Effect of tellurium on the deformation of sulfides in rolling process

-

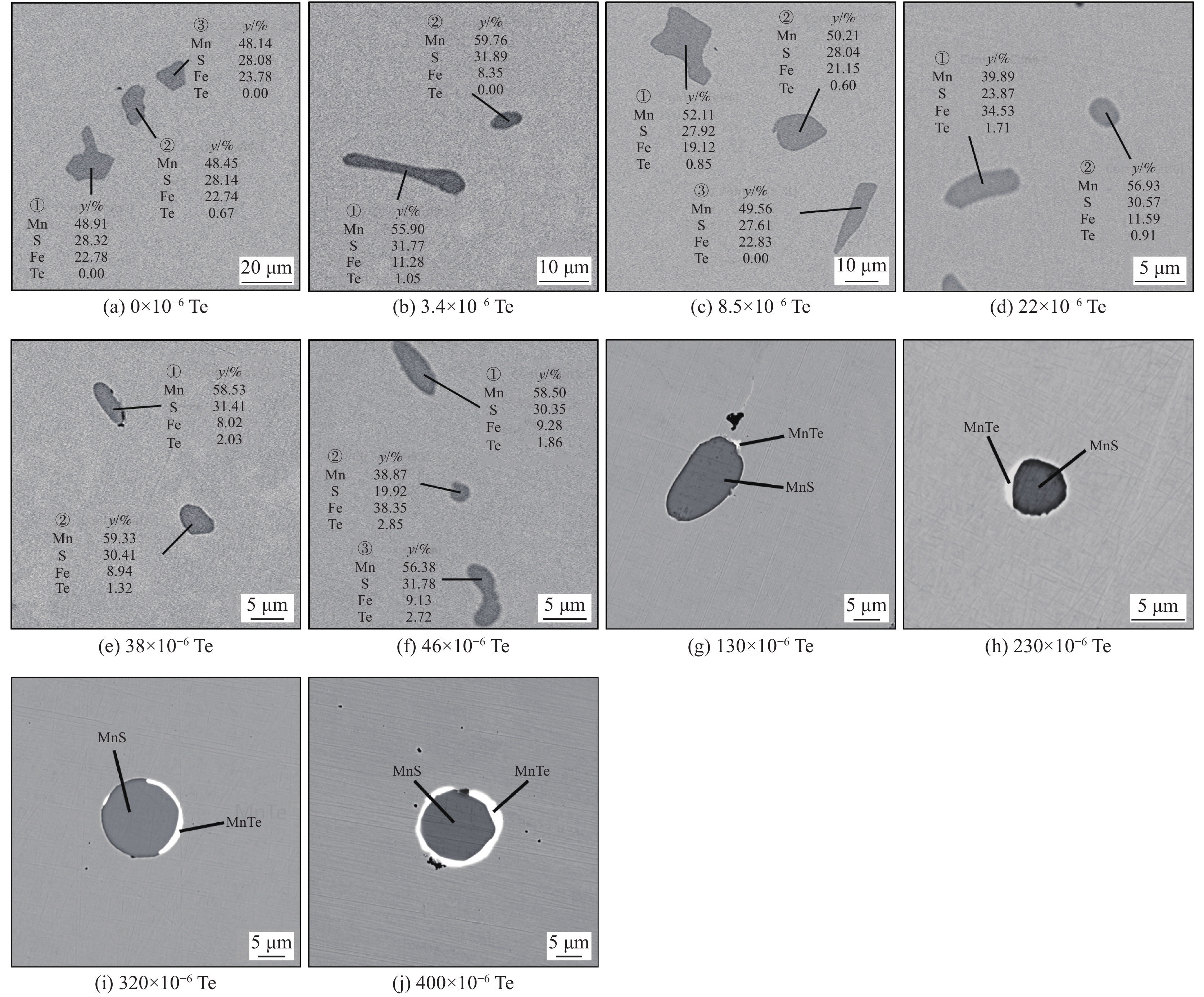

摘要: 采用扫描电镜对38MnVS6钢中Te的赋存状态进行了分析,采用Gleeble-3500模拟了轧制过程。对MnS夹杂和基体的硬度进行了检测,并对夹杂物进行了统计,由此对夹杂物的变形行为进行研究。结果表明,少量的Te首先固溶在MnS中,当Te含量超过130×10−6时开始析出MnTe。经过热压缩后,随着Te含量的增加,夹杂物的长宽比从2.3逐渐降低至1.8左右。钢中Te含量增加,夹杂物与钢基体的硬度比H夹/H钢基本为一个常数,不能造成夹杂物的抗变形能力增加。经过热压缩后,较小的夹杂物其长宽比也较小。钢中加Te后可使夹杂物尺寸减小,进而减小了夹杂物的变形量,抑制了轧制过程中夹杂物的变形。Abstract: Modification of MnS inclusion by Te is one of the most efficient methods to improve the morphology and distribution of MnS inclusions. However, previous researches did not generate acceptable opinions on the deformation behaviors of MnS inclusions during the rolling process after adding Te. In the present study, the existing form of Te in the 38MnVS6 steel was detected by SEM-EDS. Gleeble-3500 was employed to simulate the rolling process. The hardness of MnS inclusions and steel matrix was measured and the statistics of inclusions were performed to analyze the effect of Te on the deformability of inclusions. The results show that Te initially dissolves in MnS inclusion after adding a small amount of Te. When the Te content reaches 130 ×10−6, MnTe starts to generate. After hot-pressing, the inclusions were deformed. With the increase of Te content, the aspect ratio of inclusions decreases from 2.3 to approximately 1.8 and gradually reaches a constant value. The hardness determination result indicates that the deformation resistance of inclusions is not caused by the increase of inclusion hardness, since the hardness ratio

Hinclusion/ Hmatrix keeps relatively constant after adding different Te content. The statistics of inclusions prove that the inclusion with a small diameter shows low aspect ratio after hot-pressing. The addition of Te can reduce the size of inclusions, leading to less deformation of inclusions. -

Key words:

- 38MnVS6 /

- Te /

- MnS inclusion /

- Gleeble

-

表 1 原始38MnVS6钢成分

Table 1. Chemical compositions of original 38MnVS6 steel

% C Si Mn P S Cr V Al Ti Nb Ni 0.383 0.574 1.399 0.01 0.051 0.179 0.099 0.018 0.017 0.016 0.123 表 2 不同钢中Te含量×106

Table 2. Te content in different steels

1 2 3 4 5 6 7 8 9 10 0 3.4 8.5 22 38 46 130 230 320 400 -

[1] Shao X, Wang X, Jiang M, et al. Effect of heat treatment conditions on shape control of large-sized elongated MnS inclusions in resulfurized free-cutting steels[J]. ISIJ International, 2011,51(12):1995−2001. doi: 10.2355/isijinternational.51.1995 [2] Kishi K, Eda H, Kitsunai Y. Fatigue strength of tellurium free cutting steel-the effect of machined surface layer and inclusion on fatigue strength (1st Report)[J]. Journal of the Japan Society of Precision Engineering, 1972,38(445):174−181. doi: 10.2493/jjspe1933.38.174 [3] Li Xuebao, Zhou Xiaobin, Pan Zhelin. Application of rolling technology for low-carbon high-sulphur free cutting steel[J]. Southern Metals, 2020,(2):17−20. (李学保, 周小兵, 潘泽林. 低碳高含硫钢易切削钢轧制技术应用[J]. 南方金属, 2020,(2):17−20. doi: 10.3969/j.issn.1009-9700.2020.02.005 [4] Ai Kenan, Zhang Panpan, Zhao Menghao, et al. Analysis of formation mechanism of surface crack of 1215 free-cutting steel during drawing[J]. Iron and Steel, 2020,55(2):88−94. (艾克南, 张盼盼, 赵梦豪, 等. 1215易切削钢拉拔表面裂纹形成机制分析[J]. 钢铁, 2020,55(2):88−94. [5] Dong Zhengqiang, Jiang Bo, Zhang Chaolei, et al. Evolution of MnS in non-quenched and tempered crankshaft steel C38N2 during rolling[J]. Transactions of Materials and Heat Treatment, 2015,36(8):144−149. (董正强, 蒋波, 张朝磊, 等. 曲轴用非调质钢C38N2轧制过程中MnS夹杂演变规律[J]. 材料热处理学报, 2015,36(8):144−149. [6] Shen P, Fu J. Morphology study on inclusion modifications using Mg-Ca treatment in resulfurized special steel[J]. Materials, 2019,12(2):197. doi: 10.3390/ma12020197 [7] (周平, 董杰, 朱荣, 等. 用钙和稀土联合处理研制低碳易切削钢[C]//冶金工程科学论坛,2005: 363−366.)Zhou Ping, Dong Jie, Zhu Rong, et al. Development of low carbon free cutting steel through calcium-rare earth treatment[C]//Metallurgical Engineering Science Forum, 2005: 363−366. [8] Shen P, Yang Q K, Zhang D, et al. Application of tellurium in free-cutting steels[J]. Journal of Iron & Steel Research International, 2018,25(8):787−795. [9] Katoh T, Abeyama S, Kimura A, et al. A study on resulfurized free-machining steel containing a small amount of tellurium[J]. Denki Seiko(Electr. Furn. Steel), 1982,53(3):195−202. doi: 10.4262/denkiseiko.53.195 [10] Yaguchi H,Onodera N. The effect of tellurium on the machinability of AISI 12L14+Te steel[J]. Transactions of the Iron & Steel Institute of Japan, 1988,28(12):1051−1059. [11] Zheng L, Malfliet A, Wollants P, et al. Effect of surfactant Te on the formation of MnS inclusions in steel[J]. Metallurgical & Materials Transactions B, 2017,48(5):1−12. [12] Okamoto H,Tanner L E. The Fe-Te (iron-tellurium) system[J]. Bulletin of Alloy Phase Diagrams, 1990,11(4):371−376. doi: 10.1007/BF02843316 [13] Tien T Y, Van Vlack L H, Martin R J. The system MnTe-MnS: progress report[J]. Umr, 1967:1−6. [14] Tan Mengxi. Extracting hardnetss-displacement relations and elastic modulus using nanoindentation loading curves[J]. Acta Metallurgica Sinica, 2005,41(10):1020−1024. (谭孟曦. 利用纳米压痕加载曲线计算硬度-压入深度关系及弹性模量[J]. 金属学报, 2005,41(10):1020−1024. doi: 10.3321/j.issn:0412-1961.2005.10.003 [15] Xu Feifei, Cheng Shuseng. Deformation of spherical inclusions in steel sheet during cold rolling process[J]. China Metallurgy, 2014,24(7):36−41. (续飞飞, 程树森. 冷轧过程轧板内圆形夹杂物变形[J]. 中国冶金, 2014,24(7):36−41. doi: 10.3969/j.issn.1006-9356.2014.07.009 -

下载:

下载: