Analysis on the formation of V-shape segregation in rail steel bloom

-

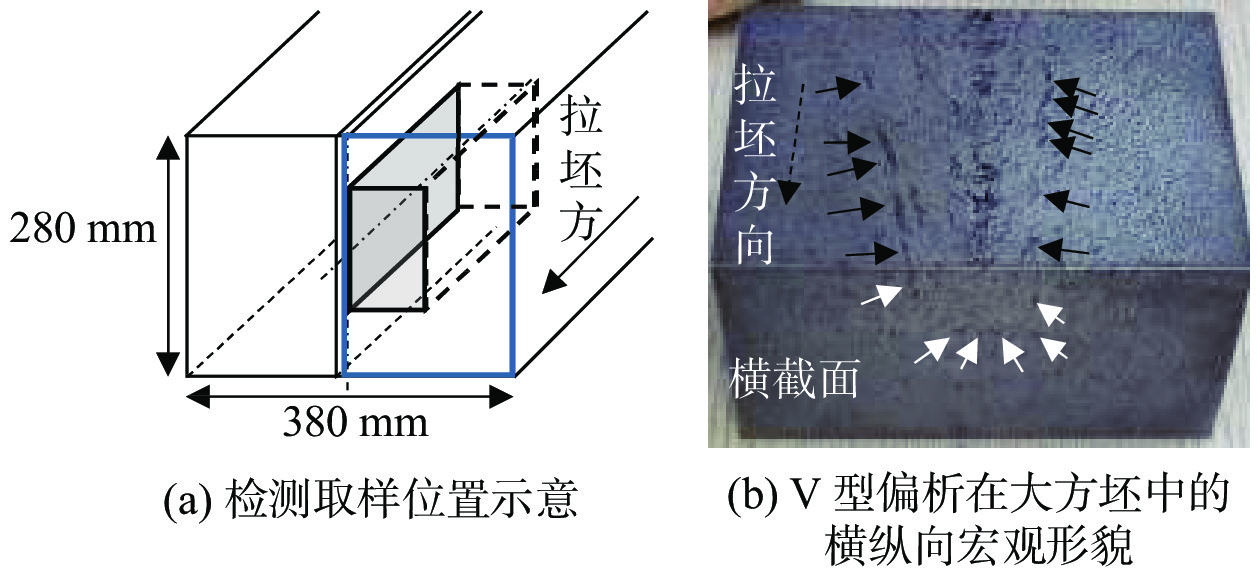

摘要: 针对重轨钢连铸大方坯V型偏析,检测了V型偏析的宏观形貌特征和凝固组织,计算对比了理论收缩体积与实际V型体积。通过凝固末端压下工艺对比、钢种对比及凝固组织调控试验,探究了V型偏析形成的影响因素。结果表明,重轨钢大方坯V型偏析分两步形成,首先是凝固前沿捕捉的晶核充分长大成粗大球化等轴晶组织后发生搭接,搭接产生封闭的富集溶质微区而形成初始V型偏析,进一步在钢液静压力和凝固收缩的负压抽吸等综合作用下发生组织滑移产生中心凹陷,导致V型偏析的宏观形貌进一步改变(减小V型角)而形成最终的V型偏析。建立了协同改善重轨钢大方坯V型偏析和中心偏析的关键工艺,实现了连铸坯V型偏析和中心偏析协同改善。Abstract: In order to improve V-shape segregation in rail steel bloom, the feature of macro-profile and microstructure were tested and theoretical shrinkage value and actual volume of V-shape was compared. The influencing factors including dynamic soft reduction processes, grade of steel and technology of micro-structure control were experimentally investigated. Result shows the V-shape segregation of rail steel bloom tends to form from two steps. The first step is ‘initial V-shape segregation formed’ where the crystal nucleus caught by solidification front of bloom fully developes into coarse connected equiaxed crystals, this results into the closed micro-regions, the molten steel in micro-regions tend to be solute rich during the solidification process. And then the second step is V-shape changed, which is formed from the microstructure subside and slip by the effect of the static pressure and the negative pressure suction due to shrinkage. Based the results the key processes has been established to improve both V-shape segregation and central segregation of rail steel bloom.

-

Key words:

- rail steel /

- solidification structure /

- V-shape segregation /

- central segregation

-

表 1 试验铸机关键装备技术条件

Table 1. The key equipment and technical parameters of continuous casting machine for experiment

连铸机机型 铸机流数 铸坯规格/mm 基本半径/m 冶金长度/m 结晶器电磁搅拌 轻压下 凝固末端电搅 全弧形 6机6流 280×380 12 35.60 有 有 有 表 2 凝固组织调控试验的关键工艺

Table 2. The key processes of experiment for solidification structure control

项目 电磁搅拌 二冷(弱冷)/(L·kg−1) 拉速/(m·min−1) M-EMS F-EMS 电流/A 频率/Hz 电流/A 频率/Hz 工艺一 200~300 2.0~2.5 0.25~0.28 0.67 工艺二 50~100 2.0~2.5 300~400 5.5~7.0 0.30~0.34 0.65 表 3 铸坯中心C偏析度统计

Table 3. Statistical result of C segregation degree for bloom center

项目 原工艺(n=30) 试验工艺(n=30) MAX 1.34 1.12 MIN 0.95 0.99 平均 1.15 1.06 -

[1] Li Ping, Wang Lei, Zhou Qingfeng. Formation reasons of countermeasures of cmentite network in the center of 82B wire rods[J]. Journal of Iron and Steel Research, 2014,26(9):33−36. (李平, 王雷, 周青峰. 82B中心网状渗碳体产生原因及改善方法[J]. 钢铁研究学报, 2014,26(9):33−36.Li Ping, Wang Lei, Zhou Qingfeng. Formation Reasons of Countermeasures of Cementite Network in the Center of 82 B Wire Rods[J]. Journal of Iron and Steel Research, 2014, 26(09): 33-36. [2] 纪元. 连铸还偏析及其铸轧遗传性研究[D]. 北京: 北京科技大学, 2018.Ji Yuan. Segregation of billet castings and its heredity effect on the hot-rolled products[D]. Beijing: University of Science and Technology, 2018. [3] Zong Nanfu, Zhang Hui, Liu Yang, et al. Causes and harms of defects in solidification structure and segregation of continuous casting bearing steel[J]. Bearing, 2018,(6):62−67. (宗男夫, 张慧, 刘洋, 等. 连铸轴承钢偏析和凝固组织缺陷的成因及其危害[J]. 轴承, 2018,(6):62−67. doi: 10.19533/j.issn1000-3762.2018.06.017Zong Nanfu, Zhang Hui, Liu Yang, et al. Causes and Harms of Defects in Solidification Structure and Segregation of Continuous Casting Bearing Steel[J]. Bearing, 2018(06): 62-67. doi: 10.19533/j.issn1000-3762.2018.06.017 [4] Song Yancheng, Liu Jigang. Analysis of the effects of segregation on the porosity of slab[J]. Modern Metallurgy, 2019,47(2):7−10. (宋延成, 刘吉刚. 偏析对于连铸坯性能的影响分析[J]. 现代冶金, 2019,47(2):7−10.Song Yancheng, Liu Jigang. Analysis of the effects of segregation on the porosity of slab[J]. Modern Metallurgy, 2019, 47(02): 7-10. [5] Chen Yuhui, Song Yancheng. Analysis of the effects of segregation of slab on the mechanical property of steel plate[J]. Modern Metallurgy, 2018,46(5):13−15. (陈玉辉, 宋延成. 连铸坯偏析对钢板机械性能的影响分析[J]. 现代冶金, 2018,46(5):13−15.Chen Yuhui, Song Yancheng. Analysis of the effects of segregation of slab on the mechanical property of steel plate[J]. Modern Metallurgy, 2018, 46(05): 13-15. [6] Li Bo, Zhang Zhonghua, Liu Huasong, et al. Characteristics and evolution of the spot segregations and banded defects in high strength corrosion resistant tube steel[J]. Acta Metallurgica Sinica, 2019,55(6):762−772. (李博, 张忠铧, 刘华松, 等. 高强耐蚀管钢点状偏析及带状缺陷的特征与演变[J]. 金属学报, 2019,55(6):762−772.Li Bo, Zhang Zhonghua, Liu Huasong, et al. Characteristics and Evolution of the Spot Segregations and Banded Defects in High Strength Corrosion Resistant Tube Steel[J]. ACTA METALLURGICA SINICA, 2019, 55(06): 762-772. [7] 王升千. GCr15轴承钢低倍检验孔洞的形成机理及控制研究[D]. 北京: 北京科技大学, 2016.Wang Shengqian. Study on formation mechanism and control of pits during inspection process in GCr15 bearing steel[D]. Beijing: University of Science and Technology, 2016. [8] Ji Y, Lan P, Geng H, et al. Behavior of spot segregation in continuously cast blooms and the resulting segregated band in oil pipe steels[J]. Steel Research International, 2018,89(3):1700331. doi: 10.1002/srin.201700331 [9] Lu Zhifang, Zhang Zhiguang, Zhao Zhengzheng, et al. Influence of superheat on internal structure of the bearing steel[J]. Chinese Journal of Engineering, 2016,38(S1):45. (逯志方, 张治广, 赵铮铮, 等. 过热度对轴承钢内部组织的影响[J]. 工程科学学报, 2016,38(S1):45.Lu Zhifang, Zhang Zhiguang, Zhao Zhengzheng, et al. Influence of superheat on internal structure of the bearing steel[J]. Chinese Journal of Engineering, 2016, 38(S1): 45. [10] Pikkarainen T, Vuorenmaa V, Rentola I, et al. Effect of superheat on macrostructure and macro-segregation in continuous cast low-alloy steel slabs[C]//IOP Conference Series: Materials Science and Engineering. Bristol: IOP Publishing, 2016: 012064. [11] Zeng Zhi, Ji Chenxi, Zhang Hongyan, et al. Optimization experiment of soft reduction for continuous casting slab[J]. Continuous Casting, 2018,43(4):23. (曾智, 季晨曦, 张宏艳, 等. 板坯连铸轻压下工艺参数优化试验研究[J]. 连铸, 2018,43(4):23.Zeng Zhi, Ji Chenxi, Zhang Hongyan, et al. Optimization experiment of soft reduction for continuous casting slab[J]. Continuous Casting, 2018, 43(4): 23. [12] Huang Tuo, Ren Jinzhao, Ma Zhongwei, et al. An analysis on morphology of macro and micro structure of V-segregation in Ø380 mm continuous casting bloom of bearing steel GCr15[J]. Special Steel, 2014,35(4):48−51. (黄拓, 任金朝, 马忠伟, 等. GCr15轴承钢Ø380 mm连铸圆坯V-偏析的宏观与微观形貌分析[J]. 特殊钢, 2014,35(4):48−51. doi: 10.3969/j.issn.1003-8620.2014.04.014Huang Tuo, Ren Jinzhao, Ma Zhongwei, et al. An Analysis on Morphology of Macro and Micro Structure of V-Segregation in Φ380 mm Continuous Casting Bloom of Bearing Steel GCr15[J]. Special Steel, 2014, 35(04): 48-51. doi: 10.3969/j.issn.1003-8620.2014.04.014 [13] Huang Tuo, Ma Zhongwei, Ren Jinzhao, et al. Phenomenon and control measurements of V-shape segregation in 82B steel billet[J]. Iron Steel Vanadium Titanium, 2014,35(6):108−112. (黄拓, 马忠伟, 任金朝, 等. 82B连铸坯V型偏析现象及控制[J]. 钢铁钒钛, 2014,35(6):108−112.Huang Tuo, Ma Zhongwei, Ren Jinzhao, et al. Phenomenon and Control Measurements of V-shape Segregation in 82 B Steel Billet[J]. Iron Steel Vanadium Titanium, 2014, 35(06): 108-112. [14] Mcdonald R J, Hunt J D. Fluid motion through the partially solid regions of a casting and its importance in a-type segregation[J]. Trans. Metal. Soc. Aime, 1969,245:1993−1997. [15] Suzuki K, Miyamoto T. Study on the formation of a segregation in steel ingot[J]. Trans. ISIJ, 1978,18:80−89. doi: 10.2355/isijinternational1966.18.80 [16] 李红光, 祭程, 姜东滨, 等. 重载钢轨钢连铸大方坯半宏观偏析形成机制与控制研究[J]. 钢铁, 2021, 56(6): 59-66.Li Hongguang , Ji Cheng, Jiang Dongbin, et al. Research on the formation mechanism and control of semi-macro segregation in rail steel bloom[J] Iron and Steel, 2021, 56(6): 59-66. -

下载:

下载: