/j.msec.2014.12.053

|

| [19] |

Huang T, Zheng Y. Uniform and accelerated degradation of pure iron patterned by Pt disc arrays[J]. Scientific Reports, 2016,6:23627. doi: 10.1038/srep23627

|

| [20] |

Zhou J C, Yang Y Y, Alonso Frank M, et al. Accelerated degradation behavior and cytocompatibility of pure iron treated with sandblasting[J]. ACS Applied Materials & Interfaces, 2016,8(40):26482−26492. doi: 10.1021/acsami.6b07068

|

| [21] |

Bagherifard S, Molla M F, Kajanek D, et al. Accelerated biodegradation and improved mechanical performance of pure iron through surface grain refinement[J]. Acta Biomaterialia, 2019,98:88−102. doi: 10.1016/j.actbio.2019.05.033

|

| [22] |

Wang H N, Zheng Y, Li Y, et al. Improvement of in vitro corrosion and cytocompatibility of biodegradable Fe surface modified by Zn ion implantation[J]. Applied Surface Science, 2017,403:168−176. doi: 10.1016/j.apsusc.2017.01.158

|

| [23] |

Chen H Y, Zhang E L, Yang K. Microstructure, corrosion properties and bio-compatibility of calcium zinc phosphate coating on pure iron for biomedical application[J]. Materials Science and Engineering:C, 2014,34:201−206. doi: 10.1016/j.msec.2013.09.010

|

| [24] |

Zhu S, Huang N, Shu H, et al. Corrosion resistance and blood compatibility of lanthanum ion implanted pure iron by MEVVA[J]. Applied Surface Science, 2009,256(1):99−104. doi: 10.1016/j.apsusc.2009.07.082

|

| [25] |

Zhu S F, Huang N, Xu L, et al. Biocompatibility of Fe–O films synthesized by plasma immersion ion implantation and deposition[J]. Surface and Coatings Technology, 2009,203(10):1523−1529. doi: 10.1016/j.surfcoat.2008.11.033

|

| [26] |

Hermawan H, Dubé M D. Development of degradable Fe-35Mn alloy for biomedical application[J]. Advanced Materials Research, 2006,15-17:107−112. doi: 10.4028/www.scientific.net/AMR.15-17.107

|

| [27] |

Hermawan H, Purnama A, Dube D, et al. Fe-Mn alloys for metallic biodegradable stents: degradation and cell viability studies[J]. Acta Biomaterialia, 2010,6(5):1852−1860. doi: 10.1016/j.actbio.2009.11.025

|

| [28] |

Capek J, Kubasek J, Vojtech D, et al. Microstructural, mechanical, corrosion and cytotoxicity characterization of the hot forged FeMn30(%) alloy[J]. Materials Science and Engineering:C, 2016,58:900−908. doi: 10.1016/j.msec.2015.09.049

|

| [29] |

Traverson M, Heiden M, Stanciu L A, et al. In Vivo evaluation of biodegradability and biocompatibility of Fe30Mn alloy[J]. Veterinary and Comparative Orthopaedics and Traumatology, 2018,31(1):10−16. doi: 10.3415/VCOT-17-06-0080

|

| [30] |

Sotoudehbagha P, Sheibani S, Khakbiz M, et al. Novel antibacterial biodegradable Fe-Mn-Ag alloys produced by mechanical alloying[J]. Materials Science and Engineering:C, 2018,88:88−94. doi: 10.1016/j.msec.2018.03.005

|

| [31] |

Niendorf T, Brenne F, Hoyer P, et al. Processing of new materials by additive manufacturing: Iron-based alloys containing silver for biomedical applications[J]. Metallurgical and Materials Transactions A, 2015,46(7):2829−2833. doi: 10.1007/s11661-015-2932-2

|

| [32] |

Hong D, Chou D T, Velikokhatnyi O I, et al. Binder-jetting 3D printing and alloy development of new biodegradable Fe-Mn-Ca/Mg alloys[J]. Acta Biomaterialia, 2016,45:375−386. doi: 10.1016/j.actbio.2016.08.032

|

| [33] |

Xu W, Lu X, Tan L, et al. Study on properties of a novel biodegradable Fe-30Mn-1C alloy[J]. Acta Metallurgica Sinica, 2011,47(10):1342−1347. doi: 10.3724/SP.J.1037.2011.00258

|

| [34] |

Harjanto S, Pratesa Y, Suharno B, et al. Corrosion behavior of Fe-Mn-C alloy as degradable materials candidate fabricated via powder metallurgy process[J]. Advanced Materials Research, 2012: 386-389.

|

| [35] |

Liu B, Zheng Y F, Ruan L Q. In vitro investigation of Fe30Mn6Si shape memory alloy as potential biodegradable metallic material[J]. Materials Letters, 2011,65(3):540−543. doi: 10.1016/j.matlet.2010.10.068

|

| [36] |

Drevet R, Zhukova Y, Kadirov P, et al. Tunable corrosion behavior of calcium phosphate coated Fe-Mn-Si alloys for bone implant applications[J]. Metallurgical and Materials Transactions A, 2018,49(12):6553−6560. doi: 10.1007/s11661-018-4907-6

|

| [37] |

Hufenbach J, Wendrock H, Kochta F, et al. Novel biodegradable Fe-Mn-C-S alloy with superior mechanical and corrosion properties[J]. Materials Letters, 2017,186:330−333. doi: 10.1016/j.matlet.2016.10.037

|

| [38] |

Hufenbach J, Kochta F, Wendrock H, et al. S and B microalloying of biodegradable Fe-30Mn-1C - effects on microstructure, tensile properties, in vitro degradation and cytotoxicity[J]. Materials & Design, 2018,142:22−35. doi: 10.1016/j.matdes.2018.01.005

|

| [39] |

Venezuela J, Dargusch M S. Addressing the slow corrosion rate of biodegradable Fe-Mn: Current approaches and future trends[J]. Current Opinion in Solid State and Materials Science, 2020,24(3):100822. doi: 10.1016/j.cossms.2020.100822

|

| [40] |

Lin W, Zhang G, Cao P, et al. Cytotoxicity and its test methodology for a bioabsorbable nitrided iron stent[J]. Journal of Biomedical Materials Researcheh, 2015,103(4):764−776. doi: 10.1002/jbm.b.33246

|

| [41] |

Lin W, Qin L, Qi H, et al. Long-term in vivo corrosion behavior, biocompatibility and bioresorption mechanism of a bioresorbable nitrided iron scaffold[J]. Acta Biomaterialia, 2017,54:454−468. doi: 10.1016/j.actbio.2017.03.020

|

| [42] |

Wang H, Zheng Y, Liu J, et al. In vitro corrosion properties and cytocompatibility of Fe-Ga alloys as potential biodegradable metallic materials[J]. Materials Science and Engineering:C, 2017,71:60−66. doi: 10.1016/j.msec.2016.09.086

|

| [43] |

Capek J, Msallamova S, Jablonska E, et al. A novel high-strength and highly corrosive biodegradable Fe-Pd alloy: Structural, mechanical and in vitro corrosion and cytotoxicity study[J]. Materials Science and Engineering:C, 2017,79:550−562. doi: 10.1016/j.msec.2017.05.100

|

| [44] |

Mostavan A, Paternoster C, Tolouei R, et al. Effect of electrolyte composition and deposition current for Fe/Fe-P electroformed bilayers for biodegradable metallic medical applications[J]. Materials Science and Engineering:C, 2017,70(1):195−206. doi: 10.1016/j.msec.2016.08.026

|

| [45] |

Liu B, Zheng Y F. Effects of alloying elements (Mn, Co, Al, W, Sn, B, C and S) on biodegradability and in vitro biocompatibility of pure iron[J]. Acta Biomaterialia, 2011,7(3):1407−1420. doi: 10.1016/j.actbio.2010.11.001

|

| [46] |

Xu Y N, Wang W Q, Yu F, et al. Effects of pulse frequency and current density on microstructure and properties of biodegradable Fe-Zn alloy[J]. Journal of Materials Research and Technology, 2022,18:44−58. doi: 10.1016/j.jmrt.2022.02.096

|

| [47] |

Xu Y N, Wang W Q, Yu F Y, et al. The enhancement of mechanical properties and uniform degradation of electrodeposited Fe-Zn alloys by multilayered design for biodegradable stent applications[J]. Acta Biomaterialia, 2023. https://doi.org/10.1016/j.actbio.2023.02.029.

|

| [48] |

Zheng J F, Xi Z W, Li Y, et al. Long-term safety and absorption assessment of a novel bioresorbable nitrided iron scaffold in porcine coronary artery[J]. Bioactive Materials, 2022,17:496−505. doi: 10.1016/j.bioactmat.2022.01.005

|

| [49] |

Zheng J F, Qiu H, Tian Y, et al. Preclinical evaluation of a novel sirolimus-eluting iron bioresorbable coronary scaffold in porcine coronary artery at 6 months[J]. JACC:Cardiovascular Interventions, 2019,12(3):245−255. doi: 10.1016/j.jcin.2018.10.020

|

下载:

下载: