Study on deformation behavior and microstructure evolution at elevated temperatures of nickel based superalloy GH4065A

-

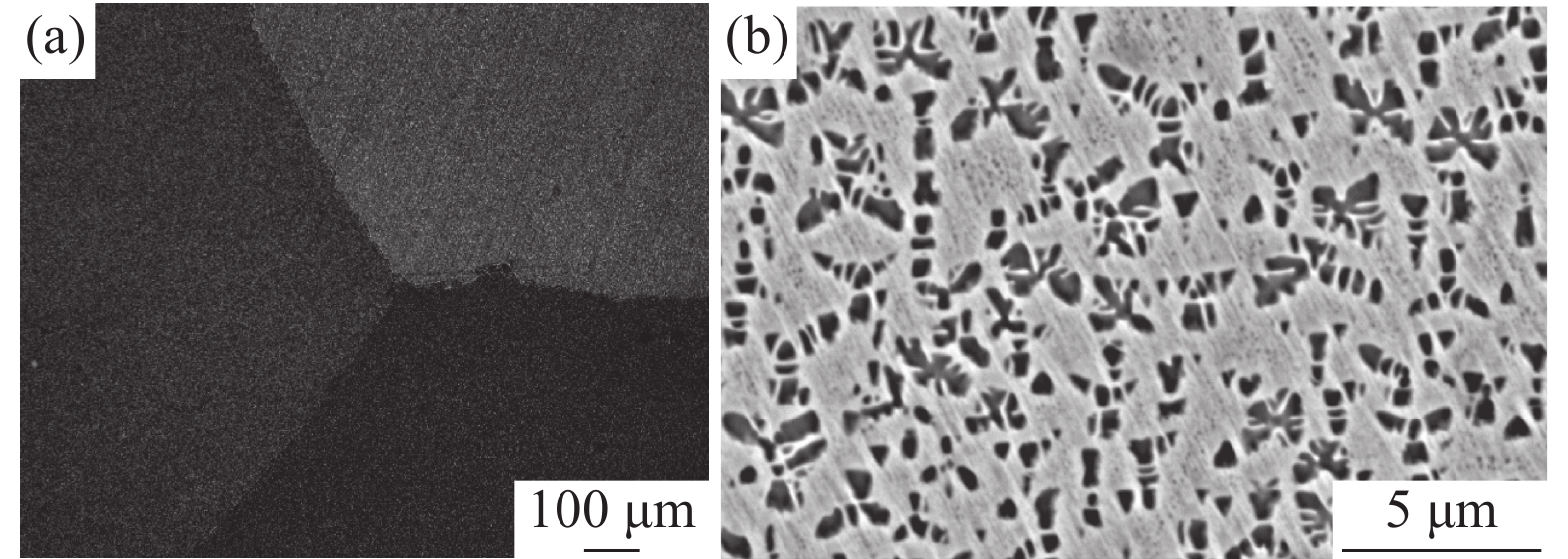

摘要: 运用热力压缩试验设备对取自工业三联工艺(VIM+ESR+VAR)铸锭并完成均匀化的GH4065A样品进行试验。结果揭示了热加工工艺参数变形温度、应变速率和工程应变量对GH4065A流变应力的影响,并通过试验数据建立起GH4065A 50%工程应变量下的本构方程。在此基础上,通过试验数据绘制了GH4065A的热加工图和失稳判据图,明确了其稳定变形的加工区间。通过对变形组织演变规律的研究,明确了γ’相析出范围、未再结晶工艺条件、部分再结晶工艺条件、完全再结晶工艺条件,并绘制了GH4065A的再结晶图。Abstract: This paper performs thermal compression studies on GH4065A samples from a sample disk that is obtained from an industrial plant and has undergone VIM+ESR+VAR and homogenization. This study reveals the impact of thermal compression parameters such as deformation temperature, strain rate and engineering strain on the flow stress of GH4065A, and constructs constitutive equations of GH4065A at the 50% engineering strain. Based on experimental data, the thermal processing map and instability criterion map of GH4065A are proposed, by which the stable processing zones of GH4065A can be identified. This paper also studies the microstructure evolution of GH4065A, and the results reveal the precipitation range of γ’ phase, non-recrystallization processing range, partial recrystallization processing range, and full recrystallization processing range of GH4065A, by which the recrystallization map is proposed.

-

表 1 GH4065A经均匀化后的自耗锭样品成分范围

Table 1. Composition range of the GH4065A sample disk from a homogenized VAR ingot

% Al Co Cr Mo Nb Ti W Fe Ni 2.19~2.20 13.40~13.49 16.17~16.27 4.10~4.18 0.695-0.752 3.53~3.69 3.61-3.68 0.21~0.22 55.73-56.12 -

[1] Heaney J A, Lasonde M L, Powell A M, et al. Development of a new cast and wrought alloy (Rene65) for high temperature disk applications[C]//Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives. USA, Pittsburgh: TMS, 2014: 67-77. [2] Bond B J , O’Brien C M, Russell J L, et al. Rene65 billet material for forged turbine components[C]//Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives. USA, Pittsburgh: TMS, 2014: 107-118. [3] Wojcik T, Rath M, Kozeschnik E. Charaterisation of secondary phases in Ni-based superalloy Rene 65[J]. Materials Science and Technology, 2018,34:1−7. [4] Zhao Guangpu, Huang Shuo, Zhang Beijiang, et al. Microstructure control and mechanical properties of the newest nickel-based wrought superally GH4065A[J]. Journal of Iron and Steel Research, 2015,27(2):40−47. (赵光普, 黄烁, 张北江, 等. 新一代镍基变形高温合金GH40654A的组织控制与力学性[J]. 钢铁研究学报, 2015,27(2):40−47.Zhao Guangpu, Huang Shuo, Zhang Beijiang, et al. Microstructure control and mechanical properties of the newest nickel-based wrought superally GH4065 A [J]. Journal of Iron and Steel Research, 2015, 27(2): 40-47. [5] Du Jinhui, Zhao Guangpu, Deng Qun, et al. Develop of wrought superalloy in China[J]. Journal of Aeronautical Materials, 2016,36(3):27−39. (杜金辉, 赵光普, 邓群, 等. 中国变形高温合金研制进展[J]. 航空材料学报, 2016,36(3):27−39.Du Jinhui, Zhao Guangpu, Deng Qun, et al. Develop of wrought superalloy in China[J]. Journal of Aeronautical Materials, 2016, 36(3): 27-39. [6] Liu Qiaomu, Huang Shunzhou, Liu Jia, et al. Progress and application of high temperature structural materials on aero-engine[J]. Gas Turbine Experiment and Research, 2014,27(4):51−56. (刘巧沐, 黄顺洲, 刘佳, 等. 高温材料研究进展及其在航空发动机上的应用[J]. 燃气涡轮试验与研究, 2014,27(4):51−56.Liu Qiaomu, Huang Shunzhou, Liu Jia, et al. Progress and application of high temperature structural materials on aero-engine[J]. Gas Turbine Experiment and Research, 2014, 27(4): 51-56. [7] Zhang Beijiang, Zhao Guangpu, Zhang Wenyun, et al. Investigation of high performance disc alloy Gh4065 and associated advanced processing technologies[J]. Acta Metallurgica Sinica, 2015,51(10):1227−1234. (张北江, 赵光普, 张文云, 等. 高性能涡轮盘材料GH4065及其先进制备技术研究[J]. 金属学报, 2015,51(10):1227−1234.Zhang Beijiang, Zhao Guangpu, Zhang Wenyun, et al. Investigation of high performance disc alloy Gh4065 and associated advanced processing technologies[J]. Acta Metallurgica Sinica, 2015, 51(10): 1227-1234. [8] Zhang Beijiang, Huang Shuo, Zhang Wenyun, et al. Recent development of nickel-based disc alloys and corresponding cast-wrought processing techniques[J]. Acta Metallurgica Sinica, 2019,55(9):1095−1114. (张北江, 黄烁, 张文云, 等. 变形高温合金盘材及其制备技术研究进展[J]. 金属学报, 2019,55(9):1095−1114.Zhang Beijiang, Huang Shuo, Zhang Wenyun, et al. Recent development of nickel-based disc alloys and corresponding cast-wrought processing techniques[J]. Acta Metallurgica Sinica, 2019, 55(9): 1095-1114. [9] Laurence A, Cormier J, Villechaise P, et al. Impact of the solution cooling rate and of thermal aging on the creep properties of the new cast & wrought rené 65 ni-based superalloy[C]//Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives. USA, Pittsburgh: TMS, 2014: 333-348. [10] Olufayo O A, Che H, Songmene V, et al. Machinability of Rene 65 superalloy[J]. Materials, 2019,12:2034. doi: 10.3390/ma12122034 [11] Huang Shuo, Zhang Beijiang, Tian Qiang, et al. Isothermal and static oxidation behavior of superalloy GH4065A[J]. Journal of Iron and Steel Research, 2016,28(7):55−60. (黄烁, 张北江, 田强, 等. 高温合金GH4065A的恒温静态氧化行为[J]. 钢铁研究学报, 2016,28(7):55−60.Huang Shuo, Zhang Beijiang, Tian Qiang, et al. Isothermal and static oxidation behavior of superalloy GH4065 A[J]. Journal of Iron and Steel Research, 2016, 28(7): 55-60. [12] Wang Zixing, Huang Shuo, Zhang Beijiang, et al. Study on freckle of a high-alloyed GH4065 nickel base wrought superalloy[J]. Acta Metallurgica Sinica, 2019,55(3):417−426. (王资兴, 黄烁, 张北江, 等. 高合金化GH4065镍基变形高温合金点状偏析研究[J]. 金属学报, 2019,55(3):417−426.Wang Zixing, Huang Shuo, Zhang Beijiang, et al. Study on freckle of a high-alloyed GH4065 nickel base wrought superalloy[J]. Acta Metallurgica Sinica, 2019, 55(3): 417-426. [13] 董建新. 镍基合金管材挤压及组织控制[M]. 北京: 冶金工业出版社, 2014: 26-37.Dong Jianxin. Extrusion and microstructure control of nickel based alloy pipe [M]. Beijing: Metallurgical Industry Press, 2014: 26-37. -

下载:

下载: