Study on the differences in microstructure, mechanical properties, and deformation mechanism between DH and DP steels

-

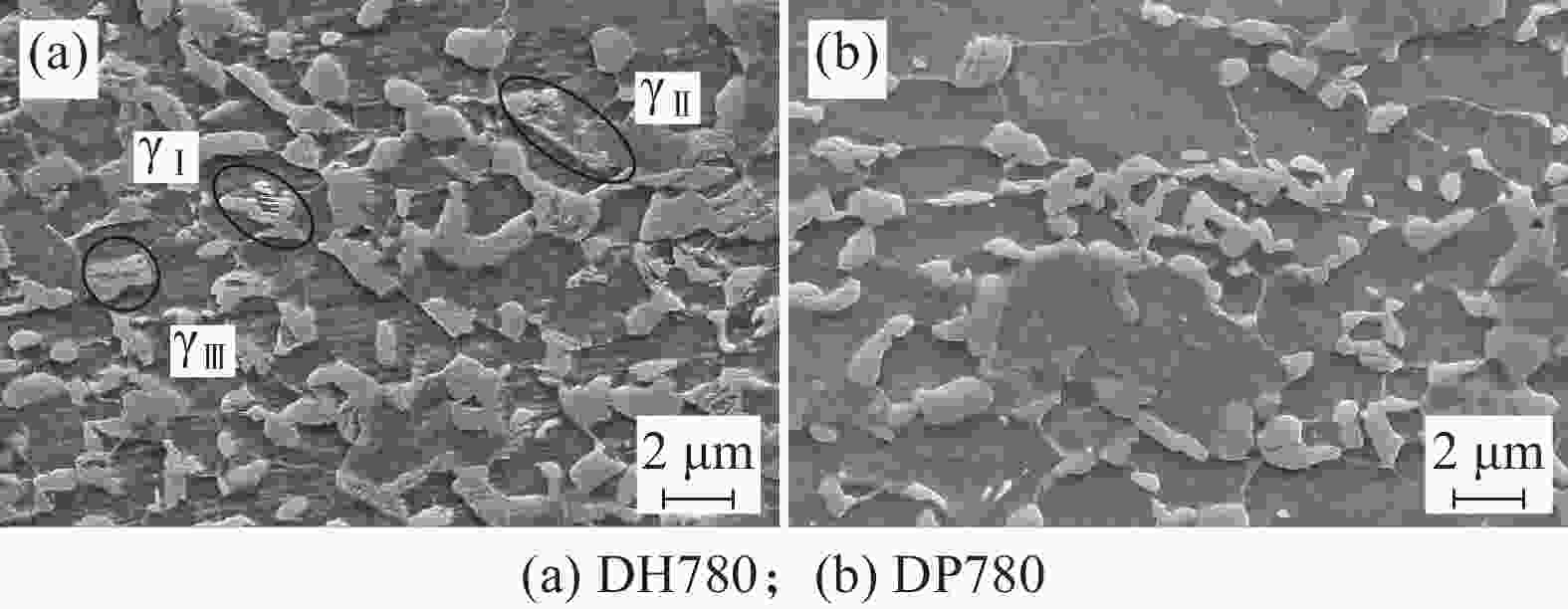

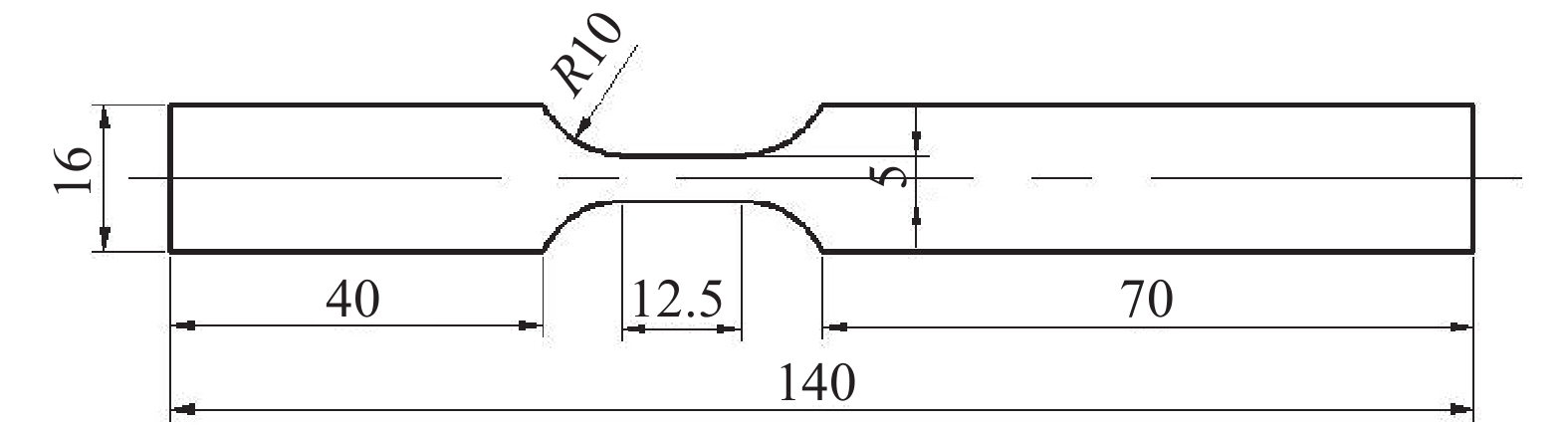

摘要: 采用高速拉伸试验、综合成形试验、场发射扫描电镜(SEM)、X射线衍射(XRD)、电子背散射衍射(EBSD)等表征方法研究了DH780与DP780冷轧双相钢组织性能差异。研究表明,DH780与DP780显微组织差异关键在于是否存在残余奥氏体,前者存在约5.1%残余奥氏体,呈块状、薄膜状、链状与细小粒状位于相界面与铁素体晶界处,在变形过程中具有显著TRIP效应,同时残余奥氏体具有更多滑移系可有效减缓位错塞积、延缓应力集中与裂纹源的形成,使得DH780较DP780具有更优良的强塑积及扩孔性能。高速拉伸试验表明,DH780较DP780具有更高的应变速率敏感性特征;随着应变速率的提升,DH780强塑积增加至38.83 GPa·%,吸能性能显著增强。Abstract: High speed tensile test, comprehensive forming test, field emission scanning electron microscope (SEM), X-ray diffraction (XRD), electron backscatter diffraction (EBSD) and other characterization methods were used to study the differences of microstructure and properties between DH780 and DP780 cold-rolled dual phase steels. The research shows that the main differences between the microstructures of DH780 and DP780 steels depend on the occurrence of retained austenite. The former has about 5.1% retained austenite, which is located at the phase interfaces and ferrite grain boundary in the blocks, thin films, chains and fine particles appearances. It has a significant TRIP effect during deformation. At the same time, the retained austenite has more slip systems, which can effectively retard the dislocation accumulation, stress concentration and crack initiation. DH780 has better strength-ductility balance (TS × EL) and hole expanding performance than DP780. High speed tensile test shows that DH780 has higher strain rate sensitivity than DP780; With the increase of strain rate, the strength-ductility balance (TS × EL) of DH780 increases to 38.83 GPa·%, and the energy absorption performance is significantly enhanced.

-

表 1 试验钢主要化学成分

Table 1. Main chemical compositions of experimental steels

% 牌号 C Mn Si P S Cr Al Nb Ti DH780 0.17~0.19 2.1~2.3 0.4~0.5 ≤0.010 ≤0.005 0.18~0.21 0.7~0.9 0.02~0.04 - DP780 0.09~0.12 2.0~2.4 0.5~0.6 ≤0.010 ≤0.005 0.28~0.30 - 0.02~0.03 0.02~0.04 表 2 准静态力学性能(ε=0.01 s−1)

Table 2. Quasi-static mechanical properties(ε=0.01 s−1)

牌号 方向 屈服强度/MPa 抗拉强度/MPa 断后伸长率/% 强塑积/(GPa·%) DH780 0° 501 823 31.3 25.76 45° 487 804 31.6 25.41 90° 522 831 30.8 25.59 DP780 0° 511 818 19.5 18.41 45° 529 821 24.7 17.82 90° 541 843 18.3 16.27 -

[1] 唐荻, 赵征志, 米振莉, 等. 汽车用先进高强板带钢[M]. 北京: 冶金工业出版社, 2016.Tang Di, Zhao Zhengzhi, Mi Zhenli, et al. Advanced high strength strip steel for automobile[M]. Beijing: Metallurgical Industry Press, 2016. [2] 康永林. 现代汽车板工艺及成形理论与技术[M]. 北京: 冶金工业出版社, 2009.Kang Yonglin. Theory and technolog of processing and forming for advanced automobile steel sheets[M]. Beijing: Metallurgical Industry Press, 2009. [3] Liang Jiangtao, Zhao Zhengzhi, Liu Kun, et al. Microstructure and properties of 1300 MPa grade Nb microalloying DH steel[J]. Chinese Journal of Engineering, 2021,43(3):392−399. (梁江涛, 赵征志, 刘锟, 等. 1300 MPa级Nb微合金化DH钢的组织性能[J]. 工程科学学报, 2021,43(3):392−399.Liang Jiangtao, Zhao Zhengzhi, Liu Kun, et al. Microstructure and properties of 1300 MPa grade Nb microalloying DH steel[J]. Chinese Journal of Engineering, 2021, 43(3): 392-399. [4] Wang Hui, Deng Zhaojun, Lin Chengjiang, et al. Effect of temper-aging temperature on the microstructures and properties of the annealed high aluminum dual phase steel[J]. Rare Metal Materials and Engineering, 2011,40(S2):184−187. (王辉, 邓照军, 林承江, 等. 连退时效温度对高铝双相钢组织及性能的影响[J]. 稀有金属材料与工程, 2011,40(S2):184−187.Wang Hui, Deng Zhaojun, Lin Chengjiang, et al. Effect of temper-aging temperature on the microstructures and properties of the annealed high aluminum dual phase steel[J]. Rare Metal Materials and Engineering, 2011, 40(S2): 184-187. [5] Deng Zhaojun, Liu Jing, Wang Hui, et al. Influence of annealing temperature on microstructure of a high aluminum dual phase steel[J]. Transactions of Materials and Heat Treatment, 2011,32(3):111−114. (邓照军, 刘静, 王辉, 等. 退火温度对高铝双相钢微观组织的影响[J]. 材料热处理学报, 2011,32(3):111−114.Deng Zhaojun, Liu Jing, Wang Hui, et al. Influence of annealing temperature on microstructure of a high aluminum dual phase steel[J]. Transactions of Materials and Heat Treatment, 2011, 32(3): 111-114. [6] Zhou Li, Xue Renjie, Cao Xiao, en, et al. Study on microstructure and properties of high aluminum dual phase steel 980DH with high formability[J]. Iron Steel Vanadium Titanium, 2022,43(2):186−191. (周莉, 薛仁杰, 曹晓恩, 等. 高铝增强成形性双相钢980DH组织性能研究[J]. 钢铁钒钛, 2022,43(2):186−191.Zhou Li, Xue Renjie, Cao Xiao, en, et al. Study on microstructure and properties of high aluminum dual phase steel 980 DH with high formability[J]. Iron Steel Vanadium Titanium, 2022, 43(2): 186-191. [7] Du Yifei, Li Wang, Tian Yaqiang. Application progress of Nb, V and Ti microalloying in TRIP steel for automobile[J]. Heat Treatment of Metals, 2019,44(8):50−59. (杜一飞, 黎旺, 田亚强. Nb、V、Ti微合金化在汽车用TRIP钢中的应用进展[J]. 金属热处理, 2019,44(8):50−59.Du Yifei, Li Wang, Tian Yaqiang. Application progress of Nb, V and Ti microalloying in TRIP steel for automobile[J]. Heat Treatment of Metals, 2019, 44(8): 50-59. [8] Lu Lin, Tang Di, Jiang Haitao. Microstructure and properties of high aluminum 1000 MPa cold rolling hot dip galvanized dual phase steel[J]. Transactions of Materials and Heat Treatment, 2015,36(4):116−120. (卢淋, 唐荻, 江海涛. 高铝1000 MPa级热镀锌双相钢的组织和性能[J]. 材料热处理学报, 2015,36(4):116−120.Lu Lin, Tang Di, Jiang Haitao. Microstructure and properties of high aluminum 1000 MPa cold rolling hot dip galvanized dual phase steel[J]. Transactions of Materials and Heat Treatment, 2015, 36(4): 116-120. [9] Tian Yaqiang, Tian Geng, Zheng Xiaoping, et al. C and Mn elements characterization and stability of retained austenite in different locations of quenching and partitioning bainite steels[J]. Acta Metallurgica Sinica, 2019,55(3):332−340. (田亚强, 田耕, 郑小平, 等. 淬火配分贝氏体钢不同位置残余奥氏体C、Mn元素表征及其稳定性[J]. 金属学报, 2019,55(3):332−340. doi: 10.11900/0412.1961.2018.00270Tian Yaqiang, Tian Geng, Zheng Xiaoping, et al. C and Mn elements characterization and stability of retained austenite in different locations of quenching and partitioning bainite steels[J]. Acta Metallurgica Sinica, 2019, 55(3): 332-340. doi: 10.11900/0412.1961.2018.00270 [10] YB/T5338-2019. 钢中奥氏体定量测定X射线衍射仪法[S].YB/T5338-2019. Retained austenite in steel-quantitative deternination-method of X-ray diffractometer[S]. [11] Hou Xiaoying, Bi Yongjie, Hao Liang. Analysis on microstructure and strengthening mechanisms of hot-rolled TRIP980 steel[J]. Iron and Steel, 2019,54(4):63−67. (侯晓英, 毕永杰, 郝亮. 热轧TRIP980钢微观组织及强化机制分析[J]. 钢铁, 2019,54(4):63−67.Hou Xiaoying, Bi Yongjie, Hao Liang. Analysis on microstructure and strengthening mechanisms of hot-rolled TRIP980 steel[J]. Iron and Steel, 2019, 54(4): 63-67. [12] Zhang Wei, Pan Yue, Liu Huasai, et al. Effect of strain rate on properties of dual phase steel with high formability[J]. Iron and Steel, 2022,57(4):123−129. (张伟, 潘跃, 刘华赛, 等. 应变速率对增强成形性双相钢性能影响分析[J]. 钢铁, 2022,57(4):123−129.Zhang Wei, Pan Yue, Liu Huasai, et al. Effect of strain rate on properties of dual phase steel with high formability[J]. Iron and Steel, 2022, 57(4): 123-129. -

下载:

下载: