Research on microwave enhanced direct reduction of vanadium titano-magnetite

-

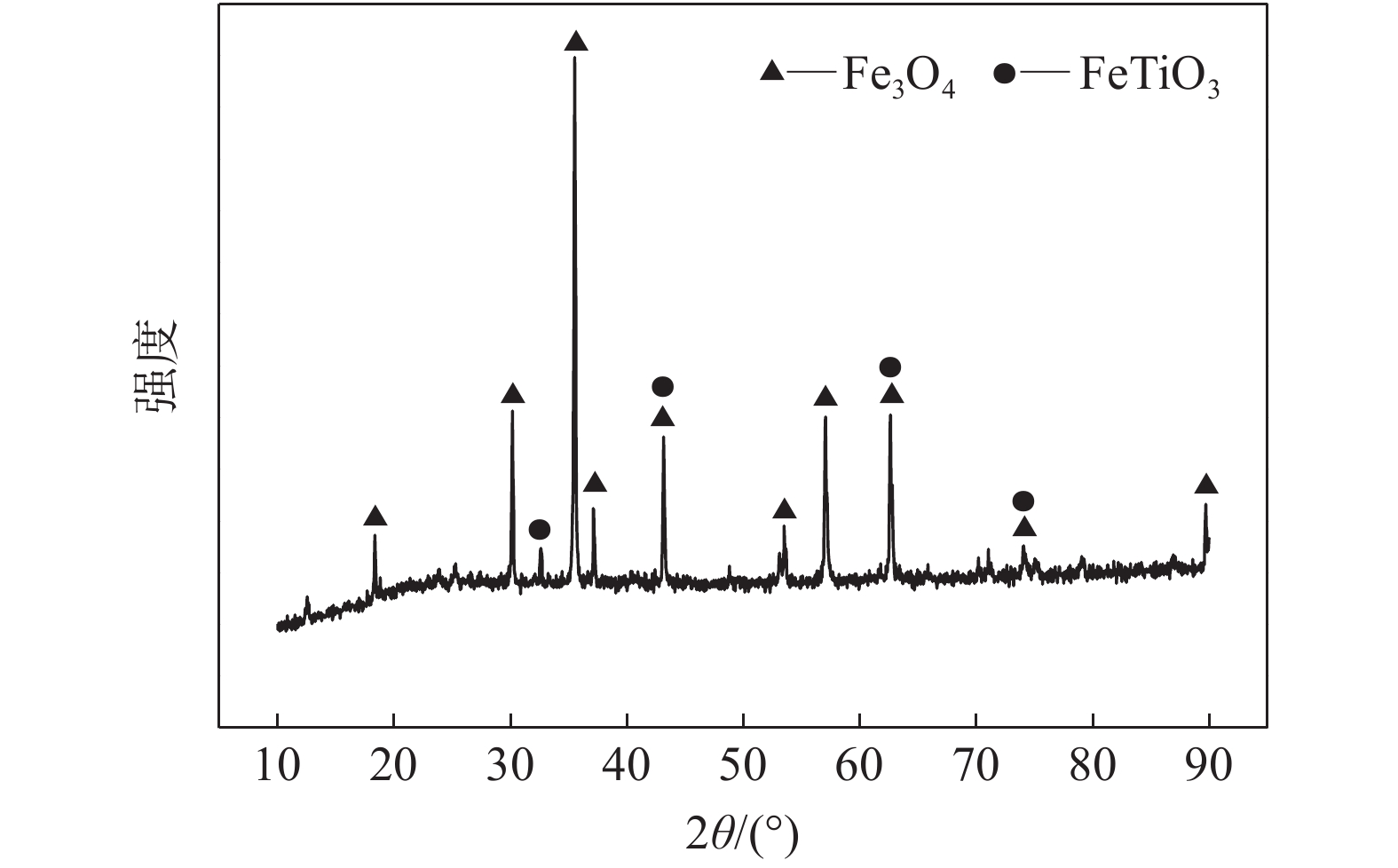

摘要: 以钒钛磁铁精矿为原料,直接还原工艺为基础,系统比较了不同加热方式对还原过程的影响。结果表明:与传统加热相比,微波加热能加快钒钛磁铁矿还原反应的进行,并且随温度升高效果越显著,在1350℃时铁金属化率可达到91.91%,提高了5.32个百分点;微波加热不会改变还原产物的物相组成,但使还原产物结构致密,气孔减少,晶粒粗大且分布均匀,脉石与金属铁嵌布紧密程度降低,相互之间夹杂的现象减少,有利于后续磨矿磁选过程中金属铁与脉石相的分离;另外,微波加热可以明显去除还原产物中P元素,而对于S元素的去除效果不显著,在1350℃时传统加热获得的产物中P含量为0.077%,S含量为0.29%,微波加热获得的产物中P含量为0.038%,S含量为0.28%。Abstract: In this paper, the vanadium titano-magnetite concentrate was used as the raw material, and the influence of different heating methods on the reduction process was systematically compared based on the direct reduction process. The results show that compared with traditional heating, microwave heating can accelerate the reduction reaction of vanadium titano-magnetite, and the effect is more significant with the increase of temperature. At 1 350 ℃, the metallization rate of iron can reach 91.91%, increased by 5.32%. Microwave heating does not change the phase composition of the reduction product, but make the reduction product structure compact, less pores, coarse grains and uniform distribution. In addition, microwave heating can obviously remove the P element in the reduction product, but the removal effect of the S element is not significant. When heating temperature is 1350℃, P and S contents in resulted product for tranditional process are 0.077% and 0.29%, respectively, while for microwave process those values are 0.038% and 0.28%, respectively.

-

Key words:

- vanadium titano-magnetite /

- direct reduction /

- microwave heating /

- metallization rate

-

表 1 钒钛磁铁精矿的主要化学成分

Table 1. Main chemical components of vanadium titano-magnetite ore concentrate

% TFe FeO TiO2 SiO2 Al2O3 MgO CaO V2O5 P S 58.61 27.63 7.01 3.2 3.0 1.35 0.92 0.291 0.028 0.19 表 2 无烟煤的工业分析

Table 2. Industry analysis results of anthracite

固定碳/

%挥发份/

%灰分/

%S/

%弹筒发热量/

(MJ·kg−1)82.49 9.20 8.78 0.30 28.35 表 3 不同加热方式还原产物的S、P含量

Table 3. S and P contents of reduction products under different heating methods

温度/℃ w(S)/% w(P)/% 传统加热 微波加热 传统加热 微波加热 1100 0.24 0.31 0.10 0.027 1150 0.24 0.32 0.11 0.035 1200 0.28 0.35 0.095 0.041 1250 0.32 0.30 0.081 0.024 1300 0.32 0.29 0.090 0.032 1350 0.29 0.28 0.077 0.038 -

[1] (杜鹤桂. 高炉冶炼钒钛磁铁矿原理[M]. 北京: 科学出版社, 1996: 1−16.)Du Hegui. Principle of smelting vanadium titanium magnetite in blast furnace[M]. Beijing: Science Press, 1996: 1−16. [2] (王喜庆. 钒钛磁铁矿高炉冶炼[M]. 北京: 冶金工业出版社, 1994: 1−18.)Wang Xiqing. Blast furnace smelting of vanadium titanium magnetite[M]. Beijing: Metallurgical Industry Press, 1994: 1−18. [3] Tan Qiyou, Chen Bo, Zhang Yushu, et al. Resource characteristics and comprehensive recycling status of vanadium titanium magnetite in Panxi area[J]. Comprehensive Utilization of Mineral Resources, 2011,(6):6−9. (谭其尤, 陈 波, 张裕书, 等. 攀西地区钒钛磁铁矿资源特点与综合回收利用现状[J]. 矿产综合利用, 2011,(6):6−9. doi: 10.3969/j.issn.1000-6532.2011.06.002 [4] Liang Diande. Discussion on the application of direct reduction technology in separation and extraction of vanadium from vanadium titanium magnetite[J]. Chongqing Iron and Steel Technology, 2002,45(3):1−6. (梁典德. 直接还原技术在钒钛磁铁矿铁钛分离和提钒工艺中的利用探讨[J]. 重钢技术, 2002,45(3):1−6. [5] Liu Gongguo. Experimental study on comprehensive utilization of vanadium titanium magnetite based on rotary hearth furnace direct reduction process[J]. Iron and Steel Research, 2012,40(2):4−7. (刘功国. 基于转底炉直接还原工艺的钒钛磁铁矿综合利用试验研究[J]. 钢铁研究, 2012,40(2):4−7. [6] Zhang Dajiang, Chen Dengfu, Xu Chushao, et al. Study on direct reduction process of coal based rotary kiln for low grade iron ore[J]. Acta Sinica Sinica, 2009,(S1):152−156. (张大江, 陈登福, 徐楚韶, 等. 低品位铁矿石煤基回转窑直接还原研究过程[J]. 工程学报, 2009,(S1):152−156. [7] Li Zhanjun, Liu Gongguo, Qin Jie, et al. Causes and countermeasures of bottom rise in direct reduction of vanadium titanium ore with rotary hearth furnace[J]. Metallurgy of China, 2015,(7):40−45. (李占军, 刘功国, 秦 洁, 等. 钒钛矿转底炉直接还原炉底上涨成因及对策[J]. 中国冶金, 2015,(7):40−45. [8] Zheng Peng. Experimental study on reduction smelting of vanadium titanium magnetite[J]. Nonferrous Mining and Metallurgy, 2017,33(4):35−37, 17. (郑 鹏. 钒钛磁铁矿还原熔炼试验研究[J]. 有色矿冶, 2017,33(4):35−37, 17. [9] Zhang Wenpu. Research and development progress of microwave heating technology in metallurgical industry[J]. China Molybdenum Industry, 2007,31(6):20−23. (张文朴. 微波加热技术在冶金工业中的应用研发进展[J]. 中国钼业, 2007,31(6):20−23. doi: 10.3969/j.issn.1006-2602.2007.06.004 [10] Wu Wenhua, Tang Huiqing, Huang Wudi. Microwave drying and roasting pellets[J]. Journal of Beijing University of Science and Technology, 1994,16(2):118−122. (武文华, 唐惠庆, 黄务涤. 微波干燥和焙烧球团矿[J]. 北京科技大学学报, 1994,16(2):118−122. [11] Wang Junpeng, Jiang Tao, Liu Yajing, et al. Microwave assisted grinding experiment of vanadium titanium magnetite[J]. Journal of Northeast University (Natural Science Edition), 2017,38(11):1559−1563. (王俊鹏, 姜 涛, 刘亚静, 等. 钒钛磁铁矿微波助磨试验[J]. 东北大学学报(自然科学版), 2017,38(11):1559−1563. doi: 10.12068/j.issn.1005-3026.2017.11.009 [12] Duan Dongping, Wan Tianji, Guo Zhancheng. Transformation behavior of sulfur in carbon containing pellets[J]. Acta Iron and Steel Research, 2005,17(5):16−21. (段东平, 万天骥, 郭占成. 硫在含碳球团内的转化行为[J]. 钢铁研究学报, 2005,17(5):16−21. [13] Zhang Hui, Jin Yonglong, He Zhijun. Study on extraction and dephosphorization of high phosphorus iron ore by microwave[J]. Gansu Metallurgy, 2011,33(1):1−3. (张辉, 金永龙, 何志军. 微波作用高磷铁矿提铁脱磷的研究[J]. 甘肃冶金, 2011,33(1):1−3. doi: 10.3969/j.issn.1672-4461.2011.01.001 -

下载:

下载: