Study on the comprehensive recovery of Fe and Ti from a low grade vanadium-titanium magnetite in Xinjiang

-

摘要: 针对新疆某低品位钒钛磁铁矿资源,进行了铁、钛选矿高效综合回收试验研究,根据矿石特性,开发了阶磨阶选回收铁—强磁预富集+浮选回收钛的铁、钛综合回收技术工艺流程。选铁流程最终获得产率16.43%,TFe品位57.08%,Fe回收率53.24%的铁精矿产品;选钛预富集最终获得产率23.35%,TiO2品位16.30%,回收率50.22%的钛铁矿入浮物料产品;浮选选钛最终获得产率25.60%,TiO2品位48.02%、TiO2作业回收率为75.62%的钛精矿产品。指标良好,为该地区低品位钒钛磁铁矿的铁、钛资源回收提供了技术参考。Abstract: Aiming at a low-grade vanadium titanomagnetite resource in Xinjiang, an experimental study on efficient comprehensive recovery of iron and titanium benefication was carried out. According to the specific properties of the ore, a technological process of iron and titanium comprehensive recovery was developed, including stage grinding stage selection of iron, strong magnetic preconcentration, and flotation to recover titanium. The iron concentrate product with a yield of 16.43%, a TFe grade of 57.08%, and a Fe recovery of 53.24% was finally obtained from the iron separation process. Ilmenite flotation material products with yield of 23.35%, TiO2 grade of 16.30% and recovery of 50.22% were finally obtained by titanium separation and preconcentration. The final result of titanium flotation is a titanium concentrate product with a yield of 25.60%, a TiO2 grade of 48.02%, and a TiO2 recovery rate of 75.62%. With such good index, this process provides a technical reference for iron and titanium recycling of low-grade vanadium titanium magnetite in such areas.

-

Key words:

- vanadium titanomagnetite /

- low-grade ore /

- mineral separation /

- iron /

- titanium /

- recovery rate

-

表 1 试验原矿化学多项分析结果

Table 1. Chemical multiple analysis results of the test raw ore

% TFe FeO Fe2O3 TiO2 V2O5 SiO2 Al2O3 17.40 10.06 13.42 7.78 0.154 35.38 4.46 CaO MgO Cu Co Ni S P 14.53 9.68 0.029 0.013 0.024 0.063 0.046 表 2 原矿铁化学物相分析结果

Table 2. Chemical phase analysis results of raw iron ore

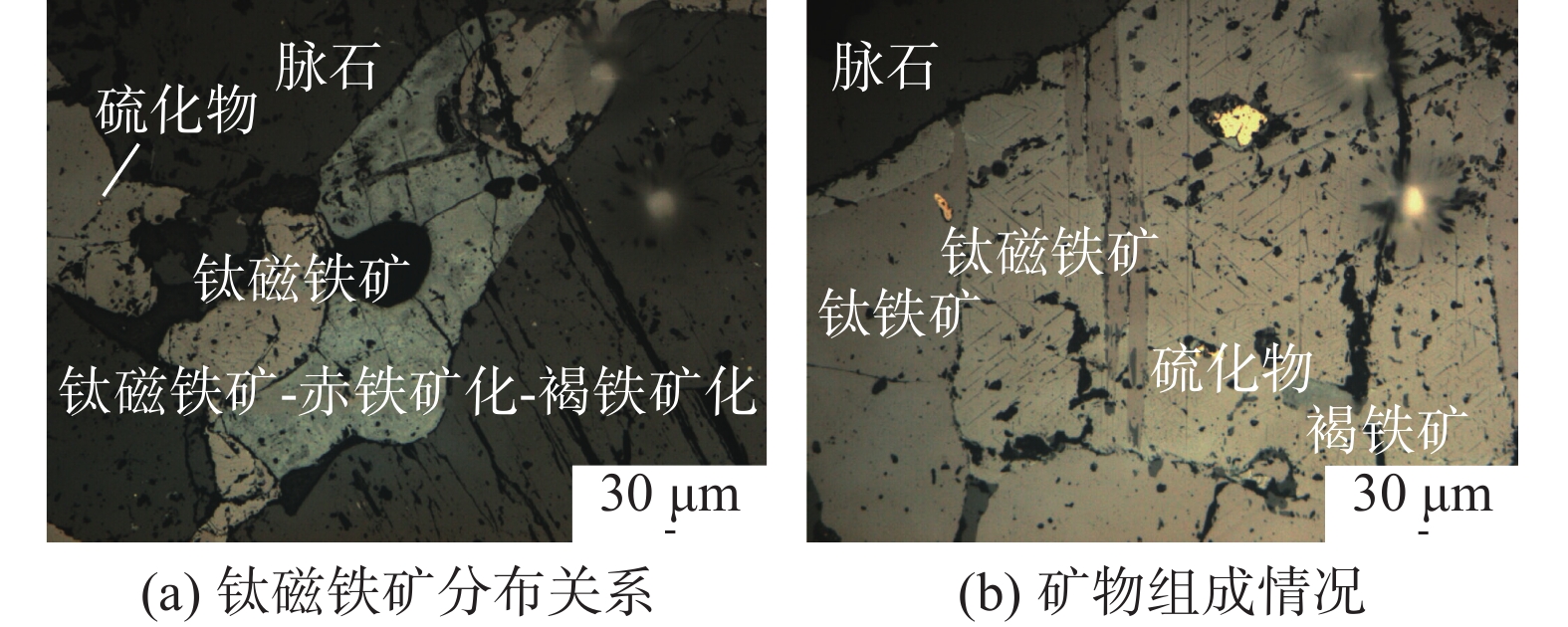

% 钛磁铁

矿中铁钛铁矿

中铁赤、褐

铁中铁菱铁矿

中铁硫化铁

中铁硅酸铁

中铁合计 含 量 9.79 1.15 2.56 0.59 0.26 2.89 17.24 占有率 56.79 6.67 14.85 3.42 1.51 16.76 100.00 表 3 原矿钛化学物相分析结果

Table 3. Chemical phase analysis results of raw titanium ore

% 钛铁矿中TiO2 钛磁铁矿中TiO2 其它TiO2 合计 含量 4.30 1.40 2.05 7.75 占有率 55.48 18.07 26.45 100.00 表 4 钛磁铁矿粒度统计

Table 4. Particle size statistics of titanium magnetite

粒级/mm 钛磁铁矿 钛铁矿 含量/% 累计/% 含量/% 累计/% 0.5 6.9 6.9 9.28 9.28 −0.5~+0.1 48.15 55.05 52.9 62.18 −0.10~+0.074 29.25 84.3 20.25 82.43 −0.074~+0.043 7.96 92.26 6.89 89.32 −0.043 7.74 100 10.68 100 -

[1] Zhang Jianting, Chen Bi. Occurrence state and recycling of main elements of Panxi vanadium titanium magnetite[J]. Mineral Protection and Utilization, 2008,(5):38−41. (张建廷, 陈碧. 攀西钒钛磁铁矿主要元素赋存状态及回收利用[J]. 矿产保护与利用, 2008,(5):38−41.Zhang Jianting, Chen Bi. Occurrence state and recycling of main elements of Panxi vanadium titanium magnetite [J]. Mineral Protection and Utilization, 2008 (5): 38-41. [2] Yu Hongdong, Wang Lina, Qu Jingkui, et al. Process mineralogy characteristics and ore value of typical vanadium titanium magnetite in China[J]. Journal of Northeast University (Natural Science Edition), 2020,41(2):275−281. (于宏东, 王丽娜, 曲景奎, 等. 中国典型钒钛磁铁矿的工艺矿物学特征与矿石价值[J]. 东北大学学报(自然科学版), 2020,41(2):275−281.Yu Hongdong, Wang Lina, Qu Jingkui, et al. Process mineralogy characteristics and ore value of typical vanadium titanium magnetite in China [J]. Journal of Northeast University (Natural Science Edition), 2020, 41 (2): 275 – 281. [3] Chen Chao, Zhang Yushu, Li Xiaoyu, et al. Research progress of titanium magnetite beneficiation technology[J]. Mineral Comprehensive Utilization, 2021,(3):99−105. (陈超, 张裕书, 李潇雨, 等. 钛磁铁矿选矿技术研究进展[J]. 矿产综合利用, 2021,(3):99−105.Chen Chao, Zhang Yushu, Li Xiaoyu, et al. Research progress of titanium magnetite beneficiation technology [J]. Mineral Comprehensive Utilization, 2021 (3): 99-105. [4] Yang Yaohui, Xu Longhua, Deng Jian. Influence of particle size on flotation separation of ilmenite, olivine, and pyroxene[J]. Physicochemical Problems of Mineral Processing, 2021,57(5):106−117. [5] Ou Yang, Sun Yongsheng, Yu Jianwen, et al. Research status and development trend of processing and utilization of vanadium titanium magnetite[J]. Journal of Iron and Steel Research, 2021,33(4):267−278. (欧杨, 孙永升, 余建文, 等. 钒钛磁铁矿加工利用研究现状及发展趋势[J]. 钢铁研究学报, 2021,33(4):267−278.Ou Yang, Sun Yongsheng, Yu Jianwen, et al. Research status and development trend of processing and utilization of vanadium titanium magnetite [J]. Journal of Iron and Steel Research, 2021, 33 (4): 267-278. [6] Zeng Xiaobo, Zhang Yuan, Xiong Wenliang, et al. Experimental study on beneficiation of a low-grade vanadium titanium magnetite[J]. Comprehensive Utilization of Mineral Resources, 2017,(3):67−70. (曾小波, 张渊, 熊文良, 等. 某低品位钒钛磁铁矿选矿试验研究[J]. 矿产综合利用, 2017,(3):67−70.Zeng Xiaobo, Zhang Yuan, Xiong Wenliang, et al. Experimental study on beneficiation of a low-grade vanadium titanium magnetite [J]. Comprehensive Utilization of Mineral Resources, 2017 (3): 67-70. [7] Deng Jian, Yang Yaohui, Wang Hongbin, et al. Experimental study on optimization of flotation reagents for ilmenite in an iron dressing tailings in Panxi[J]. Iron Steel Vanadium Titanium, 2022,43(3):77−83. (邓建, 杨耀辉, 王洪彬, 等. 攀西某选铁尾矿中钛铁矿浮选药剂优化试验研究[J]. 钢铁钒钛, 2022,43(3):77−83.Deng Jian, Yang Yaohui, Wang Hongbin, et al. Experimental study on optimization of flotation reagents for ilmenite in an iron dressing tailings in Panxi [J]. Iron Steel Vanadium Titanium, 2022, 43 (3): 77-83. [8] Wang Xun, Han Yuexin, Li Yanjun, et al. Research status of comprehensive utilization of vanadium titanium magnetite[J]. Metal Mines, 2019,(6):33−37. (王勋, 韩跃新, 李艳军, 等. 钒钛磁铁矿综合利用研究现状[J]. 金属矿山, 2019,(6):33−37.Wang Xun, Han Yuexin, Li Yanjun, et al. Research status of comprehensive utilization of vanadium titanium magnetite [J]. Metal Mines, 2019 (6): 33-37. [9] Yang Yaohui, Xu Longhua, Liu Yachuan, et al. Flotation separation of ilmenite from titanaugite using mixed collectors[J]. Separation Science and Technology, 2016,51:1840-1846. [10] Yang Yaohui, Hui Bo, Yan Weiping, et al. Research on process mineralogy of Panxi fine ilmenite[J]. Multipurpose Utilization of Mineral Resources, 2020,(3):131−135. (杨耀辉, 惠博, 严伟平, 等. 攀西微细粒钛铁矿工艺矿物学研究[J]. 矿产综合利用, 2020,(3):131−135.Yang Yaohui, Hui Bo, Yan Weping, et al. Research on process mineralogy of Panxi fine ilmenite [J]. Multipurpose Utilization of Mineral Resources, 2020 (3): 131-135. [11] Feng Youquan. Discussion on comprehensive development and utilization scheme of an ultra poor vanadium titanium magnetite in Xinjiang[J]. Mining Engineering, 2021,19(1):36−38. (冯友全. 新疆某超贫钒钛磁铁矿综合开发利用方案探讨[J]. 矿业工程, 2021,19(1):36−38.Feng Youquan. Discussion on comprehensive development and utilization scheme of an ultra poor vanadium titanium magnetite in Xinjiang [J]. Mining Engineering, 2021, 19 (1): 36-38. [12] Ma Donglin, Gong Weijun, Li Guangtao. Prospects for comprehensive development and utilization of low-grade vanadium titanium magnetite resources in Xinjiang[J]. China Metal Bulletin, 2021,(16):79−80. (马东林, 巩伟军, 李广涛. 新疆低品位钒钛磁铁矿资源综合开发利用的前景[J]. 中国金属通报, 2021,(16):79−80. doi: 10.3969/j.issn.1672-1667.2021.16.040Ma Donglin, Gong Weijun, Li Guangtao. Prospects for comprehensive development and utilization of low-grade vanadium titanium magnetite resources in Xinjiang [J]. China Metal Bulletin, 2021 (16): 79-80. doi: 10.3969/j.issn.1672-1667.2021.16.040 -

下载:

下载: