Multivariate correlation analysis of qualified liquid and vanadium pentoxide composition during vanadium precipitation

-

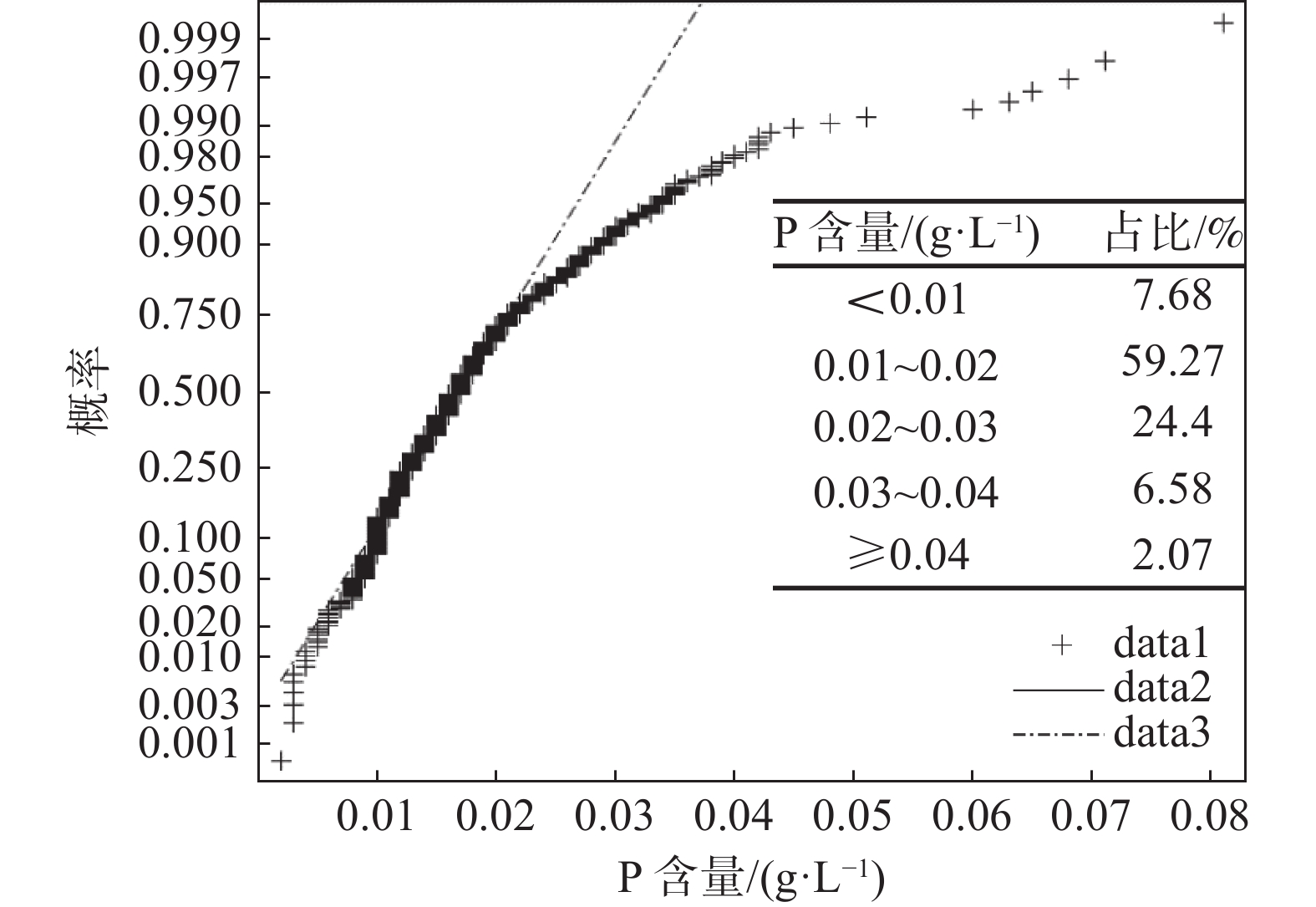

摘要: 通过Pearson系数统计方法、概率密度分析方法和概率密度累积分布分析方法研究沉钒过程合格液中磷、铁、锰、硅、钒等元素对五氧化二钒成分的多元相关影响。结果表明,合格液中P、Mn含量与五氧化二钒中P含量的Pearson系数分别为0.6847、0.6663,线性相关程度最高;合格液中Mn与五氧化二钒中Mn的Pearson系数为0.3612,合格液中Fe与五氧化二钒中Si的Pearson系数为0.3564,具有一定的线性相关;合格液中P与五氧化二钒中Si的Pearson系数为−0.3291,合格液中V与五氧化二钒中P的Pearson系数为−0.2259,具有一定的负线性相关。合格液中其余元素含量与五氧化二钒中元素含量的Pearson系数的绝对值均小于0.16,说明相关性不强。五氧化二钒和合格液中P、Mn、Fe、Si、V含量均不服从正态分布,反映出统一样本过程不稳定,即生产过程不稳定,因此减少合格液成分异常波动,规避沉钒过程中对五氧化二钒质量产生较大影响的因素,可以提高五氧化二钒成分的稳定性。该研究为生产合格五氧化二钒提供了一定的理论技术支撑。Abstract: The effects of phosphorus, iron, manganese, silicon and vanadium in the qualified solution during vanadium precipitation on the composition of vanadium pentoxide were investigated through multivariate correlation analysis using Pearson coefficient statistics, probability density analysis and probability density cumulative distribution analysis methods. The results show that the Pearson coefficients of P, Mn content in qualified solution and P content in vanadium pentoxide are 0.6847 and 0.6663, respectively, with the highest degree of linear dependence. The Pearson coefficients of Mn, Fe in qualified liquid and Mn, Si in vanadium pentoxide are 0.3612 and 0.3564, respectively, indicating a certain degree of linear dependence. The Pearson coefficients of P, V in qualified liquid and Si, P in vanadium pentoxide are −0.3291 and −0.2258, respectively, representing a certain degree of negative linear correlation. The absolute value of Pearson coefficients for the content of other elements in the qualified solution and vanadium pentoxide are all less than 0.16, indicating a weak correlation. The contents of P, Mn, Fe, Si and V in vanadium pentoxide and qualified solution do not follow a normal distribution, reflecting the instability of the unified sample process, that is, the unstable production process. Therefore, it is necessary to reduce the abnormal fluctuation of qualified solution composition and avoid the factors that have relatively great impacts on the vanadium precipitation, which contributes to improve the stability of vanadium oxide composition. This work can provide some theoretical and technical support for the production of qualified vanadium oxide.

-

表 1 合格液样本数据

Table 1. Data of qualified liquid samples

元素 样本数量/个 含量/(g·L−1) 方差 标准差 均值 中位数 V 820 23.3528 23.2600 5.3362 2.3100 P 820 0.0182 0.0170 7.3699×10−5 0.0086 Mn 819 13.6500 13.6500 9.1627 3.0270 Si 820 0.4639 0.4600 0.0132 0.1148 Fe 819 0.0406 0.0400 4.9814×10−4 0.0223 表 2 五氧化二钒样本数据

Table 2. Vanadium pentoxide samples data

成分 样本数量/个 含量/% 方差 标准差 均值 中位数 V2O5 2046 98.4312 98.4600 0.3315 0.5757 P 2051 0.0235 0.0220 1.1502×10−4 0.0107 Mn 1608 0.2843 0.2600 0.0142 0.1194 Si 2046 0.1728 0.1600 0.0056 0.0748 Fe 2046 0.2671 0.2600 0.0187 0.1366 表 3 合格液中P与五氧化二钒中各元素的相关系数(Pearson系数)

Table 3. Correlation coefficient between P in qualified liquid and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-P) r(V2O5-Fe,HGY-P) r(V2O5-Si,HGY-P) r(V2O5-V2O5,HGY-P) r(V2O5-P,HGY-P) 0.2025 −0.0922 −0.3291 0.0670 0.6847 表 4 合格液中P与五氧化二钒中P各阶段的相关系数(Pearson系数)

Table 4. Correlation coefficients of P in qualified liquid and P in vanadium pentoxide at various stages

1段 2段 3段 4段 5段 6段 合计 0.5024 0.5580 0.8138 0.7046 0.6422 0.7162 0.6847 表 5 合格液中Mn与五氧化二钒中各元素的相关系数(Pearson系数)

Table 5. Correlation coefficient between Mn in qualified liquid and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-Mn) r(V2O5-Fe,HGY-Mn) r(V2O5-Si,HGY-Mn) r(V2O5-V2O5,HGY-Mn) r(V2O5-P,HGY-Mn) 0.3612 0.0145 −0.1088 −0.0815 0.6663 表 6 合格液中Fe与五氧化二钒中各元素的相关系数(Pearson系数)

Table 6. Correlation coefficient between Fe in qualified liquid and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-Fe) r(V2O5-Fe,HGY-Fe) r(V2O5-Si,HGY-Fe) r(V2O5-V2O5,HGY-Fe) 0.0705 0.0296 0.3564 −0.1455 表 7 合格液中Si与五氧化二钒中各元素的相关系数(Pearson系数)

Table 7. Correlation coefficient between Si in qualified liquid and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-Si) r(V2O5-Fe,HGY-Si) r(V2O5-Si,HGY-Si) r(V2O5-V2O5,HGY-Si) r(V2O5-P,HGY-Si) −0.1538 0.0258 −0.0357 0.0482 0.1302 表 8 合格液中V与五氧化二钒中各元素的相关系数(Pearson系数)

Table 8. Correlation coefficient between V in qualified liquid and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-V) r(V2O5-Fe,HGY-V) r(V2O5-Si,HGY-V) r(V2O5-V2O5,HGY-V) r(V2O5-P,HGY-V) 0.0429 −0.1599 0.0977 0.0126 −0.2259 表 9 合格液中pH与五氧化二钒中各元素的相关系数(Pearson系数)

Table 9. Correlation coefficient between pH in qualified solution and various elements in vanadium pentoxide

r(V2O5-Mn,HGY-pH) r(V2O5-Fe,HGY-pH) r(V2O5-Si,HGY-pH) r(V2O5-V2O5,HGY-pH) r(V2O5-P,HGY-pH) 0.0403 −0.0804 −0.0380 0.0115 −0.0150 -

[1] 陈嫚丽. 钙化转炉钒渣硫酸浸取液除磷工艺研究[D]. 重庆: 重庆大学, 2016.Chen Manli. Study on phosphorus removal process from sulfuric acid leaching solution of calcified converter vanadium slag[D]. Chongqing: Chongqing University, 2016. [2] 廖世明, 柏谈论. 国外钒冶金[M]. 北京: 冶金工业出版社, 1985: 147-160.Liao Shiming, Bai Tanlun. Vanadium metallurgy abroad[M]. Beijing: Metallurgical Industry Press, 1985: 147-160. [3] 段冉. 高纯五氧化二钒的制备及偏钒酸铵结晶机理的研究[D]. 长沙: 中南大学, 2011.Duan Ran. Preparation of high-purity vanadium pentoxide and study on the crystallization mechanism of ammonium metavanadate[D]. Changsha: Central South University, 2011. [4] Yang He, Mao Linqiang, Xue Xiangxin, et al. The effect of impurity ions on the precipitation of ammonium polyvanadate[J]. Iron Steel Vanadium Titanium, 2013,34(3):13−18. (杨合, 毛林强, 薛向欣, 等. 杂质离子对沉淀多钒酸铵的影响[J]. 钢铁钒钛, 2013,34(3):13−18. doi: 10.7513/j.issn.1004-7638.2013.03.003Yang He, Mao Linqiang, Xue Xiangxin, et al. The effect of impurity ions on the precipitation of ammonium polyvanadate[J]. Iron Steel Vanadium Titanium, 2013, 34 (3): 13-18 doi: 10.7513/j.issn.1004-7638.2013.03.003 [5] 张喜水, 李敏, 沈国军. 酸性铵盐沉钒研究[C]//第二届钒产业先进技术交流会论文集. 昆明: 钒钛资源综合利用产业技术创新战略联盟, 中国钢铁工业协会钒业分会, 2013: 107-110.Zhang Xishui, Li Min, Shen Guojun. Research on acid ammonium salt vanadium precipitation[C]//Proceedings of the Second Vanadium Industry Advanced Technology Exchange Conference. Kunming: Strategic Alliance for Technological Innovation in the Comprehensive Utilization of Vanadium and Titanium Resources, Vanadium Industry Branch of the China Iron and Steel Industry Association, 2013: 107-110. [6] Fu Chaoyang, Zhang Yimin, Liu Tao, et al. The effect of impurities in the stripping solution of vanadium extraction from stone coal on the precipitation of vanadium by acidic ammonium salts[J]. Rare Metals, 2016,40(10):1060−1065. (付朝阳, 张一敏, 刘涛, 等. 石煤提钒反萃液中杂质离子对酸性铵盐沉钒的影响[J]. 稀有金属, 2016,40(10):1060−1065. doi: 10.13373/j.cnki.cjrm.xy15032601Fu Chaoyang, Zhang Yimin, Liu Tao, et al. The effect of impurities in the stripping solution of vanadium extraction from stone coal on the precipitation of vanadium by acidic ammonium salts[J]. Rare Metals, 2016, 40 (10): 1060-1065 doi: 10.13373/j.cnki.cjrm.xy15032601 [7] Zhang Juhua, Liang Yue, Zhang Wei, et al. Recovery of manganese from mother liquor of vanadium precipitation by calcification acid leaching[J]. Journal of Process Engineering, 2020,20(10):1174−1181. (张菊花, 梁月, 张伟, 等. 钙化-酸浸提钒沉钒母液中锰的回收[J]. 过程工程学报, 2020,20(10):1174−1181. doi: 10.12034/j.issn.1009-606X.219354Zhang Juhua, Liang Yue, Zhang Wei, et al. Recovery of manganese from mother liquor of vanadium precipitation by calcification acid leaching[J]. Journal of Process Engineering, 2020, 20 (10): 1174-1181 doi: 10.12034/j.issn.1009-606X.219354 [8] Xie Mingwen. The relationship between covariance, correlation coefficient, and correlation[J]. Mathematical Statistics and Management, 2004,(3):33−36. (谢明文. 关于协方差、相关系数与相关性的关系[J]. 数理统计与管理, 2004,(3):33−36. doi: 10.3969/j.issn.1002-1566.2004.03.008Xie Mingwen. The relationship between covariance, correlation coefficient, and correlation[J]. Mathematical Statistics and Management, 2004 (3): 33-36 doi: 10.3969/j.issn.1002-1566.2004.03.008 [9] Zhang Zhanyang, Zhou Minghui, Gao Yanlong, et al. Analysis of Tangshan platform fault CO2 based on Pearson correlation coefficient between concentration and ground temperature and its relationship with earthquakes[J]. Inland Earthquake, 2022,36(3):227−236. (张占阳, 周铭辉, 高艳龙, 等. 基于Pearson相关系数分析唐山台断层CO2浓度与地温相关性及其与地震的关系[J]. 内陆地震, 2022,36(3):227−236.Zhang Zhanyang, Zhou Minghui, Gao Yanlong, et al. Analysis of Tangshan platform fault CO2 based on Pearson correlation coefficient between concentration and ground temperature and its relationship with earthquakes[J]. Inland Earthquake, 2022, 36 (3): 227-236 [10] Huo Xiaoqing, Wang Shouyu, Wang Xiaochun, et al. Multifactor analysis of accelerator failure rate based on Pearson correlation coefficient[J]. China Medical Equipment, 2021,36(5):34−36, 50. (霍晓庆, 王守宇, 王晓春, 等. 基于Pearson相关系数的影响加速器故障率的多因素分析[J]. 中国医疗设备, 2021,36(5):34−36, 50. doi: 10.3969/j.issn.1674-1633.2021.05.008Huo Xiaoqing, Wang Shouyu, Wang Xiaochun, et al. Multifactor analysis of accelerator failure rate based on Pearson correlation coefficient[J]. China Medical Equipment, 2021, 36 (5): 34-36, 50 doi: 10.3969/j.issn.1674-1633.2021.05.008 [11] He Wenyi. Vanadium precipitation test with calcified roasting acid leaching solution of vanadium slag at Pangang[J]. Metal Mines, 2014,(5):166−170. (何文艺. 攀钢钒渣钙化焙烧酸浸液沉钒试验[J]. 金属矿山, 2014,(5):166−170.He Wenyi. Vanadium precipitation test with calcified roasting acid leaching solution of vanadium slag at Pangang[J]. Metal Mines, 2014 (5): 166-170 -

下载:

下载: