Research and modeling on thermal conductivity of high temperature heat storage material based on vanadium tailings

-

摘要: 利用提钒尾渣为主要原料,高硅粘土为辅料,石墨材料为改性剂,通过碳热还原-粉末冶金方法进行了高温显热蓄热材料的制备研究,分析石墨含量对显热蓄热材料的物相演变、比热容变化及导热变化规律。XRD物相分析表明,材料的主要物相包括石英、含高硅组分的钠长石、钛铁矿以及碳酸盐等物相,随着石墨含量的增加,石英相比率随之减少。比热容测试结果表明,比热容随石墨含量的增加先增大后减小,当石墨含量为3%时,比热容最高,在 500~700 ℃下的比热容值为820~3 180 J/(kg·K)。导热系数测试结果表明,当石墨含量小于5%时,蓄热材料导热系数变化不大,基本保持在0.75 W/(m·K)左右;当石墨含量大于5%时,导热系数呈现明显的上升趋势。为了进一步探索石墨对蓄热材料导热性能的影响,进行了模拟计算,利用非线性修正项代替分散体体积分数项,修正后的Maxwell模型可很好地预测试验结果。Abstract: Using vanadium tailings as the base material, high silicon containing clay as auxiliary material and graphite material as modifier, the preparation of the high temperature sensible heat storage materials was carried out by means of carbon thermal reduction followed by powder metallurgy. The effects of graphite content on phase evolution, specific heat capacity and heat conduction of sensible heat storage material were studied. XRD phase analysis result shows that the main phases of the material include quartz, albite, ilmenite and carbonate. With the increase of graphite content, the ratio of quartz decreases. The specific heat capacity test results show that the specific heat capacity firstly increases and then decreases with the increase of graphite content. When the graphite content is 3%, the specific heat capacity is the highest, and the specific heat capacity at 500~700 ℃ is 820~3 180 J/(kg·K). The thermal conductivity test results show that when the graphite content is less than 5%, the thermal conductivity of the heat storage material changes slightly, basically remains at about 0.75 W/(m·K); when the graphite content is more than 5%, the thermal conductivity presents an upward trend. In order to further explore the effect of graphite on thermal conductivity of heat storage materials, the modeling calculation is carried out, and by replacing the volume fraction term of dispersion with the nonlinear correction term, the modified Maxwell model could well predict the experimental data.

-

表 1 提钒尾渣化学成分

Table 1. Chemical components of vanadium tailings

% Na2O Fe2O3 SiO2 TiO2 MnO Al2O3 MgO CaO V2O5 Cr2O3 其他 9.6 40.1 17.0 11.0 6.5 5.4 3.1 2.4 1.6 1.1 2.2 表 2 提铁尾渣化学成分

Table 2. Chemical components of iron tailings

% Fe2O3 SiO2 TiO2 MgO Al2O3 CaO Cr2O3 MnO 2.22 15.94 16.94 2.98 3.9 4.0 1.5 11.23 表 3 粘土的化学成分

Table 3. Chemical components of clay

% Fe SiO2 TiO2 MgO Al2O3 CaO Mn 2.65 32.16 0.12 4.61 9.6 0.38 0.17 表 4 制备钒钛蓄热材料的材料配比

Table 4. Material proportioning in the preparation of vanadium-titanium heat storage material

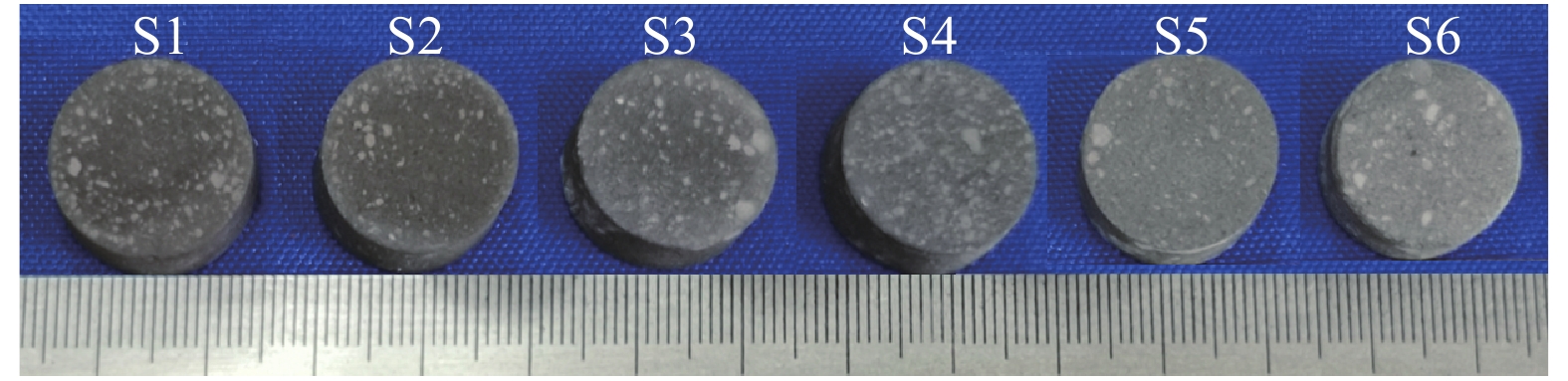

试验号 提铁尾渣/g 粘土/g 石墨/g 石墨含量/% S1 3 3 0 0 S2 2.91 2.91 0.18 3 S3 2.85 2.85 0.3 5 S4 2.79 2.79 0.42 7 S5 2.7 2.7 0.6 10 S6 2.55 2.55 0.9 15 表 5 修正Maxwell模型中的A和B值

Table 5. A and B values in modified Maxwell model

类别 A B 前期研究系列[13]:尾渣+石墨基蓄热材料 −0.044 95 4.139 32 本研究系列:尾渣+粘土+石墨基蓄热材料 0.130 188 −2.642 8 -

[1] (劳新斌. 利用煤系高岭土原位合成α-Al2O3-SiCw系太阳能储热复相陶瓷材料的研究[D]. 武汉: 武汉理工大学, 2016.)Lao Xinbin.Utilization study of coal series kaolin in in-situ synthesis of α-Al2O3-SiCw composite ceramics for solar thermal storage[D].Wuhan: Wuhan University of Technology, 2016. [2] Tiskatine R, Oaddi R, Cadi R A E, et al. Suitability and characteristics of rocks for sensible heat storage in CSP plants[J]. Solar Energy Materials and Solar Cells, 2017,169:245−257. doi: 10.1016/j.solmat.2017.05.033 [3] Cabeza L F, Galindo E, Prieto C, et al. Key performance indicators in thermal energy storage: Survey and assessment[J]. Renewable Energy, 2015,83:820−827. doi: 10.1016/j.renene.2015.05.019 [4] Geissbuhler L, Kolman M, Zanganeh G, et al. Analysis of industrial-scale high-temperature combined sensible/latent thermal energy storage[J]. Applied Thermal Engineering, 2016,101:657−668. doi: 10.1016/j.applthermaleng.2015.12.031 [5] Leng Guanghui, Qiao Geng, Zhang Yelong, et al. The new research progress of thermal energy storage materials[J]. Energy Storage Science and Technology, 2017,6(5):1058−1075. (冷光辉, 谯耕, 张叶龙, 等. 储热材料研究现状及发展趋势[J]. 储能科学与技术, 2017,6(5):1058−1075. doi: 10.12028/j.issn.2095-4239.2017.00094 [6] Kuravi S, Trahan J, Goswami D Y, et al. Thermal energy storage technologies and systems for concentrating solar power plants[J]. Progress in Energy and Combustion Science, 2013,39(4):285−319. doi: 10.1016/j.pecs.2013.02.001 [7] Ataer O E. Storage of Thermal Energy[C]//Energy Storage Systems.Edited by Gogus Y A. Encyclopedia of Life Support Systems (EOLSS). UK Oxford: Eolss Publishers, 2006. [8] Li Lanjie, Zhao Beibei, Wang Haixu, et al. The process of high efficiency dealkalization and ore blending in ironmaking of the extracted vanadium residue[J]. The Chinese Journal of Process Engineering, 2017,17(1):138−143. (李兰杰, 赵备备, 王海旭, 等. 提钒尾渣高效脱碱及配矿炼铁工艺[J]. 过程工程学报, 2017,17(1):138−143. doi: 10.12034/j.issn.1009-606X.216215 [9] Meng Lipeng, Zhao Chu, Wang Shaona, et al. Improvement of vanadium extraction from extracted vanadium residue in China[J]. Iron Steel Vanadium Titanium, 2015,36(3):49−56. (孟利鹏, 赵楚, 王少娜, 等. 国内提钒尾渣再提钒技术研究进展[J]. 钢铁钒钛, 2015,36(3):49−56. doi: 10.7513/j.issn.1004-7638.2015.03.011 [10] Hou Jing, Wu Enhui, Li Jun. Current situation and progress of comprehensive utilization of vanadium extraction tailings[J]. Conservation and Utilization of Mineral Resources, 2017,(6):103−108. (侯静, 吴恩辉, 李军. 提钒尾渣的综合利用研究现状及进展[J]. 矿产保护与利用, 2017,(6):103−108. [11] Xiu Dapeng, Cao Shuliang, Xu Jianhua, et al. Application of ceramic solar plate heating system[J]. Shandong Science, 2013,26(2):72−77. (修大鹏, 曹树梁, 许建华, 等. 黑瓷复合陶瓷太阳板集热系统的应用研究[J]. 山东科学, 2013,26(2):72−77. [12] Kingery W D, Bowen H K, Uhlmann D R. Introduction to ceramics[M].Kendall Hunt Pub Co, 1976. [13] Piao Rongxun, Li Xuan, Li Guowei, et al. Preparation of high temperature sensible heat storage material from vanadium extraction tailings and graphite[J]. Iron Steel Vanadium Titanium, 2020,41(6):52−59. (朴荣勋, 李轩, 李国伟, 等. 利用提钒尾渣和石墨制备高温显热蓄热材料的研究[J]. 钢铁钒钛, 2020,41(6):52−59. doi: 10.7513/j.issn.1004-7638.2020.06.011 [14] (李国伟. 利用提钒尾渣制备黑瓷及其太阳能集热应用[D]. 成都: 西华大学, 2015.)Li Guowei. The preparation and application of black porcelain solar heat utilization of vanadium titanium slag system[D].Chengdu: Xihua University, 2015. [15] (吴恩辉, 刘黔蜀, 黄平, 等. 提钒尾渣制备太阳能集热功能材料探索试验研究[C]//中国太阳能热利用行业年会暨"十三五"太阳能热利用发展论坛. 苏州: 2015.)Wu Enhui, Liu Qianshu, Huang Ping, et al. Experimental study on preparation of solar energy collection functional materials from vanadium tailings[C]//2015 Annual Meeting of China's Solar Thermal Utilization Industry and "13th Five Year Plan" Solar Thermal Utilization Development Forum. Suzhou: 2015. [16] Schön Jürgen H. Physical Properties of rocks:Fundamentals and principles of petrophysics,chapter 9 - thermal properties[J]. Developments in Petroleum Science, 2015,65:369−414. [17] Xu J, Gao B, Du H, et al. A statistical model for effective thermal conductivity of composite materials[J]. International Journal of Thermal Ences, 2016,104:348−356. doi: 10.1016/j.ijthermalsci.2015.12.023 [18] Carson, James K. Thermal diffusivity and thermal conductivity of dispersed glass sphere composites over a range of volume fractions[J]. International Journal of Thermophysics, 2018,39(6):1−11. [19] Speight J G, Lange N A. Lange's Handbook of Che005 mistry 16th edition[M]. Newyork: McGraw-Hill, 2005. [20] Maxwell J C. A treatise on electricity and manetism[M]. Oxford: Clarendon Press, 1881. [21] Wang Licheng, Chang Ze, Bao Jiuwen. Prediction model for the thermal conductivity of concrete based on its composite structure[J]. Journal of Hydraulic Engineering, 2017,48(7):765−772. (王立成, 常泽, 鲍玖文. 基于多相复合材料的混凝土导热系数预测模型[J]. 水利学报, 2017,48(7):765−772. [22] Kumar S, Bhoopal R S, Sharma P K, et al. Non-linear effect of volume fraction of inclusions on the effective thermal conductivity of composite materials: A modified maxwell model[J]. Open Journal of Composite Materials, 2011,1(1):10−18. doi: 10.4236/ojcm.2011.11002 -

下载:

下载: