Effect of on-line solution treatment on the microstructure and mechanical properties of 2507 duplex stainless steels

-

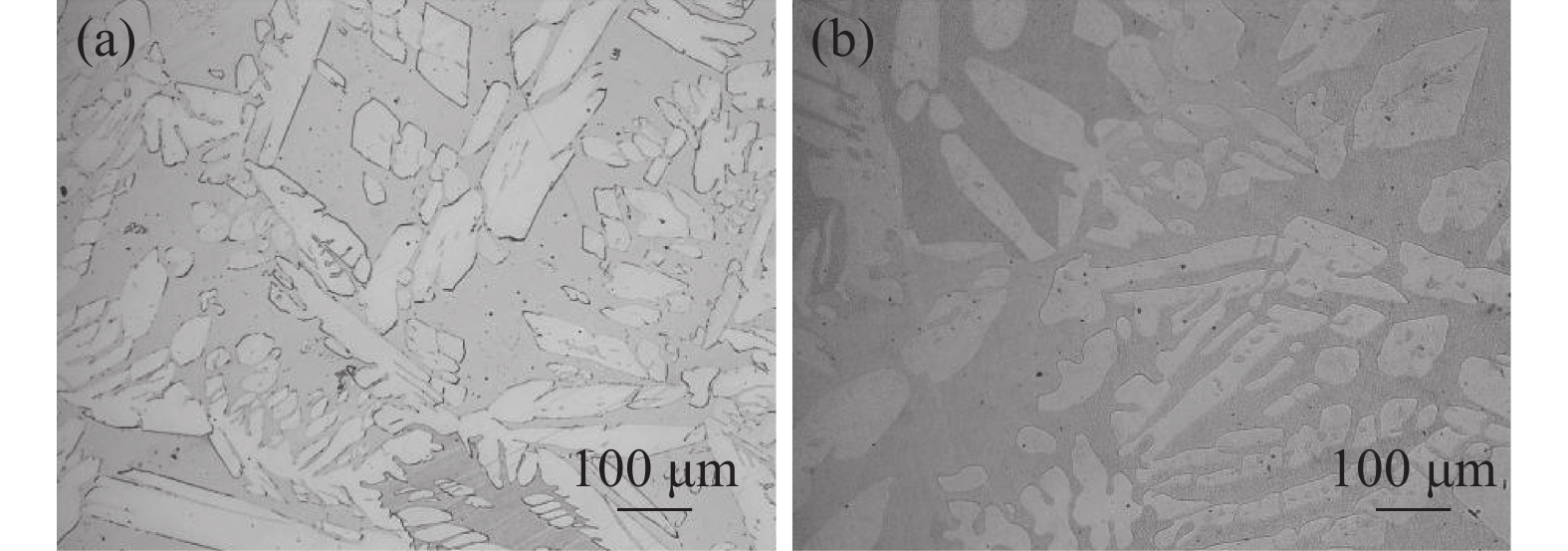

摘要: 利用热轧试验机组、Zeiss光学金相显微镜及透射电子显微镜(TEM)研究了在线固溶处理工艺及轧后待温时间对其组织和性能的影响。结果表明,在线固溶处理与离线固溶处理相比铁素体含量更高,屈服强度和抗拉强度较高,塑性和低温韧性降低较为明显,随着轧后待温时间的增加,锯齿状奥氏体含量逐渐降低,并最终转变为岛状奥氏体。TEM分析表明,在线固溶处理的铁素体相内分布大量位错。随着待温时间增加,铁素体和奥氏体的相界处有Cr2N相析出,造成钢板的塑性和耐蚀性能降低,考虑到脆性相析出数量及奥氏体形态演变,轧后钢板应快速入水。Abstract: Effects of on-line solution treatment and holding time on the microstructure and mechanical properties of 2507 duplex stainless steels were studied by hot-rolling experiments, Zeiss optical microscope (OM) and transmission electron microscopy (TEM). The results show that the volume fraction of ferrite, yield strength and tensile strength of the on-line solution treated steels are slightly higher than those of the off-line aging specimens, while the elongation and low temperature impact toughness are obviously decreased. With increasing the holding time after rolling, the amount of zigzag austenite at phase boundaries decreases and changes to island austenite eventually. TEM analysis shows that a large number of dislocations are distributed in the ferrite phases by on-line solution treatment. With increasing the holding time, the Cr2N particles precipitate at the phase boundaries between ferrite and austenite, which lead to the reduction of the ductility and corrosion resistance. Considering the amount of brittle phase and the evolution of austenite morphology, the steel plates should be quickly immersed in the cooling system after rolling.

-

Key words:

- 2507 duplex stainless steel /

- ductility /

- solution treatment /

- microstructure /

- Cr2N precipitates

-

表 1 不同工艺下2507双相不锈钢的力学性能

Table 1. Mechanical properties of 2507 steels produced by different technical methods

工艺 σ0.2/MPa σb/MPa 延伸率/% −20 ℃冲击功/J 在线处理 606 842 28.4 161 离线处理 581 812 33.4 183 -

[1] Bai Qingqing, Zhang Zhihong, Zheng Huaibei, et al. Precipitation behavior of σ phase in 2507 super duplex stainless steel[J]. Heat Treatment of Metals, 2022,47(4):108−115. (白青青, 张志宏, 郑淮北, 等. 2507超级双相不锈钢中σ相的析出行为[J]. 金属热处理, 2022,47(4):108−115.Bai Qingqing, Zhang Zhihong, Zheng Huaibei, et al. Precipitation behavior of σ phase in 2507 super duplex stainless steel[J]. Heat Treatment of Metals, 2022, 47(4): 108-115. [2] Wu Zhongzhong, Song Zhigang, Zheng Weijie, et al. Influence of solution temperature on structure and properties of super duplex stainless steel 00Cr25Ni7Mo4N[J]. Special Steel, 2006,27(4):11−13. (吴忠忠, 宋志刚, 郑文杰, 等. 固溶温度对超级双相不锈钢00Cr25Ni7Mo4N组织和性能的影响[J]. 特殊钢, 2006,27(4):11−13.Wu Zhongzhong, Song Zhigang, Zheng Weijie, et al. Influence of solution temperature on structure and properties of super duplex stainless steel 00 Cr25 Ni7 Mo4 N[J]. Special Steel, 2006, 27(4): 1113. [3] Chen Jiayan, Yang Zhuoyue, Yang Wu, et al. Characteristic of phase σ precipitation and its effects on behavior in duplex stainless steel[J]. Journal of Iron and Steel Research, 2006,18(8):1−4. (陈嘉砚, 杨卓越, 杨武, 等. 双相不锈钢中σ相的形成特点及其对性能的影响[J]. 钢铁研究学报, 2006,18(8):1−4. doi: 10.3321/j.issn:1001-0963.2006.08.001Chen Jiayan, Yang Zhuoyue, Yang Wu, et al. Characteristic of phase σ precipitation and its effects on behavior in duplex stainless steel[J]. Journal of Iron and Steel Research, 2006, 18(8): 1-4. doi: 10.3321/j.issn:1001-0963.2006.08.001 [4] Bin Yuanhong, Li Peifen, Li Zhizheng, et al. Precipitation of σ-phase and its effect on impact toughness of a duplex stainless steel solution-treated at different temperatures[J]. Transactions of Material and Heat Treatment, 2013,(8):136−141. (宾远红, 李培芬, 李志铮, 等. 不同固溶温度对双相不锈钢σ相析出及冲击韧性的影响[J]. 材料热处理学报, 2013,(8):136−141. doi: 10.13289/j.issn.1009-6264.2013.08.018Bin Yuanhong, Li Peifen, Li Zhizheng, et al. Precipitation of σ-phase and its effect on impact toughness of a duplex stainless steel solution-treated at different temperatures[J]. Transactions of Material and Heat Treatment, 2013, (8): 136-141. doi: 10.13289/j.issn.1009-6264.2013.08.018 [5] Wu Min, Li Jianchun, Li Guoping, et al. Hot deformation and microstructure evolution of as-cast super duplex stainless steel S32750[J]. Special Steel, 2019,40(5):16−20. (武敏, 李建春, 李国平, 等. 铸态超级双相不锈钢S32750热变形行为及组织演变[J]. 特殊钢, 2019,40(5):16−20.Wu Min, Li Jianchun, Li Guoping, et al. Hot deformation and microstructure evolution of as-cast super duplex stainless steel S32750 [J]. Special Steel, 2019, 40(5): 16-20. [6] Ye Youxiang, Jiang Laizhu, Miao Yuchuan, et al. Effect of TMCP on the microstructure and property of duplex stainless steel S32101 plate[J]. Shanghai Metals, 2015,37(1):14−18. (叶友祥, 江来珠, 苗雨川, 等. TMCP工艺对双相不锈钢S32101中厚板组织和性能的影响[J]. 上海金属, 2015,37(1):14−18. doi: 10.3969/j.issn.1001-7208.2015.01.004Ye Youxiang, Jiang Laizhu, Miao Yuchuan, et al. Effect of TMCP on the microstructure and property of duplex stainless steel S32101 plate[J]. Shanghai Metals, 2015, 37 (1): 14-18. doi: 10.3969/j.issn.1001-7208.2015.01.004 [7] Wang Guodong. Practice and industry applications for the new generation TMCP[J]. Shanghai Metals, 2008,30(3):1−4. (王国栋. 新一代TMCP的实践和工业应用举例[J]. 上海金属, 2008,30(3):1−4. doi: 10.3969/j.issn.1001-7208.2008.03.001Wang Guodong. Practice and industry applications for the new generation TMCP[J]. Shanghai Metals, 2008, 30 (3): 1-4. doi: 10.3969/j.issn.1001-7208.2008.03.001 [8] Yurioka N. TMCP steels and their welding[J]. Welding in the World, 1997,43(2):2−17. [9] Ikeda S, Tone S, Takashima S, et al. Effect of thermo-mechanical control process on strengthening of a 22Mn-13Cr-5Ni austenitic stainless steel plate for cryogenic use[J]. ISIJ International, 1990,30(8):600−607. doi: 10.2355/isijinternational.30.600 [10] Wu Mingrui, Jiang Laizhu, Song Hongmei, et al. Effect of TMCP on properties of duplex stainless steel 2205 heavy plate[J]. Transactions of Materials and Heat Treatment, 2012,33(5):85−90. (吴明睿, 江来珠, 宋红梅, 等. TMCP工艺对双相不锈钢2205厚板性能的影响[J]. 材料热处理学报, 2012,33(5):85−90. doi: 10.13289/j.issn.1009-6264.2012.05.022WuMingrui, Jiang Laizhu, SongHongmei, et al. Effect of TMCP on properties of duplex stainless steel 2205 heavy plate[J]. Heat Transactions ofMaterials and Heat Treatment, 2012, 33(5): 85-90. doi: 10.13289/j.issn.1009-6264.2012.05.022 [11] Xu Haijian, Han Chufei, Bai Yupu, et al. Hot deformation behaviour of microstructural evolution in 2507 super duplex stainless steel during high-temperature straining[J]. Ironmaking & Steelmking, 2022,49(10):1021−1031. -

下载:

下载: