Flotation dynamics test and analysis for ilmenite

-

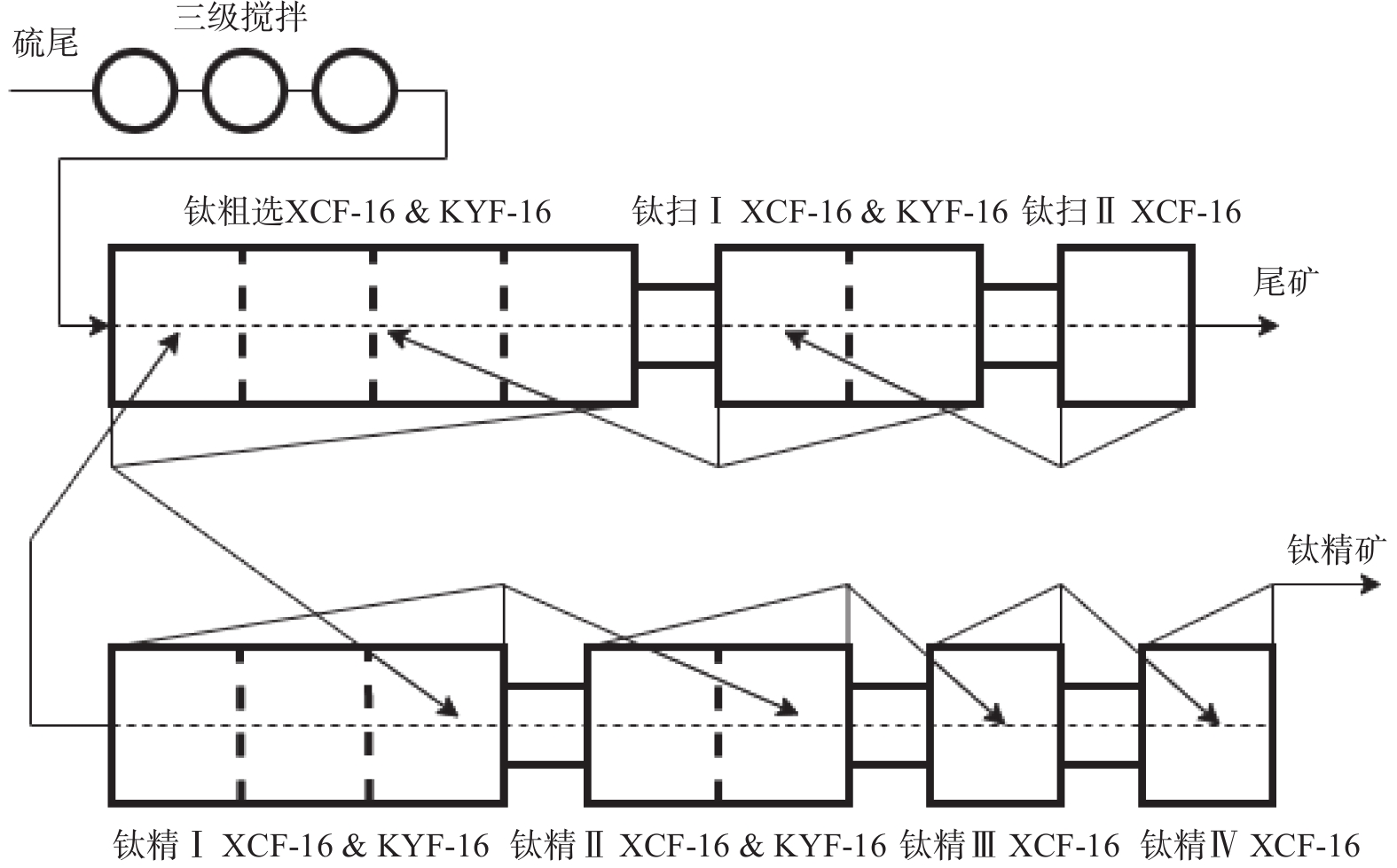

摘要: 磁选加浮选逐渐成为钛铁矿综合回收的最佳工艺流程,浮选回收面临着矿石比重大、粒度粗、矿浆浓度高(约65%)、作业产率大等特点。针对某厂现有浮选流程,进行了选钛浮选机浮选动力学测试及分析。空气分散度测试表明各台浮选机空气分散度偏小,空气在槽体截面上分散不均,同时吸浆槽浮选机空气分散度明显小于直流槽,空气分散效果不理想;气泡负载率测试表明粗粒级矿物上升运输过程中脱落概率大,回收效果较差;矿浆悬浮能力测试表明浮选机均存在明显的矿浆分层现象,即距溢流堰1100 mm以下矿浆浓度相差不大,随着距溢流堰深度减小,浓度明显下降,近溢流堰区域的矿浆浓度明显小于叶轮区域;浮选机气含率分布不均匀,表明浮选机操作过程中缺乏规律,不能够保证矿物颗粒与气泡间的碰撞、粘附概率。Abstract: Magnetic separation plus flotation has gradually become the best process for comprehensive recovery of ilmenite. Flotation recovery is faced with the characteristics of large specific ore, coarse particle size, high slurry concentration (ca. 65%), and high mass pull. According to the existing flotation process, the flotation dynamics test and analysis of the titanium flotation equipment were carried out. The air dispersion test shows that the air dispersion of each flotation equipment is low, and the air is unevenly dispersed on the cross section of the tank. At the same time, the air dispersion of the slurry suction flotation cell is obviously lower than that of the direct flow tank, and the effect of air dispersion is not good enough. The bubble loading rate test shows that the coarse-grained minerals have a high probability of falling off during the upward transportation process, and the recovery effect is poor. The slurry suspension test shows that there is obvious slurry stratification phenomenon in all flotation equipment, that is, the slurry concentration is not much different below 1100 mm from the overflow weir. As the depth from the overflow weir decreased, the concentration decreased significantly. The slurry concentration in the area near the overflow weir is obviously lower than that in the area of the impeller. The uneven distribution of gas holdup in the flotation equipment indicates that there is no regularity in the operation of the flotation equipment, and the probability of collision and adhesion between mineral particles and air bubbles cannot be guaranteed.

-

Key words:

- ilmenite /

- flotation /

- air dispersion /

- air bubble loading rate /

- air holdup /

- slurry suspension

-

表 1 Ⅳ系列各槽充气量Jg及空气分散度η

Table 1. Series Ⅳ Air filling volume Jg and air dispersion η of each tank

作业名称 浮选机序号 充气量 Jg /[m3·(m2·min)−1] 空气分散度 η 粗选 1 0.68 0.82 2 0.70 0.79 3 0.76 0.93 4 0.37 1.6 扫选Ⅰ 1 0.31 0.77 2 0.18 1.46 扫选Ⅱ 1 0.41 0.69 精选Ⅰ 1 0.62 3.11 2 0.53 1.23 3 0.13 0.83 精选Ⅱ 1 0.83 0.68 2 0.79 0.65 精选Ⅲ 1 0.72 0.77 精选Ⅳ 1 1.63 0.81 表 2 Ⅰ系列各槽充气量Jg

Table 2. Series Ⅰ Air filling volume Jg of each tank

作业名称 浮选机序号 充气量Jg /[m3·(m2·min)−1] 粗选 1 0.53 2 0.74 3 0.90 4 0.81 扫选Ⅰ 1 0.77 2 0.43 3 0.26 扫选Ⅱ 1 0.73 2 0.36 精选Ⅰ 1 0.87 2 0.40 3 0.30 精选Ⅱ 1 0.64 2 0.49 精选Ⅲ 1 0.86 2 0.60 3 0.43 精选Ⅳ 1 1.01 2 0.82 表 3 气泡负载率分布

Table 3. Air bubble loading distribution

距溢流堰

深度/mm粗选 扫选Ⅰ 扫选Ⅱ 精选Ⅰ TiO2品位/% 气泡负载率/(g·L−1) TiO2品位/% 气泡负载率/(g·L−1) TiO2品位/% 气泡负载率/(g·L−1) TiO2品位/% 气泡负载率/(g·L−1) 270 44.79 53.65 37.19 36.00 29.34 18.27 48.15 251.37 640 44.42 67.37 33.36 60.34 30.26 67.71 49.14 249.5 1010 45.65 49.74 32.57 69.67 27.71 91.07 48.46 415.95 表 4 Ⅳ系列各作业第2台浮选机矿浆浓度

Table 4. Series Ⅳ slurry concentration of the second flotation machine in each operation

距溢流

堰

深度/mm矿浆浓度/% 粗选 扫选Ⅰ 扫选Ⅱ 精选Ⅰ 精选Ⅱ 精选Ⅲ 精选Ⅳ 600 25.87 14.84 15.24 23.09 26.18 18.94 27.65 1100 36.45 15.52 26.98 24.47 26.19 24.06 30.31 1600 51.77 38.59 43.77 33.05 31.22 42.98 38.17 2100 52.53 41.39 46.08 38.15 31.15 46.71 44.09 表 5 I系列各作业第2台浮选机矿浆浓度

Table 5. Series Ⅴ slurry concentration of the second flotation machine in each operation

距溢流

堰深度/mm矿浆浓度/% 粗选 扫选I 精选I 精选III 500 36.04 24.22 23.92 30.78 900 37.88 29.14 25.54 33.45 1300 38.09 30.34 27.56 37.49 表 6 各作业气含率测试及浮选时间核算结果

Table 6. Gas holdup test and flotation time calculation results of each bank

作业

名称设备

型号浮选容

积/m3气含

率/%泡沫层厚

度/mm容积

系数处理量/

(m3·h−1)核算浮选

时间/min粗选 X/K-16 64 6.3 220 0.84 238.1 13.56 扫选I X/K-16 32 4.2 110 0.90 169.56 10.30 扫选II X/K-16 16 4 70 0.92 131.92 6.76 精选I X/K-16 48 10.4 110 0.85 134.41 18.17 精选II X/K-16 32 6.3 410 0.76 105.48 13.79 精选III XCF-16 16 6.3 400 0.76 143.18 5.11 精选IV XCF-16 16 10.2 540 0.66 122.7 5.18 -

[1] Tan Qiyou, Chen Bo, Zhang Yushu, et al. Characteristics and current situation of comprehensive utilization of vanadium titano-magnetite resources in Panxi region[J]. Multipurpose Utilization of Mineral Resources, 2011,(6):6−10. (谭其尤, 陈波, 张裕书, 等. 攀西地区钒钛磁铁矿资源特点与综合回收利用现状[J]. 矿产综合利用, 2011,(6):6−10.Tan Qiyou, Chen Bo, Zhang Yushu, et al. Characteristics and current situation of comprehensive utilization of vanadium titano-magnetite resources in Panxi region[J]. Multipurpose Utilization of Mineral Resources, 2011(6): 6-10. [2] Xiao Liangchu. Improvement research on titanium concentration technology for Panxi vanadium-titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2012,(2):57−60. (肖良初. 攀西钒钛磁铁矿选钛工艺改进研究[J]. 矿产综合利用, 2012,(2):57−60.Xiao Liangchu. Improvement research on titanium concentration technology for Panxi vanadium-titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2012(2): 57-60. [3] Fan Xuesai, Chen Jun, Shi Shuaixing, et al. Titanium flotation dynamics analysis for vanadium-titanium magnetite[J]. Iron Steel Vanadium Titanium, 2019,40(2):97−101. (樊学赛, 陈俊, 史帅星, 等. 钒钛磁铁矿选钛浮选机动力学特性分析[J]. 钢铁钒钛, 2019,40(2):97−101.Fan Xuesai, Chen Jun, Shi Shuaixing, et al. Titanium flotation dynamics analysis for vanadium-titanium magnetite[J]. Iron Steel Vanadium Titanium, 2019, 40(2): 97-101. [4] Chen Dong, Xia Xiaoou, Yang Lijun, et al. Kinetics research and application of the 320 m3 self-aeration flotation cell[J]. Mining and Metallurgy, 2019,28(4):118−125. (陈东, 夏晓鸥, 杨丽君. 等. 320 m3自吸气浮选机动力学性能研究和工程化[J]. 矿冶, 2019,28(4):118−125. doi: 10.3969/j.issn.1005-7854.2019.04.022Chen Dong, Xia Xiaoou, Yang Lijun, et al. Kinetics research and application of the 320 m³ self-aeration flotation cell[J]. Mining and Metallurgy, 2019, 28(4): 118-125. doi: 10.3969/j.issn.1005-7854.2019.04.022 [5] Han Dengfeng, Wu Feng, Zhang Fuya, et al. Innovation and application of bubble load measuring device[J]. Nonferrous Metals(Mineral Processing Section), 2020,(1):91−97. (韩登峰, 吴峰, 张福亚, 等. 气泡负载测量装置的创新及应用[J]. 有色金属(选矿部分), 2020,(1):91−97.Han Dengfeng, Wu Feng, Zhang Fuya, et al. Innovation and application of bubble load measuring device[J]. Nonferrous Metals(Mineral Processing Section), 2020(1): 91-97. [6] Shen Zhengchang, Lu Shijie, Chen Dong, et al. Research of solids suspension in large-scale mechanical flotation cell[J]. Nonferrous Metals(Mineral Processing Section), 2009,(4):37−40. (沈政昌, 卢世杰, 陈东, 等. 大型机械搅拌式浮选机槽内固体悬浮的研究[J]. 有色金属(选矿部分), 2009,(4):37−40.Shen Zhengchang, Lu Shijie, Chen Dong, et al. Research of solids suspension in large-scale mechanical flotation cell[J]. Nonferrous Metals(Mineral Processing Section), 2009(4): 37-40. [7] Zhang Yuejun, Ren Linhai, Chen Feifei, et al. Study on flotation dynamics of KYF-320 flotation cell in molybdenum rougher and scavenger bank[J]. Nonferrous Metals(Mineral Processing Section), 2019,(5):102−107. (张跃军, 任林海, 陈飞飞, 等. 钼粗扫选作业KYF-320浮选机浮选动力学研究[J]. 有色金属(选矿部分), 2019,(5):102−107.Zhang Yuejun, Ren Linhai, Chen Feifei, et al. Study on flotation dynamics of KYF-320 flotation cell in molybdenum rougher and scavenger bank[J]. Nonferrous Metals(Mineral Processing Section), 2019(5): 102-107. -

下载:

下载: