Bainite design in quenching and partitioning steel based on numerical calculation

-

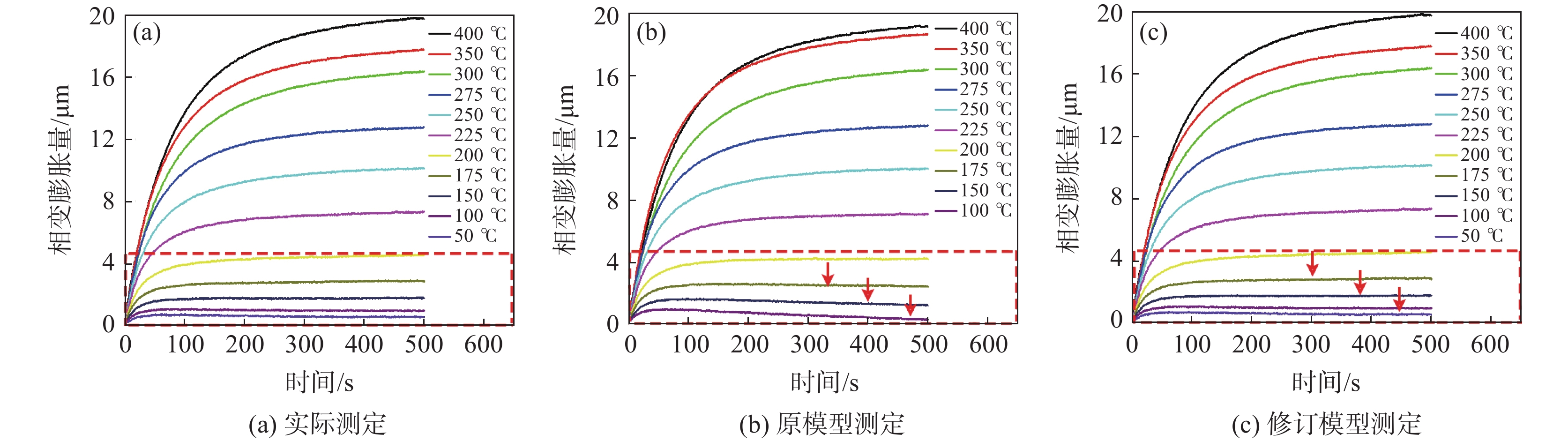

摘要: 将材料热、动力学与中试试验相结合,针对商用淬火配分(Q&P,Quenching and Partitioning)钢的贝氏体进行优化设计。基于试验膨胀数据建立Bohemen切变模型,充分考虑淬火配分工艺下过时效等温阶段的组织演变复杂性,特别是回火阶段马氏体中碳化物析出特性以及对膨胀结果的影响,通过合理化数据对Bohemen模型进行修订,建立等温贝氏体相变动力学模型,实现贝氏体相变的精准预测。结合修订的Bohemen模型计算结果分析淬火配分钢中贝氏体/马氏体交互作用对残余奥氏体保留及稳定性的影响。结果显示,低淬火温度下马氏体板条间的残余奥氏体含量高,占据变形过程中的主导地位;反之,高淬火温度下贝氏体中的残余奥氏体含量高。由此形成基于材料计算下淬火配分钢的贝氏体优化设计。

-

关键词:

- 材料计算 /

- Boheman切变模型 /

- 贝氏体/马氏体交互作用 /

- 残余奥氏体 /

- 贝氏体优化设计

Abstract: In this study, an optimum design of bainite phase in the commercial quenching and partitioning (Q&P) steel was achieved through the combined results from thermodynamics, kinetics analysis and the pilot experiments. Considering the complex microstructure evolution during partitioning stage of the Q&P treatment, especially the precipitation characteristics of carbides in martensite and their influence on the expansion result, the Boheman model was established and further revised based on the result of expansion experiment. A kinetic model of isothermal bainitic transformation was also set up to simulate this transformation accurately. According to the predicated result from the revised Bohemen model, the effect of the interaction between bainite and martensite on volume fraction and stability of retained austenite was analyzed. The results show that at a low quenching temperature, retained austenite between martensitic laths has a higher volume fraction and plays a dominant role during the deformation. On the contrary, under high temperature quenching condition the volume fraction of retained austenite in bainite is high. -

表 1 试验钢的化学成分

Table 1. Chemical composition of the experimental steel

% C Mn Si Fe 0.20 2.0 1.5 余量 表 2 XRD的测试参数

Table 2. Parameters of the XRD measurement

电压/

kV电流/

mA射线

类型射线波

长/nm扫描步

长/(°·min−1)2θ角扫

描范围/(°)56 182 CuKα 0.154 4 40~120 表 3 经式(4)拟合所得参数值

Table 3. Fitting parameters for equation (4)

淬火温度/ ℃ fmax/% κ λ 拟合R值 50 1.221 62 0.122 81 0 0.322 515 524 347 53 100 2.089 36 0.090 66 0 0.207 776 105 612 78 150 3.861 87 0.049 72 0 0.984 293 070 028 93 175 6.243 20 0.036 52 0 0.954 124 876 733 97 200 11.100 82 0.024 15 0 0.919 254 606 097 86 225 16.299 07 0.019 23 0 0.947 761 646 501 55 250 22.541 96 0.016 23 0 0.964 945 985 838 93 275 28.466 01 0.015 52 0 0.974 133 379 392 81 300 36.432 97 0.011 69 0 0.986 639 580 484 85 350 39.550 00 0.012 64 0 0.986 370 940 368 93 400 43.992 98 0.011 61 0 0.992 992 684 819 78 -

[1] Kang Yonglin. Lightweight vehicle, advanced high strength steel and energy-saving and emission reduction[J]. Iron and Steel, 2008,43(6):1−7. (康永林. 汽车轻量化先进高强钢与节能减排[J]. 钢铁, 2008,43(6):1−7. doi: 10.3321/j.issn:0449-749X.2008.06.001Kang Yong Lin. Lightweight vehicle, advanced high strength steel and energy-saving and emission reduction[J]. Iron and Steel, 2008, 43(6): 1-7 doi: 10.3321/j.issn:0449-749X.2008.06.001 [2] Wang Li, Yang Xiongfei, Lu Jiangxin. Development of high strength steel sheets for lightweigt automobile[J]. Iron and Steel, 2006,41(9):4−11. (王利, 杨雄飞, 陆匠心. 汽车轻量化用高强度钢板的发展[J]. 钢铁, 2006,41(9):4−11. doi: 10.3321/j.issn:0449-749X.2006.09.001Wang Li, Yang Xiong Fei, Lu Jiang Xin. Development of high strength steel sheets for lightweigt automobile[J]. Iron and Steel, 2006, 41(9): 4-11 doi: 10.3321/j.issn:0449-749X.2006.09.001 [3] Ma Mingtu, Shi M F. Advanced high strength steel and it’s applications in automobile industry[J]. Iron and Steel, 2004,39(7):68−72. (马鸣图, Shi M F. 先进的高强度钢及其在汽车工业中的应用[J]. 钢铁, 2004,39(7):68−72. doi: 10.3321/j.issn:0449-749X.2004.07.018Ma Ming Tu, Shi M F. Advanced high strength steel and it’s applications in automobile industry[J]. Iron and Steel, 2004, 39(7): 68-72 doi: 10.3321/j.issn:0449-749X.2004.07.018 [4] Speer John, Matlock David. Design considerations for the next generation of advanced high strength sheet steels[C]//Lee H C. Proceedings of 3rd International Conference on Structural Steels. Seoul: Korean, Institute of Metals and Materials, 2006: 774-781. [5] Speer John, Matlock David, Cooman Bruno C De, et al. Carbon partitioning into austenite after martensite transformation. Acta Materialia, 2003, 51(9): 2611-2622. [6] Wan Yong, Huang Jian, Pan Yi, et al. Development of new materials and advanced manufacturing in 2011[J]. Advanced Materials Industry, 2012,(3):48−50. (万勇, 黄健, 潘懿, 等. 2011年新材料与先进制造领域发展回望[J]. 新材料产业, 2012,(3):48−50. doi: 10.3969/j.issn.1008-892X.2012.03.012Wan Yong, Huang Jiang, Pan Yi, et al. Development of New Materials and Advanced Manufacturing in 2011[J]. Advanced materials industry, 2012(3): 48-50 doi: 10.3969/j.issn.1008-892X.2012.03.012 [7] Wan Yong, Huang Jian, Feng Ruihua, et al. Anaylysis of American “Material genome project”[J]. Advanced Materials Industry, 2012,(7):62−64. (万勇, 黄健、冯瑞华, 等. 浅析美国“材料基因组计划”[J]. 新材料产业, 2012,(7):62−64. doi: 10.3969/j.issn.1008-892X.2012.07.011Wan Yong, Huang Jian, Feng Rui Hua, et al. Anaylysis of American “Material genome project”[J]. Advanced materials industry, 2012(7): 62-64 doi: 10.3969/j.issn.1008-892X.2012.07.011 [8] Van Bohemen Stefan, Sietsma Jilt. Modeling of isothermal bainite formation based on the nucleation kinetics[J]. International Journal of Materials Research, 2008,99(7):739−747. doi: 10.3139/146.101695 [9] Kitahara Hiromoto, Ueji Rintaro, Tsuji Nobuhiro, et al. Crystallographic features of lath martensite in low-carbon steel[J]. Acta Materialia, 2006,54(5):1279−1288. doi: 10.1016/j.actamat.2005.11.001 [10] Silva Elisabete, Xu Wei, Föjer Cecilia, et al. Phase transformations during the decomposition of austenite below Ms in a low-carbon steel[J]. Materials Characterization, 2014,95(3):85−93. [11] Bhadeshia Harry. The lower bainite transformation and the significance of carbide precipitation[J]. Acta Metallurgica, 1980,28(8):1103−1114. doi: 10.1016/0001-6160(80)90093-0 [12] Clarke Amy, Speer John, Miller Michael, et al. Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment[J]. Acta Materialia, 2008,56(1):16−22. doi: 10.1016/j.actamat.2007.08.051 -

下载:

下载: