Preparation and properties of high-strength fired water permeable brick containing vanadium-titanium iron ore tailings

-

摘要: 以钒钛铁尾矿为主要原料制备高强烧结透水砖,采用正交试验法、X射线衍射(XRD)、扫描电镜 (SEM)和能谱分析 (EDS)研究了钒钛铁尾矿高强烧结透水砖的基本性能、烧结机理。结果表明,当烧结透水砖中钒钛铁尾矿掺量为77%,烧结温度为1070 ℃,保温时间110 min时,烧制的产品抗压强度和透水系数分别达到65.7 MPa和0.063 cm/s,符合《透水砖》 (JC/T 945-2005) 中Cc60级产品的要求;高强烧结透水砖烧结后的产物为透辉石(CaMgSi2O6)和普通辉石(Ca(Mg,Fe,Al)(Si,Al)2O6)。随着烧结温度和保温时间的延长,低熔点元素P、Na、K溶出,烧结产物中Fe、Al元素的含量增多,透辉石中的多数Ca2+被Fe3+置换,使得普通辉石成为主晶相。烧结产物中的孔洞随着烧结温度的提高,发生了由大小不一的密闭孔→孔径不规则的联通孔→不规则塌陷孔→孔径小且均匀圆形孔的变化,这种变化为高强烧结透水砖的透水性提供了保障。该研究提高了钒钛铁尾矿的利用率,为钒钛铁尾矿的大规模应用提供了新途径。Abstract: In order to promote the efficient comprehensive utilization of vanadium-titanium iron ore tailings (VTIOTs), the basic properties and firing mechanism of high-strength fired water permeable bricks (HSFWPB) containing VTIOTs were investigated by using orthogonal test method, X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy spectrum analysis (EDS). The results show that when the content of VTIOTs in HSFWPB is 77%, the firing temperature (FT) is 1070 ℃ and the holding time is 110 min, the compressive strength and permeability coefficient of the fired product reach 65.7 MPa and 0.063 cm/s, respectively, which meet the requirements of Cc60 grade products set by “water permeable brick” standard (JC/T 945—2005). The products of HSFWPB containing VTIOTs after firing are diopside (CaMgSi2O6) and augite (Ca(Mg,Fe,Al)(Si,Al)2O6). With the increase of FT and the extension of HT, the low melting point elements of P, Na, K dissolve out, and the contents of Fe and Al in the firing products increase; most of Ca2+ in diopside is replaced by Fe3+, and thus, augite becomes the main crystal phase. With the increase of FT, the pores in the fired products change as follows: closed holes with different sizes→connected pores with irregular diameters→irregular collapse pores→small and uniform circular pores, which provides a guarantee for the permeability of HSFWPB containing VTIOTs. The research has improved the utilization rate of VTIOTs and provides a new approach for the large-scale application of VTIOTs.

-

图 2 钒钛铁尾矿的SEM形貌[60]

Figure 2. SEM images of VTIOTs

表 1 原料的主要化学成分

Table 1. Main chemical components of raw materials

% 原料 SiO2 Al2O3 Fe2O3 CaO K2O MgO Na2O P2O5 TiO2 其他 烧失量 钒钛铁尾矿 41.13 7.83 11.05 20.38 0.42 12.52 0.54 0.26 0.87 1.90 3.10 湖泊底泥 52.08 13.64 4.89 5.27 3.06 1.97 0.35 2.07 0.15 2.41 14.11 铜尾矿 47.59 6.08 5.50 5.16 1.73 26.25 0.65 0.08 2.74 4.22 未煅烧煤矸石 36.75 30.81 0.62 1.34 0.18 0.64 1.14 0.07 2.08 26.37 煅烧煤矸石 52.01 35.88 3.51 1.72 0.37 0.79 2.24 0.12 2.53 0.83 表 2 正交试验方案及测试结果

Table 2. Orthogonal test scheme and results for HSFWPB containing VTIOTs

编号 因素 方案 抗压强

度/MPa透水系数/

(cmˑs−1)A

(掺量/%)B(烧结

温度/ ℃)C(保温

时间/min)1 75 1010 50 A1B1C1 40.2 0.108 2 75 1030 80 A1B2C2 49.6 0.092 3 75 1050 110 A1B3C3 60.7 0.079 4 75 1070 140 A1B4C4 67.5 0.057 5 77 1010 80 A2B1C2 38.1 0.115 6 77 1030 50 A2B2C1 42.2 0.098 7 77 1050 140 A2B3C4 58.3 0.077 8 77 1070 110 A2B4C3 65.7 0.063 9 79 1010 110 A3B1C3 37.6 0.115 10 79 1030 140 A3B2C4 44.2 0.088 11 79 1050 50 A3B3C1 45.4 0.090 12 79 1070 80 A3B4C2 58.5 0.079 13 81 1010 140 A4B1C4 36.3 0.119 14 81 1030 110 A4B2C3 38.7 0.112 15 81 1050 80 A4B3C2 42.5 0.087 16 81 1070 50 A4B4C1 44.6 0.082 表 3 钒钛铁尾矿高强烧结基本性能方差分析

Table 3. Variance analysis table of basic properties for HSFWPB containing VTIOTs

性能指标 方差来源 掺量/% 烧结温度/ ℃ 保温时间/min 误差 总和 抗压强度 离差平方和 444.6875 992.1875 173.1875 25.375 1635.4375 自由度 3 3 3 6 15 均方 148.229 330.729 57.729 4.229 检验统计量 35.05 78.21 13.65 临界值 F0.05(3,6)=4.76 F0.25(3,6)=1.78 显著性 显著 显著 显著 透水系数 离差平方和 0.00054 0.00044 0.00024 0.00412 0.00534 自由度 3 3 3 6 15 均方 0.000180 0.000147 0.000080 0.000687 检验统计量 0.26 0.21 0.12 临界值 F0.05(3,6)=4.76 F0.25(3,6)=1.78 显著性 不显著 不显著 不显著 -

[1] Sun Y, Gu X W, Xu X C. Ecological restoration and mechanical reinforcement effect of slope of tailings reservoir[J]. Environmental Earth Sciences, 2021,80:1−12. doi: 10.1007/s12665-020-09327-2 [2] Jiang P, Lv S W, Wang Y, et al. Investigation on direct shear and energy dissipation characteristics of iron tailings powder reinforced by polypropylene fiber[J]. Applied Sciences, 2019,23(9):5098−5113. [3] Chen D Q, Cui Y F, Li Z H, et al. Watch out for the tailings pond, a sharp edge hanging over our heads: Lessons learned and perceptions from the Brumadinho tailings dam failure disaster[J]. Remote Sensing, 2021,13(9):1775−1796. doi: 10.3390/rs13091775 [4] Rey N J, Demers I, Bussière B, et al. A geochemical evaluation of a monolayer cover with an elevated water table for the reclamation of the Doyon-Westwood tailings ponds, Canada[J]. Environmental Earth Sciences, 2020,79:58−69. doi: 10.1007/s12665-019-8797-8 [5] Zhao X, Fourie A, Qi C C. Mechanics and safety issues in tailing-based backfill: A review[J]. International Journal of Minerals, Metallurgy and Materials, 2020,27(9):1165−1178. doi: 10.1007/s12613-020-2004-5 [6] Li X S, Li Q H, Hu Y J. Study on three-dimensional dynamic stability of open-pit high slope under blasting vibration[J]. Lithosphere, 2022,2021:6426550. doi: 10.2113/2022/6426550 [7] Tang Y, Lin H, Wang Y X. Rock slope stability analysis considering the effect of locked section[J]. Bulletin of Engineering Geology and the Environment, 2021,80:7241−7251. doi: 10.1007/s10064-021-02366-4 [8] Peng J S, Guan Y H, Lin X J, et al. Comparative understanding of metal hyperaccumulation in plants: A mini-review[J]. Environmental Geochemistry and Health, 2020,43:1599−1607. [9] Li L, Sun J W, Jiang J J, et al. The effect of environmental regulation competition on haze pollution: Evidence from China’s province-level data[J]. Environmental Geochemistry and Health, 2021,44:3057−3080. [10] Tang Z E, Deng R J, Zhang J, et al. Regional distribution characteristics and ecological risk assessment of heavy metal pollution of different land use in an antimony mining area[J]. Human and Ecological Risk Assessment, 2019,26:1779−1794. [11] Jiang F, Ren B Z, Hursthouse A S, et al. Trace metal pollution in topsoil surrounding the Xiangtan man-ganese mine area (South-Central China): source identification, spatial distribution and assessment of potential eco-logical risks[J]. International Journal of Environmental Research and Public Health, 2018,15(11):2412−2427. doi: 10.3390/ijerph15112412 [12] Luo X, Ren B Z, Hursthouse A S, et al. Potentially toxic elements (PTEs) in crops, soil, and water near Xiangtan manganese mine, China: Potential risk to health in the foodchain[J]. Environmental Geochemistry and Health, 2019,42:1965−1976. [13] Wang K, Yang P, Karen H E, et al. Status and development for the prevention and management of tailings dam failure accidents[J]. Chinese Journal of Engineering, 2018,40(5):526−539. [14] Li L, Jiang T, Zhou M, et al. Overall utilization of vanadium–titanium magnetite tailings to prepare lightweight foam ceramics[J]. Process Safety and Environmental Protection, 2020,139:305−314. doi: 10.1016/j.psep.2020.04.034 [15] Zhu X Y, Sun N, Huang Y, et al. Preparation of full tailings-based foam ceramics and auxiliary foaming effect of vanadium-titanium magnetite tailings[J]. Journal of Non-Crystalline Solids, 2021,571:121063. doi: 10.1016/j.jnoncrysol.2021.121063 [16] Gan C D, Cui S F, Wu Z Z, et al. Multiple heavy metal distribution and microbial community characteristics of vanadium-titanium magnetite tailing profiles under different management modes[J]. Journal of Hazardous Materials, 2022,429:128032. doi: 10.1016/j.jhazmat.2021.128032 [17] Huang Y, Zhou D, Wang L, et al. Role of tailing colloid from vanadium-titanium magnetite in the adsorption and cotransport with vanadium[J]. Environmental Science and Pollution Research, 2023,30:34069−34084. [18] Li L, Jiang T, Chen B J, et al. Integrated utilization of vanadium-titanium magnetite tailings for synthesis of lightweight foamed ceramics: Effect of chemical composition on the properties and phase evolution[J]. Journal of Sustainable Metallurgy, 2022,8:646−657. doi: 10.1007/s40831-022-00517-9 [19] Zhang Y, Zhang T A, Dreisinger D, et al. Recovery of vanadium from calcification roasted-acid leaching tailing by enhanced acid leaching[J]. Journal of Hazardous Materials, 2019,369:632641. [20] Sun H Y, Wei X F, Sun X M, et al. Bioaccumulation and translocation characteristics of heavy metals in a soil-maize system in reclaimed land and surrounding areas of typical vanadium-titanium magnetite tailings[J]. Environmental Science, 2021,42(3):1166−1176. [21] Yu X M, Kang X, Li Y M, et al. Rhizobia population was favoured during in situ phytoremediation of vanadium-titanium magnetite mine tailings dam using Pongamia pinnata[J]. Environmental Pollution, 2019,255:113167. doi: 10.1016/j.envpol.2019.113167 [22] Chen S Y, Fu X J, Chu M S, et al. Life cycle assessment of the comprehensive utilization of vanadium titan-magnetite[J]. Journal of Cleaner Production, 2015,101:122−128. doi: 10.1016/j.jclepro.2015.03.076 [23] Chen T, Jian S, Xie X, et al. Research progress on comprehensive utilization of vanadium-titanium magnetite tailings[J]. Conservation and Utilization of Mineral Resources, 2021,41(2):174−178. [24] Xi C P, Zheng F, Xu J H, et al. Preparation of glass-ceramics foam using extracted titanium tailing and glass waste as raw materials[J]. Construction and Building Materials, 2018,190:896−909. doi: 10.1016/j.conbuildmat.2018.09.170 [25] Wang Changlong, Ma Jingtao, Yang Fenghao, et al. Preparation and properties of composite cementitious materials containing vanadium-titanium iron ore tailings[J]. Iron Steel Vanadium Titanium, 2023,44(1):98−105. (王长龙, 马锦涛, 杨丰豪, 等. 钒钛铁尾矿复合胶凝材料的制备及性能[J]. 钢铁钒钛, 2023,44(1):98−105.Wang Changlong, Ma Jingtao, Yang Fenghao, et al. Preparation and properties of composite cementitious materials containing vanadium-titanium iron ore tailings[J]. Iron Steel Vanadium Titanium, 2023, 44(1): 98-105 [26] Liu Haijun, Zhao Lili. Experimental study on activation of vanadium-titanium magnetite tailings and its use as cement admixture[J]. Iron Steel Vanadium Titanium, 2020,41(4):97−102. (刘海军, 赵丽丽. 钒钛磁铁矿尾矿的活化及用作水泥混合材的试验研究[J]. 钢铁钒钛, 2020,41(4):97−102.Liu Haijun, Zhao Lili. Experimental study on activation of vanadium-titanium magnetite tailings and its use as cement admixture[J]. Iron Steel Vanadium Titanium, 2020, 41(4): 97-102 [27] 王长龙, 王肇嘉, 杨飞华, 等. 尾矿及钢渣制备新型绿色建筑材料[M]. 北京: 科学出版社, 2022.Wang Changlong, Wang Zhaojia, Yang Feihua, et al. Preparation of new green building materials from tailings and steel slag[M]. Beijing: Science Press, 2022. [28] 王长龙, 李颖, 蔡红, 等. 新型工业固废基混凝土[M]. 北京: 科学出版社, 2021.Wang Changlong, Li Ying, Cai Hong, et al. New type of concrete based industrial solid waste[M]. Beijing: Science Press, 2021. [29] Wang Xiugui, Qin Lianyin. Experimental study on preparation of high-strength concrete with vanadium-titanium magnetite tailings[J]. Iron Steel Vanadium Titanium, 2019,40(3):77−82. (王修贵, 秦连银. 利用钒钛磁铁矿尾矿制备高强度混凝土的试验研究[J]. 钢铁钒钛, 2019,40(3):77−82.Wang Xiugui, Qin Lianyin. Experimental study on preparation of high-strength concrete with vanadium-titanium magnetite tailings[J]. Iron Steel Vanadium Titanium, 2019, 40(3): 77-82 [30] Yang Fei, Sun Xiaomin. Preparation of ordinary portland clinker with vanadium-titanium magnetite tailings[J]. Iron Steel Vanadium Titanium, 2020,41(2):75−81. (杨飞, 孙晓敏. 利用钒钛磁铁矿尾矿制备普通硅酸盐水泥熟料的研究[J]. 钢铁钒钛, 2020,41(2):75−81.Yang Fei, Sun Xiaomin. Preparation of ordinary portland clinker with vanadium-titanium magnetite tailings[J]. Iron Steel Vanadium Titanium, 2020, 41(2): 75-81 [31] Shi Lei, Song Xiao. Influence of vanadium-titanium magnetite tailings on autoclaved aerated concrete blocks[J]. Iron Steel Vanadium Titanium, 2020,41(3):84−89. (石磊, 宋宵. 钒钛磁铁矿尾矿对蒸压加气混凝土砌块的影响[J]. 钢铁钒钛, 2020,41(3):84−89. doi: 10.7513/j.issn.1004-7638.2020.03.014Shi Lei, Song Xiao. Influence of vanadium-titanium magnetite tailings on autoclaved aerated concrete blocks[J]. Iron Steel Vanadium Titanium, 2020, 41(3): 84-89 doi: 10.7513/j.issn.1004-7638.2020.03.014 [32] Guan X, Wang J Y, Xiao F P. Sponge city strategy and application of pavement materials in sponge city[J]. Journal of Cleaner Production, 2021,303:127022. doi: 10.1016/j.jclepro.2021.127022 [33] Xu Y S, Shen S L, Lai Y, et al. Design of sponge city: Lessons learnt from an ancient drainage system in Ganzhou, China[J]. Journal of Hydrology, 2018,563:900−908. doi: 10.1016/j.jhydrol.2018.06.075 [34] Nguyen T T, Ngo H H, Guo W S, et al. Implementation of a specific urban water management-Sponge city[J]. Science of The Total Environment, 2019,652:147−162. doi: 10.1016/j.scitotenv.2018.10.168 [35] Yu T J, Liu D G, Zhang H T, et al. Influence of pore water phase change on service performance for permeable pavement in sponge city[J]. Water Science and Technology, 2021,84(12):3769−3779. doi: 10.2166/wst.2021.459 [36] Qi B W, Gao S W, Xu P L. The application of rubber aggregate-combined permeable concrete mixture in sponge city construction[J]. Coating, 2023,13(1):87−100. doi: 10.3390/coatings13010087 [37] Song C. Application of nature-based measures in China's sponge city initiative: Current trends and perspectives[J]. Nature-Based Solutions, 2022,2:100010. doi: 10.1016/j.nbsj.2022.100010 [38] Qin Z, Yao Y J, Zhao J W, et al. Investigation of migration rule of rainwater for sponge city roads under different rainfall intensities[J]. Environmental Geochemistry and Health, 2022,44:3395−3407. doi: 10.1007/s10653-021-01104-9 [39] Li J H, Li X L, Liang S, et al. Preparation of water-permeable bricks derived from fly ash by autoclaving[J]. Construction and Building Materials, 2021,271:121556. doi: 10.1016/j.conbuildmat.2020.121556 [40] Wang H F, Liu Y, Mei Z. Basic physical characteristics of the water-permeable brick with composite structure[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2022,37:645−655. doi: 10.1007/s11595-022-2579-y [41] Lv R B, Liang S, Li X L, et al. Production of water-permeable ceramic bricks derived from fly ash via a simple pellet method: Mechanism of mechanical strength and permeability[J]. Construction and Building Materials, 2022,351:128989. doi: 10.1016/j.conbuildmat.2022.128989 [42] Wang Y G, Gao S, Liu X M, et al. Preparation of non-sintered permeable bricks using electrolytic manganese residue: Environmental and NH3-N recovery benefits[J]. Journal of Hazardous Materials, 2019,378:120768. doi: 10.1016/j.jhazmat.2019.120768 [43] Liu Y, Tang W, Singh R P. Study on compressive strength and water permeability of steel slag-fly ash mixed permeable brick[J]. Applied Sciences, 2019,9(8):1542−1552. doi: 10.3390/app9081542 [44] Cai J W, Lv N W, Jia X Y, et al. Properties of permeable ceramic brick prepared with felsite tailing[J]. Journal of Building Engineering, 2021,44:103426. doi: 10.1016/j.jobe.2021.103426 [45] Yang M, Ju C G, Xue K R, et al. Environmental-friendly non-sintered permeable bricks: Preparation from wrap-shell lightweight aggregates of dredged sediments and its performance[J]. Construction and Building Materials, 2021,273:121751. doi: 10.1016/j.conbuildmat.2020.121751 [46] Liu L, Cheng X, Miao X W, et al. Preparation and characterization of majority solid waste based eco-unburned permeable bricks[J]. Construction and Building Materials, 2020,259:120400. doi: 10.1016/j.conbuildmat.2020.120400 [47] He B J, Zhu J, Zhao D X, et al. Co-benefits approach: Opportunities for implementing sponge city and urban heat island mitigation[J]. Land Use Policy, 2019,86:147−157. doi: 10.1016/j.landusepol.2019.05.003 [48] Luo P P, Liu L M, Wang S T, et al. Influence assessment of new inner tube porous brick with absorbent concrete on urban floods control[J]. Case Studies in Construction Materials, 2022,17:e01236. doi: 10.1016/j.cscm.2022.e01236 [49] Asaeda T, Ca V T. Characteristics of permeable pavement during hot summer weather and impact on the thermal environment[J]. Building and Environment, 2000,35(4):363−375. doi: 10.1016/S0360-1323(99)00020-7 [50] Seifeddine K, Amziane S, Toussaint E. Experimental investigation of physical characteristics to improve the cooling effect of permeable pavements[J]. Construction and Building Materials, 2022,345:128342. doi: 10.1016/j.conbuildmat.2022.128342 [51] Han J, Wang C Q, Demg S H, et al. China’s sponge cities alleviate urban flooding and water shortage: a review[J]. Environmental Chemistry Letters, 2023,21:1−18. doi: 10.1007/s10311-022-01411-2 [52] Sansalone J J, Kuang X, Ranieri V. Porous pavement as a hydraulic and filtration interface for urban drainage[J]. Journal of Irrigation and Drainage Engineering, 2008,134(5):666−674. doi: 10.1061/(ASCE)0733-9437(2008)134:5(666) [53] Fang M J, Wang X, Liu J J, et al. Design, application and performance improvement of eco-permeable pavement materials (Eco-PPMs): A review[J]. Construction and Building Materials, 2022,360:129558. doi: 10.1016/j.conbuildmat.2022.129558 [54] Yan Z Q, Qing Z Q, Guo M, et al. Pilot and industrial scale tests of high-performance permeable bricks producing from ceramic waste[J]. Journal of Cleaner Production, 2020,254:120167. doi: 10.1016/j.jclepro.2020.120167 [55] Kim Y, Lee Y, Kim M, et al. Preparation of high porosity bricks by utilizing red mud and mine tailing[J]. Journal of Cleaner Production, 2019,207:490−497. doi: 10.1016/j.jclepro.2018.10.044 [56] Xu Sha, Cao Baoyue, Liu Xuan, et al. Preparation of permeable brick from activated sludge doped tailings and its properties[J]. Non-metallic Minerals, 2019,42(5):28−30. (徐珊, 曹宝月, 刘璇, 等. 活性污泥掺杂尾矿制备透水砖及性能研究[J]. 非金属矿, 2019,42(5):28−30.Xu S, Cao B Y, Liu X, et al. Study on preparation of permeable brick by activated sludge doping tailings and its performance[J]. Non-metallic Minerals, 2019, 42(5): 28-30. [57] Luo L Q, Li K Y, Fu W, et al. Preparation, characteristics and mechanisms of the composite sintered bricks produced from shale, sewage sludge, coal gangue powder and iron ore tailings[J]. Construction and Building Materials, 2020,232:117−250. [58] Wang Zhiyu, Guo Jialin, Li Chun. Study on the preparation and performance of iron tailing-based glass permeable bricks[J]. Mineral Protection and Utilization, 2019,34(4):66−70. (王之宇, 郭家林, 李春. 铁尾矿基玻璃透水砖的制备及性能研究[J]. 矿产保护与利用, 2019,34(4):66−70. doi: 10.13779/j.cnki.issn1001-0076.2019.04.011Wang Zhiyu, Guo Jialin, Li Chun. Study on the preparation and performance of iron tailing-based glass permeable bricks[J]. Mineral Protection and Utilization, 2019, 34(4): 66-70 doi: 10.13779/j.cnki.issn1001-0076.2019.04.011 [59] 叶鹏飞. 钒钛铁尾矿高强烧结透水砖的制备及机理研究[D]. 邯郸: 河北工程大学, 2021.Ye Pengfei. Preparation and mechanism of high-strength permeable brick from vanadium-titanium iron ore tailings[D]. Handan: Hebei University of Engineering, 2021. [60] Wang Shaoxi, Zhang Kaifan, Zhang Suhua, et al. Preparation and properties study of high-strength sintered permeable brick with multiple solid waste[J]. Metal Mine, 2021,(9):206−215. (王绍熙, 张凯帆, 张苏花, 等. 多元固废制备高强烧结透水砖及其性能研究[J]. 金属矿山, 2021,(9):206−215. doi: 10.19614/j.cnki.jsks.202109029Wang Shaoxi, Zhang Kaifan, Zhang Suhua, et al. Preparation and properties study of high-strength sintered permeable brick with multiple solid waste[J]. Metal Mine, 2021(9): 206-215 doi: 10.19614/j.cnki.jsks.202109029 [61] Wang C L, Ren Z Z, Zheng Y C, et al. Effects of heat treatment system on mechanical strength and crystallinity of CaO-MgO-Al2O3-SiO2 glass-ceramics containing coal gangue and iron ore tailings[J]. Journal of New Materials for Electrochemical Systems, 2019,22(2):70−78. [62] Zhang J J, Liu B, Zhang S G. A review of glass ceramic foams prepared from solid wastes: Processing, heavy-metal solidification and volatilization, applications[J]. Science of The Total Environment, 2021,781:146727. doi: 10.1016/j.scitotenv.2021.146727 [63] Liu X M, Li B, Wu Y F. The pretreatment of non-ferrous metallurgical waste slag and its research progress in the preparation of glass-ceramics[J]. Journal of Cleaner Production, 2023,404:136930. doi: 10.1016/j.jclepro.2023.136930 -

下载:

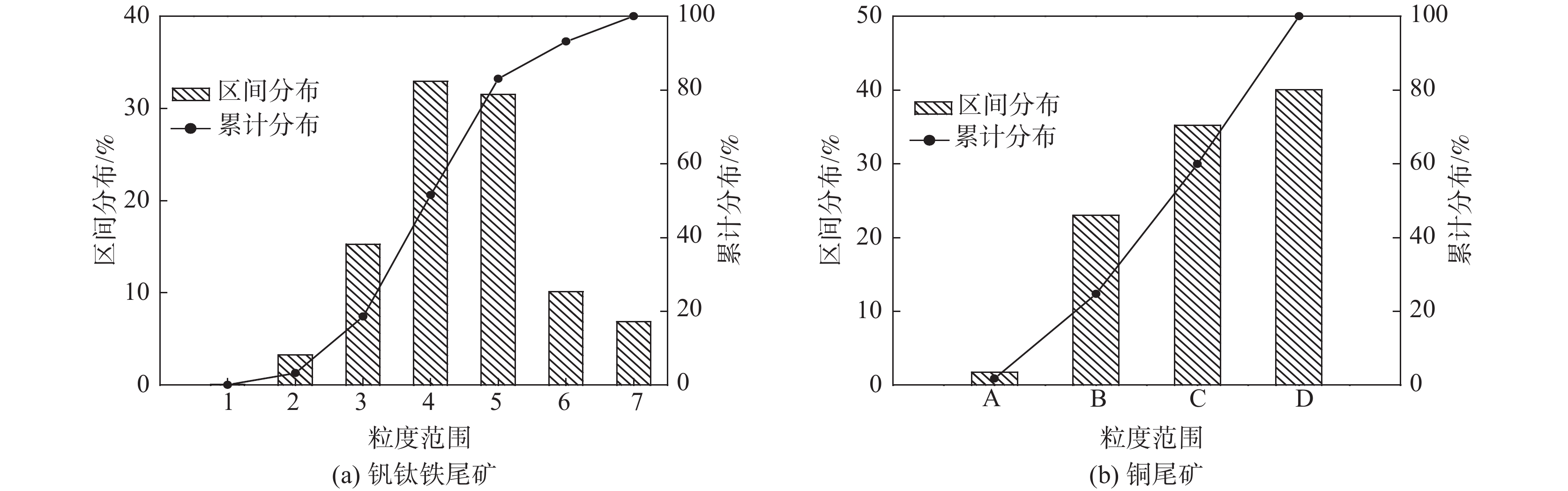

下载: