Effect of Cr content on the austenitization of 500 MPa class high-strength seismic rebars

-

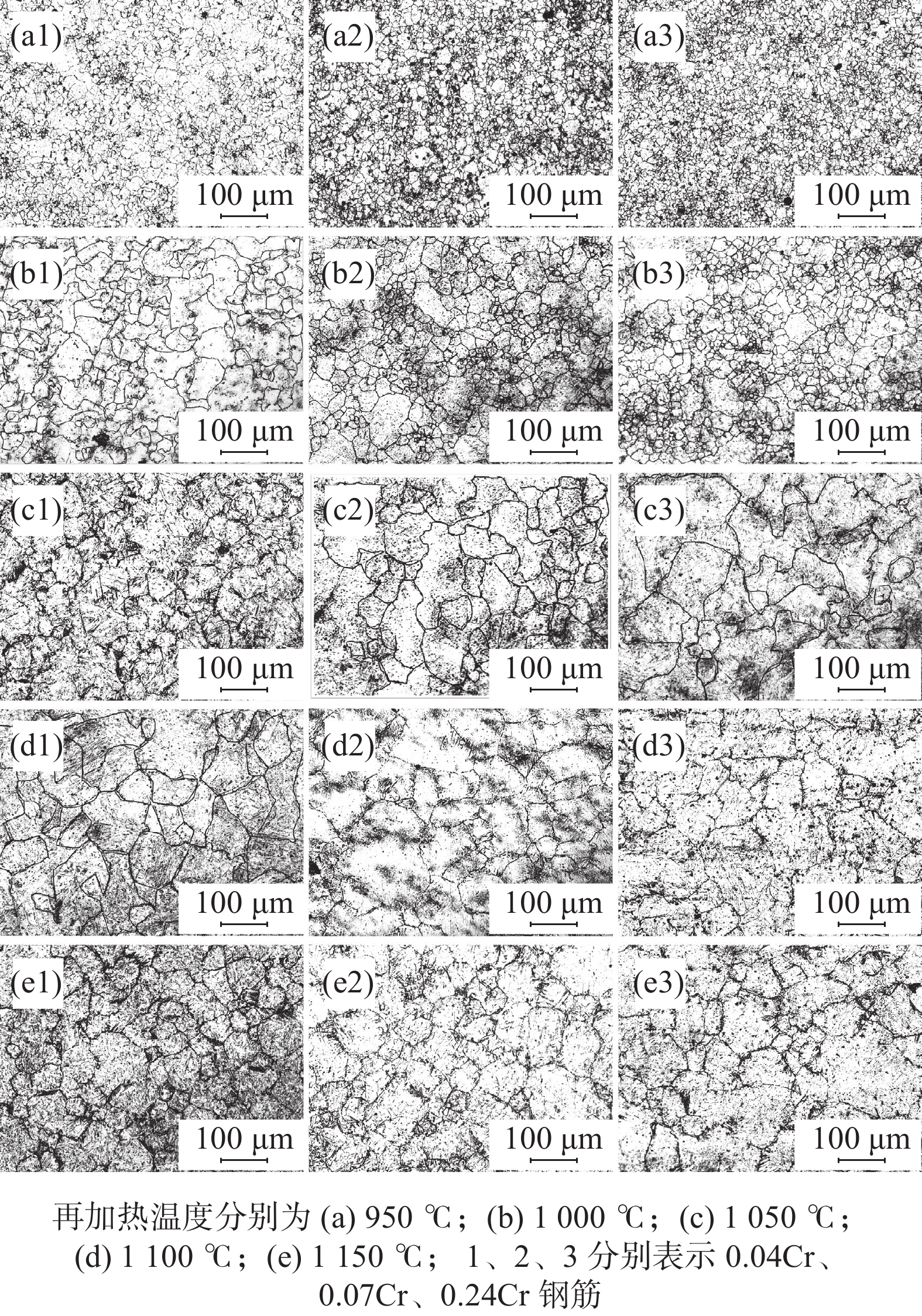

摘要: 应用光学显微镜、扫描电镜等手段观察显微组织,研究了不同Cr含量钢筋在不同铸坯再加热温度和保温时间下奥氏体晶粒的变化,探讨了Cr含量对500 MPa级高强抗震钢筋奥氏体化的影响。结果表明,不同再加热温度范围内,Cr含量对试验钢奥氏体晶粒的影响规律不同。在950~1050 ℃温度区间时,含Cr钢奥氏体晶粒的生长速率慢,随钢中Cr含量的增加,奥氏体晶粒尺寸减小;高于1050 ℃时,奥氏体晶粒生长速率加快,随钢中Cr含量的增加,奥氏体晶粒尺寸增大。相同再加热温度下,随保温时间的延长,奥氏体晶粒长大。当Cr含量较高时,随着再加热温度的升高或保温时间的延长,Cr元素在晶界处偏聚减弱,导致奥氏体晶粒更容易长大和粗化。在再加热温度为1050 ℃、保温时间为30 min条件下含Cr试验钢可得到细小均匀的奥氏体组织。Abstract: The microstructure was observed by means of optical microscope, scanning electron microscope, etc. The change of austenite grains of the steels with different Cr contents under different reheating temperature and holding time of the casting billet was studied. The effect of Cr content on austenitization of 500 MPa high-strength seismic-resistant rebar was discussed. The results show that the effect of Cr content on austenite grain is different in different reheating temperature range. In the temperature range of 950~1150 ℃, the growth rate of austenite grain in Cr-containing steel is slow when the reheating temperature is lower than 1050 ℃, and the size of austenite grain decreases with the increase of Cr content. When the temperature is higher than 1050 ℃, the growth rate of austenite grain increases, and the size of austenite grain increases with the increase of Cr content. At the same reheating temperature, austenite grains grow up with the extension of holding time. When the content of Cr is high, with the increase of the reheating temperature or the extension of the holding time, the segregation of Cr at the grain boundary is weakened, leading to the growth and coarsening of austenite grains more easily. Fine and uniform austenite structure can be obtained under the condition of 1050 ℃ and 30 min reheating temperature.

-

Key words:

- Cr-containing rebars /

- austenitization /

- slab /

- reheating temperature /

- growth rate

-

表 1 不同Cr含量试验钢的化学成分

Table 1. Compositions of experimental steels with different Cr contents

% 编号 C Si Mn S P Cr N V Fe 0.04Cr 0.22 0.53 1.57 0.044 0.021 0.043 0.015 0.091 余量 0.07Cr 0.24 0.42 1.50 0.035 0.021 0.069 0.015 0.090 余量 0.24Cr 0.21 0.44 1.35 0.025 0.015 0.238 0.018 0.089 余量 -

[1] Niu Yanlong, Sun Xinjun, Liu Qingyou, et al. Effect of Cr on static recrystallization of low carbon and high niobium X80 pipeline steel[J]. China Metallurgy, 2009,19(10):25−29. (牛延龙, 孙新军, 刘清友, 等. Cr对低碳高铌X80管线钢静态再结晶的影响[J]. 中国冶金, 2009,19(10):25−29. doi: 10.13228/j.boyuan.issn1006-9356.2009.10.009Niu Yanlong, Sun Xinjun, Liu Qingyou, et al. Effect of Cr on static recrystallization of low carbon and high niobium X80 pipeline steel [J]. China Metallurgy, 2009, 19(10) : 25-29. doi: 10.13228/j.boyuan.issn1006-9356.2009.10.009 [2] 胡铁军, 国富兴, 韩春良. 钒铬微合金化高强抗震钢筋工艺研究[C]. 2013钒钛高强钢开发与应用技术交流会论文集. 北京: 钒钛资源综合利用产业技术创新战略联盟, 2013.Hu Tiejun, Guo Fuxing, Han Chunliang. Research on the technology of vanadium-chromium microalloyed high-strength seismic steel bar [C]//Proceedings of the 2013 Vanadium-titanium High-strength Steel Development and Application Technology Exchange Conference. Beijing: The Strategic Alliance of the Vanadium and Titanium Resources Comprehensive Utilization and Industrial Technology Innovation, 2013. [3] Yang Yuqing, Wang Qingjuan, Du Zhongze. Research status of high-strength earthquake-resistant steel bars[J]. Materials Review, 2015,29(19):5. (杨雨晴, 王庆娟, 杜忠泽. 高强抗震钢筋的研究现状[J]. 材料导报, 2015,29(19):5.Yang Yuqing, Wang Qingjuan, Du Zhongze. Research status of high-strength earthquake-resistant steel bars [J]. Materials Review, 2015, 29(19): 5. [4] 徐斌. 高强度抗震钢筋V-Cr复合微合金化的实验研究[D]. 武汉: 武汉科技大学, 2011.Xu Bin. Experimental study on V-Cr composite microalloying of high-strength seismic steel bars[D]. Wuhan : Wuhan University of Science and Technology, 2011. [5] Chen Wei, Wu Guangyao, Zhang Weiqiang. Trial production of 600 MPa high-strength seismic steel bars by high nitrogen vanadium-chromium microalloying process[J]. Iron Steel Vanadium Titanium, 2016,37(2):66−72. (陈伟, 吴光耀, 张卫强. 高氮钒铬微合金化工艺试制600 MPa高强抗震钢筋[J]. 钢铁钒钛, 2016,37(2):66−72. doi: 10.7513/j.issn.1004-7638.2016.02.012Chen Wei, Wu Guangyao, Zhang Weiqiang. Trial production of 600 MPa high-strength seismic steel bars by high nitrogen vanadium-chromium microalloying process [J]. Iron Steel Vanadium Titanium, 2016, 37(2): 66-72. doi: 10.7513/j.issn.1004-7638.2016.02.012 [6] 雍岐龙. 钢铁材料中的第二相[M]. 北京: 冶金工业出版社, 2006.Yong Qilong. The second phase in steel materials[M]. Beijing: Metallurgical Industry Press, 2006. [7] Liu Wensheng, Tang Fang, Ma Yunzhu, et al. Effect of Cr addition on the microstructure and properties of 93W-4.9Ni-2.1Fe alloy[J]. Rare Metal Materials and Engineering, 2008,(7):1237−1240. (刘文胜, 唐 芳, 马运柱, 等. 添加Cr元素对93W-4.9Ni-2.1Fe合金微观结构和性能的影响[J]. 稀有金属材料与工程, 2008,(7):1237−1240.Liu Wensheng, Tang Fang, Ma Yunzhu, et al. Effect of Cr addition on the microstructure and properties of 93 W-4.9 Ni-2.1 Fe alloy[J]. Rare Metal Materials and Engineering, 2008(7): 1237-1240. [8] Zhao Yuxin, Li Pengxing, Xu Zuyao. Effect of Cr on the segregation of phosphorus at grain boundaries in low alloy steel[J]. Chinese Journal of Metals, 1987,(5):356−361. (赵宇新, 李朋兴, 徐祖耀. 低合金钢中Cr对磷在晶界偏聚的影响[J]. 金属学报, 1987,(5):356−361.Zhao Yuxin, Li Pengxing, Xu Zuyao. Effect of Cr on the segregation of phosphorus at grain boundaries in low alloy steel [J]. Chinese Journal of Metals, 1987(5): 356-361. [9] Liao Shuquan, Zhang Rui, Sun Zhongwei, et al. Effect of Cr element on austenitization kinetics of high carbon wire rods[J]. Modern Metallurgy, 2021,49(2):1−3. (廖书全, 张锐, 孙中伟, 等. Cr元素对高碳盘条奥氏体化动力学的影响[J]. 现代冶金, 2021,49(2):1−3.Liao Shuquan, Zhang Rui, Sun Zhongwei, et al. Effect of Cr element on austenitization kinetics of high carbon wire rods[J]. Modern Metallurgy, 2021, 49(2): 1-3. [10] Wang Ge, Wang Dongran, Liu Ligang, et al. Grain growth law of austenite in Cr8 steel[J]. Journal of Materials Heat Treatment, 2014,35(2):94−99. (王葛, 王东冉, 刘利刚, 等. Cr8钢奥氏体晶粒长大规律[J]. 材料热处理学报, 2014,35(2):94−99. doi: 10.13289/j.issn.1009-6264.2014.02.018Wang Ge, Wang Dongran, Liu Ligang, et al. Grain growth law of austenite in Cr8 steel [J]. Journal of Materials Heat Treatment, 2014, 35(2): 94-99. doi: 10.13289/j.issn.1009-6264.2014.02.018 [11] Sellers C M, Whiteman J A. Recrystallization and grain growth in hot rolling[J]. Metal Sci, 1979,13(3-4):187. doi: 10.1179/msc.1979.13.3-4.187 [12] 肖少彬. Bcc-Fe晶界C/Cr元素偏聚的分子动力学研究[D]. 秦皇岛: 燕山大学, 2019.Xiao Shaobin. Molecular dynamics study on segregation of C/Cr elements at Bcc-Fe grain boundary[D]. Qinghuangdao: Yanshan University, 2019. -

下载:

下载: