Study on surface coating modification of silicon anode material with titanium dioxide

-

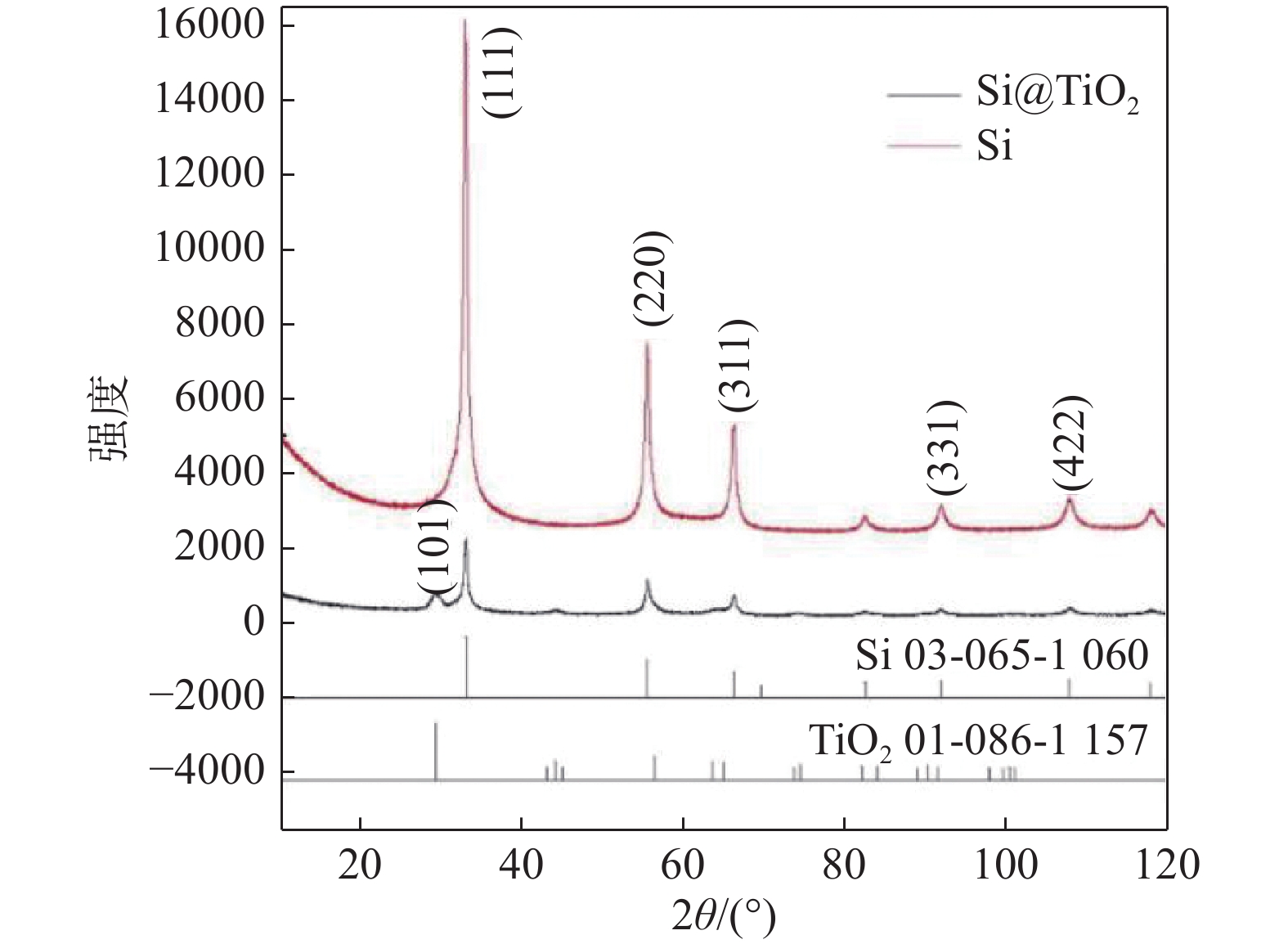

摘要: 以TiCl4为钛源,商用纳米Si为硅源,采用水解法制备了核—壳结构的硅@二氧化钛(Si@TiO2)纳米复合材料。借助XRD、SEM、TEM和电化学性能测试等对材料进行了详细研究。结果显示,坚固的TiO2外壳在充放电过程中极大缓解了硅的体积膨胀,使得Si@TiO2展现出较好的电化学性能,其在1600 mAh/g大电流密度下的放电比容量为614.3 mAh/g。电流密度500 mA/g,循环100次后仍有877 mAh/g的放电比容量,容量保持率为51.8%。Abstract: Titanium dioxide coated silicon (Si@TiO2) nanocomposites with core-shell structure was prepared by hydrolysis method using TiCl4 as titanium source and commercial nano-Si as silicon source. The materials were characterized and tested by XRD, SEM, TEM and electrochemical platform. The results show that Si@TiO2 nanocomposites exhibit good electrochemical performance because the solid TiO2 shell greatly alleviates the volume expansion of silicon during the charging and discharging process (showing a discharge specific capacity is of 614.3 mAh/g at a high current density of 1600 mAh/g and a specific discharge capacity of 877 mAh/g with a capacity retention rate of 51.8% after 100 cycles at a current density of 500 mAh/g).

-

Key words:

- Si@TiO2 nanocomposite /

- hydrolysis /

- TiCl4 /

- silicon /

- negative electrode /

- electrochemical performance

-

表 1 不同钛源制备的硅基复合材料储锂性能比较

Table 1. Comparison of lithium storage performance of composite materials prepared from different titanium sources

-

[1] Zhang Lei, Wu Haobin, Xu Rong, et al. Porous Fe2O3 nanocubes derived from MOFs for highly reversible lithium storage.[J]. Crystengcomm, 2013,15:9332−9335. doi: 10.1039/c3ce40996a [2] Cheng Zhongling, Hu Yi, Wu Keshi, et al. Si/TiO2/Ti2O3 composite carbon nanofiber by one-step heat treatment with highly enhanced ion/electron diffusion rates for next-generation lithium-ion batteries[J]. Electrochimica Acta, 2020,337:135789. doi: 10.1016/j.electacta.2020.135789 [3] Li Bing, Fei Yao, Jung Jun Bae, et al. Hollow carbon nanospheres/silicon/alumina core-shell film as an anode for lithium-ion batteries[J]. Scientific Reports, 2015,5:7659. doi: 10.1038/srep07659 [4] Zhang Wenhui, Luo Gaixia, Xu Qi, et al. Enhanced reversible lithium storage for nano-Si with a <10 nm homogenous porous carbon coating layer[J]. Electrochimica Acta, 2018,269:1−10. doi: 10.1016/j.electacta.2018.02.143 [5] Jin Y, Li S, Kushima A, et al. Self-healing SEI enables full-cell cycling of a silicon-majority anode with a coulombic efficiency exceeding 99.9%[J]. Energy & Environmental Science, 2017,10(2):580−592. [6] Wang Kai, Li Ningning, Xie Jiayue, et al. Dual confinement of carbon/TiO2 hollow shells enables improved lithium storage of Si nanoparticles[J]. Electrochimica Acta, 2021,372:137863. doi: 10.1016/j.electacta.2021.137863 [7] Lu Bing, Ma B, Deng X, et al. Dual stabilized architecture of hollow Si@TiO2@C nanospheres as anode of high-performance Li-ion battery[J]. Chemical Engineering Journal, 2018,351:269−279. doi: 10.1016/j.cej.2018.06.109 [8] Jiao X W, Tian Y H, Zhang X J. Hollow Si nanospheres with amorphous TiO2 layer used as anode for high-performance Li-ion battery[J]. Applied Surface Science, 2021,(9):150682. [9] Geng H, Ang H, Ding X, et al. Metal coordination polymer derived mesoporous Co3O4 nanorods with uniform TiO2 coating as advanced anodes for lithium ion batteries[J]. Nanoscale, 2016,8(5):2967−2973. doi: 10.1039/C5NR08570E [10] Shen D, Huang C, Gan L, et al. Rational design of Si@SiO2/C composite using sustainable cellulose as carbon resource for anode in lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2018,10(9):7946−7954. [11] Zhou Xiaosi, Yin Yaxia, Wan Lijun, et al. Self-assembled nanocomposite of silicon nanoparticles encapsulated in graphene through electrostatic attraction for lithium-ion batteries[J]. Advanced Energy Materials, 2012,2(9):1086−1090. doi: 10.1002/aenm.201200158 [12] Jin J, Huang S Z, Shu J, et al. Highly porous TiO2 hollow microspheres constructed by radially oriented nanorods chains for high capacity, high rate and long cycle capability lithium battery[J]. Nano Energy, 2015,16:339−349. doi: 10.1016/j.nanoen.2015.07.001 [13] Yang T, Tian X, Li X, et al. Preparation of Si-based composite encapsulated by an incomplete multifunction-coating for lithium storage[J]. Electrochimica Acta, 2019,295:75−81. doi: 10.1016/j.electacta.2018.10.142 [14] Hu J, Wang Q, Fu L, et al. Titanium monoxide-stabilized silicon nanoparticles with a litchi-like structure as an advanced anode for Li-ion batteries[J]. ACS Applied Mater Interfaces, 2020,12(43):48467−48475. doi: 10.1021/acsami.0c10418 -

下载:

下载: