Experimental study on beneficiation of a foreign refractory ilmenite ore

-

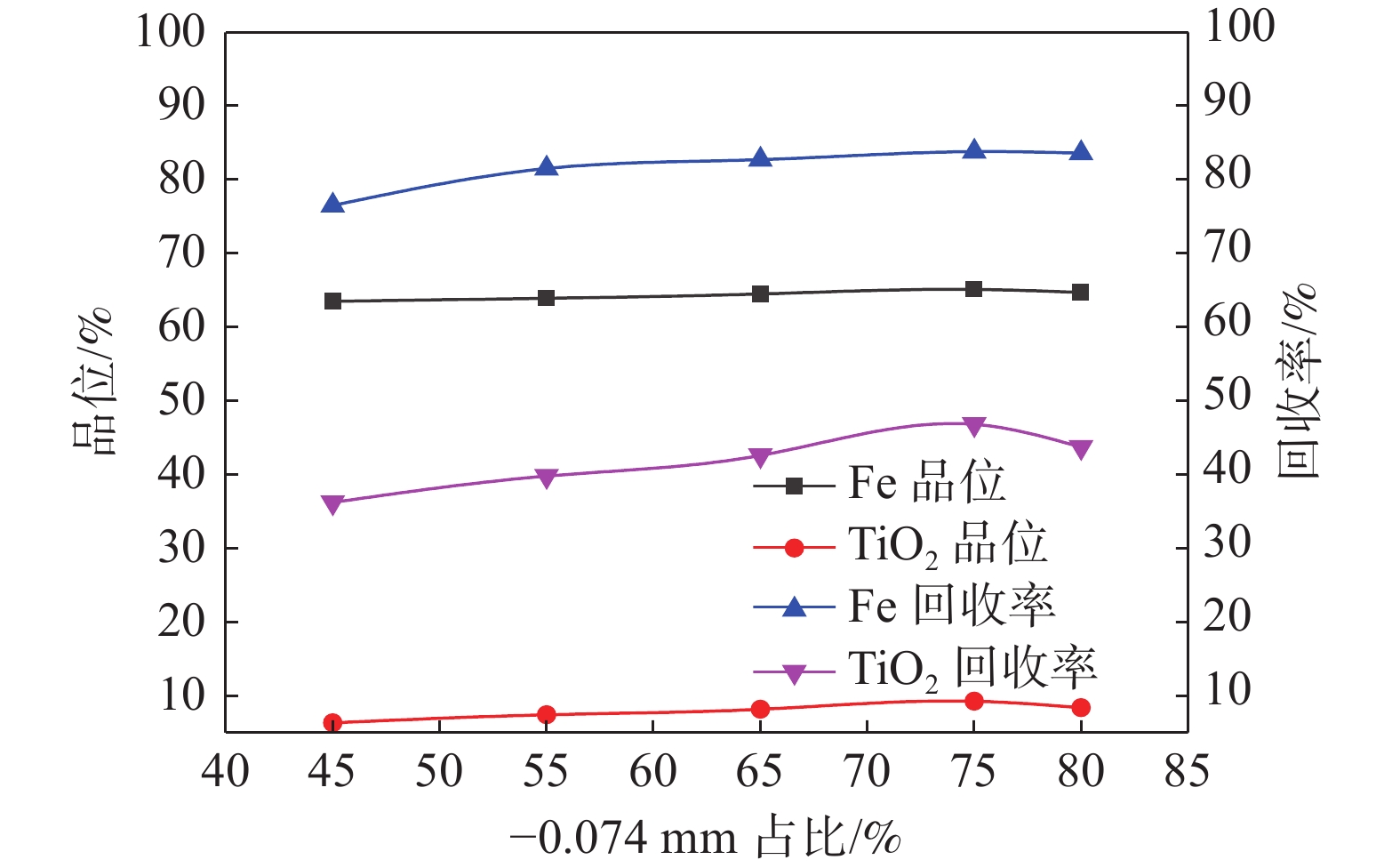

摘要: 针对国外某钛铁矿矿物组成复杂,有价矿物之间共生关系密切,且钛铁矿嵌布粒度细等问题,采用阶段磨矿—阶段选别的磁选—浮选工艺流程对该难选钛铁矿矿石进行了选矿工艺试验研究。结果表明,对含TFe 55.36%、TiO2 9.91%的原矿,采用该工艺后,可获得TFe品位64.50%,回收率81.70%的铁精矿和TiO2品位为47.22%、回收率为50.55%的钛精矿。该工艺为开发利用该矿产资源提供了技术支撑。Abstract: In view of the complex mineral composition of a ilmenite from overseas, the close symbiotic relationship between valuable minerals and the fine particle size of ilmenite, the experimental study on the beneficiation process of the refractory ilmenite ore was carried out using the stage grinding-stage separation magnetic separation-flotation process flow. The results show that the iron concentrate with TFe grade of 64.50% and recovery rate of 81.70%, the titanium concentrate with TiO2 grade of 47.22% and recovery rate of 50.55% can be obtained from the run-of-mine with TFe grade of 55.36% and TiO2 grade of 9.91%. This process provides a technical support for the open utilization of the mineral resources.

-

Key words:

- ilmenite /

- titanomagnetite /

- stage-grinding /

- stage-separation /

- magnetic separation /

- flotation

-

表 1 原矿多元素分析

Table 1. Multi-element results of run-of-mine

% TiO2 TFe Al2O3 Cu Zn Pb Bi CaF2 SiO2 MgO CaO Na2O K2O V2O3 P S 烧失量 9.91 55.36 10.87 0.011 0.006 0.012 0.0047 0.32 8.79 5.59 6.21 1.92 0.47 0.026 0.090 0.21 0.202 表 2 铁物相分析结果

Table 2. Mineral composition of iron in run-of-mine

% 铁物相 含量 分布率 硫化矿中的铁 0.07 0.13 赤铁矿中的铁 2.42 4.37 褐铁矿中的铁 3.44 6.20 钛磁铁矿中的铁 45.41 82.03 钛铁矿中的铁 3.14 5.67 硅酸铁中的铁 0.27 0.11 碳酸铁中的铁 0.61 1.48 合计 55.36 100.00 表 3 钛物相分析结果

Table 3. Mineral composition of titanium in run-of-mine

% 钛物相 含量 分布率 钛磁铁矿中的钛 2.65 26.74 钛铁矿中的钛 5.66 57.11 金红石中的钛 0.72 7.27 辉石中的钛 0.06 0.61 榍石中的钛 0.27 2.72 角闪石中的钛 0.06 0.61 褐铁矿中的钛 0.07 0.70 金云母中的钛 0.42 4.24 合计 9.91 100.00 表 4 回收铁开路试验结果

Table 4. Open circuit test results of iron recovery

% 产品名称 产率 TFe品位 TFe回收率 铁精矿 70.12 64.50 81.70 磁选尾矿 29.88 14.56 18.30 原矿 100.00 55.36 100.00 表 5 全流程闭路试验结果

Table 5. Results of closed-circuit flotation test

% 产品名称 产率 TiO2品位 TiO2回收率 精矿 8.45 47.22 50.55 尾矿 91.55 3.43 49.45 原矿 100.00 9.91 100.00 -

[1] Dai Xinyu. Progress in beneficiation technology of primary ilmenite[J]. China Mining, 2002,(2):40−42. (戴新宇. 原生钛铁矿选矿技术的进展[J]. 中国矿业, 2002,(2):40−42. doi: 10.3969/j.issn.1004-4051.2002.02.013Dai Xinyu. Progress in beneficiation technology of primary ilmenite [J]. China Mining, 2002 (02): 41-43 doi: 10.3969/j.issn.1004-4051.2002.02.013 [2] Yi Yunlai, Wei Qian, Liu Zhongrong. Experimental study on beneficiation of a complex ilmenite abroad[J]. Mining and Metallurgy Engineering, 2014,34(1):41−43. (易运来, 魏茜, 刘忠荣. 国外某复杂钛铁矿的选矿试验研究[J]. 矿冶工程, 2014,34(1):41−43. doi: 10.3969/j.issn.0253-6099.2014.01.011Yi Yunlai, Wei Qian, Liu Zhongrong. Experimental study on beneficiation of a complex ilmenite abroad [J]. Mining and Metallurgy Engineering, 2014, 34 (1): 41-43 doi: 10.3969/j.issn.0253-6099.2014.01.011 [3] Zhong Senlin, Xie Baohua, Wang Fengyu, et al. Experimental study on the beneficiation process of a foreign primary ilmenite[J]. Iron Steel Vanadium Titanium, 2022,43(3):98−103. (钟森林, 谢宝华, 王丰雨, 等. 国外某原生钛铁矿选矿工艺试验研究[J]. 钢铁钒钛, 2022,43(3):98−103.ZhongSenlin, XieBaohua, Wang Fengyu, et al. Experimental study on the beneficiation process of a foreign primary ilmenite [J]. Vanadium-titanium steel, 2022, 43 (03): 98-103 [4] Zhang Song, Wen Shuming, Liu Jian, et al. Research progress in mineral processing technology of fine ilmenite[J]. Mineral Protection and Utilization, 2019,39(1):131−137. (张松, 文书明, 刘建, 等. 微细粒钛铁矿选矿技术研究进展[J]. 矿产保护与利用, 2019,39(1):131−137.Zhang Song, Wen Shuming, Liu Jian, Xian Yongjun, Han Guang, Wang Yu. Research Progress in Mineral Processing Technology of Fine Ilmenite [J]. Mineral Protection and Utilization, 2019, 39 (01): 131-137 [5] Liu Zhenhui, Zhang Chonghui, Bu Xianzong, et al. Experimental study on titanium separation from an iron tailings in Xinjiang[J]. Mining and Metallurgy Engineering, 2012,(4):37−40. (刘振辉, 张崇辉, 卜显宗, 等. 新疆某选铁尾矿选钛试验研究[J]. 矿冶工程, 2012,(4):37−40. doi: 10.3969/j.issn.0253-6099.2012.04.010Liu Zhenhui, Zhang Chonghui, Bu Xianzong, et al. Experimental study on titanium separation from an iron tailings in Xinjiang [J]. Mining and Metallurgy Engineering, 2012 (4): 37-40 doi: 10.3969/j.issn.0253-6099.2012.04.010 [6] Wang Fengyu, Xu Xiaoyi, Liang Taomao, et al. Magnetic separation enrichment method for panzhihua ultra-fine ilmenite[J]. Iron Steel Vanadium Titanium, 2021,42(2):79−85. (王丰雨, 徐晓衣, 梁焘茂, 等. 攀枝花超细粒级钛铁矿磁选富集方法[J]. 钢铁钒钛, 2021,42(2):79−85. doi: 10.7513/j.issn.1004-7638.2021.02.014Wang Fengyu, Xu Xiaoyi, Liang Taomao, et al. Magnetic separation enrichment method for panzhihua ultra-fine ilmenite [J]. Iron and Steel Vanadium and Titanium, 2021, 42 (02): 79-85 doi: 10.7513/j.issn.1004-7638.2021.02.014 [7] Liu Jianguo, Zhang Jun, Tang Yuhe. Application of gravity and magnetic preconcentration process in several typical ilmenite beneficiation processes[J]. Mineral Protection and Utilization, 2018,(1):96−100. (刘建国, 张军, 汤玉和. 重、磁预选工艺在几种典型钛铁矿选矿工艺中的应用[J]. 矿产保护与利用, 2018,(1):96−100. doi: 10.13779/j.cnki.issn1001-0076.2018.01.017Liu Jianguo, Zhang Jun, Tang Yuhe. Application of gravity and magnetic preconcentration process in several typical ilmenite beneficiation processes [J]. Mineral Protection and Utilization, 2018 (01): 96-100 doi: 10.13779/j.cnki.issn1001-0076.2018.01.017 [8] Cao Yuchuan, Li Huiyue, Li Luhong, et al. Research on titanium separation process of a vanadium-titanium magnetite in Panxi region[J]. Iron Steel Vanadium Titanium, 2021,42(2):91−98. (曹玉川, 李辉跃, 李禄宏, 等. 攀西地区某钒钛磁铁矿选钛工艺研究[J]. 钢铁钒钛, 2021,42(2):91−98. doi: 10.7513/j.issn.1004-7638.2021.02.016Cao Yuchuan, Li Huiyue, Li Luhong, et al. Research on titanium separation process of a vanadium-titanium magnetite in Panxi region [J]. Iron and Steel Vanadium-titanium, 2021, 42 (02): 91-98 doi: 10.7513/j.issn.1004-7638.2021.02.016 [9] Xie Baohua, Wu Chengcai, Wang Fengyu, et al. Research on the application of vertical ring high gradient magnetic separator to separate hematite[J]. Material Research and Application, 2018,12(2):143−147. (谢宝华, 吴城材, 王丰雨, 等. 立环高梯度磁选机分选赤铁矿应用研究[J]. 材料研究与应用, 2018,12(2):143−147. doi: 10.3969/j.issn.1673-9981.2018.02.015XieBaohua, Wu Chengcai, Wang Fengyu, et al. Research on the application of vertical ring high gradient magnetic separator to separate hematite [J]. Material Research and Application, 2018, 12 (02): 143-147. doi: 10.3969/j.issn.1673-9981.2018.02.015 -

下载:

下载: