Study on the composite inclusions of MnS-Al2O3 in wheel steel

-

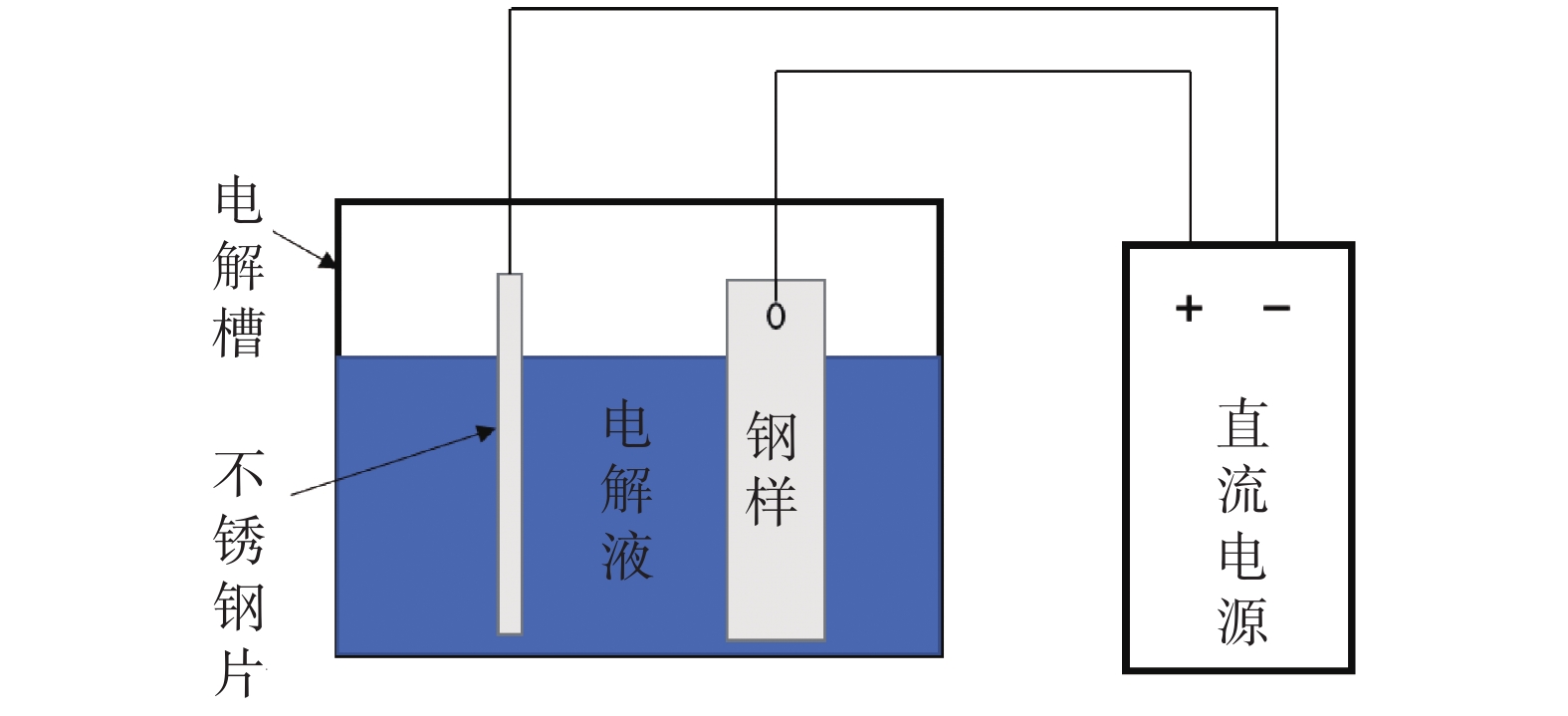

摘要: 高速车轮钢中的MnS-Al2O3复合夹杂物能够降低Al2O3夹杂物对于车轮钢疲劳性能的危害。通过检测实验室制备的车轮钢,确定了车轮钢中存在MnS夹杂物、Al2O3夹杂物和MnS-Al2O3复合夹杂物。采用酸溶法提取Al2O3夹杂物,根据XRD检测结果确定钢中Al2O3夹杂物的晶体类型为α-Al2O3。通过非水溶液电解法提取了钢中的复合夹杂物,并检测MnS-Al2O3复合夹杂物的形貌。根据钢的成分进行热力学计算,分析试验钢的固相线和液相线温度和夹杂物析出温度的关系,表明车轮钢中Al2O3夹杂物能够为MnS的析出提供形核条件。最后,通过计算MnS-Al2O3复合夹杂物界面两相的晶面错配度,说明了MnS的(100)面在Al2O3 (0001)面上可以有效形核析出。这为钢中形成MnS-Al2O3复合夹杂物,降低Al2O3夹杂物危害提供了一定的理论基础。Abstract: The composite inclusions of MnS-Al2O3 in high-speed railway wheel steel can reduce the effect of Al2O3 on fatigue properties of wheel steel. In this study, the types of inclusions in wheel steel were determined as MnS, Al2O3 and MnS-Al2O3 composite inclusions by testing wheel steel prepared in laboratory. The inclusions of Al2O3 were extracted by acid dissolution method. XRD results showed that crystal texture of Al2O3 inclusion in steel was α-Al2O3. The composite inclusion in steel was extracted by non-aqueous electrolysis method, and the morphology of MnS-Al2O3 composite inclusion was detected. Based on the thermodynamic calculation of steel composition, the relationship between the solidus and liquidus temperatures of experimental steel and the precipitation temperature of inclusions was analyzed. The results show that Al2O3 inclusions in wheel steel can provide nucleation sites for the precipitation of MnS. It was clarified that the surface of (100) of MnS can precipitate on the Al2O3 (0001) through the calculation of the mismatch between the two phases of MnS and Al2O3. This works provides a theoretical basis for the formation of MnS-Al2O3 composite inclusions in steel and the reduction of the damage of Al2O3 inclusions.

-

Key words:

- wheel steel /

- composite inclusions /

- MnS-Al2O3 /

- mismatch /

- non-aqueous electrolysis

-

表 1 试验钢主要化学成分

Table 1. Main chemical composition of experimental steel

% C Si Mn Cr S Als O 0.50 0.30 0.72 0.21 0.011 0.070 0.0017 表 2 α-Al2O3的晶格参数

Table 2. The lattice parameters of α-Al2O3

晶格参数

(三方晶系)晶格常数/nm 角度/(°) a b c α β γ Al2O3 (PDF卡片) 0.476 0.476 1.299 90 90 120 表 3 MnS和Al2O3不同晶面的错配度

Table 3. Mismatches of different crystal planes of MnS and Al2O3

Al2O3晶面 错配度 /% MnS(100) MnS(110) MnS(111) Al2O3 (0001) 0.92 18.25 20.82 Al2O3 (11−20) 17.22 24.79 10.94 Al2O3 (10−14) 6.45 16.36 20.20 -

[1] 范新光. 列车车轮滚动接触疲劳裂纹萌生及扩展研究[D]. 北京: 北京交通大学, 2019.Fan Xinguang. Research on rolling contact fatigue crack initiation and propagation of train wheels [D]. Beijing: Beijing Jiaotong University, 2019. [2] Li Wei, Cheng Shengwei, Zhang Jinwen, et al. Research on technology of preventing rims crack from railway wheel fatigue[J]. Physical Testing and Measurement, 2019,37(5):32−37. (李伟, 成生伟, 张锦文, 等. 防止铁道车轮疲劳辋裂技术探讨[J]. 物理测试, 2019,37(5):32−37.Li Wei, Cheng Shengwei, Zhang Jinwen, et al. Research on Technology of Preventing Rims Crack from Railway Wheel Fatigue [J]. Physical Testing and Measurement, 2019, 37(05): 32-37. [3] 丛韬. 铁路车轮超高周疲劳行为研究和寿命评估方法[D]. 北京:北京交通大学, 2019.Cong Tao. Research on ultra-high cycle fatigue behavior and life evaluation method of railway wheels [D].Beijing :Beijing Jiaotong University, 2019. [4] 孟炜. 诱发车轮轮辋辋裂的夹杂物临界尺寸预测[D]. 成都: 西南交通大学, 2019.Meng Wei. Prediction of critical size of inclusions induced wheel rim crack [D]. Chengdu: Southwest Jiaotong University, 2019. [5] Mi G, Nan H, Liu Y, et al. Influence of inclusion on crack initiation in wheel rim[J]. Journal of Iron and Steel Research International, 2011,18(1):49−54. doi: 10.1016/S1006-706X(11)60010-1 [6] 徐周. Mg处理对低碳微合金钢中夹杂物、组织及性能的影响[D]. 苏州: 苏州大学, 2018.Xu Zhou. Effect of Mg treatment on inclusions, microstructure and properties of low carbon microalloyed steel [D]. Suzhou: Soochow University, 2018. [7] Guo Zhenhe, Deng Liqin. Effect of magnesium and calcium treatment on inclusions and fatigue properties of wheel steel[J]. Baosteel Technology, 2016,(4):16−20. (郭振和, 邓丽琴. 镁钙处理对车轮钢中夹杂物及疲劳性能的影响[J]. 宝钢技术, 2016,(4):16−20.Guo Zhenhe, Deng Liqin. Effect of Magnesium and Calcium Treatment on Inclusions and Fatigue Properties of Wheel Steel [J]. Baosteel Technology. 2016(04): 16-20. [8] Tang Qingyu, Yang Jichun, Yang Wenkui, et al. Effect of rare earth Ce on microstructure and impact properties of CL50 wheel steel[J]. Journal of Inner Mongolia University of Science and Technology, 2017,36(3):221−224. (唐庆余, 杨吉春, 杨文魁, 等. 稀土Ce对CL50车轮钢显微组织和冲击性能的影响[J]. 内蒙古科技大学学报, 2017,36(3):221−224.Tang Qingyu, Yang Jichun, Yang Wenkui, et al. Effect of Rare Earth Ce on microstructure and impact Properties of CL50 Wheel Steel [J]. Journal of Inner Mongolia University of Science and Technology, 2017, 36(03): 221-224. [9] Wu Zhanfang , Liu Zhenyu , Qiu Shengtao, et al. Effect of composition and morphology of non-metallic inclusions on fracture toughness in as-cast AHSS[J], Metall. Res. Technol., 2019, 116: 623. [10] 余音宏. 硫含量对高速车轮钢第二相析出及力学性能的影响[D]. 昆明: 昆明理工大学, 2013.Yu Yinhong. Effect of sulfur content on second phase precipitation and mechanical properties of high-speed wheel steel [D]. Kunming: Kunming University of Science and Technology, 2013. [11] Lei Shaolong, Jiang Min, Yang Die, et al. Effects of oxides on MnS precipitation in Al deoxidized steel[J]. Journal of University of Science and Technology Beijing, 2013,35(11):1443−1449. (雷少龙, 姜敏, 杨叠, 等. Al脱氧钢中氧化物对MnS析出的影响[J]. 北京科技大学学报, 2013,35(11):1443−1449.Lei Shaolong, Jiang Min, Yang Diai, et al. Effects of oxides on MnS precipitation in Al deoxidized steel [J]. Journal of University of Science and Technology Beijing, 2013, 35(11): 1443-1449. [12] Hou Chuan’an, Huang Ye, Li Jingshe, et al. Effect of cooling rate on the inclusion ratio of MnS+Al2O3 composite in steel[J]. Industrial Heating, 2016,45(3):20−22. (侯传安, 黄野, 李京社, 等. 冷却速率对钢中MnS+Al2O3复合夹杂物包裹率的影响研究[J]. 工业加热, 2016,45(3):20−22.Hou Chuan-an, Huang Ye, Li Jingshe, et al. Effect of Cooling Rate on the Inclusion Ratio of MnS+Al2 O3 Composite in Steel [J]. Industrial Heating. 2016, 45(03): 20-22. [13] Shen Chang, Lu Qiang, Guo Junbo, et al. Process development and practice of forming MnS plastic inclusion in middle and high carbon aluminum killed steel[J]. Iron and Steel, 2021,56(12):62−67,74. (沈昶, 陆强, 郭俊波, 等. 中高碳铝镇静钢形成MnS塑性夹杂的工艺开发与实践[J]. 钢铁, 2021,56(12):62−67,74. doi: 10.13228/j.boyuan.issn0449-749x.20210210Shen Chang, Lu Qiang, Guo Junbo, et al. Process Development and Practice of Forming MnS Plastic Inclusion in Middle and High Carbon Aluminum Killed Steel [J]. Iron and Steel. , 2021.56(12): 62-67, 74. doi: 10.13228/j.boyuan.issn0449-749x.20210210 [14] Li Li, Xue Dongmei, Pan Tao, et al. Effect of heating temperature on chemical metallurgy of high sulfur wheel steel inclusions[J]. Continuous Casting, 2017,42(3):43−48. (李丽, 薛东妹, 潘涛, 等. 加热温度对高硫车轮钢夹杂物化学冶金的影响[J]. 连铸, 2017,42(3):43−48.Li Li, Xue Dongmei, Pan Tao, et al. Effect of Heating Temperature on Chemical Metallurgy of High Sulfur Wheel Steel inclusions [J]. Continuous Casting, 2017, 42(03): 43-48. [15] 李昭东. 新型高铁车轮材料的组织和性能调控研究[C]//第十一届中国钢铁年会论文集. 北京: 中国金属学会, 2017.Li Zhaodong. Study on microstructure and property control of new high-speed railway wheel materials [C]//Proceedings of the 11th China Steel Annual Conference. Beijing: The Chinese Society for Metals, 2017. [16] Li Shengjun, Ren Xuechong, Gao Kewei, et al. Effect of heat treatment on morphology and distribution of inclusions in wheel steel[J]. Journal of Materials and Heat Treatment, 2011,32(12):48−54. (李胜军, 任学冲, 高克玮, 等. 热处理对车轮钢中夹杂物的形态和分布的影响[J]. 材料热处理学报, 2011,32(12):48−54.Li Shengjun, Ren Xuechong, Gao Kewei, et al. Effect of Heat Treatment on Morphology and Distribution of inclusions in Wheel Steel [J]. Journal of Materials and Heat Treatment. 2011, 32(12): 48-54. [17] Chen P, Zhu C, Li G, et al. Effect of sulphur concentration on precipitation behaviors of MnS-containing inclusions in GCr15 bearing steels after LF refining[J]. ISIJ International, 2017,57(6):1019. doi: 10.2355/isijinternational.ISIJINT-2017-007 [18] Yang Jichun, Liu Xiangjun, Zhou Li, et al. Effect of rare earth Ce on mechanical properties and corrosion resistance of CL50D high-speed wheel steel[J]. Heat Treatment of Metals, 2019,44(4):15−18. (杨吉春, 刘香军, 周莉, 等. 稀土Ce对CL50D高速车轮钢力学性能及耐腐蚀性能的影响[J]. 金属热处理, 2019,44(4):15−18.Yang Jichun, Liu Xiangjun, Zhou Li, et al. Effect of Rare Earth Ce on Mechanical Properties and Corrosion Resistance of CL50 D High-speed Wheel Steel [J]. Heat Treatment of Metals. 2019, 44(04): 15-18. [19] Thomas B G, Samarasekera I V, Brimacombe J K. Mathematical model of the thermal processing of steel ingots: Part I. Heat flow model[J]. Metallurgical Transactions B, 1987,18(1):119−130. doi: 10.1007/BF02658437 [20] Chen J X. Manual of chart and data in common use of steel making[M]. Beijing: Metallurgical Industry Press, 2010. [21] Tiller W A, Takahashi T. The electrostatic contribution in heterogeneous nucleation theory: Pure liquids[J]. Acta Metallurgica, 1969,17(4):483−496. doi: 10.1016/0001-6160(69)90030-3 [22] Turnbull D, Vonnegut B. Nucleation catalysis[J]. Industrial & Engineering Chemistry, 1952,44(6):1292−1298. [23] Bramfitt B L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron[J]. Metallurgical Transactions, 1970,1(7):1987−1995. doi: 10.1007/BF02642799 -

下载:

下载: