Study on thermal deformation behavior and microstructure evolution of Ti-55511 alloy

-

摘要: 通过等温热压缩模拟方法在温度为700~950 ℃和应变速率为0.001~10 s−1的工艺下研究了Ti-55511合金的热变形行为。结果表明,合金的软化机制对热加工参数的变化很敏感,在高应变速率及低变形温度的匹配下,合金因动态回复/再结晶所造成的软化行为在与形变硬化的竞争中占据主导地位,表现为流变应力的降低。此外,再结晶软化与形变硬化在高变形温度与低应变速率的匹配下达到平衡状态。对比功率耗散因子(η)可以发现,低应变速率条件下的η值较高,组织分布较为均匀,热加工性能良好。

-

关键词:

- Ti-55511合金 /

- 热压缩模拟 /

- 显微组织 /

- 回复再结晶 /

- 热加工性能

Abstract: The thermal deformation behavior of Ti-55511 alloy was studied by isothermal compression simulation method at the temperature of 700~950 ℃ and strain rate of 0.001~10 s−1. The results show that the softening mechanism of the alloy is very sensitive to the change of hot working parameters. Under the matching of high strain rate and low deformation temperature, the softening behavior of the alloy caused by dynamic recovery/recrystallization plays a dominant role in the competition with deformation hardening, which is manifested as the reduction of flow stress. In addition, recrystallization softening and deformation hardening reach an equilibrium state under the matching of high deformation temperature and low strain rate. By contrast, the power dissipation factor (η)is higher under the condition of low strain rate, the microstructure distribution is more uniform, and the thermal processing ability is good. -

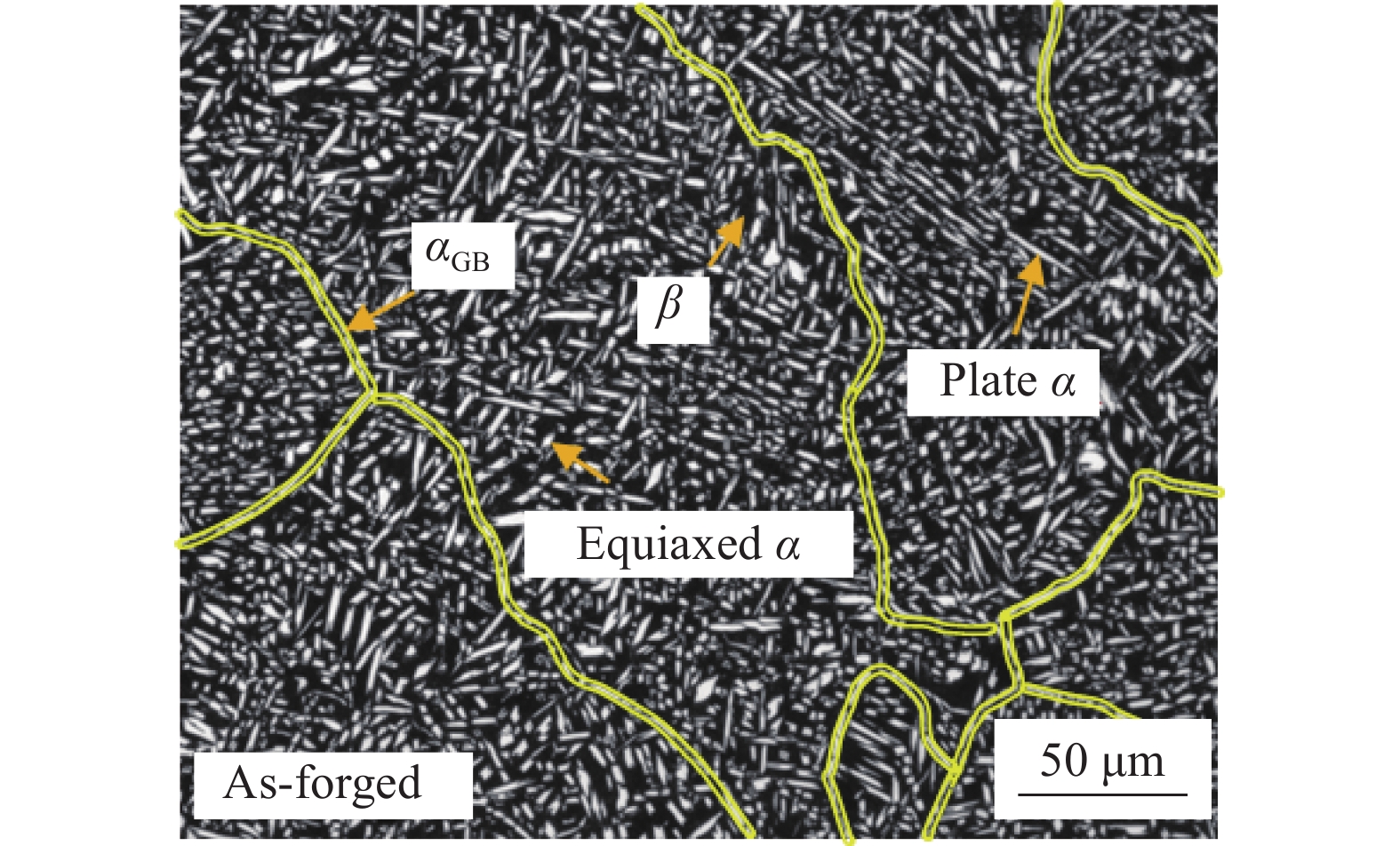

图 6 (a)

$ \ln\dot{\varepsilon } $ -$ \ln\sigma $ 三次样条差值拟合曲线;(b)Ti-55511合金的功率耗散图($ \varepsilon = $ 0.9); (c)$ \ln\left[m/\left(m+1\right)\right] $ -$ \ln\dot{\varepsilon } $ 三次样条差值拟合曲线;(d)Ti-55511合金Prasad准则下的热加工图($ \varepsilon = $ 0.9);(e)-(e1)$ \eta $ =0.99时的Ti-55511合金微观组织;(f)-(f1)$ \eta $ =0.57时的Ti-55511合金微观组织Figure 6. (a) Cubic spline difference fitting graph of

$ \ln\dot{\varepsilon } $ -$ \ln\sigma $ ; (b) Power dissipation diagram of Ti-55511 alloy ($\varepsilon =$ 0.9); (c) Cubic spline difference fitting graph of$ \ln\left[m/\left(m+1\right)\right] $ -$\ln\dot{\varepsilon }$ ; (d) Hot working diagram of Ti-55511 alloy under Prasad criterion ($\varepsilon =$ 0.9); (e)-(e1) Microstructure of Ti-55511 alloy when$ \eta $ =0.99 ; (f)-(f1) Microstructure of Ti-55511 alloy when$ \eta $ =0.57表 1 Ti-55511钛合金化学成分

Table 1. Chemical composition of Ti-55511 alloy

% Al Mo V Cr Fe C Si Zr O N H Ti 5.47 4.52 4.81 1.03 1.5 0.013 0.011 0.121 0.14 0.0064 <0.001 Bal. 表 2 Ti-55511合金高温变形参数

Table 2. High temperature deformation parameters of Ti-55511 alloy

变形量/% 真应变 应变速率/s−1 变形温度/ ℃ 60 0.92 0.001,0.01,0.1,

1,10700,750,800,

850,900,950 -

[1] Banerjee D, Williams J C. Perspectives on titanium science and technology[J]. Acta Materialia, 2013,61(3):844−879. doi: 10.1016/j.actamat.2012.10.043 [2] Viswanathan G B, Karthikeyan S R W. Creep behaviour of Ti-6Al-2Sn-4Zr-2Mo: II. Mechanisms of deformation[J]. Acta Materialia, 2002,50(20):4965−4980. doi: 10.1016/S1359-6454(02)00280-X [3] Nyakana S L, Fanning J C, Boyer R R. Quick reference guide for β titanium alloys in the 00s[J]. Journal of Materials Engineering and Performance, 2005,14(6):799−811. doi: 10.1361/105994905X75646 [4] Weiss I, Semiatin S L. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Materials Science and Engineering: A, 1998,243(1):46−65. [5] Chen Y Y, Du Z X, Xiao S L, et al. Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy[J]. Journal of Alloys and Compounds, 2014,586:588−592. doi: 10.1016/j.jallcom.2013.10.096 [6] Jones N G, Dashwood R J, Dye D, et al. Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr[J]. Materials Science and Engineering: A, 2008,490(1):369−377. [7] Jones N G, Dashwood R J, Dye D, et al. The flow behavior and microstructural evolution of Ti-5Al-5Mo-5V-3Cr during subtransus isothermal forging[J]. Metallurgical and Materials Transactions A, 2009,40(8):1944−1954. doi: 10.1007/s11661-009-9866-5 [8] Dikovits M, Poletti C, Warchomicka F. Deformation mechanisms in the near-β titanium alloy Ti-55531[J]. Metallurgical and Materials Transactions A, 2014,45(3):1586−1596. doi: 10.1007/s11661-013-2073-4 [9] Li L, Li M Q, Luo J. Mechanism in the β phase evolution during hot deformation of Ti-5Al-2Sn-2Zr-4Mo-4Cr with a transformed microstructure[J]. Acta Materialia, 2015,94:36−45. doi: 10.1016/j.actamat.2015.04.045 [10] Li C M, Huang L, Zhao M J, et al. Hot deformation behavior and mechanism of a new metastable β titanium alloy Ti-6Cr-5Mo-5V-4Al in single phase region[J]. Materials Science and Engineering: A, 2021,814:141231. doi: 10.1016/j.msea.2021.141231 [11] Shu Ying, Zeng Weidong, Zhou Jun, et al. A study of hot deformation behavior for BT20 aloy[J]. Materials Science and Technology, 2005,(1):66−69. (舒滢, 曾卫东, 周军, 等. BT20合金高温变形行为的研究[J]. 材料科学与工艺, 2005,(1):66−69.Shu Ying, Zeng Weidong, Zhou Jun, et al. A study of hot deformation behavior for BT20 aloy[J]. Materials Science and Technology, 2005(1): 66-69. [12] Mcqueen H J, Yue S, Ryan N D. Hot working characteristics of steels in austenitic state[J]. Journal of Materials Processing Technology, 1995,53(1):293−310. [13] 王丽敏. 高强度硼钢板热冲压成形过程及数值模拟研究[D]. 南昌: 南昌大学, 2011.Wang Limin. Study on hot stamping process and numerical simulation of high strength boron steel sheet[D]. Nanchang: Nanchang University, 2011. [14] Prasad Y V R K, Gegel H L, Doraivelu S M, et al. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984,15(10):1883−1892. doi: 10.1007/BF02664902 -

下载:

下载: